An X-ray tool for the prediction of catastrophic failure during semiconductor manufacture (Jordan Valley)

Submitting Institution

University of DurhamUnit of Assessment

PhysicsSummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Materials Engineering

Summary of the impact

Semiconductor wafers are subject to damage from misaligned handling tools, leading to cracks.

Most of these are benign, but a few propagate to cause silicon wafer breakage during high

temperature processing, leading to losses in production time costing millions of dollars per year.

Research in Durham showed that X-ray Diffraction Imaging can be used to identify which cracks

will catastrophically fail. As a consequence, Jordan Valley UK Ltd has designed and already sold

over £M [text removed for publication] worth of X-ray imaging tools to the semiconductor industry.

The company identifies this product as being critical to its continuation, safeguarding more than 25

jobs, and growth over the past 2 years.

Underpinning research

Brittle fracture is a stochastic process and

confident prediction of the probability of propagation

of a specific crack even under accurately controlled

stresses represents a huge challenge. Most studies

of fractures rely predominantly on a statistical

approach, and the few attempts at a deterministic

model suggest that crack length is a key parameter,

but that other factors such as location and the

detailed form of the applied stress were also

important. This has commercial applications in

semiconductor manufacturing, where catastrophic

silicon wafer breakage during high temperature

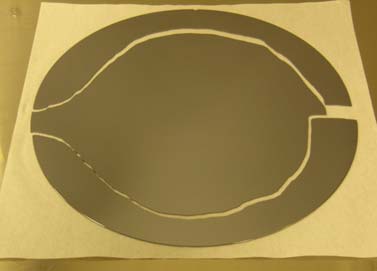

processing is an increasingly expensive hazard (Fig

1). Most silicon wafers show damage due to

handling in the manufacturing process, yet only a few of these propagate to cause catastrophic

failure during rapid thermal annealing, so it is not economic to simply remove all damaged wafers.

What is required is a way to distinguish which cracks are critical and which are benign.

Fig 1. Catastrophic fracture of a 200mm diameter silicon wafer

Fig 1. Catastrophic fracture of a 200mm diameter silicon wafer

Physically, a crack will propagate where the opening stress on the crack is larger than the back

stress at its tip, but neither of these quantities can be measured easily from standard images. In

January 2008, a research consortium led by Durham University, and coordinated by Professor

Brian Tanner of the Physics Department, began work to develop a method of predicting which

wafers were at risk using X-ray Diffraction Imaging (XRDI, also known as X-ray topography) to

assess the damage due to handling on the wafers. Unlike normal imaging, XRDI measures the

residual strain on the material as a diffraction image is sensitive to the change in lattice plane

spacing.

The international consortium included both academic (Durham, Freiburg, Dublin City and

Navarra Universities) and industrial partners, funded under a €2M European Commission

Framework 7 ICT project, `Investigation of Silicon wafer damage in manufacturing processes'

(SIDAM) [1] ran from 2008-2011. It was strongly supported by major semiconductor companies,

with an advisory board which included representatives from Intel, MEMC, Siltronic and AMD

(Global Foundaries). The SME industrial partner was Bede Scientific Instruments Ltd., a 30 year-

old spin-out from Durham University Physics Department that had floated as Bede plc on the

London Stock Exchange in 2000. This was acquired by the Israeli company Jordan Valley

Semiconductors in April 2008 and rebranded as its new UK subsidiary, Jordan Valley

Semiconductors (UK) Ltd. This took the place of Bede Scientific in the consortium.

By working closely with advisory board members, the consortium established that misaligned

handling tools generated cracks at the edge of Si wafers. The team were able to reproduce this

pattern of cracking in a controlled manner using nano-indentation close to the wafer edge. These

`control' wafers were studied at high resolution using the XRDI at the Diamond Light Source (see

Fig 2 and [2]). The key research breakthrough was in 2011, led by Prof Tanner of Durham

University, where he showed that the crack propagation condition could be simply assessed as the

length of the crack was a measure of the opening stress, while the width of the crack tip on the

XRDI measures the back stress [3]. Cracks with a small length to image width ratio are benign;

those with a large length to image width are highly likely to lead to fracture. This condition can be

used predict whether a crack will or will not propagate under specific thermal processing conditions

(see Fig 3). The team confirmed the basic mechanism of crack propagation using in-situ

experiments conducted at the ANKA synchrotron radiation source [4].

![Fig 2: XRDI of dual cracks emanating from a single edge defect (left). The crack propagation condition is directly determined by the ratio, κ, of its length to tip width as in the XRDI image [3] Fig 2: XRDI of dual cracks emanating from a single edge defect (left). The crack propagation condition is directly determined by the ratio, κ, of its length to tip width as in the XRDI image [3]](getImage.aspx?ID=23) Fig 2: XRDI of dual cracks emanating from a single edge defect (left). The crack propagation condition is directly determined by the ratio, κ, of its length to tip width as in the XRDI image [3]

Fig 2: XRDI of dual cracks emanating from a single edge defect (left). The crack propagation condition is directly determined by the ratio, κ, of its length to tip width as in the XRDI image [3]

![Fig 3 The actual failure probability f

against predicted failure probability, r,

determined from the ratio κ, (see Fig

2) for each crack [3]. Fig 3 The actual failure probability f

against predicted failure probability, r,

determined from the ratio κ, (see Fig

2) for each crack [3].](getImage.aspx?ID=24) Fig 3 The actual failure probability f

against predicted failure probability, r,

determined from the ratio κ, (see Fig

2) for each crack [3].

Fig 3 The actual failure probability f

against predicted failure probability, r,

determined from the ratio κ, (see Fig

2) for each crack [3].

References to the research

1. SIDAM project web site www.sidamproject.eu contains all project reports and "Deliverables"

Grant No. FP7-ICT-216382, was funded at €2M by the European Commission

2. X-ray diffraction imaging of dislocation generation related to microcracks in Si-wafers, J. Wittge,

A. Danilewsky, D. Allen, P. McNally, Z. J. Li, T. Baumbach, E. Gorostegui-Colinas, J. Garagorri,

M.R. Elizalde, D. Jacques, M. C. Fossati, D. K. Bowen and B. K. Tanner, Powder Diffraction 25

(2010) 99-103 [and also Adv. X-ray Analysis 53 (2010)] 153-163]

3. Prediction of the propagation probability of individual cracks in brittle single crystal materials, B.

K. Tanner, M. C. Fossati, J. Garagorri, M. R. Elizalde, D. Allen, P. J. McNally, D. Jacques, J.

Wittge and A. N. Danilewsky , Appl Phys Lett 101 (2012) 041903

4. Crack propagation and fracture in silicon wafers under thermal stress, A. N. Danilewsky, J.

Wittge, K. Kiefl, D. Allen, P. J. McNally, J. Garagorri, M. R. Elizalde, T. Baumbach and B.K.

Tanner, J. Appl. Cryst 46 (2013) 849-855

5. X-ray Diffraction Imaging for Predictive Metrology of Crack Propagation in 450mm Diameter

Silicon Wafers, B K Tanner, J Wittge, P Vagovič, T Baumbach, D Allen, P J McNally, R Bytheway,

D Jacques, M C Fossati, D K Bowen, J Garagorri, M R Elizalde and A N Danilewsky, Powder

Diffraction 28 (2013) 95-99

Evidence of the quality of the research is that the assessors of the SIDAM project final report

stated that "the project had fully achieved its objectives and technical goals ....and even exceeded

expectations" The work is also cited in the Scientific Highlights of the Diamond Light Source

Annual Report, pp81-82

Details of the impact

During the project, work by Fossati, a Durham PhD (2008-2013) student under Tanner's

supervision, established that the prototype XRDI system developed by Bede Scientific/Jordan

Valley gave diffraction images which gave comparable results to those taken using white beam

synchrotron radiation at the large facilities [5]. These smaller instruments could assess the failure

probability of a 300(450) mm diameter wafers in 15(40) minutes [5], making this a commercially

feasible scanner system for an industrial semiconductor wafer fab.

As a result of the research, Jordan Valley Semiconductors UK made the strategic decision in

2011 to invest in design, development and manufacture of clean-room compatible X-ray Diffraction

Imaging tools for off-line inspection of all wafers. They developed both transmission (QC-TT) and

reflection (QC-RT) geometry systems (Fig 4), but the smaller footprint (and hence lower price) of

the QC-RT system makes it more attractive. Prior to this, potential customers had resisted

purchase of such tools on the grounds that the instruments revealed edge defects from handling

but were incapable of determining which defects were critical and which were benign. With the

additional capability of accurate defect identification, achieved by incorporating image recognition

software and the predictive model derived by the SIDAM consortium, Jordan Valley

Semiconductors now market an: "X-Ray Diffraction Imaging (XRDI) inspection system that detects

crystalline defects in patterned and blanket wafers [which will]

- Identify cracks which will cause breakage BEFORE the breakage occurs

- Detect slip, which may cause overlay issues, on 300mm wafers in minutes

- Identify dislocations on wafers during manufacture without dislocation etching

- Full 300mm scanning, with rapid coarse reflection scans of either the full wafer area or

selected regions

- Can mount part 450mm wafers

- Monitoring of defects down to single dislocations.... at any doping and wafer backside

treatment.

-

Capability for a wide range of crystalline substrates" [C1]

The importance of these tools was recognised at the annual SEMICON West exhibition held in

San Francisco in July 2012 and attended by 29,263 people. The 2012 "Best of West" award was

presented to Jordan Valley Semiconductor UK Ltd. for the QC-TT defect inspection system. "The

Best of West Award is given to recognize important product and technology developments in the

microelectronics industries....based on the submission's financial impact on the industry,

engineering or scientific achievement, or societal impact and benefits" [C2]. The CEO of Jordan

Valley Semiconductor (the parent company) said, "One thing I'm really proud of is that it [the

system] was developed in the U.K. It's hitting significant needs for 300-millimeter and 450-

millimeter [wafers]." [C2]

In January 2013, The Vice President Corporate and UK Site Manager of Jordan Valley

Semiconductors (UK), said: "We have sold [text removed for publication] XRDI systems in the last

2 years, into 4 different countries with a total value of approximately £M [text removed for

publication]. At least 2 of these systems are for production lines, and we anticipate repeat sales for

these1 along with other production line sales to other companies. Without the involvement in the

SiDAM project, led by Durham University, it is unlikely the XRDI technique would have been

developed into a product of value for the semiconductor industry. The interest gained from the

SiDAM project, including [from] the industrial partners, [was] critical in deciding to invest

significantly in the development of these products.

The addition of these products has been critical in the growth of JV-UK in the last 2 years, both

financially (from administration to >$6M revenues and profitable in 2011) and in the number of

employees (from 25 to 28 in the last year with plans to hire an additional 2 employees in the next 6

months). They have been instrumental in decreasing the reliance of the company on a single

market."[C3]

An assessment of the impact on the industry can be construed from the fact that

semiconductor companies are now investing in X-ray Diffraction Imaging tools in order to reduce

the number of catastrophic wafer failures occurring [C2]. It is estimated by the industry body,

SEMATECH, that for every silicon fabrication line producing 20,000 300mm or 50,000 200 mm

wafers per month, the cost of catastrophic wafer failure during high temperature processing is $2M

per annum at the 180nm node, rising to over $25M per annum at the 47nm node [C5]. The cost

continues to rise as the inverse square of the node size. One of the leading semiconductor

manufacturers, Toshiba, began shipping flash memory NAND gates based on 24nm technology as

early as August 2010 and since April 2012, Intel has been shipping microprocessors based on

22nm technology. Even a fractional reduction in the number of failures thus has huge economic

significance. The Intel representative on the SIDAM Industrial Advisory Board (IAB) said

"Attendance at the IAB gave a new understanding of the issue which shows the industry how to

solve it. Personally I think that the SIDAM research consortium, led by Professor Tanner, has

transformed an interesting X-ray technique into a powerful tool for the assessment of the risk of

wafer breaks at high temperature processing steps" [C6].

![Fig 4 Jordan Valley XRDI inspection systems for semiconductor wafers (a) QC-TT operating in

transmission geometry and (b) QC-RT operating in reflection geometry [C1] Fig 4 Jordan Valley XRDI inspection systems for semiconductor wafers (a) QC-TT operating in

transmission geometry and (b) QC-RT operating in reflection geometry [C1]](getImage.aspx?ID=25)

![Fig 4 Jordan Valley XRDI inspection systems for semiconductor wafers (a) QC-TT operating in

transmission geometry and (b) QC-RT operating in reflection geometry [C1] Fig 4 Jordan Valley XRDI inspection systems for semiconductor wafers (a) QC-TT operating in

transmission geometry and (b) QC-RT operating in reflection geometry [C1]](getImage.aspx?ID=26) Fig 4 Jordan Valley XRDI inspection systems for semiconductor wafers (a) QC-TT operating in

transmission geometry and (b) QC-RT operating in reflection geometry [C1]

Fig 4 Jordan Valley XRDI inspection systems for semiconductor wafers (a) QC-TT operating in

transmission geometry and (b) QC-RT operating in reflection geometry [C1]

Sources to corroborate the impact

[C1] Jordan Valley Semiconductor QT-TT

http://www.jvsemi.com/products/compound/qc-tt

[C2] Semicon West award and quote from Jordan Valley

http://www.jvsemi.com/company/news/21-jordan-valley-qc-tt-announced-as-winner-of-best-of-west-

2012

[C3] Dr. Paul Ryan, Vice President Corporate and UK Site Manager, Jordan Valley

Semiconductors (UK), Belmont Industrial Estate, Durham, DH1 1TW. paul.ryan@jvsemi.co.uk

Email filed with evidence

[C4] Dr. Paul Ryan, as above, on repeat sales

Email filed with evidence

[C5] International SEMATECH Industry Economic Model 2004: v8.1ss

[C6] Dr. Juan Camacho, Intel Ireland, Leixlip, Eire juan.p.camacho@intel.com

Email filed with evidence

1 First repeat sale achieved by May 2013 [C4]