Large semiconductor crystals for security and medical imaging (Kromek)

Submitting Institution

University of DurhamUnit of Assessment

PhysicsSummary Impact Type

TechnologicalResearch Subject Area(s)

Physical Sciences: Other Physical Sciences

Chemical Sciences: Macromolecular and Materials Chemistry, Physical Chemistry (incl. Structural)

Summary of the impact

Research on vapour growth of semiconductor compounds led to a key

breakthrough in growing large crystals which form the basis for sensitive

X-and gamma-ray detectors. The process was commercialised by a Durham

University spin-out company, Kromek Ltd., which floated on AIM at £55M and

has over 100 employees in the UK and USA. The X-ray detectors are in use

in Kromek's security systems for screening liquids at airports,

significantly reducing restrictions on duty free goods. This application

won the $400,000 international prize in the 2009 Global Security

Challenge. The company also markets gamma-ray detectors for nuclear

isotope identification. These have won contracts totalling $7.5M from the

US Defense Threat Reduction Agency and are in use at Fukushima.

Underpinning research

The late Professor Andy Brinkman (member of Durham Physics department

from 1980-2010) led an established research group that worked on the

growth, characterisation and exploitation of group II-VI compound

semiconductors. He had a longstanding interest in CdTe and CdZnTe, which

form the basis of energy sensitive X-(CdTe) and gamma-ray (CdZnTe)

detectors, and can also be used as substrates for thermal imaging devices.

However, commercial applications of these were limited by problems in

growing large crystals. Standard melt growth processes only produce wafers

less than 2 inches in diameter, whereas medical imaging applications

require larger area detectors. While these can be made by butting several

smaller crystals together, this is uneconomic as the cost scales with the

number of crystals rather than their size.

Prof Brinkman (in collaboration with Profs Tanner (Durham Physics

1973-present) and Durose (Durham Physics 1992-2011) led a BRITE-EURAM

grant (1994-1997), with major academic partners including the Universities

of Freiburg: Germany, Athens: Greece and Ancona: Italy) to explore and

develop methods to improve the growth of CdTe. He realised that vapour

growth was not subject to the same size limitations as melt growth

processes, but the resulting material was largely polycrystalline as the

crystal growth was disrupted by the heat from the vapour source. The key

breakthrough in growing high perfection single crystals was made by Dr

John Mullins, a postdoc working with Prof Brinkman in Durham, funded by

the BRITE-EURAM grant. He realised that the vapour source and deposition

region could be thermally decoupled by using a bent tube rather than a

straight tube, so that the growing crystal was not heated directly by the

source. The first high quality CdTe crystals were grown using this

technique in 1997, and the process was patented in 1998 [P1]. The first

results were published in a peer reviewed journal in 1999 [1], with a full

description of the growth system in 2000 [2].

Research on this technique continued with £0.17M grant support from EPSRC

(2000-2003). The potential of the process became increasingly clear, and

development of this into a commercial product was supported by a £0.15M

PPARC PIPPS grant (2005-2006) and £0.93M from a DTI basic technology award

via EPSRC (2006-2010). This work culminated in 2007 with the

heteroepitaxial growth of the first high perfection wafers of CdTe with

good electrical qualities, using GaAs as the substrate [e.g. 3-5]. By 2009

they could scale this up to grow 4 inch diameter crystals of CdTe, and in

2011 succeeded in making similarly large crystals of CdZnTe [6].

References to the research

All Journals are international and peer reviewed

[P1] Granted Patents: Apparatus and process for crystal growth, US

6375739 B1, EP1019568A1 filed July 27 1998

Grants to Prof Brinkman:

EPSRC GR/N04287 £177,480 Jan 2000 to Dec 2002. Controlled Vapour Growth of

CdTe

PIPPS PP/C503470/1 £152,545 Jan 2005 to Dec 2006. Evaluation of

Foreign and Hybrid crystal growth

EPSRC EP/DO48737/1 £931,012 Jul 2006 to June 2010.New Materials for High

Energy Colour X-ray Imaging

Details of the impact

In 2003, with venture capital from Prof. Max Robinson, a business angel

who was at that time a member of the Durham University Technology Transfer

team, the intellectual property was licensed to a spin-out company, Durham

Scientific Crystals, subsequently renamed Kromek, in order to directly

exploit the new vapour growth process. Supplemented by a DTI SMART award,

the first commercial crystal growth facility was established in the

company's first premises in the Mountjoy Research Centre, which was then

the University business incubator. There were initially two staff members,

Drs Arnab Basu and Ben Cantwell, both of whom had just completed their

PhDs with Prof Brinkman in the Physics Department in Durham. The company

rapidly outgrew its original accommodation and moved to NETPark (North

East Technology Park), Sedgefield in 2005. Continued growth necessitated a

move to larger, purpose built premises in NETPark (see Fig 1 & 2),

opened by Prince Andrew in 2010 [C1]. The company now employs over 50

people, including several sub-contractors, at NETPark.

Fig 1 Kromek’s NETPark (Sedgefield) premises

Fig 1 Kromek’s NETPark (Sedgefield) premises

Fig 2 Part of the crystal growth facility

Fig 2 Part of the crystal growth facility

The business model initially focused on the growth of large, high purity

CdTe and CdZnTe crystals for sale to other companies building X-and

gamma-ray detectors or infrared imaging systems. However, the company

then took the strategic decision to move up the product value chain by

fabricating their own imaging detectors, incorporating ASIC (Application

Specific Integrated Circuit) electronics. The potential of these attracted

£1M investment in 2005 from Amphion, the UK arm of a US venture capital

company investing in high tech start-up companies. Subsequent calls for

venture capital resulted in investment of over £24M, with a round in 2009 raising £12.3M [C2].

To ensure direct supply of the ASIC technology, Kromek bought Nova

R&D in 2010, an electronics company employing 13 staff at its

Riverside, California base [C3]. In June 2011, Kromek and Nova held 34

granted patents. In February 2013, Kromek acquired Endicott Interconnect

Detection and Imaging Systems (EIDS), based in Saxonburg, PA, USA in a

strategic move to consolidate the market in melt-grown CdZnTe material.

This acquisition added another 40 staff, 25 patents and 300 trade secrets

to the Kromek Group. EIDS is now trading again as eV Products [C4].

Initially the company explored applications in the medical imaging market

where there are multiple applications for colour X-ray imaging. Kromek had

a $1.5M contract from the US National Institute for Health to develop an

advanced X-ray camera for breast cancer detection, building on expertise

developed from an earlier contract with Siemens to build pixelated X-ray

detectors for computerised tomography (CT) scanners [C5]. However,

security systems presented even more opportunities with new requirements

for screening airport carry-on baggage since 9/11. Supported by the UK

Home Office and its investors, the company incorporated their detectors

into X-ray systems for liquid explosive detection. In 2008 (the same year

it was awarded the ISO2001 manufacturing quality stamp) it launched a

bottle scanner which can deal with individual containers. The system, now

in use at airports around the world, has a direct impact on all airline

passengers as it allows duty free liquids to be carried through airport

security screens [C6]. The liquid scanning system (see Fig 3) readily

distinguishes Coca-Cola from Pepsi, and was awarded the

newly created Standard 3 for Liquid Explosive Detection Systems (LEDS)

following recent regulatory trials (August 2013). Kromek Chief Executive

Officer, Dr Arnab Basu said: ''This achievement, together with a 20%

reduction in scan time, design changes that include a much faster and

simpler user interface, and a roadmap to further reduce the scanning

time by 50% put Kromek's explosives detection equipment ahead of the

pack.....What makes the Identifier unique is its ability to scan metal

cans, Tetra Pak and foil pouches, in addition to all types of glass

and plastic containers; this means the Kromek Identifier is the only

ECAC Standard 3 approved system that can scan every container type with

a simple one button operation." [C7]

Fig 3. Bottle scanner in use in airport security

Fig 3. Bottle scanner in use in airport security

The company went from winning regional awards in 2007 (Business Link

North East Business award, Business Innovation Centre), to national

competitions in 2008 (IET Innovation award), and European success in 2009

(Western Europe Global Security Challenge for Best Security SME). This

series culminated in the $400,000 Global Security Challenge award in 2009

for Best Security SME, while Dr Arnab Basu, now Kromek's CEO, won the 2009

Ernst and Young title of UK Young Entrepreneur of the Year [C8].

Other security applications use CdZnTe (CZT) crystals for gamma-ray

detection systems. In 2010 the company won a $4M contract with the US

Defense Threat Reduction Agency (DTRA) to develop detectors for

radioactive materials as part of its on-going anti-terrorist measures

[C9], and the resulting products are also on sale as handheld radiation

monitors e.g. Kromek's GR1 detectors (Fig 4) which are in use at Fukushima

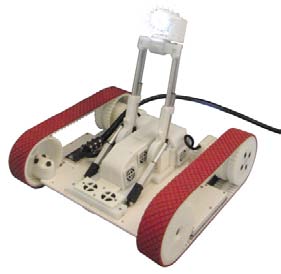

for decommissioning the nuclear plant [C10]. These can be combined with a

wall climbing, radio controlled robot to provide nuclide identification in

hard-to-reach, high-risk environments where safety is paramount (Fig 5).

The company has also developed a home radiation monitor, RadAngel, which

can be used with most iOS or Windows devices. This product was launched in

Japan in July 2012 and is now available directly to consumers for around

$2000 (Fig 5). Other Kromek products [C11] include the RayMon10 handheld

radiation monitor and isotope identifier, and RadViz a CZT based gamma ray

camera that enables remote nuclear characterisation with 3D dose mapping

capability for the nuclear industry. Kromek was awarded a further $3.5M

from the DTRA in collaboration with Northrop Grumman.

Fig 4: GR1 gamma ray detector as used in Fukushima

Fig 4: GR1 gamma ray detector as used in Fukushima

Fig 5: radio controlled wall climbing vehicle with GR1

Fig 5: radio controlled wall climbing vehicle with GR1

Fig 6: RadAngel home radiation monitor

Fig 6: RadAngel home radiation monitor

Since the original company spun out, there has been continuing research

collaboration between the University and the company. Prof. Tanner, a

member of staff of the Physics Department, is the Deputy Chairman of the

company board and Prof Brinkman was a Kromek Director until his death in

2011. The company has supported PhD students, as well as staff time buyout

for Prof Brinkman. A former CASE student in the group, (Paul Scott), and

an ex-PhD student of Prof Tanner, (Alex Pym), have been employed by

Kromek, as is the original inventor of the growth technique, Dr. John

Mullins.

The company was valued in May 2013 (and also on 7th November)

at £74M. Turnover grew from £13,231 in 2006-7 to £2.8M in 2011-12 and

£2.7M for the year ending April 2013. It is predicted to be £5.07M for the

year ending April 2013; shipments of product and services in April 2013

alone reached £1M. The order book stood at $5.85M in May 2013. The Kromek

Group plc was listed on the London AIM Stock Exchange on 16th October 2013

at a value of £55M, raising £15M on the floatation.

Sources to corroborate the impact

C1 Prince Andrew opening Kromek building

http://www.nebusiness.co.uk/business-news/latest-business-news/2010/07/14/kromek-s-crowning-glory-51140-26850379/

C2. Amphion 2009 Investment funding http://www.amphionplc.com/regulatory_03152010.php

C3 Nova R&D acquisition http://www.kromek.com/aboutus_nova.asp

C4 EDIS now ev products acquisition http://www.kromek.com/aboutus_evproducts.asp

C5. Medical imaging

http://www.proactiveinvestors.co.uk/companies/news/23431/amphion-innovations-partner-kromek-secures-us15m-contract-from-umass-23431.html

C6. Newcastle airport trials http://news.bbc.co.uk/1/hi/uk/8244150.stm

C7 Identifier bottle scanner achieves Standard 3 for Liquid Explosive

Detection Systems

http://www.kromek.com/news_loadstory.asp?NewsID=431&KeepThis=true&TB_iframe=true&heigh

t=520&width =800

C8. Awards http://www.kromek.com/news_awards.asp

C9 US Defence Threat Reduction Agency

http://www.nebusiness.co.uk/business-news/latest-business-news/2009/12/03/kromek-secures-2-4m-deal-with-us-government-51140-25309390/

C10 GR1 in use at Fukushima

http://www.iii.co.uk/investment/detail/?display=discussion&code=cotn%3AAMP.L&it=le&action=detail&id=8795623

C11 Kromek Products http://www.kromek.com/products.asp