Unique materials signature identified from nanotechnology research leads to spinout company to combat forgery (Ingenia)

Submitting Institution

University of DurhamUnit of Assessment

PhysicsSummary Impact Type

TechnologicalResearch Subject Area(s)

Chemical Sciences: Physical Chemistry (incl. Structural), Theoretical and Computational Chemistry

Engineering: Materials Engineering

Summary of the impact

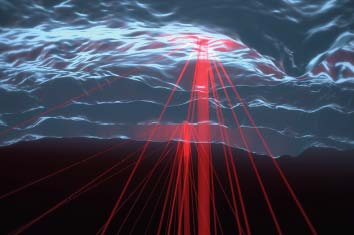

Fundamental research in Durham Physics Department in 2002-4 demonstrated

that the nanoscale structure of materials gives a unique signature from

its effect on the diffuse scattering of laser light. Paper has a large

scale stochastic pattern from the wood fibres which is distinctive enough

to allow identification of the manufacturer, while small scale random

variations can uniquely identify an individual sheet. This technique can

be used to combat forgery by `fingerprinting' documents, packaging and

even gold bullion. The impact from this intellectual property is exploited

through a spinout company, Ingenia technology, which has won

multiple awards.

Underpinning research

The magnetism group in Durham Physics Department focuses on thin film

materials for spintronic devices. Such devices can provide a non-volatile

alternative to standard silicon memory chips, but the polarity of the

magnetic domains is difficult to switch reliably due to stochastic

fluctuations in the size of the domains. Russell Cowburn joined this group

as a lecturer in October 2000, and worked on characterising these

fluctuations in magnetic structures as a prerequisite to controlling them

[e.g. 1]. He used laser speckle imaging to determine the characteristic

size scale of the magnetic domains, where each point on the illuminated

surface acts as a secondary source of diffuse spherical waves which

interfere to produce a speckle pattern whose properties are determined by

the surface roughness over the entire illuminated surface (Fig 1). One day

the memory chip being tested fell off its paper backing, and the laser hit

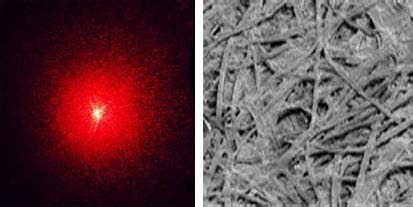

the paper instead. Prof Cowburn realised that the speckle pattern (Fig 2)

that resulted from the paper fibres (Fig 3) had all the right

characteristics for a security device as it depended on the random, and

hence unique, alignment of nanoscale structures over the macroscopic size

of the sample.

Fig 1: Surface roughness

giving rise to diffuse light

Fig 1: Surface roughness

giving rise to diffuse light

Fig 2: Laser speckle pattern from surface roughness

Fig 2: Laser speckle pattern from surface roughness

Fig 3: Electron microscope

image of paper fibres

Cowburn's team at this time consisted of Atkinson (staff member in Durham

Physics 2001-present), Allwood (postdoc in Durham Physics 2001-2005, then

moving to Sheffield), Petit and Xiong (postdocs in Durham Physics

2001-2005, then moved to Imperial), Buchanan (PhD student and postdoc in

Durham 2000-2005, then moving to Imperial ), Jausovec (PhD student in

Durham 2003-2005, then moving to Imperial), and two undergraduate project

students, Kate Fenton (Durham MSci Physics 2001-2005), and Peter Seem

(summer student from Cornell BSc Engineering Physics 2001-2005). They were

able to show that the overall properties of the speckle pattern could be

used to identify the generic type of paper and its manufacturer, and that

the specific details of the speckle pattern were unique to each piece of

paper. An individual sheet of paper could be identified by its speckle pattern after being mixed back

into the full ream from which it was taken. This pattern is also very

stable as it depends solely on the topography of the fibres (Fig 3). This

meant that the paper could still be identified even after being charred

black by heat or soaked in water [2].

Cowburn's nanomagnetism research programme in Durham was supported to a

total of about £4M by Ingenia Holdings, a venture capital company then

operating under the name of Eastgate Investments Ltd. Initial patents

including both the process itself and technical aspects of pattern

matching via Fourier transforms were filed in March and August 2004 [P1-3]

and assigned to Ingenia Holdings under the terms of the research funding

agreement. In January 2005, Prof Cowburn moved to Imperial College, London

to take up a Chair in Nanotechnology, together with several of his

research group. The article describing the application of the technique to

the detection of forgery in documents and packaging appeared in Nature in

July 2005 [2]. Hence the majority of this underpinning research, described

in the paper, was performed in Durham, Prof Cowburn's Durham team

(including the undergraduate project students) being co-authors of the

paper.

References to the research

[2] Buchanan,

J.D.R., Cowburn, R.P., Jausovec, A-V, Petit, D., Seem, P., Xiong, G.,

Atkinson, D., Fenton, K., Allwood, D.A. and Bryan, M.T. 2005. Forgery:

`Fingerprinting' documents and packaging Nature 436: 475

(all authors were in Durham for the majority of their contribution to the

research) 78 citations

[P1] Cowburn, R.P. Determining

a signature from an article to determine its authenticity, UK

patent GB2411954B. Assignee Ingenia Technology, Application date 12th

March 2004, Publication date 14th September 2005

[P2] Cowburn R.P., Authenticity

verification methods, products and apparatuses, UK patent

GB2417074, Application date 13th August 2004, Publication date

15th February 2006

[P3] Cowburn R.P., Verification

of articles utilizing fourier transform thumbnails, UK patent

GB 2417592, Application date 13th August 2004, Publication date

1st March 2006

Details of the impact

A recent report from the UN's Office on Drugs and Crime (UNODC) on

organised crime across the Asia-Pacific region estimated that the market

in counterfeit goods is worth $24.4 billion i.e. about 2% of world trade,

and that it is as profitable for criminal gangs as the trade in illegal

drugs [C1]. This highlights the scale of the problem, and also the scale

of the potential impact of successfully combating forgery.

Ingenia Technology (UK) Ltd was incorporated in October 2006 to

commercialise the technique, now known as Laser Surface Authentification

(LSA). There followed much more research and development after Prof

Cowburn's move to Imperial College in order to turn the process into a

feasible, practical and robust technique to counter forgery and

counterfeiting, resulting in a whole series of subsequent patents which

cite the original work [e.g. P4-6].

LSA has major advantages over previous methods of authentication such as

watermarks or holograms in that the surface is an inherent rather than an

additional feature of the document so does not require additional

manufacturing. The speckle pattern depends on the nanoscale fluctuations

over the entire illuminated surface, and there is no known method to

fraudulently reproduce this, unlike watermarks/holograms which are

difficult but not impossible to replicate (if you can make it, you can

fake it). Ingenia Technology claims that it "has been described as

being like a fingerprint or DNA sequence for the item, is unique for

every document, card and carton and can be used to uniquely and

unambiguously identify the item." [C2]

Much of the business is in designing bespoke implementations, with

applications in security (Fig 4, from C2), customs, and law enforcement.

These are highly sensitive, so the company will not release details.

However, several applications are public, including authenticating

packaging of luxury goods and pharmaceutical products. The packaging is

scanned on the production line and the speckle pattern stored on a secure

custom database (LSANet). A mobile LSA field unit (Fig 5) can scan the

package anywhere in the world and authenticate it against the database

[C3]. This application was developed in partnership with Bayer Technology

Services GmbH, a subsidiary of Bayer GmbH which offers fully integrated

solutions for chemical/pharmaceutical plants [C4]. It is also used by

Cartondruck, a German based folding carton manufacturer, who installed an

LSA system on one of its production lines for packaging high-end perfumes,

cosmetics and other luxury products. Cartondruck Head of Sales and

Marketing says: "The LSA system is simple and 100% reliable, and it

works with different materials. Our customers don't have to come to us

or to send the product to us to have a scan made. We are happy to have

this market advantage." [C5]. The newest scanners, released in April

2013, are capable of processing 50 items per second, and the LSANet

database can now hold up to 100 billion items [C6].

Fig 4: securities application of LSA technology

Fig 4: securities application of LSA technology

Fig 5: LSA portable unit designed for use in

the field

Fig 5: LSA portable unit designed for use in

the field

The technology is not limited to paper but can be used on other systems

which exhibit stochastic fluctuations. Ingenia Technolgy has developed a

complete authentication system for precious metals with leading Swiss

refiner PAMP. This Veriscan™ system uses Ingenia's Laser Surface

Authentication system to scan and code every gold and silver bar produced

by PAMP and then enables authentication by multiple users across the

world. Ingenia hosts the secure database for PAMP and has developed a

customised version of their hardware and software for them [C7-8].

In 2010 Ingenia Technology signed a partnership agreement with IDT

Systems Ltd, a leading 2D and 3D in-surface decoration systems provider.

IDT will include LSA as part of its in-surface decoration and

personalisation offerings, specifically targeting the consumer electronics

sector. "Working with Ingenia Technology will allow us to offer a much

more comprehensive authentication and identification package for our

customers," commented the CEO of IDT Systems. "Ingenia's LSA

technology is the most robust and sophisticated solution for product

tracing and anti-counterfeiting that we have seen in the marketplace"

[C9].

Ingenia Technology (UK) Limited has its headquarters in London with

satellite offices in Vienna and Zurich. At 31st December 2011,

it had shareholder funds of just over £5M on its balance sheet [C10]. The

Ingenia team consists of 15 people, with a mix of business and security

experts. It includes three members who were originally part of the

university research team as well as specialist engineers and physicists

with many years of experience in electronic and product engineering [C11].

The company have won multiple awards including the prestigious 2006 Global

Security Challenge Award for the most promising Security Start-Up of the

year, with subsequent awards in 2007 from Hermes for Best Technology

(together with Bayer Technology Services), and two awards for Emerging

Technology Companies (Red Herring Europe 100 and Red Herring Global 100)

[C12].

Sources to corroborate the impact

[C1] UN report on transnational organised crime in East Asia and the

Pacific

http://www.unodc.org/documents/data-and-analysis/Studies/TOCTA_EAP_web.pdf

[C2] Ingenia web site securities application

http://www.ingeniatechnology.com/the-lsa-technology/

[C3] Ingenia web site — mobile field scanner

http://www.ingeniatechnology.com/product/

[C4] Ingenia presentation — Bayer Technology Services pharmaceutical

production line

http://www.who.int/impact/activities/McGlade.pdf

[C5] Packaging Today 2nd April 2012.

www.packagingtoday.co.uk/features/featurelooking-the-part

[C6] Ingenia high speed scanner launch

http://www.ingeniatechnology.com/wp-content/uploads/2013/04/ING130408_HighSpeedScannerLaunch.pdf

[C7] PAMP press release on Veriscan (not available on the web)

Filed with corroborating documents, also referenced in the PAMP news item

01/29/2013

http://www.pamp.ch/allnews

[C8] Andrew Gilbert, Business Development Director and Deputy Managing

Director of Ingenia Email filed with corroborating documents

[C9] Ingenia and IDT sign partnership agreement

http://www.businesswire.com/news/home/20101029005385/en/Ingenia-Technology-IDT-Systems-Sign-Partnership-Agreement

[C10] Ingenia accounts from FAME database

filed with corroborating documents

[C11] Ingenia about us

http://www.ingeniatechnology.com/about-us/

[C12] Wikipedia entry for Ingenia

http://en.wikipedia.org/wiki/Ingenia_Technology#Awards