Topical oxygen therapy for wound healing

Submitting Institution

University of CambridgeUnit of Assessment

Electrical and Electronic Engineering, Metallurgy and MaterialsSummary Impact Type

TechnologicalResearch Subject Area(s)

Chemical Sciences: Inorganic Chemistry, Macromolecular and Materials Chemistry, Physical Chemistry (incl. Structural)

Summary of the impact

A small, battery-powered device for oxygen generation and distribution (Natrox™),

has been developed that, with air as input, can supply humidified oxygen

evenly to wounds, such as ulcers, surgical wounds and burns, allowing the

patient to be treated in a discrete efficient way without interfering with

their lifestyle. With conventional approaches, oxygen can be supplied to

hospital patients with ulcers only via gas bottles or piped oxygen, with

the limb or body being enclosed in a plastic bag. Many successful trials

of the Natrox™ device have been performed, initiating considerable

interest, leading to the manufacturing and distribution of the device by InotecAMD

Ltd, a University of Cambridge spin-out.

Underpinning research

The Materials Chemistry Group, Dept of Materials Science &

Metallurgy, University of Cambridge has been very active, for many years,

in aqueous electrochemistry. In particular, Nafion membranes,

which are proton conductors under humid conditions, were used to create

hydrogen sensors [1] and membranes for electrowinning cells [2,3].

Furthermore, in work initiated in 1993, hydrophobic porous membranes were

used to create fine bubbles (sparging) in electrowinning cells

[2,3]. Critical lessons (on the benefits of smaller gas bubbles and how

they can be achieved) from this hydrometallurgy work were directly

applicable in developing the Natrox™ device for oxygen generation.

An earlier oxygen-generating device had been developed by others in the

US, but this device had several disadvantages, including: failure of the

cell due to drying out of the electrolyte; formation of hydrogen peroxide

which is a known carcinogen; and, lastly, oxygen was fed by a

small-diameter tube (cannula) to the wound (a method not favoured

by UK clinicians).

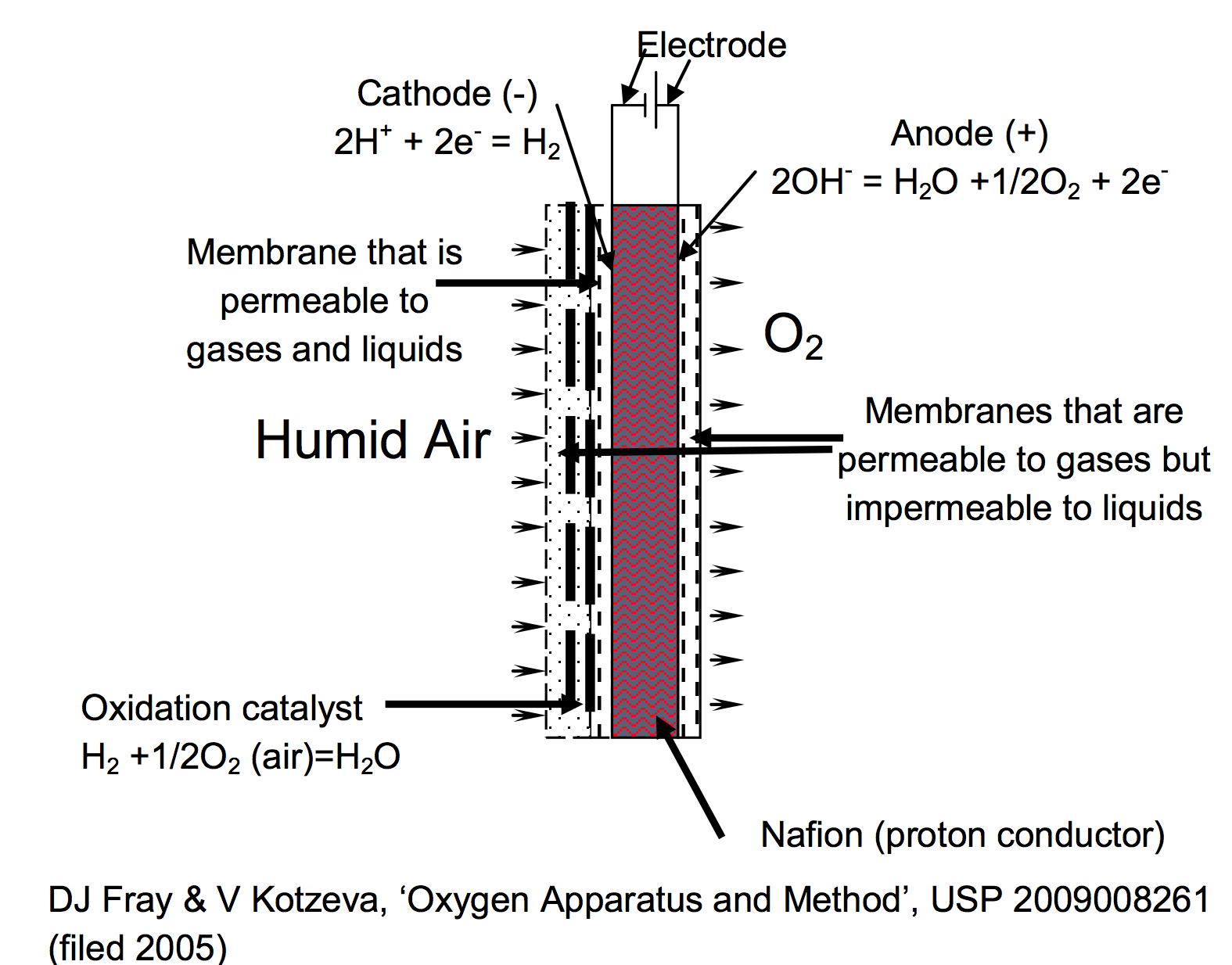

Figure 1. Diagram of Natrox™ oxygen generator showing, on the right, the electrochemical cell that produces the oxygen from water in the membrane and the oxidation catalyst, on the left, where the hydrogen is reacted with oxygen from the air, to produce water that is returned to the membrane.

Figure 1. Diagram of Natrox™ oxygen generator showing, on the right, the electrochemical cell that produces the oxygen from water in the membrane and the oxidation catalyst, on the left, where the hydrogen is reacted with oxygen from the air, to produce water that is returned to the membrane.

Building upon previous research, described in the first paragraph, Derek

Fray (Professor of Materials Chemistry 2001-2007, Director of

Research and Emeritus Professor of Materials Chemistry 2007-)

concluded that it was feasible to create a device that overcame all of

these problems. Together with Dr Vega Kotzeva, (Post Doctoral

Research Associate 2005-2006), a small cell was built, based on a design

that had been previously used for a hydrogen sensor [1], which used a Nafion

membrane surrounded by a small reservoir of water.

This successfully demonstrated that, by applying a small voltage (1.5 V)

across the membrane, a flow of oxygen was created which would satisfy the

needs of an average ulcer (15 ml/h) with a weekly consumption of water of

1 ml. It was thought desirable to oxidize the hydrogen (a by-product of

the electrolysis process) by placing a catalyst layer a short distance

from the cathode, allowing the hydrogen to react with air to form water

which then returns to the membrane [4,5]. Rather surprisingly, it was

found that with a combination of hydrophobic and hydrophilic membranes it

was possible to operate the device indefinitely, producing humidified

oxygen without the need for a water reservoir, provided the batteries were

kept charged. A diagram of the cell is shown in Figure 1. The distribution

pad for the oxygen was, again, created using the discoveries in the

hydrometallurgical studies of sparging. This previous research

showed that, by applying a modest gas pressure, a porous hydrophobic

membrane allowed the creation of a uniform supply of bubbles [2,3]. This

is ideal for supply of oxygen to a wound but, in order for the exudate to

escape, it is necessary to also have very much larger holes in the

membrane. The end result is a pad that allows oxygen bubbles to be created

at the wound and the exudate successfully removed (Figure 2 [6]).

Furthermore, unlike the cannula approach, the hydrophobic pad does not

stick to the wound which makes the removal of the pad from the wound easy

and painless. The combination of the oxygen generator and oxygen-delivery

system has been trademarked as Natrox™.

References to the research

2*. F Tailoka & DJ Fray: Enhancement of mass-transfer using

microporous sparger materials, Trans Inst Mining Metal 102

(1993) C1.

3. F Tailoka & DJ Fray: Electrowinning of copper from chloride

solutions in presence of gas sparging, Trans Inst Mining Metal 102

(1993) C7.

4*. DJ Fray & VP Kotzeva, `Oxygen Apparatus and Method'. Filed

3/03/2005. Published patents: US2009008261, WO2006092612, GB2431668*,

EP1856307, CN2068001317*

5. MF Vinton & DJ Fray, `Oxygen Concentrator and Method'. Filed

13/09/2010. Published patents: WO2102035298, GB248520*

6. MF Vinton, A Hurst & DJ Fray, `Hyperbaric Dressing'. Patent filed

1/04/2005. Published patents: US2008269658,WO2005094744, GB2412589*,

EP1755510, CN200580017913*

*references best indicating the quality of the underpinning

research.

The three patents [4-6 above] have been published and are either under

examination or granted. The distinction of Professor Fray's research in

electrochemistry has been widely recognised. During the REF assessment

period he was elected to Fellowship of the Royal Society, and he was the

first person to receive the Federation of European Materials Societies' Innovation

Award. In 2011, an International Conference (with some 450

delegates) was held in his honour in Cancun, Mexico.

Details of the impact

Professor Fray first had the ideas for exploiting the

hydrometallurgical results and adapting them for oxygen generation in 2001

(ie before the assessment period for research in the REF). It wasn't until

2003, when in discussion with Melvin Vinton, it was decided to

form a company, InotecAMD Ltd [i] (references in Section 5), to

initially design an oxygen-distribution system, funded by a Smart Award.

In 2005, the Dept of Materials Science & Metallurgy at UCAM funded a

one-year research project (£100k) to develop the oxygen-generation system.

This device was a success and was patented by the University in 2005 and,

subsequently, licensed to InotecAMD Ltd on 27 July 2009, with an

effective date of 1 January 2008. From 1 January 2008 to 31 July 2013,

[text removed for publication]

This allowed the oxygen-generation system to be industrialized and the

oxygen-distribution system to be perfected.

Natrox™ is the first device that can successfully

deliver oxygen, almost indefinitely if the batteries are kept recharged,

to patients without interfering with their lifestyle.

Over 200 Natrox™ units have been made with many being used for random

controlled trials at three hospitals in Prague. The remainder have

been used for trials in the UK and sent to agents/distributors in the UK,

USA, France, Singapore, Malaysia, Turkey and Dubai.

Figure 2. The oxygen generator and circular pad in close-up (on the left), and positioned on the leg of a mannequin (right). The oxygen is evenly distributed over the wound by the pad and the large spaces in the pad allow the escape of exudate.

Figure 2. The oxygen generator and circular pad in close-up (on the left), and positioned on the leg of a mannequin (right). The oxygen is evenly distributed over the wound by the pad and the large spaces in the pad allow the escape of exudate.

Health impacts

To check the viability of the Natrox™ device, trials were

performed at the end of 2009 at a Tissue Viability Clinic in Eastbourne,

which dramatically showed the efficacy of such a device with 10 patients

who had been referred to the clinic by the NHS as not treatable; 8 showed

considerable improvement after six weeks treatment [iv]. A bonus not

originally considered was that the pain, experienced by the patients, also

decreased considerably when oxygen was fed to their wounds [iv]. Further

successful trials have been carried out at Doncaster Royal Infirmary

on hard-to-heal wounds as the result of surgery. An evaluation of oxygen

therapy was undertaken on a range of complex surgical wounds, which

included post-mastectomy wounds which had dehisced (ie opened) following

surgery. It was found that, after about six weeks treatment with oxygen,

the wounds improved dramatically and conventional treatment could then be

applied to procure a complete recovery. It was concluded that this therapy

was successful, both in promoting healing and improving the quality of

life in a group of anxious patients [v]. In early 2012, the Natrox™

system was subjected to a safety study at the FNKV Hospital in Prague on

ten patients with non-healing leg ulcers and all patients showed

considerable shrinkage of their ulcers.

In June 2012, InotecAMD Ltd received a CE mark

for the oxygen-delivery system giving all the regulatory approvals for

sales in the EU. In July 2012, the US FDA awarded the 510(k) approval

for the Natrox™ system meaning that Natrox™

can be sold in the US [vi].

At present, a random controlled trial is being performed in Prague on ~60

patients so that the treatment can be sold to the NHS. In November 2013,

Doncaster & Bassetlaw hospitals will embark on a 12-month trial

studying non-healing surgical wounds and breast reconstruction [v].

Overall, about 80 patients have been successfully treated, ie healed,

with a considerable decrease in their suffering, coupled with an

increase in their general wellbeing.

Impacts on public policy and services

About 2 million patients in the European Union suffer from non-healing

ulcers, and the annual cost of treating these is estimated to be 10

billion Euros. The clinical trials provide hard evidence that the use of Natrox™

would decrease the number of patients and shorten treatment times. Natrox™

has opened up possibilities for more cost-effective healthcare, with

better outcomes. Secondly, the rationale for the trials at Doncaster &

Bassetlaw hospitals is to study oxygen as an anti-microbial treatment, as

many patients have increased resistance to antibiotics [v]. The use of

oxygen instead of antibiotics for treating infected wounds would again

improve both outcomes and the cost-effectiveness of the service.

Economic impacts

As well as cost savings to national budgets, the manufacture and supply

of Natrox™ devices will generate employment and income for the UK.

In 2013, the company employed a part-time CEO, a full-time Chief Technical

Officer and three other part-time staff. In addition, much of the

equipment, circuitry, oxygen-distribution pad and units are manufactured,

under subcontract, in the UK. The random controlled trial is being

organized by UK-based SME Wound Market Consulting

(www.woundmarketconsulting.com). Sales of Natrox™ devices have

commenced in the Far East, and distributors in UK and France are

organizing trials, prior to sales. Virtually all the investment of [text

removed for publication]

increase the rate of production, to

investigate a wider range of applications for the device such as treatment

of other types of ulcers, burns and surgical wounds, and to employ more

technical and sales personnel.

Sources to corroborate the impact

[i] InotecAMD Ltd (Chairman, Chief Executive Officer, Chief

Technical Officer) (www.inotecAMD.com)

— for corroboration of all information on the development of the Natrox™

device, current tests, approvals, marketing, orders, etc.

[ii] 2005 http://www.angelnews.co.uk/article.jsf?articleId=1158

[iii] 2009 http://www.praxisunico.org.uk/news/member-detail.asp?ItemID=254

[iv] R Mani: Topical oxygen therapy for chronic wounds: a report on the

potential of Inotec® a new device for delivering enriched oxygen to

chronic wounds, J. Wound Technology, no. 9 (July 2010)

1-4.

[v] Doncaster and Bassetlaw Hospitals NHS Foundation Trust: (Sister,

Wound Care Service) — for corroboration of effectiveness of the Natrox™

device for wound care, particularly after mastectomy.

[vi] 2012 FDA approval of Natrox™ —

http://www.accessdata.fda.gov/cdrh_docs/pdf11/K112634.pdf