Profiled Endwalls for Reduced Fuel Burn

Submitting Institution

University of DurhamUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Mechanical Engineering, Interdisciplinary Engineering

Summary of the impact

This impact is the improvement of aircraft engine efficiency by the

application of profiled endwalls to turbine blades. The technology was

researched by Durham University and exploited by Rolls-Royce by deploying

the technology on airframes. Engines with profiled endwalls include the

Trent 900 (A380 airframe), Trent 1000 (787 Airframe) and Trent XWB (A350

airframe). This (as of April 2013) totals around 2000 aircraft engine

orders with profiled endwall technology applied. A saving of 1750 litres

of fuel per flight from Zurich to Singapore was estimated when profiled

endwalls are applied. This gives a 4400 kg reduction in carbon dioxide

emissions for such a journey with a fuel cost saving of over $1100. In

addition to the environmental benefit and the obvious cash savings for

airlines an economic benefit for UK industry has arisen as Rolls-Royce is

able to sell engines with a reduced fuel burn as well.

Underpinning research

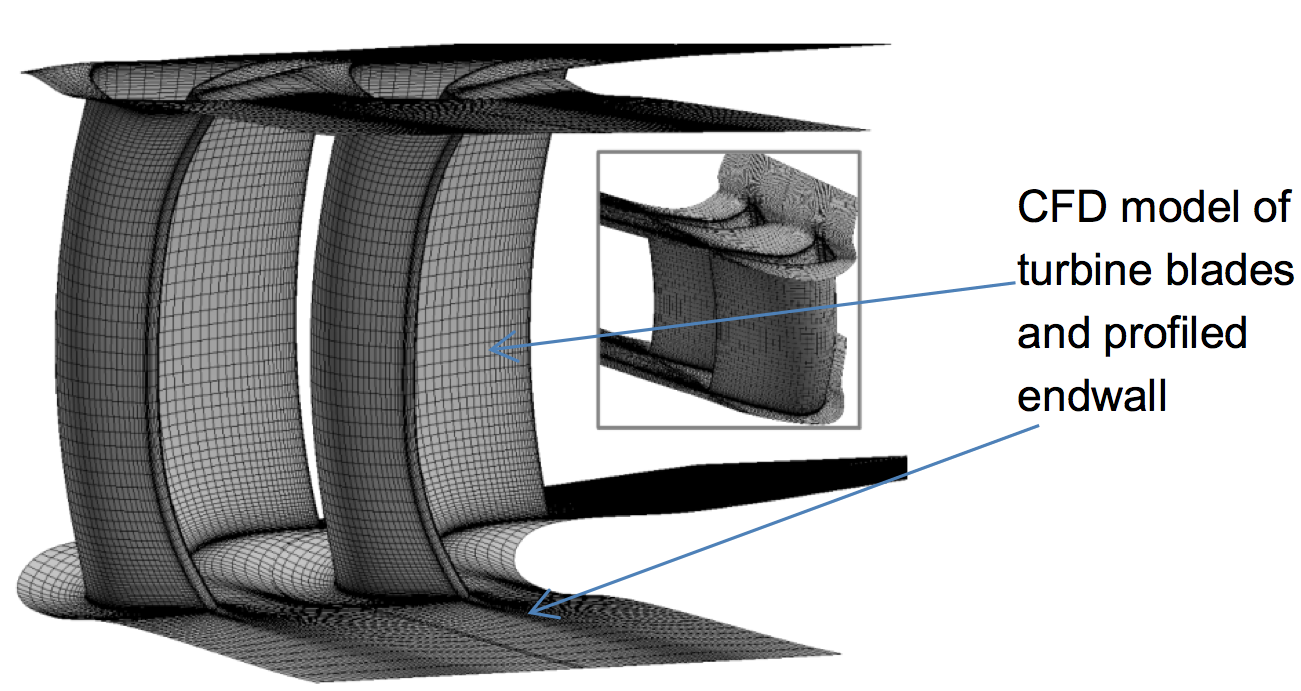

David Gregory-Smith at Durham carried out research on "secondary flow"

turbine aerodynamics throughout the 1990s examining the complex 3D flow

patterns around turbine blades in aircraft engines. In the early 21st

century this fundamental understanding was used to improve the aerodynamic

efficiency of blades by applying profiled endwalls, i.e. using profiled

surfaces within the turbine to optimise fluid flows as shown in the figure

below.

The first contribution was to demonstrate that profiled endwalls would

work in a simplified model of a turbine [Outputs 1 & 2]. Further

studies explained how the performance gains arose by making a detailed

examination of the flow structures present inside a turbine blade row

[Output 3]. These papers were the first reported tests on systematically

designed profiled endwalls.

Durham research also defined the boundaries of application by running a

test campaign on "aggressive" endwall geometries, that deliberately pushed

the performance of these devices to the point they were no longer

aerodynamically effective (essentially pushing the device into a "stall"

type condition) [Output 4]. A key aspect of the research was managing

imperfect numerical calculations of the fluid flow within the turbine

blades. Precise computations of the Navier-Stokes equations are impossible

without accurate modelling of turbulence and transition. Such a model does

not exist and remains one of the major unsolved problems in physics. The

solution was to use a proxy parameter based on inviscid flowfield

parameters to infer viscous losses. The obvious drawback of such a method

is that the range of application of these proxies is very limited. The

approach of using "Secondary Kinetic Energy" as the design variable is

described in of our joint papers with Rolls-Royce [Output 1].

Ingram, who assisted with significant parts of this research is now a

fulltime member of academic staff at Durham.

References to the research

The underpinning research comprised a series of tests in the Durham

thermofluids lab using cascades, and subsequent analysis of the results,

also at Durham. This research was largely funded by Rolls-Royce in two

projects:

• October 1999-July 2003 Brochure B1D1-1501DC with funding from the then

DTI and MoD CARAD programme. PI: Dr David Gregory-Smith

• July 2003 — July 2007 "Three Dimensional Turbine Blade Passage Design."

Brochure: R-RAEPS2001 DPC5752 (Budget: £249k) PI: David Gregory-Smith

(retired 2005) Grant Ingram (2006 to contract end).

Outputs 1 & 2 describe the design and test of the first ever

systematically designed profiled endwall geometry for loss reduction.

• Output 1: Harvey, NW, Rose, MG, Taylor, MD, Shahpar, S, Hartland, J

and Gregory-Smith, DG Nonaxisymmetric Turbine End Wall Design: Part I —

Three-Dimensional Linear Design System J. Turbomach. 122, 278 (2000).

• Output 2: Hartland, JC, Gregory-Smith, DG, Harvey, N.W. and Rose,

MG Nonaxisymmetric Turbine End Wall Design: Part II — Experimental

Validation J. Turbomach. 122, 286 (2000)

Output 3 explores the underlying flow physics behind the performance

enhancements seen and contains detailed measurements inside the blade row.

• Output 3: Ingram, G., Gregory-Smith, D., Rose, M., Harvey, N. &

Brennan, G. 2002, The effect of end-wall profiling on secondary flow and

loss development in a turbine cascade, ASME Turbo Expo 2002 Land, Sea

and Air (GT2002). GT2002-30339.

Output 4 provided an indication as to the limit of the technological

application by designing an endwall for maximum performance but instead

introducing flow separations. This reduced the risk of application of

endwall profile technology in real machines.

• Output 4: Ingram, G., Gregory-Smith, D. and Harvey, N.

Investigation of a Novel Secondary Flow Feature in a Turbine Cascade

With End Wall Profiling J. Turbomach. 127, 209 (2005).

Outputs 5 & 6 cover an extension of the profiled endwall concept to

combine with blading modifications and won the 2008 PE Publishing Award

for the best paper in Part A of the IMechE Journal of Power and Energy.

This work was also the subject of a Rolls-Royce patent which Durham staff

(Bagshaw, a research associate on the project) were named inventors.

• Output 5: Bagshaw DA, Ingram GL, Gregory-Smith DG & Stokes MR

2008. An experimental study of three-dimensional turbine blades combined

with profiled endwalls. Proceedings of the Institution of Mechanical

Engineers, Part A: Journal of Power and Energy 222(1): 103-110.

• Output 6: Bagshaw DA Ingram GL, Gregory-Smith DG, Stokes MR &

Harvey NW 2008. The design of three-dimensional turbine blades combined

with profiled endwalls. Proceedings of the Institution of Mechanical

Engineers, Part A: Journal of Power and Energy 222(1): 93-102.

Details of the impact

The impact of this research is that profiled endwalls in turbomachinery

such as aircraft engines provide both economic and environmental benefits.

Durham's research has given manufacturers confidence to apply profiled

endwalls to engine representative test rigs and then into real products.

Without the underpinning research outlining the benefits in simple test

rigs these concepts would not have been put into production engines.

The early research (Outputs 1 & 2) gave the industrial partner

(Rolls-Royce) confidence to apply this in cold flow engine test rigs (with

a running cost of around £1M per test point) and then in aircraft engines

for sale (first application in the Trent 500 performance upgrade). The

limits established by Durham University in the test campaign on aggressive

endwall geometries (Output 4) were incorporated into Rolls-Royce's

in-house design codes.

The environmental benefit of this research is via reduced fuel burn in

aircraft engines due to a 0.6% to 0.9% increase in turbine stage

efficiency. The quantification of the level of improvement was obtained

from cold-flow full scale rig testing at Rolls-Royce. This has been

translated into a saving of 1750 litres of fuel per flight from Zurich to

Singapore by Prof. Patrick Jenny, Institute of Fluid Dynamics at ETH. A

similar order of magnitude effect can be estimated from Cumpsty's book

"Jet Propulsion" which quotes a 1.13% change in sfc for a 1% change in

high pressure turbine efficiency.

In financial terms the fuel saving on the Zurich to Singapore flight

equates to $1192 per flight. If the route runs once per way in each

direction this gives annual fuel saving of around $870,160 per year. In

carbon dioxide terms this equates to a 4448 kg reduction per trip using

the 2013 UK Government conversion factors published by DEFRA. These

factors include other influences than simply the combustion process. For

the route as a whole this is a reduction of 3247 tonnes.

The first application of profiled endwalls was the Trent 500 performance

improvement package applied to the A340 airframe. The first new engine

with profiled endwalls was the Trent 900 for the Airbus A380. Profiled

endwalls are now used as a routine design tool and are also applied on the

Trent 1000 (787 Airframe) and Trent XWB (A350 airframe).

As of April 2013 there have been fifty one A380 aircraft delivered with

Rolls-Royce engines for a total of 204 engines in service on that

airframe. Rolls-Royce engines have been selected for 238 of Boeing 787

orders for a total of 476 engines and Rolls-Royce make the only powerplant

for the A350 which has 616 orders for a total of 1232 aircraft engines.

Each of which are more efficient as a result of the underpinning research.

Profiled endwalls can also potentially improve the efficiency of any

rotating machine and Rolls-Royce has also applied profiled endwalls to

stationary gas turbines used for pumping applications, the Avon engine.

This technology is offered as an upgrade kit for existing engines and

allows operators to reduce fuel burn whilst providing additional business

for the manufacturer.

A second important impact of this research has been to provide improved

products for industry and keep the products that UK industry offers at a

competitive efficiency level. Rolls-Royce have also applied for patents

based directly on the results of Durham research e.g: Rolls-Royce plc.

Aerofoil members for a turbomachine. Pat. GB0704426.6, date lodged

08.03.2007, 2007.

Other engine manufacturers have sponsored research programmes on profiled

endwalls including Pratt and Whitney with Carleton University and MTU with

ETH Zurich and Stuttgart. Although there is no direct link between Durham

and these organisations the presentation of the Durham and Rolls-Royce

work at conferences has led to a worldwide impact.

Sources to corroborate the impact

- Source for 0.6-0.9% efficiency gain: Rose et al. (2001) reporting a

stage efficiency increase of 0.59%±0.25% and Harvey et al. (2002)

reporting a stage efficiency increase of 0.9%±0.4%. Rose, M., Harvey,

N., Seaman, P., Newman, D., and McManus, D. (2001). Hp turbine using

non-axisymmetric end walls. part ii: Experimental validation. ASME

Paper 2001-GT-0505. Harvey, N., Brennan, G., Newman, D., and Rose, M.

(2002). Improving turbine efficiency using non-axisymmetric end walls:

Validation in the multi-row environment and with low aspect ratio

blading. ASME Paper GT-2002-30337.

- Source for 1750 litres fuel saving from: Philipp Jenny, Laboratory for

Energy Conversion ETH Zurich. http://www.esc.ethz.ch/events/frontiers/10_Jenny_FiER.pdf

Accessed 1st May 2013.

- 1.13% change in sfc for a 1% change in high pressure turbine

efficiency is from: N. Cumpsty, Jet Propulsion: A Simple Guide to the

Aerodynamic and Thermodynamic Design and Performance of Jet Engines,

ISBN-10: 0521541441, 2nd Edition, 2003.

- Source for fuel cost is from the International Air Transport

Association (IATA) fuel price analysis web page.

http://www.iata.org/publications/economics/fuel-monitor/Pages/price-analysis.aspx

Accessed 13th September 2013.

- The conversion from litres of fuel to carbon dioxide is taken from the

Department for Environment Food & Rural Affairs' Greenhouse Gas

Conversion Factor Repository. Accessed on the 13th of September 2013 http://www.ukconversionfactorscarbonsmart.co.uk/

- Source for A380 and A350 airframe sales:

http://www.airbus.com/company/market/orders-deliveries/ Accessed

15th of May 2013.

- The engine breakdown for A380 sales is from http://www.rolls-royce.com/civil/products/largeaircraft/trent_900/

Accessed 15th of May 2013.

- Source for 787 sales: Boeing website:

http://active.boeing.com/commercial/orders/ Accessed 15th of May

2013

- Rolls-Royce Website Advertising the use of "3D profiled end wall

aerodynamics" in Trent 1000 engine. http://www.rolls-royce.com/civil/products/largeaircraft/trent_1000/

(Under Technical Tab, HP/IP turbine)

- Rolls-Royce Brochure Advertising the application of profiled endwalls

to the Avon 200 Stationary Gas Turbine. http://www.rolls-royce.com/Images/Avon200_112011_tcm92-15721.pdf

Accessed 1st May 2013