Novel high strength, low wear leucite glass-ceramics

Submitting Institution

Queen Mary, University of LondonUnit of Assessment

Allied Health Professions, Dentistry, Nursing and PharmacySummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Biomedical Engineering, Materials Engineering

Medical and Health Sciences: Dentistry

Summary of the impact

Novel low-wear, high-strength glass-ceramics were developed at Queen Mary

in 2000-2011 by Dr Cattell's team to prevent facture and wear of dental

ceramic restorations. Over three million restorations have been provided

for patients and sold in 46 countries. The product has won industry awards

for clinical and cosmetic excellence from the Clinical Research Associates

and Dental Advisor, who externally assess products for consumers. The

product uses a 100% pain-free minimally invasive approach, saving as much

as 20% enamel reduction per patient, as tooth preparation and anaesthesia

are not required. We also estimate a substantial reduction in tooth enamel

wear of 43-46% for this nano-scale product compared to commercial

porcelain. It has high patient acceptance and satisfaction, and has

received media coverage worldwide.

Underpinning research

Dr Cattell, Senior Lecturer in Dental Technology, undertook this research

(2000-2011) with his team at Queen Mary to address problems encountered in

clinical dentistry, particularly in general practice, with brittle

fracture of porcelain restorations and their poor survival rates over ten

years (crowns = 52% and veneers = 47%) and substantial costs (£117.5M and

£6.5M respectively). The team also considered problems of tooth wear

against current abrasive porcelains, as 14% of people in the UK suffer

from bruxism (teeth grinding). The objectives were to produce low-wear and

high-strength aesthetic glass-ceramics to resolve these problems and

reduce patient pain.

Fundamental work

Dr Cattell conducted the fundamental work on leucite glass-ceramics

(2000-2004) that led to the Cerinate heat extruded commercial product.

Processing of these leucite glass-ceramics using heat extrusion to produce

dental restorations led to an even distribution of fine crystallites and

increases in tested reliability (m = 9.4, m = Weibull Modulus) and

flexural strength (159.1 MPa) compared with current materials (120.1 MPa,

m = 6.1) [1]. During this work he discovered a process of controlling the

leucite crystal size in a thermally compatible glass [2]. His team

discovered that control of the chemistry and physical properties of the

glass, together with crystallite size, were key to enhancing the

properties of the glass-ceramic. They also demonstrated efficient adhesive

bonding of these materials and further surface strengthening (200.2 MPa)

[3].

Discovery of high-strength / low-wear leucite glass-ceramics

Dr Cattell's team (2005-2011) worked with Professor Hill on the original

glass formulation together with a range of new glasses. These glasses were

designed using Appen factors so properties like refractive index, thermal

expansion and fusion temperature could be predicted before the glasses

were made. Tailoring these properties to that of the leucite crystal phase

allowed the production of transparent and highly aesthetic materials, with

residual strains between the crystal and glass matrix matched to encourage

increases in mechanical properties. Controlled fusion temperature also

allowed the fabrication of dental restorations at temperatures suitable

for manufacturing.

The team also focussed on the fundamental aspects of nucleation and

crystal growth of leucite glass-ceramics and powder processing to control

surface crystallisation and produce fine [4] and, later, nano-scale

leucite glass-ceramics. These studies were critical to reducing the size

of the abrasive leucite crystals that had enormous benefits in terms of

reduced enamel wear, improved aesthetics and increased strength. Leucite

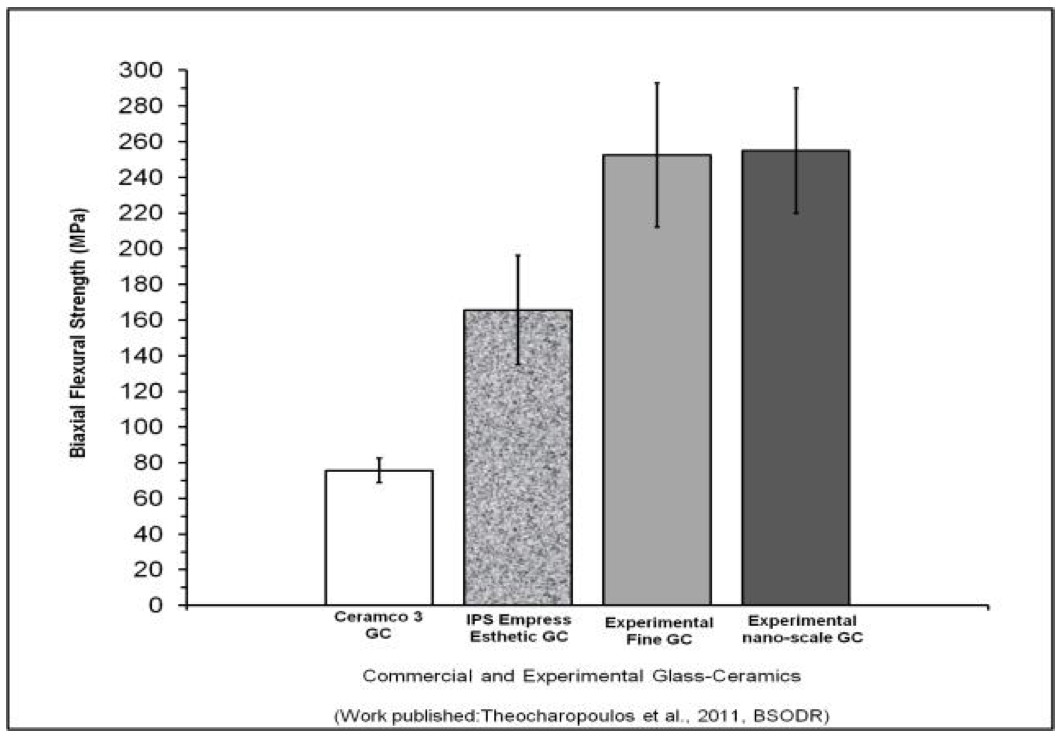

glass-ceramics were produced with significantly higher flexural strength

(>250 MPa, Figure 1) and reliability (m=11.9) when compared to a

European market leader [5]. Research ethics approval was gained to test

the wear of these new materials against human enamel (REC: 06/Q0603/98).

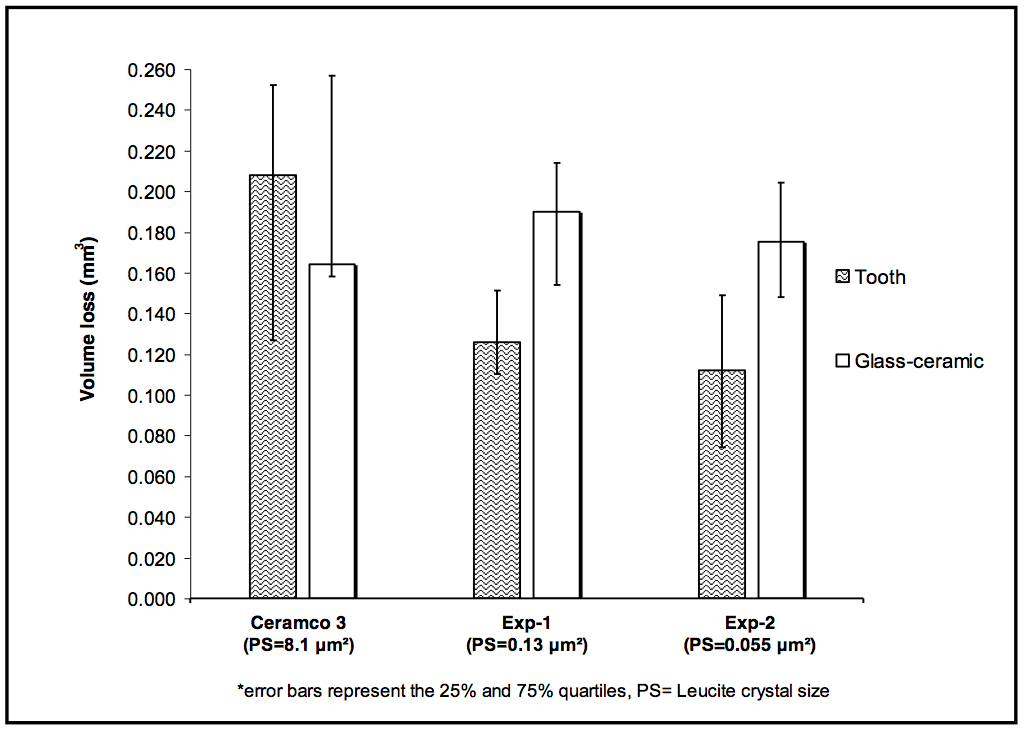

The outcome was significantly lower enamel wear compared with a commercial

market leader [6] (Figure 2).

New technologies

The group also demonstrated these materials could be processed using heat

extrusion and newer CAD-CAM and 3D-printing technologies to produce dental

restorations. This material was adopted as an aesthetic restorative

material for clinical use (Lumineers® 2, Den-Mat Holdings,

USA), and used in the fabrication of over three million dental

restorations. These stronger materials are used in thin section

encouraging minimally invasive adhesive dentistry. The outcomes are less

drilling and pain for patients and prevention of crown fracture and

destructive enamel wear.

Fig. 1: Flexural strength of the Experimental/

Commercial glass-ceramics

Fig. 1: Flexural strength of the Experimental/

Commercial glass-ceramics

Fig. 2: Wear of the Experimental/

Commercial glass-ceramics

Fig. 2: Wear of the Experimental/

Commercial glass-ceramics

References to the research

1. Cattell MJ, Chadwick TC, Knowles JC, Clarke RL, Lynch E.

Flexural strength optimization of a fleucite reinforced glass ceramic. Dental

Materials, 2001; 17: 21-33.

2. Cattell MJ, Chadwick TC, Knowles JC, Clarke RL, Samarawickrama

DYD. The nucleation and crystallization of fine grained leucite

glass-ceramics for dental applications. Dental Materials, 2006;

22, 925-933.

3. Cattell MJ, Chadwick TC, Knowles JC, Clarke RL. Development

and testing of glaze materials for application to the fit surface of

dental ceramic restorations. Dental Materials, 2009; 25, 431-441.

4. Chen XI, Chadwick TC, Wilson RM, Hill R and Cattell MJ.

Crystallization of High Strength-Fine-Sized Leucite Glass-Ceramics. Journal

of Dental Research, 2010; 89, 1510-1516.

5. Chen XI, Chadwick TC, Wilson RM, Hill R and Cattell MJ.

Crystallization and flexural strength optimization of fine-grained leucite

glass-ceramics for dentistry. Dental Materials, 2011; 2 7

1153-1161.

6. Theocharopoulos A, Chen X, Hill R and Cattell M.J.

Reduced wear of enamel with novel fine and nano-scale leucite

glass-ceramics. Journal of Dentistry, 2013; 41, 561-568.

Research was supported by grants from: Support for Oral Science

PhD studentship (Barts and the London, 2005-09); Barts and The London

Charity (2007-11); Industry (Den-Mat Corp., USA) (2006-09).

Details of the impact

4a: World distribution and sales

Over three million dental restorations have been manufactured and placed

for patients using these highly successful glass-ceramics, generating

significant industry and general dental practice profits [7]. It is now a

global product sold in 46 countries including: The Americas (USA,

Canada, Brazil, Mexico, Venezuela); Europe (UK, France, Germany,

Italy, Belgium, Spain, Russia, Poland, Greece, Hungary, Estonia, Bulgaria,

Cyprus); Asia Pacific (Australia, Japan, Hong Kong, Taiwan,

Indonesia, Vietnam, Philippines, Korea); and Middle East and Africa:

(Dubai, Kuwait, Kazakhstan, Morocco, Israel, Africa GCC, Turkey). There

has been an improved public understanding of minimally invasive dentistry

as these new materials and techniques have been covered extensively in

newspapers and magazines, including Readers Digest (circulation

>10m) [8], and on the internet and TV, making these the most

patient-requested thin veneers in dentistry.

4b: Industry and academic recognition and clinical trials

During clinical trials this leucite glass-ceramic was clinically rated

`excellent' by the Dental Advisor and by the Clinical Research Associates

(CRA), both of whom are major external assessors who evaluate products for

the dental profession and consumers. The Leucite glass-ceramic (Lumineers

2 ®) was also awarded top cosmetic product by the Dental Advisor (2009)

[9]. The research work behind this material also won the Voco prize for

Dental Biomaterials research at the International Association of Dental

Research meeting in 2010 [10]. Improved methodology for the measurement of

tooth wear using white light profilometry was developed during this work

[11], which has been cited in the literature and is of use in the

scientific community.

4c: Change in clinical practice worldwide

The major impact of this research is that these unique high-strength

glass-ceramics are used in thinner section (as thin as a contact lens)

allowing minimal or "no tooth" drilling and eliminating the associated

pain, discomfort, and local anaesthesia injections (by up to 100%)

required to prepare teeth (www.lumineers.com/h2_lumineers_why)

[12]. This also means 100% reduction in postoperative patient pain, less

tooth destruction (20% less) and fewer or no provisional restorations.

This equates to 25% more profit for dental practices when placing this

system (versus traditional materials). High aesthetics combined with a

pain-free minimally invasive tooth preparation approach [9] has led to

high patient acceptance and satisfaction with this product (Figure 3).

This information has been fed back from numerous dental practices

(>13,000 dentists in the USA use Lumineers) via patient and

practitioner testimonials [13]. These materials can be easily acid etched

and adhesively bonded to tooth structure and this has made them

particularly useful in the treatment of children with microdontia,

tetracycline staining and amelogenesis imperfecta.

4d: Patient and dentist testimonials

A patient said: "The process was amazing — it was almost too

easy! No shots, drilling or pain was associated with getting Lumineers.

I love how natural they look and feel. Who knew getting a new beautiful

smile could be so easy." [13b]. A dentist said: "Tremendous

benefits for all our patients because of the no shots or temporaries. It

produces a tremendous smile with very little or no discomfort to the

patient." [13b].

Fig. 3: Before and after the use of Lumineers

Fig. 3: Before and after the use of Lumineers

4e: New low-wear materials

Another major impact of this study was to produce fine and nano-scale

leucite glass-ceramics with dramatically reduced enamel wear properties.

Many conventional porcelains/ceramics are destructive to tooth structure

(four times more abrasive than enamel) and this is increased in patients

with bruxism. In the UK 8-10% of the population are affected by tooth

wear. The current materials have the opposite effect and will be kinder to

tooth structure. We estimate the nano-scale materials give a staggering

reduction in tooth enamel wear of 43-46% compared to the commercial

porcelain in our study (6). This is of great benefit to patients to reduce

tooth destruction, pain and the prevention of more complex dental

treatment, such as costly bridges and implants when worn teeth are

difficult to restore. These materials do not have biocompability issues

and are less cytotoxic than current lithium disilicate ceramics, many

metals and composites. There is less or no drilling and its associated

pain for patients, and up to 100% less post-operative pain. The materials

can also prevent future repeat or more complex dental treatment, hence

high satisfaction in both adults and children.

4f: Industry feedback and publications

The Leucite glass-ceramics developed at Queen Mary were translated into

two products by a US-based company (Den-Mat Holdings), with two patents

filed [14, 15], and seven published papers [eg 1-6]. Dr Cattell was

responsible for translating this lab-based research to industry and

setting up the processing technology. This led to a heat extruded leucite

glass-ceramic (Cerinate Pressable) and the Lumineers® 2 glass-ceramic used

in conjunction with new CAD-CAM and 3D-printing technologies [16]. The

versatility of these products and the ease of manufacture made them

desirable to industry and generated significant industry and general

dental practice income (veneers cost $800-2,000 per tooth in US practice).

www.lumineers.com/h2_lumineers_cost

This resulted in hiring of new staff (increased employment in California)

at the US-based dental company and investment in new technology [17]. A

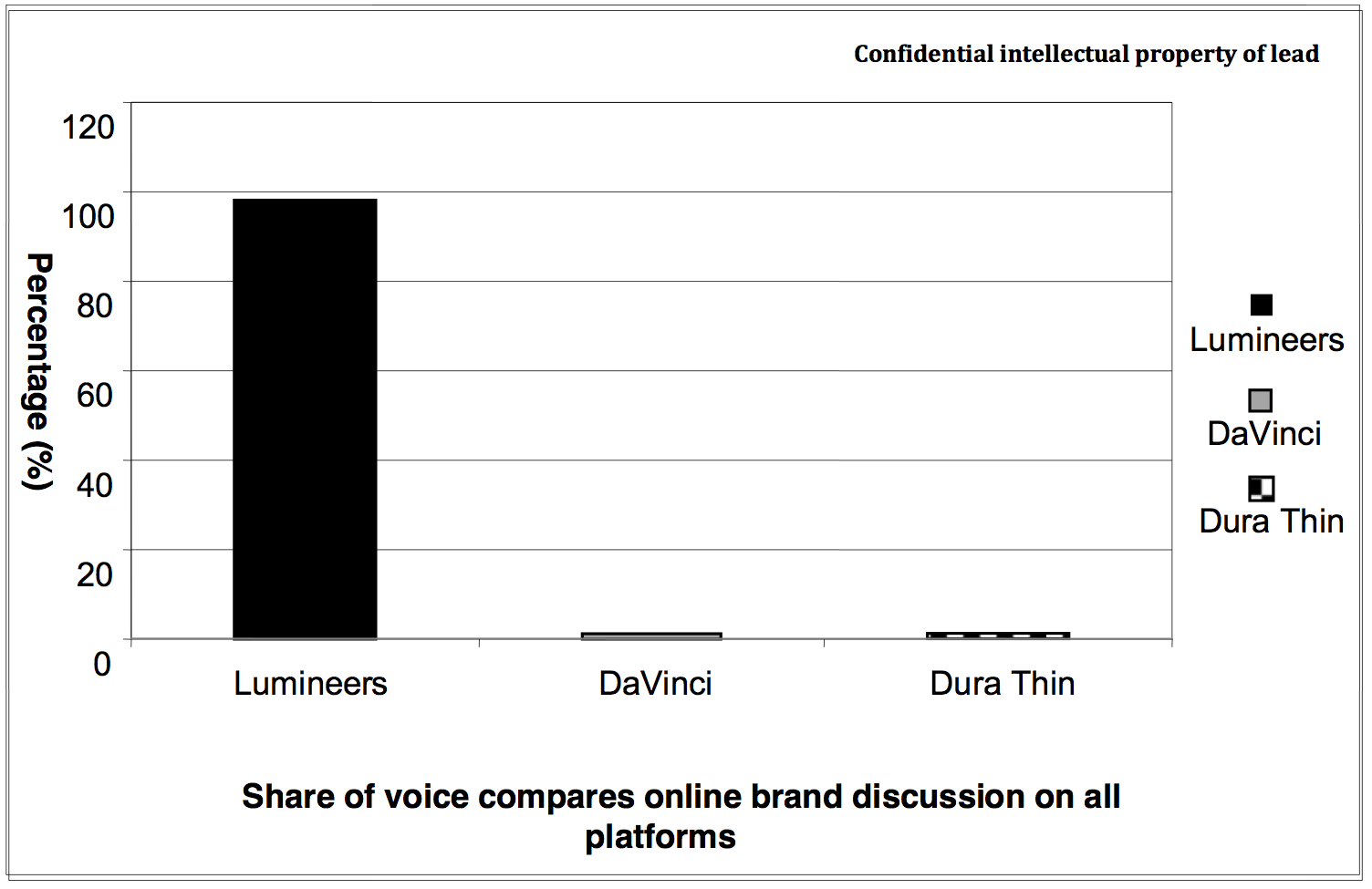

recent company consumer assessment of online conversation related to

branded dental veneers indicated the dominance of Lumineers over two of

their primary competitors (Figure 4).

Fig. 4: Competitive analysis: Share of voice

Fig. 4: Competitive analysis: Share of voice

Sources to corroborate the impact

- Senior Director Research and Development, Den-Mat Holdings, LLC

- Summary of Lumineers media coverage in US http://lumismilecentral.net/in-the-news/

- Dental Advisor report, 2009. Available from: www.dentaladvisor.com/clinical-evaluations/product-awards/2009-product-awards.shtml#anterior

- Theocharopoulos, A., Chen, X., Hill, R. and Cattell, M.J (2010) Wear

characteristics of an experimental high-strength fine-sized leucite

glass-ceramic, IADR General Session, Barcelona http://iadr.confex.com/iadr/2010barce/preliminaryprogram/abstract_132248.htm

- Theocharopoulos A, Zou L, Hill R, Cattell MJ. Wear quantification of

human enamel and dental glass-ceramics using white light profilometry. Wear,

2010; 269, 930-93.

- Lumineers® Smile Design Studio Catalogue: www.denmed.com/lumineersdds/pliki/smile-design-catalog.pdf

- Patient website testimonials available from: (a)

www.yourlifesmiles.com/before-and-after and (b) http://atlantagentledental.com/news/lumineers-testimonials/

- Ibsen R, Chen XH, Cattell MJ, Riddell JV, Chadwick TC. Control of

Ceramic Microstructure US Patent 2009/0081104 A1 March 26th

2009. www.google.com/patents/US20090081104

- Ibsen R, Chen XH, Cattell MJ, Riddell JV. Strong Glass-Ceramic US

Patent 2010 /0119431A May 13th 2010. www.google.com/patents/US20100119431

- Forward trends: veneers. Dental Products Report [Internet], April

2009, 20-21. www.nxtbook.com/nxtbooks/advanstar/dlp_200904/index.php?startid=20#/21

- Research Scientist, Research and Development, Den-Mat Holdings, LLC.