Compliant layer lubricated artificial joints

Submitting Institution

University of DurhamUnit of Assessment

General EngineeringSummary Impact Type

HealthResearch Subject Area(s)

Engineering: Biomedical Engineering, Materials Engineering

Summary of the impact

This case concerns the impact of research carried out at the Durham

Centre for Biomedical Engineering on compliant layer lubricated artificial

joints, which mimic natural human joints and have been used by a

commercial company (Active Implants, USA) to develop specific products

namely "TriboFit" and "NUsurface" conservative hip and knee replacement

systems. Our underpinning technology has allowed them to produce a

successful range of products. To date 1300 patients in Europe, Israel and

Australia have received the "TriboFit" devices and about 90 patients are

taking part in a $10M clinical trial on the "NUsurface" artificial

meniscus for the knee.

Underpinning research

The research underpinning impact in this case has been led for over two

decades by Professor Tony Unsworth at Durham University. Early research

into the lubrication of natural human joints led to the conclusion that

artificial joints with the same extremely low friction and wear as natural

joints would need much softer bearings (based on silicone elastomer) in

order to develop elasto- hydrodynamic lubrication to generate thick fluid

films to separate the articulating surfaces. Before this advance,

artificial joints were much harder (using materials such as metals,

ceramics & UHMWPE). Prior to 1993, Durham research established which

elastomeric materials could be produced in the appropriate range of

elastic modulus whilst being tough, fatigue resistant, hydrophilic and

biocompatible and also determined appropriate lubricants for the joints.

Since 1993 Unsworth has led many research projects developing these

artificial joints in a hip joint simulator, which he designed and

manufactured in the laboratory in Durham.

In 1994 Unsworth published the results of finite element analysis and

analytical techniques to obtain the optimised material sizes and shapes

for these joints. His research coincided with the increased availability

of polycarbonate urethanes which were stable against hydrolysis and had

otherwise very similar or enhanced properties. In order to achieve a

gradual change in modulus from the surface to the bone of the pelvis a

layered structure was required which proved to be more difficult than

envisaged. However with the help of an orthopaedic device manufacturer

(Howmedica Ltd) and other PhD student projects, conditions were optimised

and viable artificial joints were manufactured.

After extensive laboratory testing for friction, wear, fatigue,

delamination and degradation hip joints were designed and made for trials

in sheep. These were implanted in sheep in Australia for up to 4 years and

the results were analysed by an independent team in Cambridge (to

eliminate bias). The results were published in two papers in Biomaterials

in 2005.

Dates of developments:

1993-2010; Funded projects

1994/5; Published finite element analysis of compliant layer joints.

2006; Sheep trial concluded (with Don Howie in Australia and Imran Khan

in Cambridge)

2007 to date; Application of compliant layers to knee joints.

References to the research

Outputs:

1. Strozzi A, Unsworth, A, Axisymmetric finite element analysis of hip

replacement with an elastomeric layer: The effects of layer thickness.

Proceedings of the Institution of Mechanical Engineers, Part H: Journal of

Engineering in Medicine,1994, 208, 139-149.

doi:10.1243/PIME_PROC_1994_208_279_02

2. Ash HE, Scholes SC, Unsworth A, Jones E, The effect of bone cement

particles on the friction of polyethylene and polyurethane knee bearings.

Phys Med Biol 2004, 49, 3413-3425. doi:10.1088/0031-9155/49/15/007

3. Scholes SC, Burgess IC, Marsden HR, Unsworth A, Jones E, Smith N,

Compliant layer acetabular cups: friction testing of a range of materials

and designs for a new generation of prosthesis that mimics the natural

joint. Proc Instn Mech Engrs Pt H 2006, 220, 583-596. DOI:

10.1243/09544119H06404

4. Scholes SC, Unsworth A, Blamey JM, Burgess IC, Jones E, Smith N,

Design aspects of Compliant, soft layer bearings for an experimental hip

prosthesis, Proc Instn Mech Engrs,2005 H 219, 79-88. DOI:

10.1243/095441105X9318

5. Scholes SC, Unsworth A, Jones E, Polyurethane unicondylar knee

prostheses: simulator wear tests and lubrication studies, Phys Med Biol

2007, 52, 197-212. doi:10.1088/0031-9155/52/1/013

6. Smith SL, Ash HE and Unsworth A, A tribological study of UHMWPE

acetabular cups and polyurethane compliant layer acetabular cups. J. of

Biomed. Research, J. Applied Biomaterials 2000. 813B. 710-716. doi:

10.1002/1097-4636(2000)53:6<710::AID-JBM14>3.0.CO;2-R

7. Jones E, Scholes SC, Burgess IC, Ash HE, Unsworth A, Compliant layer

bearings in artificial joints. Part 2: simulator and fatigue testing to

assess the durability of the interface between an elastomeric layer and a

rigid substrate. Proc. Instn. Mech.Engrs, Part H, J. Engineering in

Medicine, 2009, H 223, 1-12. 10.1243/09544119JEIM446

Funding:

• COMPLIANT LAYER KNEES, Howmedica International Inc, £199652, 1997-2000

• FRICTION AND WEAR TESTING, Stryker, £156990, 2001-2003

• R080467: CAMBRIDGE HIP & COMPLIANT LAYER KNEE JOINT, Stryker,

£108253, 2004-2009

• RF080044: VARIOUS SHORT-TERM PROJECTS FOR STRYKER, Stryker, £20000,

2007-2009.

And there were two grants which overlapped the start of the Impact Period

namely

• "A new generation of artificial joints", EC Brite-Euram, £750,000

(total), 1991-5

• "Soft-layered joints for longer life", Howmedica International,

£370,000, 1992-5

Prizes:

The work led to the award of the Best paper prize for 2009 by the

Proceedings of the Institution of Mechanical Engineers Part H Journal of

Engineering in Medicine. It also contributed to several prizes awarded to

Unsworth (James Alfred Ewing Gold Medal, 2005, James Clayton award, 1999).

A large number of speaking invitations have been received from this work

including the following all of which have been funded by the organisations

listed. These relate to compliant layer joints.

• Keynote address "Compliant layer lubrication" AUSTRIB 98, Brisbane,

Australia, December 1998

• Keynote address "Tribology of artificial Joints", European Society for

Biomechanics, Dublin, 2000

• Plenary address "Tribology of artificial Joints", Nordic Orthopaedic

Society, Tampere, Finland, June 2000.

• "Woolmer Lecture", (Prestige lecture) Hip Joint replacement, Institute

of Physics and Engineering in Medicine , 2002

• Smith and Nephew Lecture, Tribology of artificial Hip Joints,

Institution of Mechanical Engineers, 2004

• Compliant Layer Lubrication in hips and knees, Invited lecture,

Emerging Orthopaedic Technologies Seminar, Flims, Switzerland, 2005.

• New advanced materials for hips and knee replacement. Invited Lecture

International Society for Technology in Arthroplasty (ISTA), Seoul, South

Korea, October 2008

• In pursuit of fluid-film lubrication, Invited Plenary session (award

winner) Bruges, Belgium, 2011.

Details of the impact

The research on compliant layer lubrication originated in the Durham

laboratories as a concept and has been developed into a viable product of

which any orthopaedic company can take advantage. The analysis in Output 1

(along with a sister paper in 1995 which covered elastic material

properties) provided confidence via modelling of the viability of the

materials and system proposed. The later papers cited above are examples

of the gradual development of the joints, to the stage where they have now

been commercially exploited.

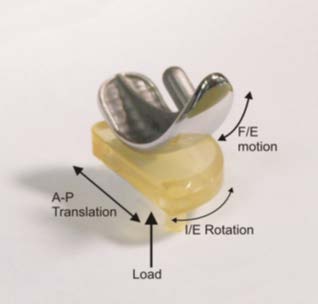

Knee joint (from Output 4)

Knee joint (from Output 4)

In the corroborating evidence supplied with this case Active Implants

Corporation (AIC), Memphis, USA can confirm how they built their company

on our published papers and PhD theses (e.g. Outputs 2-5 are specified

explicitly in their supporting letter) on this subject over many years.

This company was formed in 2004 basing its products on the compliant

bearing concepts researched in Durham. They state "This concept of

compliant bearing materials has been the focus of much of Professor

Unsworth's work and has been foundational in developing our hip system. To

date the TriboFit hip system has been used to treat more than 1300

patients throughout Europe, Israel and Australia since 2006".

Knee joint (from Output 4)

The TriboFit hip system received CE marking in 2008 and distribution

partnerships have been established in UK, Spain, Portugal, Italy, Germany

and Australia. NUsurface is a replacement meniscal system for knees also

based on compliant bearing principles. This, too, is currently undergoing

clinical trials (http://www.activeimplants.com/meniscus-clinical-study.html)

for which AIC raised $10M from investors (http://www.globes.co.il/serveen/globes/docview.asp?did=1000714802&fid=1725)

Without the Durham research, AIC would probably not have existed as a

company as it started from the current VP reading the Durham work,

attending conferences where Durham staff presented research and visiting

the laboratories. Unsworth also spoke at a number of company events and

discussed possible new ideas with AIC.

AIC states that "Professor Unsworth has been instrumental in the

development of our implant systems particularly as it relates to compliant

bearing technologies. His peer reviewed research, personal communications

and student PhD theses have all been foundational in the concept, design

and development of the first commercialised hip and knee systems utilising

compliant bearing ideas. We have copies of all his nearly 40 published

papers on this subject and have copies of two Durham PhD theses".

Sources to corroborate the impact

- Letter from the Vice President of "Active Implants Corporation" dated

30th January 2012. This refers to the originality of the concept of the

research, the foundational nature of the research to the company's

products and how Durham's research has been incredibly important to the

development of their devices.

- The Vice-President of Active Implants Corporation, Memphis, USA.

- Former Principal Scientist, Stryker, Limerick, Ireland. He can verify

the sponsorship and collaboration with Durham in the development of the

ideas for compliant layer bearing technologies.

- News story as corroboration of $10M investment for NUsurface clinical

trials:

http://www.fiercemedicaldevices.com/story/active-implants-rakes-10m-financing-round/2012-

01-11

- The website for Active Implants: http://www.activeimplants.com