Luminescent inks for mail coding and sorting

Submitting Institution

Lancaster UniversityUnit of Assessment

ChemistrySummary Impact Type

EconomicResearch Subject Area(s)

Chemical Sciences: Inorganic Chemistry, Macromolecular and Materials Chemistry, Physical Chemistry (incl. Structural)

Summary of the impact

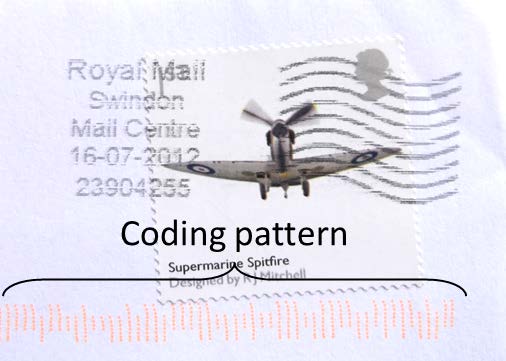

Fundamental research in collaboration with Royal

Mail into luminescence molecules constrained

within a water-soluble acrylic polymer matrix has

led to the development of novel, water-soluble, ink-jet

printable, luminescent inks. These inks are

employed by Royal Mail for printing coding patterns

on envelopes that can be read by automatic letter-sorting

machines. The inks offer excellent

performance in humid environments, on coloured

paper, and on paper containing optical brighteners,

and are safer. Royal Mail delivers, on average, 58 million letters each

day, representing annual

revenue of £5.2 billion. The research at Lancaster enabling the innovation

has a direct impact on

the commercial performance of Royal Mail, the safety of its employees and

the public, and

everyone (commercially and/or privately) using Royal Mail services to send

and receive mail

correctly, quickly, and at a low cost.

Underpinning research

In 1987, Dr A. R. "Tim" Lane, a Senior Scientist at the Royal Mail

Research Laboratories,

approached Dr John Ebdon, Senior Lecturer, Chemistry Department, Lancaster

University, for help

in improving the physical and chemical properties of ink-jet printable

inks used for printing

machine-readable patterns of dots (representing postal codes) on

envelopes, enabling the

envelopes to be automatically sorted. At the time, the inks already in use

for this purpose were

based on suspensions of relatively simple phosphors in aqueous solutions

of amino resins. These

inks were believed first to dry and then to cure (crosslink) when applied

to paper, providing a solid

hydrophobic medium in which phosphorescence could develop and be "read"

when the envelope

was passed under a UV lamp. There were three problems with the inks: (1)

the inks contained

small amounts of free formaldehyde (a suspected carcinogen); (2) they were

slow to dry/cure,

leading to an unacceptable delay before the coding pattern could be read,

and (3) they performed

poorly in humid environments.

The academic outcomes of the project are described in five papers

published jointly by Royal Mail

and Lancaster University over the period 1995-1999 [1-5]. These

demonstrate: (1) that water-soluble

acrylic polymer solutions, e.g. aqueous solutions of polyacrylic and

polymethacrylic acids,

during the process of drying undergo a "coil-collapse" process whereby the

interiors of the polymer

coils become sufficiently hydrophobic to act as hosts for hydrophobic,

luminescent materials

(guests); (2) that in these collapsed coils, luminescence of the guest can

occur without significant

quenching, even before the solution has fully dried; (3) that the onset of

coil-collapse is influenced

by temperature and pH; and (4) that the hydrophobicity of the collapsed

coil can be increased by

the incorporation of small amounts of a hydrophobic monomer, such as

styrene or methyl

methacrylate. A further outcome, not published at the time owing to

commercial sensitivity, was the

demonstration that a bi-component luminescent system in a polymer matrix,

in which energy

transfer to a fluorescent compound occurs, could be used to give long-lived

red luminescence.

The fundamental research on the behaviours of water-based polymer systems

carried out at

Lancaster, and the more applied aspects researched jointly by Lancaster

and Royal Mail, led to the

patenting of polyacrylic acid binders together with various combinations

of luminescent compounds

for use in mail coding inks, by Royal Mail in 1998 [6]. These patents

refer to the environmental

hazards posed by the earlier amino resin binders and for the desirability

that the ink should contain

a long-lived red emitter so as to allow signals to be read (a)

irrespective of the substrate colour, (b)

in the presence of a fluorescence background from any optical brighteners

in the envelope paper,

and (c) throughout the period during which the coding ink is drying. The

use of energy transfer to

achieve long-lived (>500 ms) luminescence is also disclosed.

References to the research

[1]. Ebdon J. R., Lane A. R., Lucas D. M., Soutar, I. and Swanson L.

(1995) Luminescence studies

of polymer matrices. 1. Phosphorescence of benzophenone dispersed in

poly(methyl

methacrylate), Polymer, 36, 1577-1584. DOI:

10.1016/0032-3861(95)99002-C

[2]. Ebdon J. R., Hunt B. J., Lucas D. M., Soutar I., Swanson L. and Lane

A. L. (1995)

Luminescence studies of hydrophobically modified, water-soluble

polymers. 1. Fluorescence

anisotropy and spectroscopic investigations of the conformational

behaviour of copolymers of

acrylic acid and styrene and methyl methacrylate, Canadian Journal

of Chemistry, 73, 1982-1994.

DOI: 10.1139/v95-245

[3]. Ebdon J. R., Soutar I., Brown P., McCabe A. J., Lane A. R. and

Swanson L. (1999)

Luminescence studies of polymer matrices: 2. On the phosphorescence

characteristics of 2-benzoyl

naphthalene dispersed in various acrylic polymers, High Perf.

Polym., 11, 49-62. DOI:

10.1088/0954-0083/11/1/005

[4]. Ebdon J. R., Soutar I., Brown P., McCabe A. J., Lane A. R. and

Swanson L. (1999)

Luminescence studies of polymer matrices: III. Characterization and

evaluation of acrylic acid

based polymers as hosts for a phosphorescent coding system, J.

Polym. Sci. B. Polym. Phys. Ed.,

37, 2127-2136. DOI: 10.1002/(SICI)1099-0488(19990815)37:16

[5]. Ebdon J. R., Lane A. R., Lucas D. M., Soutar I. and Swanson L.

(1999) Luminescence studies

of polymer matrices. 4. Phosphorescence of benzophenone dispersed in

acrylic acid based

polymer films, High Perf. Polym., 11, 331-341. DOI:

10.1088/0954-0083/11/3/308

[6]. Brown P. R., Hewison S., Kondratowicz A., Metson C. A. L., Rock J.

and Scott R. (1998)

Patents WO19980003596 and EP 0914392B, assigned to the Post Office.

Details of the impact

The new ink formulations were introduced in the Royal Mail processes in

2006-7, defining the date

of onset of impact.

Embedding of Technology: Key to the realisation of the impact of

this research programme was

the embedding of the technology developed at Lancaster University into

Royal Mail Research

Laboratories. Linda Swanson [1-5] was a PhD student on the programme, who

was subsequently

employed by Royal Mail for three years. Paul Brown and Alistair McCabe,

employed at Royal Mail

Research Laboratories, were members of the research team [1-5]. The

research initiated through

the partnership with Lancaster University was subsequently refined at

Royal Mail Research

Laboratories, which led to a further patent [7] where practical ink

formulations are described which

include the addition of an opacifying agent (to enhance the fluorescence

signal on highly coloured

envelopes and wrappings, and therefore enhancing the reliability of the

automated barcode

reading equipment). A further development was to incorporate dyes that

could be monitored at two

distinct excitation wavelengths (e.g. 365 nm and 420 nm) which can be

`read' using a combination

of UV and visible illumination. Such formulation is typical of what is

used by Royal Mail to print

digital postmarks (DPMs) as barcodes on letters and parcels.

The IMPACT is evident under THREE distinct headings:

SAFETY — The earlier formulations, based on formaldehyde (a

suspected carcinogen), have been

replaced by safer polyacrylic and later styrene-acrylic resins [7]. The

principal impact is on the

safety of Royal Mail workers who operate the barcoding printers where the

risk of exposure to the

wet inks is greatest. Other postal workers, such as postmen and women who

are exposed to the

cured inks throughout their daily employment, will not be subjected to

persistent formaldehyde

outgassing. Neither will the general public be exposed to formaldehyde.

Safety, of paramount

importance, is a significant impact that is directly related to the inks

developed through the

Lancaster University/Royal Mail partnership.

EFFICIENCY — Royal Mail is characterised by its massive

daily throughput of letters and parcels

(typically 58 million items per day [8]). The logistics can only be

realised in a sensible and cost-effective

way through the extensive application of intelligent automation.

Fundamental to the

automation of postal delivery is the ability to assign each postal item

uniquely, and with sufficient

data to ensure accurate delivery to the intended destination. The DPMs, as

barcodes, are readable

by intelligent letter sorting machines. Prior to 2006, most mail was still

hand sorted, which is a

"slow and cumbersome process" [8]. Royal Mail introduced a major

modernisation programme in

2006-07, coincident with the updated coding ink formulation [7], [8].

During this modernisation

programme, 64 intelligent letter sorting machines were installed, each

capable of processing up to

40,000 items of mail per hour [7]. This has also led to the adoption of

Compact Sequence Sorters

that are "walk-sequenced", so that letters are ordered to minimise the

travel distance by postmen

and women. This now accounts for about 75% of all deliveries. This has the

direct impact of

reducing the workload of the delivery personnel, and thereby increasing

efficiency of the delivery

process. In turn, this efficiency improvement leads to a reduction in

cost. During the year 2011-12,

a total of 235 new, refurbished or upgraded process sequencing machines

were installed across

the UK Royal Mail network. The coding inks are pivotal to the IMPACT

achieved in terms of postal

delivery efficiency.

FINANCIAL — Royal Mail has been hit by a general decline in

mail volumes within the last decade

due to electronic substitution of paper communication (for example, Royal

Mail observed a 3.1%

pa decline in letter volumes between 2005 and 2008). For Royal Mail to

remain competitive

alongside the trend towards electronic communication, it has been

essential to enhance their

efficiency, as described above. This will continue to be an acute risk for

Royal Mail, as they predict

letters will decline 5% pa during the period 2013-18; and 4% pa during

2018-23 [9]. The UK market

present and predicted volumes are: 2012 (Letters 13.8 billion; Parcels 1.7

billion); 2023 (Letters 8.3

billion; Parcels 2.3 billion) [9]. Recent (2011) revenue figures for Royal

Mail are £5.2 billion pa [8].

This is a significant business in its own right that is dependant for

efficiency upon the coded inks

developed from the expertise at the University of Lancaster. From a

societal standpoint, the

IMPACT is far greater, since the mail volume accounts for vital

communications within both the

domestic and business sectors, with a predicted volume in excess of 10

billion items pa up to

2023, even in the light of the trend towards electronic communication. The

recent flotation of Royal

Mail, the oversubscription of prospective shareholders, and the rapid

increase of share value by

48% [10] is clear evidence of a flourishing business with a strong future

prospect. The IMPACT of

the coding inks has played a significant part in the success of Royal Mail

through the facilitation of

considerable efficiency gains through intelligent automation. This is

IMPACT that is set to continue

to deliver for the foreseeable future [9].

With respect to corroboration, we quote below from a correspondence [11]

with Linda Swanson

who contributed to the fundamental research as a PhD student but then went

onto work for Royal

Mail and played a key role in embedding the printing inks science and

technology within Royal

Mail. She is therefore well placed to corroborate the implementation of

the technology within Royal

Mail.

`the most important and tangible output from this work is the red ink

which currently appears on letters

coded by Royal Mail — this was the ink that was designed and developed

at Lancaster during that

project.'

Sources to corroborate the impact

[7]. GB 2412659 B, 2005, assigned to the Royal Mail

[8]. Royal Mail Holdings plc, Annual Report and Financial Statements,

2011-2012.

[9]. PwC Strategy & Economics, "The outlook for UK mail volumes to

2023", PWC July 2013.

[10]. http://www.thisismoney.co.uk/money/news/article-2458523/Royal-Mail-shares-surge-stand-48-float-price.html

[accessed 5 Nov 2013]

[11] Correspondence with respect to the project from a former Royal Mail

employee associated with

embedding Lancaster's research within Royal Mail.

Contact 1: Royal Mail Group Dangerous Goods Advisor, Royal Mail

Engineering — can corroborate

implementation of printing inks technology within Royal Mail

Contact 2: Former Royal Mail employee (now at Sheffield

University) — can corroborate the

implementation of the technology