UOA15-08: Efficient, cost-effective membrane filtration

Submitting Institution

University of OxfordUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Chemical Engineering

Summary of the impact

Research at the Department of Engineering Science has led to step changes

in the way industrial membrane filtration plants are designed and operated

. Based on some key research results that have successfully tackled

membrane fouling problems, the work has triggered rapid uptake of

membrane-based technologies that are more energy-efficient than

traditional processes. Water companies are among those achieving both

economic and the environmental benefits, and the research has played a key

role in the membrane bioreactor (MBR) market, which is now growing at over

10% a year, and in the global desalination market which exceeds US$19

billion, according to GMR Data (2012) [13].

Underpinning research

Many industrial processes (e.g. water/wastewater treatment, food and

drink manufacture) use filtration plants to separate macro-molecules or

micro-particles from water. Although the benefits of using membrane

technologies for separation had long been recognised, and their use was

well-established, the issue of membrane fouling (and the associated costs

of membrane cleaning) had inhibited the adoption of these technologies by

industry. Two important breakthroughs achieved at the Department — the

concept of `critical flux' and the injection of air bubbles into membrane

systems — have unlocked the potential of membrane technologies.

Originating as separate work streams in the 1990s, the research was first

brought together in 2002. Refinement of the methods is on-going [1] and

international collaborations led by the Department over the past decade

have included scientists in France, Australia, China and Singapore.

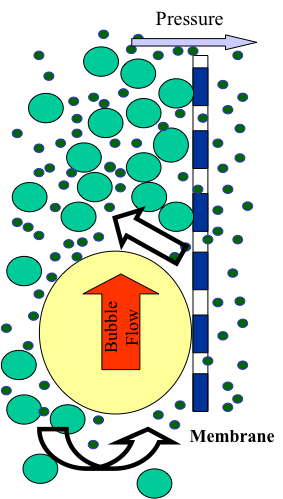

Fig. 1: Gas-liquid cross-flow membrane filtration.

Fig. 1: Gas-liquid cross-flow membrane filtration.

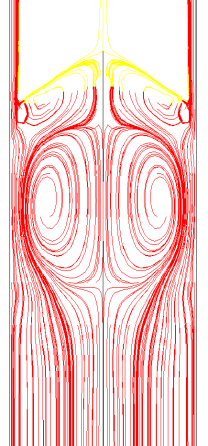

Fig. 2: CFD modelling of the new process.

Fig. 2: CFD modelling of the new process.

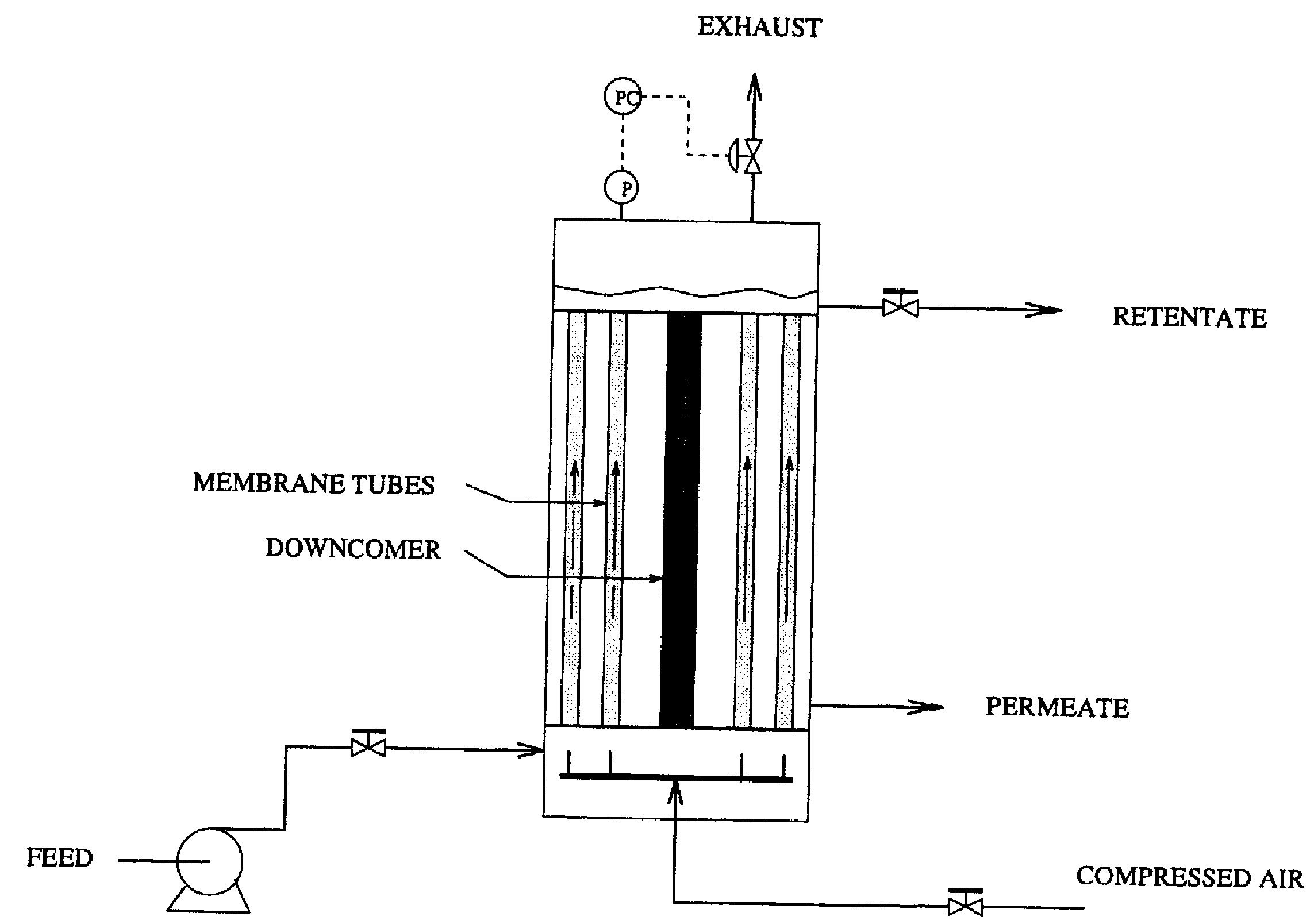

Fig. 3: Air-lift gas-liquid two-phase cross-flow filtration.

Fig. 3: Air-lift gas-liquid two-phase cross-flow filtration.

• Air bubble injection: Research began in 1994, led by Prof.

Zhanfeng Cui (who joined the Department in 1994 as a University Lecturer

and has been the Donald Pollock Professor of Chemical Engineering since

2000). To reduce membrane fouling, Cui proposed injecting air bubbles into

membrane systems to create gas-liquid two-phase flow (see Figure 1) and

bubble-induced local mixing. This concept was at first controversial:

industrial users favoured degassing solutions and believed that bubble

injection would make fouling problems worse. Cui therefore carried out a

detailed analogue analysis, based on heat transfer enhancement, and also

conducted proof-of-concept experiments. Between 1994 and 2005, he secured

nine major research grants to develop computational fluid dynamics (CFD)

models demonstrating the benefits of this new approach (e.g. see Figure 2)

and to develop industrial applications; one process developed was air-lift

gas-liquid two-phase cross-flow filtration (Figure 3) [2]. Cui has

published a series of extensively cited major papers on this research

(e.g. [3, 4]) and supervised work in this area by 12 doctoral students.

Since 2009, his work on the topic has focused on using aeration to cut

energy consumption in MBRs [1].

• Critical flux: First developed by Dr Robert Field (who joined

the Department in 2001 as a University Lecturer and is currently Professor

of Engineering Science), this concept has identified the conditions to

minimise fouling; with large driving pressures and high cross-flow

velocities no longer required, energy use and cleaning costs are both

reduced. In 2002 and 2003, Field held workshops to explore the theory and

undertook experiments to validate both the existence of a critical flux

and his predictions [5]. In 2006, he co-authored a major review paper [6]

(extensively cited, and rated by the Journal of Membrane Science one of

the top five papers of 2006-2010). Since 2009, with wastewater

applications to the fore, Field has proposed and developed (with

industrialist Dr Graeme Pearce) the new concept of a `threshold flux' to

distinguish between low-fouling and high-fouling regimes and to guide the

practical design of new membrane processes [1]; experimental research by

Field has focused on identifying and predicting the threshold flux, with

much of the work undertaken in collaboration with Singapore and China.

Cui and Field have published 16 joint papers describing their research (e.g.

[1]). They also both played a key role in the Oxford University-led, EPSRC

First Faraday `Advanced Membrane Bioreactors for Leachate Treatment'

project. Running from 2003 to 2005, this involved six UK universities and

three UK companies (e.g. Yorkshire Water and Shell) and led to

development of new technologies and establishment of a Knowledge Transfer

Network.

References to the research

(best indicators of research quality are marked `Q')

2. Cui, Z.F., Bellara, S.R. and Homewood, P. `Airlift Crossflow Membrane

Filtration: A Feasibility Study with Dextran Ultrafiltration' (1997). Journal

of Membrane Science, 128 (1), pp. 83-91.

http://dx.doi.org/10.1016/0376-7388(96)00280-3

3. Cui, Z.F. and Wright, K.I.T. `Flux Enhancements with Gas Sparging in

Downwards Crossflow Ultrafiltration: Performance and Mechanism' (1996). Journal

of Membrane Science, 117(1-2), pp 109-116.

http://dx.doi.org/10.1016/0376-7388(96)00040-3

5. Hughes, D. and Field, R.W. `Crossflow filtration of washed and

unwashed yeast suspensions at constant shear under nominally sub-critical

conditions' (2006). Journal of Membrane Science, 280, pp 89-98.

http://dx.doi.org/10.1016/j.memsci.2006.01.022

Grants supporting this research: (all awarded to Prof. Zhanfeng Cui as PI)

• EPSRC GR/506967/01: Membrane bioreactors for waste water

treatment, £58k (part of AMBRAL-MBR Faraday), 2003 - 2005.

• BBSRC E15902 (with Dr J Urban, Physiology): On-line monitoring in

tissue engineering using micromembrane probes, £229k, 2002 - 2005.

• EPSRC GR/R01729: Fractionation of macromolecules using carrier phase

ultrafiltration, £63k, 2001 - 2004.

• EPSRC GR/N66438/01: Hydrodynamics and mass transfer in gas-liquid

capillary flow, £23k, 2000 - 2002.

• BBSRC-DTI LINK BCE06424 (with Prof. BJ Bellhouse): Enhanced filtration

of fine chemicals, protein and cellular solutions using tubular membranes

and screw-thread inserts, £126k, 1997 - 1999

• BBSRC E05544: Protein fouling on ceramic membranes, £138k, 1996 - 1999

• BBSRC SPC05236: Protein fractionation with gas sparged ultrafiltration,

£94k, 1996 - 1997

• BBSRC SPC02796: Virus removal using enhanced membrane filtration, £92k,

1994 - 1997

• EPSRC GR/J46388/01: Gas-liquid two-phase crossflow ultrafiltration of

protein solutions, £75k, 1993 - 1995.

Details of the impact

This research has delivered a step change in industrial membrane

filtration practices. For several decades, membrane-based filtration

processes have been a staple technology in a range of sectors. From the

1970s to the 1990s, however, membrane fouling became a bottleneck limiting

usage. The original research led by Cui and Field resulted in solutions

that have enjoyed rapid, extensive industrial take-up and delivered

substantial improvements in the efficiency and effectiveness of membrane

filtration; for instance, injecting air bubbles into membrane systems has

proved an economic, easy-to-implement fouling control technique that has

now been adopted by many membrane manufacturers and water companies

including Siemens, GE Water and Norit Membrane Technology BV, as well as

securing widespread recognition among membrane researchers in academia.

Indeed, in the last decade, the research has led to a revolution in the

way membrane plants in the water industry are designed and operated. For

example, all MBRs now use low flux to achieve low fouling; and all MBRs

are operated with big bubble, rather than small bubble aeration. Both are

direct results triggered by the research undertaken by Cui and Field.

Several companies have now developed processes based on air bubble

injection, for which Cui provided the design basis both through

publications or direct consultancy. They include:

- The AirFlash®, AquaFlexTM and Airlift™ MBR (Fig. 4)

developed by Norit Membrane Technology BV and now Pentair X-Flow. The

underlying process was developed by Cui in the mid-1990s [2, 7] around

10 years before the products came to market.

- The MemPulse™ MBR system (Fig. 5) developed by Siemens Water

Technologies (formerly US Filter and Memtec) [8]. The adoption of gas

sparging in this was first described in [3].

- The ZeeWeed® MBR systems developed by GE Water (formerly Zenon

Environmental). Cui's analysis helped to cut the energy cost of

filtration in these systems [8, 9].

Fig. 4: X-Flow Airlift™ MBR — a commercially available system.

Fig. 4: X-Flow Airlift™ MBR — a commercially available system.

Fig. 5: Siemens' MemPulse™ MBR — a commercial installation.

Fig. 5: Siemens' MemPulse™ MBR — a commercial installation.

Fig. 5: Siemens' MemPulse™ MBR — a commercial installation.

In addition, Yorkshire Water has explored the use of Cui's concept for

water and wastewater treatment. Introduction of fouling control for

membrane processes used in food production has also significantly

increased productivity at Cargill Inc., the largest private company in the

US, by at least halving the downtime needed for cleaning during amino acid

production, according to their Senior Vice President [10].

Similarly, Field's work on critical flux has created a paradigm shift in

membrane process design:

- His contribution has been acknowledged by leading consultants. For

instance, according to the Director of Membrane Consultancy Associates:

"the `direct-flow' method of designing membrane filtration drinking

water plants (which is the new standard) was born out of critical flux

theory" [11].

- International researchers, including the Director of the Singapore

Membrane Technology Centre (SMTC), have widely recognised Field's

contribution [12]. For nearly 10 years, Field has collaborated with the

Singapore group and contributed to SMTC's development into the largest

membrane research centre in the world today.

Cui and Field's work has therefore benefited both users and suppliers of

membrane technology:

Economic Impact 1 — a growing market for membrane filtration

Rapid growth in membrane use is a direct outcome of the effective

mitigation of membrane fouling, to which the research has made a

significant contribution. Use of membranes within the water industry grew

by 20% per year worldwide between 1998 and 2008, the MBR market is

currently growing at 10.5% per year and the global desalination market now

exceeds US$19 billion [13].

Economic Impact 2 — cost savings for industry

Users of membrane systems that incorporate findings from the research

have secured economic benefits through reductions in, for example,

membrane cleaning costs and the amount of energy consumed by membrane

filtration processes. Compared to traditional filtration processes,

membrane plants are also far more compact.

Environmental Impact — benefits of reduced energy demand

Reduced energy use equates to a reduced carbon `footprint' for membrane

filtration processes, helping water companies and other users to achieve

their environmental targets.

Sources to corroborate the impact

- Cui, Z.F. UK Patent: Membrane Filtration Apparatus, PCT/GB96/01854.

Applicant: ISIS Innovation Ltd (1995). https://www.google.com/?tbm=pts#q=WO1997004857&tbm=pts

- NL Chemical Technology Inc., Membrane Discussion Forum (1995). Contact

details for President, corroborating the use of the processes.

- Consultancy for Siemens, Australia (2006); Norit, the Netherlands;

contact Senior Process Engineer, Pentair Advanced Water Technologies.

Corroborates the use of the processes.

- Consultancy for Cargill Inc., US (2008); contact Senior Vice

President, Cargill Inc. Corroborates that Cargill has significantly

increased productivity as a result of Cui's work

- Oxford Membrane Fouling and Monitoring Workshop (2012); contact

Director, Membrane Consultancy Associates Ltd. Supporting the work

within case study.

- Oxford Membrane Workshop on Critical Flux (2003); contact Director,

SMTC, Singapore. Supporting the work within case study.

- `Desalination Market 2013-2023: Commercial, Technological &

Strategic Developments in Global Desalination' (2012). GMR Data. http://gmrdata.com/the-desalination-market-2013-2023.html.

Commercially available report posted 24/04/13. See also

press release, http://www.free-press-release.com/news-the-global-desalination-market-2013-2023-by-gmr-data-1367313632.html.