Carbon nanotubes and carbon nanofibres

Submitting Institution

University of CambridgeUnit of Assessment

Electrical and Electronic Engineering, Metallurgy and MaterialsSummary Impact Type

TechnologicalResearch Subject Area(s)

Chemical Sciences: Inorganic Chemistry, Other Chemical Sciences

Engineering: Materials Engineering

Summary of the impact

Viewing carbon nanotubes (CNTs) as very rigid polymer molecules led to

research on turning them into useful materials. Strategic investments to

develop different aspects of this research have been made by two separate

companies. A process for the synthesis of CNTs was transferred to Thomas

Swan Ltd who have made significant investment, and are now Europe's

leading supplier of high-quality CNTs. In 2003 a process was invented to

spin CNT fibres directly from a synthesis reactor. The process is

intrinsically cheaper than the conventional process for carbon fibre and

it produces a tougher and more versatile product. The University of

Cambridge (UCAM) spin-out company Q-Flo Ltd (created in

2004 to achieve focus on transfer of this technology) and Plasan

(multinational manufacturer of vehicle defensive armour) formed a joint

venture in 2010 which has enabled the first-stage scale-up of manufacture.

Underpinning research

Alan Windle (Professor of Materials Science, Dept of Materials

Science & Metallurgy, UCAM, 1992 to date) has led the research

on carbon nanotubes (CNTs) and CNT fibres. His polymer-science research

spanned from flexible polymers (e.g. polyethylene) through to the most

rigid liquid-crystalline polymers. He perceived CNTs as the ultimate rigid

polymer molecule, fuelling new ideas for their processing into useful

materials such as fibres. Windle's group undertook some of the first work

on CNT composites, studying their liquid suspensions, and measuring the

influence of entanglements on properties. Work with Shaffer (PDRA,

left 2006, now Professor at Imperial) led to several research papers, e.g.

[1], and later the first report of liquid crystallinity in CNT suspensions

[2].

Research into CNT synthesis led to a patent set which was licensed to Thomas

Swan & Co Ltd, a specialist chemical manufacturer of Consett, Co

Durham, which based a new business on it. Specifically, the problem of

catalyst particle-size control was solved by forming from a precursor

deposited on a magnesium-oxide substrate, which was removed by dissolution

after CNT growth. The products now on sale (see Section 4a) consist of highly characterized

single-wall CNTs.

Windle's subsequent research explored much higher

synthesis temperatures, up to 1300°C, and moved from substrate to floating

catalyst (gaseous suspension) methods. The CNTs form a smoke; their

entanglement means the smoke is elastic and can be continuously withdrawn

from the reactor as a fibre, as fast as it is produced. Work with two

PDRAs, Ian Kinloch (2002-06, now Professor at Manchester) and Ya-Li

Li (2001-04), led to a high-profile publication [3] and to a patent,

now granted in the US and Korea, with Europe and Japan pending. The

invention is essentially an aerogel version of the (liquid) gel-drawing

process for making the polyethylene high-tech fibre marketed by DSM as Dyneema.

Process development 2004 to 2008, funded by an EPSRC grant (EP/E04218X/1,

£890,000, with Windle as PI), included fibre condensation, external

reeling, control of injection and process modelling using advanced CFD

packages, the latter work in collaboration with UCAM's Dept of Chemical

Engineering [4]. This work led to two supporting patents. The grant also

involved collaboration with Vicki Stone (Napier University, now

Professor of Toxicology and Director of Nano-Safety Research Group, School

of Life Sciences, Heriot-Watt University). Thus health issues with the

production of CNT materials were addressed as the research developed, not

as an afterthought. A collaboration with US Army Natick Soldier

Research Development and Engineering Center examined the

relationship between structure and strength [5]: in short gauge lengths,

the fibre had exceptional strength and stiffness [6], clearly exceeding

those of conventional high-performance fibres. One sample measured is

possibly the strongest fibre ever seen [6].

Since 2008, the research has continued unabated, particularly in process

control and in understanding mechanical properties, with a simple model

introduced for predicting strength. Unlike conventional carbon fibre, the

CNT fibre is exceptionally tough and weavable, largely because it is

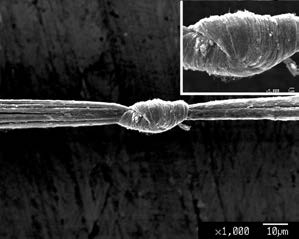

yarn-like, illustrated particularly by the fibre's ability to take knots

without reduction in strength (Fig. 1). A further breakthrough (2011) by

Windle's group has been the creation of fibres containing only single-wall

CNTs with chiralities which lead to metallic rather than semiconducting

behaviour [7]. This advance stems from recognition that small amounts of

sulfur added to the process to promote CNT detachment from the floating

catalyst particles are also effective in limiting the growth of these

particles by collision, so they can be kept to sizes of order 1 nm until

the carbon necessary for CNT growth becomes available. The reason for the

very useful selectivity for tubes of metallic chirality is not yet

completely understood and work in collaboration with the global modelling

community is addressing this key issue. Work towards composites has shown

that when the fibres are embedded in a resin matrix, the resin infiltrates

the fibre, giving excellent keying and thus interfacial shear strength on

curing.

Figure 1. A tight knot in the tough CNT fibre. The knot does not fail prematurely under tension.

Figure 1. A tight knot in the tough CNT fibre. The knot does not fail prematurely under tension.

The major commercial investment now occurring reflects the vision that

CNT fibre of this kind might replace carbon fibre in the structural

domain, and replace copper for electrical conductors, while being less

expensive on both counts.

References to the research

1. MSP Shaffer & AH Windle: Fabrication and characterization of

carbon nanotube/poly(vinyl alcohol) composites, Advanced Materials

11 (1999) 937; DOI: 10.1002/(SICI)1521-4095(199908)

2*. W Song, IA Kinloch & AH Windle: Nematic liquid crystallinity of

multi-wall carbon nanotubes, Science 302 (2003) 1363; DOI:

10.1126/science.1089764

3*. Y-L Li, IA Kinloch & AH Windle: Direct spinning of carbon

nanotube fibers from chemical vapor deposition synthesis, Science

304 (2004) 276; DOI: 10.1126/science.1094982

4. D Conroy, A Moisala, S Cardoso, AH Windle & J Davidson: Carbon

nanotube reactor: Ferrocene decomposition, iron particle growth, nanotube

aggregation and scale-up, Chemical Engineering Science 65

(2010) 2965; DOI: 10.1016/j.ces.2010.01.019

5. JJ Vilatela & AH Windle: Yarn-like carbon nanotube fibers, Advanced

Materials 22 (2010) 4959; DOI: 10.1002/adma.201002131

6*. KKK Koziol, JJ Vilatela, A Moisala, MS Motta, P Cunniff, M Sennett

& AH Windle: High-performance carbon nanotube fiber, Science 318

(2007) 1892; DOI: 10.1126/science.1147635

7. RM Sundaram, KKK Koziol & AH Windle: Continuous direct spinning of

fibers of single-walled carbon nanotubes with metallic chirality, Advanced

Materials 23 (2011) 5064; DOI: 10.1002/adma.201102754

* references best indicating the quality of the underpinning research.

(All 7 papers are in journals subjected to rigorous peer review and, as of

October 2013 they had attracted, in total, more than 1600 citations.)

Aspects of the work have frequently been presented as Plenary Lectures by

Windle, the most recent being at the Polymer Processing Society

Meeting at Nuremberg, July 2013. The spinning process and its

potential in different applications have featured in several TV

programmes; in particular, the potential of the fibre for making the

space-elevator cable was the closing feature of the Royal Institution

Christmas Lectures by Mark Miodownik, broadcast on BBC1 in 2010.

Details of the impact

(a) Technology transfer to Thomas Swan & Co Ltd

Windle's underpinning research, involving modification to synthesis

routes, was vital in that it overcame existing problems with scale-up,

where the planar substrate carpet process was ineffective. Windle's work

led to higher-temperature synthesis routes, the use of powdered substrates

as a catalyst bearer, and the production of the transition-metal catalysts

in-situ from the thermal decomposition of their salts. During the REF

impact period, following UCAM's transfer of IP to Thomas Swan, the

company sells worldwide and has become Europe's leading manufacturer of

single-wall CNTs, specializing in high-quality, mainly single-wall

material (the Elicarb® CNT product range, Fig. 2), in particular

for the energy-storage and advanced-electronics sectors. The patent

licensing and transfer of research outputs to Thomas Swan led to a

strategic shift for the company to set up their Advanced Materials

Division. [text removed for publication]. User companies have benefited

from a supply of materials with consistent and reproducible properties as

a result of Thomas Swan's development of the technology during

these early stages of adoption of CNT technologies by industry. [text

removed for publication]

Figure 2. Carbon nanotube product from the Thomas Swan Elicarb® range.

Figure 2. Carbon nanotube product from the Thomas Swan Elicarb® range.

(b) The fibre invention and technology transfer

Windle's research which led to the new process for spinning fibre,

consisting wholly of CNTs, directly from the CVD reactor zone has resulted

in three patents licensed so far (PCT/GB04/002969, PCT/GB2008/001473,

PCT/GB2011/050798) with others more recently filed. The head patent, which

describes the new process, was invented by Windle, Kinloch and Li (then

all at DMSM). The fourth inventor was Mr S Cash, a visitor from the

sponsor Thomas Swan present at the brainstorming session which

created the new idea.

The mechanism of technology transfer has been through a spin-out company

Q-Flo Ltd. Windle is both a Founder and a Director, and UCAM is a

significant share-holder. The role of this company is to market the IP

worldwide with the objective of establishing an international business to

manufacture and exploit the radically new type of carbon fibre. UCAM, as

owner of the patents, has licensed these to Q-Flo, which has

achieved its first major success through partnership with Plasan Ltd

to form a joint-venture company, TorTech Nano Fiber Ltd. Plasan is

an Israel-based company making protective armour, with plants in the US

and in France. TorTech was created in 2010 to develop, manufacture

and scale-up the process to the point where as a disruptive technology it

can challenge the existing world leaders: carbon, aramid (Kevlar)

and UHMW polyethylene (Dyneema). Not limiting its interests to the

mechanical properties of the fibre, TorTech is trying to develop

the fibre for electrical conductivity as it seeks a product that will

replace copper and aluminium in electrical cables and wires. A parallel

study has shown equal promise for the fibre's thermal conductivity which,

measured to be greater than 1200 W/m.K, is far beyond silver, especially

impressive given the far lower density of the CNT fibre.

[text removed for publication].

Main types of impact

Economic — Performance of existing business improved

through new products & processes (Thomas Swan, establishing a

new Advanced Materials Division, with new CNT-based product range); Spin-out

business created (Q-Flo, with joint venture TorTech,

bringing benefits for businesses and investors); Business sector

adopted new or significantly changed technology or process (Plasan,

through TorTech for armour production); Performance improved

through highly skilled people taking up specialist roles that draw on

their research (eg two members of Windle's group joined the new

Advanced Materials Division in Thomas Swan: Dr M Motta in 2008 and

Dr K Paton in 2010); Licensing income for UCAM.

Public policy & services — Risks to the security of nation

states reduced (Plasan lightweight CNT-based armour for

vehicles, improving safety and performance of security personnel).

Society — Research has contributed to community regeneration

(Thomas Swan investment, safeguarding and creating jobs in Co

Durham).

Sources to corroborate the impact

- Commercial Director, Advanced Materials, Thomas Swan & Co Ltd

(Claims 1 and 2)

- CEO, Q-Flo Ltd (Claim 3)

- Head of Physical Sciences, Cambridge Enterprise, UCAM (Claim 4)

Companies (for verification of areas of activity):

Thomas Swan & Co Ltd (http://www.thomas-swan.co.uk/)

Q-Flo Ltd (http://www.q-flo.com/)

Plasan Ltd (http://www.plasansasa.com/)

Patents:

Patents licensed to Thomas Swan & Co Ltd

- US Patent Number 7,135,159, European Patent Number 1390294, and

Japanese Patent Number 3930810 (National Phase of PCT/GB02/02239,

priority date 15th May 2001)

Title: Synthesis of Nanoscaled Carbon Materials

Inventors: MSP Shaffer, IA Kinloch & AH Windle

- US Patent Number 8,173,211, European Patent Application Number

03764020.8, and Japanese Patent Number 4703182 (National Phase of

PCT/GB03/003086, priority date 17th July 2002)

Title: CVD synthesis of carbon nanotubes

Inventors: MSP Shaffer, AH Windle, BFG Johnson, J Geng, D Shephard &

C Singh

- US Patent number 7,767,615, and European Patent Application Number

03775549.3 (National Phase of PCT/GB03/04925, priority date 13th

December 2002)

Title: Method for producing carbon nanotubes and/or nanofibres

Inventors: IA Kinloch, AH Windle, C Singh, MSP Shaffer & KKK Koziol

Patents licensed to Q-Flo Ltd

- US Patent Number 7,323,157, European Patent Application Number

04743311, and Japanese Patent Application Number 2011091872 (National

Phase of PCT/GB04/002969, priority date 11th July 2003)

Title: Production of agglomerates from the gas phase

Inventors: IA Kinloch, Y-L Li, AH Windle & SL Cash

- US Patent Application Number 12/597,837, and European Patent

Application Number 08737118 (National Phase of PCT/GB2008/001473,

priority date 28th April 2007)

Title: Enhancement of the structure and properties of carbon nanotube

fibres and films Inventors: KKK Koziol, J Vilatela Garcia, AH Windle

& M Pick.

- US Patent Application 13/696,582, and European Patent Application

EP117718769.0 (National Phase of PCT/GB2011/050798, priority date 6th

May 2010)

Title: Chemical Treatment of Carbon Nanotube Fibres

Inventors: KKK Koziol, AH Windle, S Boncel & R Sundaram