3 Elemental Fluorine for Fine Chemical Manufacture

Submitting Institution

University of DurhamUnit of Assessment

ChemistrySummary Impact Type

TechnologicalResearch Subject Area(s)

Chemical Sciences: Organic Chemistry, Physical Chemistry (incl. Structural), Other Chemical Sciences

Summary of the impact

Durham selective direct fluorination methodology using fluorine gas has

been scaled up by F2

Chemicals Ltd to supply the Pfizer company with multi-tonne quantities of

a key pharmaceutical

intermediate used in the synthesis of V-Fend (voriconazole). This

antifungal agent has achieved

global sales of $4.65bn from 2008-present and is used extensively for the

treatment of invasive

pulmonary aspergillosis. Multi-channel continuous flow gas/liquid

microreactor technology for direct

fluorination was licensed to the Asahi Glass Co (Japan) and other

transformations enabled by

fluorine gas are being exploited by a DU spin-out company, Brock Fine

Chemicals Ltd.

Underpinning research

Research in elemental fluorine for organic synthesis at DU was led by

Prof R.D. Chambers FRS

(Durham staff 1960-2000) and continued by Prof G Sandford (Durham staff

1993-present).

Elemental fluorine gas (F2) has long been considered to be too

reactive and uncontrollable for use

as a reagent in organic synthesis and this perception still predominates.

General comments in

standard organic chemistry textbooks such as "Direct fluorination of

aromatic rings with F2 is not

feasible at room temperature because of the extreme reactivity of F2....is

not yet of preparative

significance (J. March, Advanced Organic Chemistry)" are typical.

Despite this background, research into the use of F2 for

controlled organic synthesis began a new

phase in 1993 after encouragement from Durham led British Nuclear Fuels

(BNFL) to exploit its

expertise in handling F2 for non-nuclear purposes and to create

a subsidiary company, BNFL

Fluorochemicals Ltd (Preston, UK), later F2 Chemicals Ltd. Considerable

research funding from

the company to Durham allowed the development of a wide ranging blue-skies

research

programme into the use of F2 for organic synthesis and this

continues at Durham to the present.

Expertise was developed to overcome the many problems of using F2

for the safe synthesis of fine

chemicals. In particular, techniques involving the use of dilute F2

in nitrogen, appropriate solvent

choice (high dielectric constant media such as formic acid, sulfuric acid

or acetonitrile) [1], reactor

vessel design, gas flow regulator systems and stainless steel/monel

fluorine gas handling lines

have been developed over the years in Durham. This has allowed selective

direct fluorination of a

range of aliphatic, dicarbonyl [2], aromatic, heteroaromatic,

heterocyclic, steroid and carbohydrate

derivatives to be established and the mechanism (regiochemistry,

stereochemistry, selectivity) of

these processes to be explored. Indeed, we have shown that controlled

direct fluorination of

aromatic rings is now feasible at room temperature [1].

The control of F2 reactivity by promoting selective

electrophilic reactions using high dielectric

constant media [1] was particularly important, and F2 can now

be considered to act as a typical

electrophilic reagent for a range of electrophilic aliphatic and aromatic

substitution processes. In

particular, efficient direct selective fluorination processes of

β-dicarbonyl and β-ketoester

substrates were established for the first time using acetonitrile or

formic acid as reaction media [2]

to give various fluoro-dicarbonyl and fluoro-ketoester systems in high

yield.

Further control of selective fluorination reactions was achieved by the

design, fabrication and

commissioning of single and multi-channel continuous flow reactor systems,

establishing the use of

convenient and inexpensive flow reactors for gas/liquid processes in the

laboratory [3]. Key new

techniques for the supply of individual gas (F2) and liquid

reagents from single sources to a parallel

array of many flow channels at the same flow rate and pressure whilst

maintaining laminar flow

within the reactor channels were incorporated into the reactor designs.

Fluorine gas can also be used an enabler of other chemical

transformations. For example, reaction

of fluorine in situ with iodine leads to iodine monofluoride which

has been used in highly efficient

electrophilic iodination processes [4] within acidic reaction media for

the synthesis of iodoaromatic

systems directly from corresponding aromatic substrates.

References to the research

[1] R. D. Chambers, C. J. Skinner, J. Hutchinson and J. Thomson,

Synthesis of fluoroaromatic

compounds. J. Chem. Soc., Perkin Trans. I, 1996, 605-609. DOI:

10.1039/P19960000605.

[27 citations]

[2] R. D. Chambers, M.P. Greenhall and J. Hutchinson. Direct fluorination

of 1,3-dicarbonyl

compounds. Tetrahedron, 1996, 1-8. DOI:

10.1016/0040-4020(95)00883-A [57]

[4] R.D. Chambers, C.J. Skinner, M.J. Atherton and J.S. Moilliet. Use of

elemental fluorine for

the halogenation of aromatics. J. Chem. Soc., Perkin Trans 1,

1996, 1659-1664. DOI:

10.1039/P19960001659. [17]

The research quality of the elemental fluorine research programme

(1993-present) led by Prof RD

Chambers (RDC) and Prof G Sandford (GS) is supported by: RDC's election to

FRS in 1997; and

the 2003 award of the Prix Moissan to RDC in 2003 (the premier

international award in Fluorine

Chemistry). GS and RDC have given many plenary and keynote lectures at

major international

conferences (European Symposium on Fluorine Chemistry, ACS Winter Fluorine

Symposium, ACS

National Meetings and International Symposium on Fluorine Chemistry). R.D.

Chambers, Fluorine

in Organic Chemistry (1st edition: 1973; 2nd

edition: 2004) remains the standard textbook in the

field.

Research funding allowing the fluorination programme to be established

included: industrial

support from BNFL Fluorochemicals (three employees seconded to Durham for

3 years; 3 year

PDRA; 2 PhD studentships); the Asahi Glass Co. Japan (2 PhD studentships

including one

employee from Japan seconded to Durham); and the Royal Society (URF to GS,

1996-2001). The

development of single and multi-channel microreactors was funded by: EPSRC

ROPA (1 PDRA, 3

years) and EPSRC Crystal Faraday (1 PDRA, 3 years) schemes, both in

collaboration with F2

Chemicals.

Details of the impact

In 1992 BNFL established a spin-out company, BNFL Fluorochemicals Ltd,

later F2 Chemicals Ltd,

to develop new markets in the fine chemicals sector using their expertise

in the production and

handling of F2 developed from nuclear power generation

applications. A research team (3 PDRA

employees, 3 years) from the company was seconded to the Chemistry

Department at Durham

(1992-1995) in order to establish a skill base, expertise and IPR in the

field. The company also

provided funds for building and equipping a new, purpose-built research

laboratory for handling F2

within the Chemistry Department and RDC subsequently became a

non-executive Director of the

company. The following period (1993-1996) resulted in a suite of over 20

patent applications which

were filed, granted and maintained by F2 Chemicals arising from the Durham

research

collaboration. Most importantly, development of new selective fluorination

methodology of β-ketoesters

in high dielectric constant media was investigated and exemplified at

Durham on a 1 g

scale and published by the DU research team in collaboration with F2

Chemicals in 1996 [2]

following IPR protection [Im1]. Subsequently, Durham direct fluorination

reaction methodology

using F2 [2] was adopted and scaled up to a manufacturing

process by F2 Chemicals Ltd [Im2] with

the design, investment and construction of a 1000 litre Selective Direct

Fluorination (SDF) plant

(Fig. 1a) at their headquarters in Preston to synthesise products for

customers in the life science

industries.

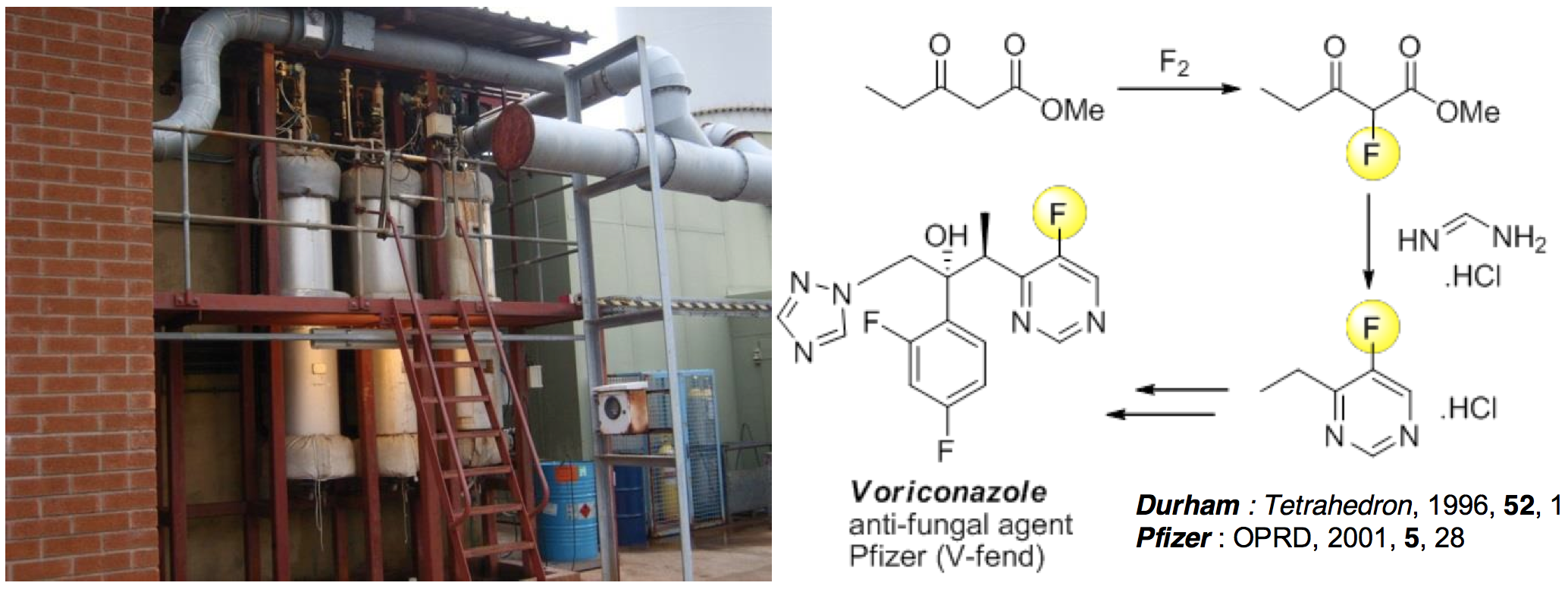

V-FEND (Voriconazole, Pfizer, Fig. 1b) is the world-wide best-selling

systemic, antifungal agent

and has a 5-fluoropyrimidine sub-unit 1 as part of its structure.

Manufacture of fluoropyrimidine

intermediate 1 had been carried out previously by multi-step,

resource intensive strategies

described by Pfizer scientists [Im3] but new Durham methods for selective

direct fluorination of β-ketoesters

using F2 [2] provided the opportunity for a more efficient

2-step process, that is far less

expensive and generates less waste than other procedures. Given this new

business opportunity,

Durham direct fluorination methodology [2] for the synthesis of

β-fluoroketoester 2 (Fig. 1b), as the

key starting material for the manufacture of 5-fluoropyrimiide system 1,

was developed and scaled-up

by F2 Chemicals and used through all the clinical trial, launch and

commercialization periods of

V-FEND by Pfizer [Im3]. In the period from January 2008 to July 2013,

multi-tonne quantities of F-ketoester

1 were manufactured by F2 Chemicals Ltd [Im2] as the exclusive

supplier for Pfizer using

Durham direct fluorination chemistry [2]. World-wide sales of V-FEND in

the 2008-2012 REF period

total $4.65 billion [Im4] making this product one of the global top 100

best-selling pharmaceuticals.

Figure: impact of Durham selective direct fluorination methodology. Left: Selective Direct Fluorination plant at F2 Chemicals (Preston). Right: new strategy for the synthesis of a fluoro-ketoester, a key intermediate of Pfizer’s V-Fend antifungal agent.

Figure: impact of Durham selective direct fluorination methodology. Left: Selective Direct Fluorination plant at F2 Chemicals (Preston). Right: new strategy for the synthesis of a fluoro-ketoester, a key intermediate of Pfizer’s V-Fend antifungal agent.

V-FEND's economic and societal impact arises from its use as a triazole

antifungal medication

[Im5] active against serious, invasive fungal infections such as

candidiasis, aspergillosis, and

certain emerging fungal infections [Im6]. Aspergillosis is primarily an

infection of the lungs caused

by the inhalation of airborne spores of the fungus Aspergillus

which is commonly found growing on

dead leaves, stored grain, compost piles, or in other decaying vegetation.

There are several forms

of aspergillosis: pulmonary aspergillosis is an allergic reaction to the

fungus that usually develops

in people who already have lung problems (such as asthma or cystic

fibrosis); aspergilloma is a

growth (fungus ball) that develops in an area of past lung disease or lung

scarring (such as

tuberculosis or lung abscess) and pulmonary aspergillosis (invasive type)

is a serious infection

associated with pneumonia that can spread to other parts of the body. This

infection almost always

occurs in people with a weakened immune system due to cancer, AIDS,

leukaemia, an organ

transplant, chemotherapy, or other conditions or medications that lower

the number of normal

white blood cells or weaken the immune system. For example, invasive

pulmonary aspergillosis

(IPA) is estimated to occur in 5-13% of people who have a bone marrow

transplant, 5-25% of

people with a heart or lung transplant and 10-20% of people who undergo

high-dose radiotherapy

for leukaemia.

Durham selective fluorination chemistry [2, Im1] has therefore played a

significant role in impacting

many patients treated by V-FEND, giving world-wide health benefits in the

treatment of fungal

infections for a wide range of disease control.

In order to further develop the use of Durham F2 chemistry for

fine chemical manufacture, a

Durham University spin-out company, Brock Fine Chemicals Ltd [Im7], was

established in April

2011 by Graham Sandford with assistance and legal expertise from Durham

Business Innovation

Services (DBIS). Brock (UK registered company 7610103) attracted proof of

concept funding

(£100K) from the NorthStar regional investment group [Im8] to further

exploit the use of fluorine for

fine chemical manufacturing, particularly for the synthesis of a range of

iodo-aromatic derivatives

using Durham fluorine-mediated iodination chemistry [4]. The company now

employs 2 FTE

chemists and associated marketing and finance expertise. It has made sales

of over 100 fine

chemical products to chemical distributors such as Fluorochem, Acros, Alfa

Aesar, Apollo Scientific

and Shigematsu since trading began. Sales in Year 1 were £8K growing to

£40K in Year 2 and

within the proof-of-concept business plan.

Multi-channel continuous flow microreactor techniques developed at Durham

[3] were patented by

Durham University [Im9] and a world-wide exclusive license negotiated by

the University (DBIS)

and granted to the Asahi Glass Co., Japan for a significant fee and a

subsequent royalty stream.

This acquisition formed a core part of the IP knowledge base in flow

reactor technology at Asahi

Glass.

Sources to corroborate the impact

[Im1] Fluorination of β-ketoesters patent: R.D. Chambers, M.P.

Greenhall, J. Hutchinson, J.S.

Moilliet, J. Thomson, PCT Intl Appl WO 95/14646 (June 1st

1995); Chem. Abstr. 1995, 123,

339705.

[Im2] F2 Chemicals: Managing Director, F2 Chemicals Ltd, www.f2chemicals.com.

[Im3] V-FEND application: the use of Durham/F2 Chemicals direct

fluorination methods for the

synthesis of V-FEND is described by Pfizer scientists in M. Butters and

co-workers, Org.

Proc. Res. Dev., 2001, 5, 28-36.

[Im4] V-FEND sales: annual global sales of V-FEND are given in successive

Pfizer Annual reports:

2008: http://www.pfizer.com/files/annualreport/2008/financial/financial2008.pdf

(p 2)

2009: http://www.pfizer.com/files/annualreport/2009/financial/financial2009.pdf

(p 21)

2010: http://www.pfizer.com/files/annualreport/2010/financial/financial2010.pdf

(p 25)

2011: http://www.pfizer.com/files/annualreport/2011/financial/financial2011.pdf

(p 21)

2012: http://www.pfizer.com/files/annualreport/2012/financial/financial2012.pdf (p115)

[Im5] V-FEND (Pfizer): trade name of Voriconazole: http://en.wikipedia.org/wiki/Voriconazole;

http://www.pfizer.com/products/rx/rx_product_vfend.jsp.

[Im6] V-FEND applications: for details on the various types of

aspergillosis and treatment regimes,

see: http://www.nhs.uk/conditions/Aspergillosis/Pages/Introduction.aspx.

[Im7] Brock Fine Chemicals Ltd: UK registered company 7610103, April 19th

2011,

www.brockfinechemicals.com; sales

figures contained in Annual Reports registered with

Companies House.

[Im8] Brock investment: investment analyst, NorthStar http://www.northstarei.com.

[Im9] Flow systems: multi-channel microreactors patented by DU: R.D.

Chambers, G. Sandford

and D. Holling, U.K. Pat Appl. 0210809.0, 11th May 2002.