Optimising Gradient and Shim Coils for Next-Generation Magnetic Resonance Imaging Systems

Submitting Institution

University of NottinghamUnit of Assessment

PhysicsSummary Impact Type

TechnologicalResearch Subject Area(s)

Physical Sciences: Other Physical Sciences

Engineering: Biomedical Engineering

Medical and Health Sciences: Neurosciences

Summary of the impact

Theoretical and computational methods for optimising the design of

gradient and shim coils with

arbitrary shapes and topologies were developed in collaboration with

Magnex Scientific as part of a

CASE award (2004-07). The resulting software was licenced to Agilent (who

now own Magnex

Scientific), for whom it has opened up new market opportunities in the

supply of novel magnetic

resonance imaging systems, leading to £3.4M sales since 2009. The software

has also been used

by Paramed Medical Systems to improve their `open' magnetic resonance

imaging systems, which

are optimised for orthopaedic imaging, allow vertical subject posture, and

facilitate image-guided

treatment, as well as offering a better patient experience. Our work has

thus resulted in impact in

the economy and healthcare.

Underpinning research

The use of gradient and shim coils is integral to the operation of

magnetic resonance imaging

(MRI) systems. The three gradient coils found in each scanner are used to

produce magnetic fields

that vary linearly with position along three orthogonal axes. These field

gradients are crucial for the

spatial encoding of the magnetic resonance signal — a process which forms

the basis of MRI.

Gradient coil performance strongly influences many aspects of magnetic

resonance (MR) image

quality, including the spatial resolution and achievable contrast. Shim

coils are used to correct

unavoidable inhomogeneities in the main static magnetic field that is also

used in MRI. These

inhomogeneities may arise from various sources, such as the magnetic

susceptibility of a human

subject, or imperfections in the magnet construction, and, if uncorrected,

result in significant image

distortions.

The Nottingham MRI group has a longstanding track record in the

development of improved

hardware for MRI systems, dating back to the early work for which Sir

Peter Mansfield shared the

2003 Nobel Prize in Medicine or Physiology. This research activity has

continued to the present

day, with a particular emphasis on gradient and shim coil technology.

Previous high impact work in

this area includes the development in the late 1980s of actively-shielded

gradient coils, which are

now used in all MR scanners, and the subsequent establishment of methods

for designing high

efficiency coils. These developments formed the basis for the substantial

improvement in gradient

system performance in the 1990s, which first allowed the routine

implementation of functional

magnetic resonance imaging of the brain and other imaging procedures that

rely on strong, rapidly

switched gradients.

Since the late 1990s, the focus of our research has shifted to the

development of methods for the

design of coils with complex geometries or topologies that are required to

enable new applications

and advances in MRI. Until recently, gradient coils for MR scanners were

designed using a simple

parameterisation of the current density that represents the energised coil

windings. This approach

is well suited to the production of gradient coils that are wound on

simple surfaces, such as the

long cylinders used in early MR scanners, but cannot easily be applied to

designing coils on more

complex surfaces that may be truncated, folded, gapped or split. Research

into these complex coil

shapes was motivated by their requirement in novel MRI systems, including:

- scanners incorporating insert gradient and shim coils that can be used

for enhanced

imaging of particular target structures — for example, insert head

gradient and shim coils

that fit closely around the head

- `open' MRI scanners which depart from the conventional tubular shape —

these can

enhance the patient experience through reduction of stress (particularly

important for

paediatric and obese patients) and can also be used for real-time

monitoring of surgery and

other complex processes; an example is the `MROpen' system, developed by

Paramed

Medical Systems (see Figure), which allows imaging of human subjects in

weight-bearing,

vertical, postures

- hybrid systems, such as combined positron emission tomography (PET)

and MRI scanners,

and combined radiotherapy and MRI systems, in which the coils must be

designed to be

compatible with the spatial arrangement and operation of the equipment

required for the

additional modality.

Boundary element methods (BEM) offer a powerful approach for coil design,

allowing the

generation of coils wound on arbitrarily-shaped surfaces, so as to produce

any form of field

variation that is consistent with Maxwell's equations. This approach

involves meshing the current-carrying

surface into an array of boundary elements and then setting the current

density at each

element, so as to minimise a functional that reflects the desired coil

characteristics.

Between 2004 and 2007, Bowtell (a member of the Nottingham MRI

group), working with CASE

Ph.D. student, Poole, applied the boundary element approach to the inverse

problem of designing

coils on arbitrarily shaped surfaces that would produce specified magnetic

field distributions. The

outcome was a novel inverse BEM (IBEM) approach. This was implemented in

software written by

Poole, and combined with a powerful mesh-generating program, so as to

allow the design and

production of coils with completely arbitrary geometry [1]. Poole's

studentship was funded by

Magnex Scientific/Varian Inc.[i] and his Ph.D. work linked into an

EPSRC-funded project which

focused on applying techniques in computational mechanics to the design

and analysis of gradient

and radio-frequency coils for MRI [ii].

In 2007, Poole and Bowtell worked with Alun Lucas, Rob

Hawkes and Adrian Carpenter (Wolfson Brain Imaging

Centre at the Addenbrooke's Hospital in Cambridge), and

Dan Green and Simon Pittard (Varian Inc., now Agilent), on

the design and construction of coils for a hybrid PET-MRI

system [2]. Combining PET and MRI within one instrument

requires many engineering compromises as the equipment

for the two modalities vies for the space closest to the

sample/subject. Nevertheless, a combined PET-MRI

system offers many potential benefits for clinical and pre-clinical

imaging. In the configuration which was developed,

the PET detectors reside in a gap between the two halves

of a 1T split-magnet cryostat. The gradient and shim coils

had to incorporate a 110 mm gap from which wires are

excluded so as to avoid compromising the process of

positron detection. It was not possible to produce coils with

this gapped geometry using conventional methods of coil

design, but Poole's IBEM software was able to cope with

the complex coil shapes. It was used to design three,

orthogonal, (magnetically) shielded gradient coils and a

shielded, zero-order shim coil. These coils were

constructed and tested in the hybrid PET-MRI system and

successfully used in simultaneous PET-MRI experiments

[2].

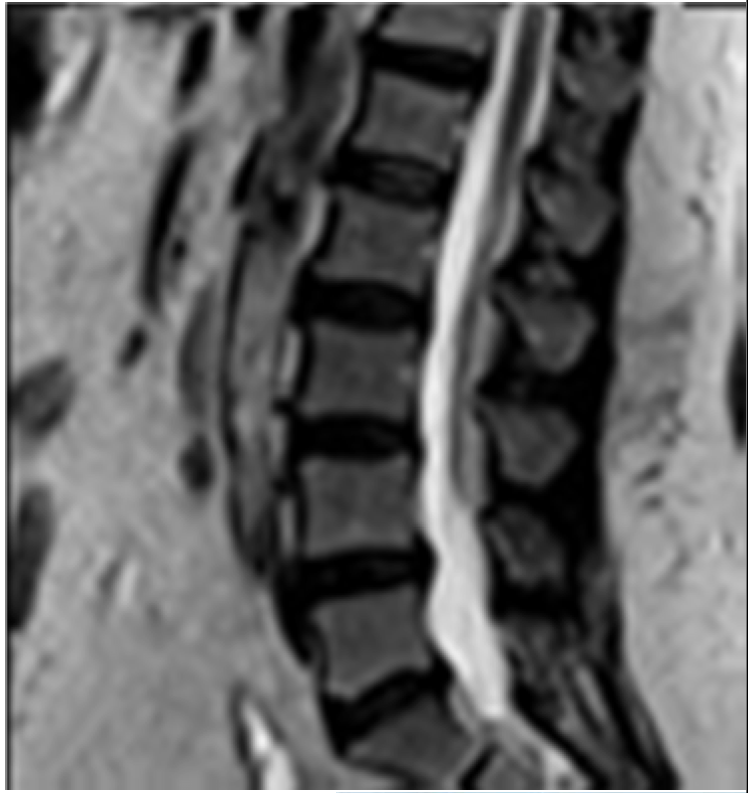

Top: Lumbar spine MRI scan (imaged under vertical compression)

Top: Lumbar spine MRI scan (imaged under vertical compression)

Left: Paramed’s MROpen scanner.

Left: Paramed’s MROpen scanner.

References to the research

(*denotes paper which best describes quality of research)

1) *M. Poole and R. Bowtell, `Novel gradient coils designed

using a boundary element method.',

Concepts in Magnetic Resonance Part B 31B, 162 (2007).

DOI: 10.1002/cmr.b.20091

2) *M. Poole, R. Bowtell, D. Green, S. Pittard, A. Lucas, R. Hawkes, A

Carpenter, `Split

gradient coils for simultaneous PET-MRI', Magnetic Resonance in

Medicine 62,1106 (2009).

DOI: 10.1002/mrm.22143

3) *R. Bowtell and R. M. Bowley `Analytic calculations of the

E-fields induced by time-varying

magnetic fields generated by cylindrical gradient coils', Magnetic

Resonance in Medicine 44, 782

(2000).

DOI: 10.1002/1522-2594

4) R. Bowtell and A. Peters `Analytic approach to the design

of transverse gradient coils with co-axial

return paths', Magnetic Resonance in Medicine 41, 600

(1999).

DOI: 10.1002/(SICI)1522-2594

5) P. Mansfield, B. L. W. Chapman, R. Bowtell, P. Glover, R. Coxon,

P. R. Harvey, `Active

acoustic screening — reduction of noise in gradient coils by Lorentz

force balancing', Magnetic

Resonance in Medicine 33, 276 (1995).

DOI: 10.1002/mrm.1910330220

Grants

i. Magnex CASE studentship (01/10/2003-31/03/2007) £22,000

ii. `Forward & inverse analysis of electromagnetic fields

for MRI using computational mechanics

techniques' I.A. Jones, R. Bowtell, A. Becker, P.M. Glover, H.

Power, EPSRC Grant

GR/T22445/01 (1/2/05-3/1/2008) £208,925

Details of the impact

The strong track record of the MRI group in the development of gradient

coil technology for

magnetic resonance scanners led to the sponsorship by Magnex Scientific

(manufacturer of

magnets, gradient coils and shim coils for MRI) of a CASE studentship for

Poole under the

supervision of Bowtell. Poole's Ph.D. project, which commenced in

2004, focused on the

development of insert gradient and shim coils for use in high-field MRI of

the human head. The

IBEM approach was developed as part of this work, so as to allow the

design of coils wound on

surfaces that fit more closely to the head than the body-sized cylinders

used in most MRI systems.

From 2005-2006, Poole developed a versatile suite of algorithms and

subsequently an IBEM

software package for designing gradient and shim coils on

arbitrarily-shaped surfaces.

This software was demonstrated to our collaborators at Magnex Scientific

during regular project

meetings in 2006 (by this time, Magnex had been bought by Varian Inc.;

Varian were then bought

by Agilent in 2010 for $1.5bn; the manufacturing base has remained in

Yarnton, Oxfordshire

throughout the changes in ownership). It rapidly become clear to Varian

that the IBEM software

offered much greater versatility than the coil design programmes that they

were then using. The

facility to design and produce coils on gapped or split surfaces generated

particular interest. To

demonstrate the potential of the IBEM software, Poole worked with Dan

Green (Varian) to

generate novel, gapped, designs of shielded gradient and shim coils for a

prototype hybrid

PET/MRI system. These coils could not be designed using the software that

Varian were using at

that time.

Subsequently, Varian constructed these coils and supplied them

commercially to Adrian Carpenter

and colleagues at the Wolfson Brain Imaging Centre in Addenbrooke's

Hospital (2008), paying a

3% royalty to the University of Nottingham. Bowtell and Poole

published a paper [2] jointly with

Carpenter's group and the Varian collaborators, describing the novel coil

designs and the first

experimental tests of their performance in the hybrid PET/MRI system.

Having seen the value of

the IBEM approach, Varian extended the agreement with the University of

Nottingham in 2007, and

this now allows them to use Poole's advanced design software, provided

that they pay a 3%

royalty on any coil sales arising from its use. Since 2008, Varian, and

subsequently Agilent, have

used the software to design a number of coil systems, including short head

gradient coils for ultra-high

field imaging, and gapped systems for use in combined radiotherapy/MRI

systems. Agilent's

Research and Development Manager for Gradient Coils [A] describes the

impact on their business:

"The ability of the software to account for complex gradient coil

geometries allows us to explore the

more challenging design aspects of bespoke and integrated systems, for

instance hybrid MRI/PET

and MRI applications in radiotherapy. Agilent's entry into these new

markets has resulted in some

£2.8 million in new system sales since 2009. We also offer some unique

solutions to our customers

in the university research sector; often their challenging requirements

can only be met by the

flexibility of the IBEM software. Sales for these upgrades are of the

order £600k since 2009.

Exploitation of these new markets would not have been possible without

Nottingham's research

into complex gradient coil design."

In 2009, Bowtell established a new collaboration with Paramed

Medical Systems (Genova, Italy)

who sell `open' MRI scanners. As described in Section 2, open MRI scanners

offer several

significant advantages over the conventional tubular design including:

better patient experience,

particularly for the paediatric, anxious or larger patient; weight bearing

and postural diagnostics in,

for instance, the upper neck (cervical) and lumbar spine cases (see

figure); the potential for real-time

monitoring of surgery. The Paramed systems are based on permanent (0.15T)

and MgB2

superconducting (0.5T) magnet technology, offering a cheaper alternative

to whole body scanners.

A Paramed scanner (MROpen; see Figure) was recently installed in the `Upright

MRI Centre', a

private healthcare centre opened in Leeds in September 2012.

Scanners of this type use bi-planar gradient coils that are mounted on

the magnet pole pieces and

so are in close proximity to large amounts of highly permeable iron. The

new collaboration, which

also involved researchers at the Istituto Italiano di Tecnologia (IIT) in

Genova, focused on adapting

the IBEM approach to take account of the nearby magnetic material when

designing coils, and was

driven by Paramed's need to incorporate active magnetic shielding of their

coils so as to improve

system performance. Following Paramed's purchase of the IBEM software, it

was modified, in

collaboration with Bowtell and IIT researchers, and has

subsequently been used in a number of

development projects and products at Paramed, including their core product

lines, the MROpen

(see figure) and MRJ3300 (now known as MRInspire) scanners. Paramed have

implemented new

design processes as a result of the IBEM software which affect their

complete product range (that

currently provides a turnover of €8M/year) and will support future

projected growth. These details,

and the associated commercial advantages which result, are highlighted by

the Research and

Development Manager at Paramed [B]:

"The availability of the IBEM software, modified by IIT and Paramed

during and after collaboration

with Nottingham School of Physics and Astronomy (since 2009), helped us

to build a new design

tool for optimizing gradient coil performances in presence of iron,

which is an extremely important

advantage for MRI system design"

In summary, our numerical methods for the optimisation of gradient coils

have been adopted by

manufacturers of MRI equipment to enhance performance, functionality and

patient care, thus

generating impact in the economy and healthcare.

Sources to corroborate the impact

(available on request).

A) Letter from Research and Development Manager, Gradient Coils, Agilent.

B) Letter from Research and Development Manager, Paramed s.r.l.