UOA10-08: Mathematics in the design and manufacture of novel glass products

Submitting Institution

University of OxfordUnit of Assessment

Mathematical SciencesSummary Impact Type

TechnologicalResearch Subject Area(s)

Mathematical Sciences: Pure Mathematics, Applied Mathematics

Engineering: Interdisciplinary Engineering

Summary of the impact

The glass industry uses theoretical modelling to control, improve, and

reduce the cost of

designing and manufacturing novel glass products. Market-leaders [text removed for

publication], Schott AG and Pilkington have developed modelling

software which is underpinned

by equations stemming from research at the University of Oxford.

[text removed for publication]. The same modelling approach is

used in software developed by

Schott which is now used in all of its modelling of drawing processes to

reduce both development

costs and the incidence of faults. Pilkington have implemented research

performed at the

University of Oxford to decrease the risk associated with manufacturing

processes.

Underpinning research

Peter Howell has been working on extensional thin layer flows with

application to the glass

industry for the last 20 years. He first studied the evolution of thin

sheets and jets of viscous fluid

by taking a mathematical limit where the aspect ratio (the ratio of the

thickness to the length or

width) is small, precisely the situation in the manufacture of glass

windows, tubing and optical

fibres, for example. The result of the research [1] is a systematic

framework for reducing the full

Navier-Stokes equations to a simplified lower-dimensional system, which

gives greater insight

into possible instabilities and allows for much more efficient

computation. These simplified

models allow glass processes to be more effectively controlled to produce

flawless products with

optimised properties and to avoid catastrophic process failures.

In a glass furnace, many tiny gas bubbles are produced as the raw

material melts and reacts. It is

essential that all of these bubbles are eliminated before the glass leaves

the furnace for further

processing, to avoid defects in the finished product. To this end, the

drainage of a bubble at the

surface of a viscous fluid was modelled mathematically by Howell [2];

explicit formulae were

found for the suction of fluid out of the thin film between the bubble and

the atmosphere and for

the expected timescale for a bubble to burst. Marangoni effects were

incorporated in [3]; this

allowed the influence of impurities on bubble bursting to be quantified.

These analyses allow the

required furnace residence time required to remove all bubbles, to be

determined. Further

research [4] allowed the deformation of any bubbles that do make it into

the processing stage to

be quantified.

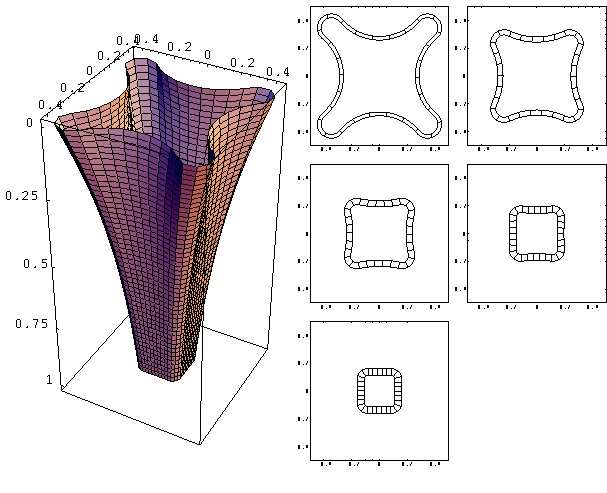

Another important facet of the University of

Oxford's glass modelling concerns the

drawing of non-axisymmetric glass tubing. A

key question is: what die shape is needed to

make tubes of a given cross-sectional

shape? Using ideas from perturbation theory

and partial differential equations, researchers

at the University of Oxford were able to solve

this inverse problem explicitly [5, and other

papers], as shown in the figure, which shows

the die shape required to draw glass tubing

with a square cross-section.

The gravitational sagging of heated glass

sheets to form windscreens also provides an inverse problem, namely, to

predict the temperature

profile required to produce a final desired windscreen shape. In research

carried out at the

University of Oxford [6], this problem was analysed mathematically and

found to reduce to an ill-posed

partial differential equation which inevitably changes type from elliptic

to hyperbolic across

some interior line in the glass sheet.

The key researchers: Peter Howell (postdoc 1994-95, research fellow

1996-99 faculty 2001 to

date); Chris Breward (postdoc 2001-03, research fellow 2003-08, faculty

2008 to date); Ian

Griffiths (postdoc 2008-2010, Research fellow 2010 to date); Domingo

Salazar (postdoc 1998-2002)

were all at the University of Oxford when the research was carried out. At

least four other

researchers, including John Ockendon, participated in the University of

Oxford's glass research

programme.

References to the research

*[1] P.D. Howell. Models for thin viscous sheets, Euro. J. Appl.

Math. (1996), 7:321-343. DOI:

10.1017/S0956792500002400.

[2] P.D. Howell. The draining of a two-dimensional bubble. J. Engrg.

Math. (1999), 35:251-272.

DOI: 10.1023/A:1004399105606.

*[3] C.J.W. Breward and P.D. Howell. The drainage of a foam lamella, J.

Fluid Mech. (2002),

458:379-406. DOI: 10.1017/S0022112002007930.

[4] P.D. Howell and M. Siegel. The evolution of a slender

non-axisymmetric drop in an

extensional flow. J. Fluid Mech. (2004), 521:155-180.

DOI:10.1017/S002211200400148X.

*[5] I.M. Griffiths and P.D. Howell. Mathematical modelling of

non-axisymmetric capillary tube

drawing, J. Fluid Mech. (2008), 605:181-206. DOI:

10.1017/S002211200800147X.

[6] D. Salazar and R. Westbrook. Inverse problems of mixed type in linear

plate theory, Euro.

J. Appl. Math. (2004), 15:129-146. DOI: 10.1017/S0956792503005345.

The three asterisked outputs best indicate the quality of the

underpinning research. All six papers

are in high quality internationally refereed journals. This is not an

exhaustive list: results from

many other papers have also led to impact on glass manufacturers.

Details of the impact

The University of Oxford's research on extensional thin layer flows has

resulted in significant

economic impact since 2008. The beneficiaries are the glass manufacturers

[text removed for publication], Schott AG and Pilkington.

Pathways to impact:

[text removed for publication]

Between 2002 and 2006, the University of Oxford team (led by Prof. John

Ockendon FRS) was a

node in the €1.4m EU Research Training Network Math ematics for the Glass

Industry:

Computing and Analysis (known as MAGICAL) which aimed to promote

collaborations between

Universities and glass companies across the EU, including Schott AG.

Schott AG posed specific

research questions which were tackled by the MAGICAL team at the

University of Oxford, and

gained access to the University of Oxford's pre-existing research base

relevant to glass flows.

Finally, Pilkington (now NSG group) has had a long standing

relationship with the University of

Oxford's Mathematical Insitute through Industrial Workshops organised by

the Oxford Centre for

Industrial and Applied Mathematics (OCIAM) and was also involved in

MAGICAL. The current

Head of the Float and Rolled Glass Technology Group says [B] "Pilkington

Group research — in

recent years the NSG European Technology Centre, have for many years

found the OCIAM

group to be much the most valuable point of contact for problems raising

complex mathematical

issues in glassmaking and glass products."

Nature and extent of the impact:

The glass industry constantly seeks improved models for production and

processing

technologies, so that it can reliably design and build improved,

fault-free products while cutting

development costs and innovating new advanced materials. It is

understandable that major

industrial glass producers, such as [text removed for publication]

and Schott, were interested

in the University of Oxford's research into modelling thin viscous sheets.

[text removed for publication]

At Schott AG, another world-leading glass and materials company

with global sales of €2 billion

(in 2011/12), research from the University of Oxford has been used even

more widely. Like [text

removed for publication], Schott has developed software, based on

Howell's methodology for

modelling thin viscous sheets and fibres, which is key in the improvement

and development of

glass forming processes. A senior scientist in the Mathematical Simulation

and Optimization

group states [D] "At Schott, we now have models based on these methods

for all our drawing

processes. A typical application is the prediction of suitable process

conditions (heater power

distribution, top roller speeds etc) for a desired glass sheet thickness

and net width in the float

process." Schott use the models to save significant sums in

development costs. The senior

scientist states [D] "In many cases, our only option in the development

process are experiments

in the actual production plant. A day in a typical production plant

costs about 50,000 Euro. I am

quite certain that the models saved us years of such experiments at the

plants." In a subsequent

email he confirms that these years of effort were post-2008.

One of Schott's major production processes, tube drawing, has also been

heavily influenced by

the University of Oxford's research into pressure-driven flows and

hollow-fibre production. In

particular, the asymptotic solutions developed at the University of Oxford

have been used to

create models which Schott claims offer improved accuracy over competing

models. The senior

scientist in the Mathematical Simulation and Optimization group states [D]

"The results in [5,

published in 2008, and other papers] are of special significance for

the tube drawing process, one

of Schott's major production processes. These asymptotic solutions for

non-circular tube

geometries are in my opinion superior to "brute force" numerical

approaches which suffer from

inaccuracies arising from the high glass viscosities downstream."

This allows manufacturing

processes for proposed new products to be reliably tested and optimised

computationally, leading

to significant savings in wastage and money.

Finally, work from the University of Oxford has allowed Schott to produce

glass with fewer faults.

Research into levitating thin sheets of glass on air cushions has allowed

Schott to reduce

dramatically the occurrence of instabilities in numerous moulding

processes, and understanding

of the presence of defects such as bubbles has helped them reduce the

incidence of faults in

many different glass-forming processes.

Pilkington is one of the leading glass suppliers in the UK and is

now part of the Japan-based

NSG Group which has manufacturing operations in 29 countries and global

sales of over £4

billion. The company uses research carried out at the University of Oxford

in several areas

concerned with risk management, which is an essential part of production

processes. The

support the University of Oxford has provided with solving the problem of

bubbles bursting on the

surface of glass has given Pilkington invaluable understanding of the

underlying physical

processes (subsequently verified experimentally) as well as significant

financial savings by

avoiding lost production costs. The Head of the Float and Rolled Glass

Technology Group at

NSG states [B] "The idea that distinctions which could be drawn between

various types of bubble

develops a way of analysing melting problems which results in a better

chance of taking the most

appropriate action".

A common procedure in the manufacture of windscreens involves heating a

sheet of glass so that

it sags under gravity into the desired shape. The inverse problem of

determining the heating

profile required to produce a particular shape after sagging is tackled in

the industry using

computational modelling, which is found to be extremely delicate. The

University of Oxford's

mathematical research on this problem has been very useful for Pilkington,

who found that

"guidance as to how much can safely be left to automated algorithms and

what requires active

intervention by the user is hugely valuable in reducing product

development time" [B].

Sources to corroborate the impact

[A] [text removed for publication]

[B] Letter from Group Head, Float and Rolled Glass Technology Group, NSG,

describing the

influence of Oxford's research on their product development. Copy held by

the University of

Oxford.

[C] [text removed for publication]

[D] Letter and emails from a Senior Scientist in the Mathematical

Simulation and Optimisation

Group, Schott AG, describing the impact of 10 relevant Oxford Mathematics

publications on

Schott's activities. Copies held by the University of Oxford.