Novel Quantum Cascade Laser technology leads to new products, processes and market opportunities

Submitting Institution

University of GlasgowUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Physical Sciences: Atomic, Molecular, Nuclear, Particle and Plasma Physics, Optical Physics, Other Physical Sciences

Summary of the impact

The commercialisation of Quantum Cascade Lasers (QCL) and the associated

novel fabrication processes developed at the University of Glasgow has

provided Compound Semiconductor Technologies Global Ltd (CSTG) with a new

foundry product supplying quantum cascade lasers for gas sensing, safety

and security, and military applications. This resulted in 40% turnover

growth from 2010-2012 and the company is now recognised as a global leader

in QCLs and their fabrication. Based on University of Glasgow research,

the company has created a manufacturing toolbox for the production of a

wide variety of QCL chip designs. CSTG has also achieved a world first,

manufacturing QCLs for systems that detect explosives at a safe distance

and can counter heat-seeking missile attacks on aircraft.

Underpinning research

Quantum cascade lasers (QCLs) were first demonstrated by Federico

Capasso's group at Bell Laboratories in the USA in 1994. QCLs are highly

compact semiconductor chips, only 1mm long, that emit light in the

mid-infrared region of the spectrum enabling many gases of economic and

environmental importance to be sensed, e.g. methane and carbon dioxide.

Professor Charles Ironside in the School of Engineering at the University

of Glasgow (Senior Lecturer 1992-94, Reader 1994-99, Professor of Quantum

Electronics 1999-present) initiated his research into QCLs to diversify

the portfolio of applications that could be addressed with this

technology.

As QCL devices have important military applications, it was not possible

to access US manufactured lasers due to US Government regulations (ITAR)

controlling the export of defence-related material and services. No group

outside the USA had the ability to manufacture QCLs and so it was

necessary to independently discover the experimental means for growing the

epitaxial structures and to develop the techniques and processes that

would enable their reliable manufacture. This was achieved in 1998 by a

consortium comprising epitaxial growth and fabrication at the University

of Glasgow, led by Ironside, and device characterisation at the University

of Sheffield, led by Prof John Cockburn (Department of Physics and

Astronomy). They were the first outside the USA to demonstrate QCLs [1].

The University of Glasgow team included Colin Stanley (Professor

1992-2010), Jane McGill (Research Fellow 1987-88, Lecturer 1988-2000) and

PhD student Corrie Farmer.

Key challenges tackled by the consortium were developing the critical

etch and lithography processes that define the laser structure. These were

overcome by the development of wet and dry etch techniques, including the

use of reactive ion etching and inductively coupled reactive ion etching

techniques and using hydrogen silsesquioxane for QCL waveguide

planarisation.

The research continued with funding from EPSRC for the project "Quantum

cascade emission devices for IR optical sensing" (2000-2002,

GR/M46983/01). In collaboration with the University of Sheffield,

Edinburgh Sensors and GEC Marconi, a successful demonstration of

spectroscopy using room temperature QCLs was achieved.

From 1999-2000 Ironside, Dr Farmer (Research Assistant, 2000-present) and

PhD student Michel Garcia (2001-2003) collaborated with Dr N Langford and

Prof D Duxbury in the Physics Department at the University of Strathclyde

to develop QCLs for gas spectroscopy. The EPSRC funded "Ultra Sensitive

Spectroscopy Using QCLs" (GR/M69043/01) led to the discovery of an

intra-pulse chirp effect that tuned the laser in a way that made it

suitable for detecting gases [2]. Cascade Technologies Ltd was founded, as

a University of Strathclyde spin-out, to manufacture sensing systems based

on this technique.

The `QCSENSE' project was funded by the DTI in 2006, in collaboration

with Cockburn at the University of Sheffield, Wyn Meredith, Commercial

Director, Compound Semiconductor Technologies Global Ltd (CSTG), Erwan

Normand, Chief Scientific Officer, Cascade Technologies and Bill Hirst,

Shell Global Solutions. Ironside, Miles Padgett (Professor of Physics,

1999-present) and Research Assistant Dr Thomas Slight (2006-2012) worked

with the consortium to develop 3.35 micron QCLs, the shortest wavelength

QCL at the time, for trace sensing of hydrocarbons such as ethane and

methane using the mid-infrared absorption of light by these gases [3].

Deep etched surface grating technology, based on initial work on

conventional direct bandgap lasers by John Marsh in 1995 (Lecturer

1986-96, Professor 1996-present), was used to make single-mode lasers.

These QCLs were suitable for robust, reliable and compact systems that

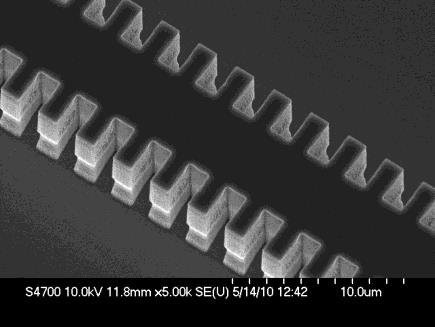

could be mounted on a mobile platform. Figure 1 illustrates the lateral

grating on the side wall of a QCL that ensures the laser operates at a

precise single frequency, which is ideal for sensing ethane.

Figure 1. Lateral grating on the side wall of a QCL.

Figure 1. Lateral grating on the side wall of a QCL.

Between 2010 and 2012, CSTG and Ironside collaborated on a Knowledge

Transfer Partnership (KTP) project increasing the commercial focus of the

research, with Slight as the KTP Associate. The project produced a QCL

with a novel laser geometry, giving very high spectral quality for

spectroscopy and sensing applications [4], and industrialised the research

processes. The project also produced a number of research outputs that

have become part of the suite of processes and designs now offered by

CSTG. These included an entirely new method for ensuring single mode

operation of QCLs with significantly reduced fabrication costs [5] and

QCLs with an integrated polarization mode converter which has applications

in ellipsometry [6].

References to the research

[1] C.D. Farmer, P.T. Keightley, C.N. Ironside, C.R. Stanley, L.R. Wilson

and J.W. Cockburn, A quantum cascade laser fabricated using planar

native-oxide layers, Appl. Phys.Letts. 77(1), 25-27, 2000. doi: 10.1063/1.126865

*

[2] M. Garcia, E. Normand , C.R. Stanley, C.N. Ironside, C.D. Farmer G.

Duxbury and N. Langford, An AlGaAs/GaAs quantum cascade laser operating

with a thermoelectric cooler for spectroscopy of NH3, Optics

Communications 226 39-43 2003. doi:

10.1016/j.optcom.2003.07.041*

[3] T.J. Slight, G. Tandoi, D. Revin, A. McKee, S. Zhang, W. Meredith,

J.W. Cockburn, C. N. Ironside, Lambda =3.35um Distributed Feedback Quantum

Cascade Lasers with High Aspect Ratio Lateral Grating, IEEE Photonics

Technology Letters, 23(7), 420-422, 2011. doi: 10.1109/LPT.2010.2103358

[4] R. Phelan, T.J. Slight, B. Kelly, J. O'Carroll, A. McKee, D. Revin,

S. Zhang, A.B. Krysa, K.L. Kennedy, J.W. Cockburn, C.N. Ironside, W.

Meredith, J. O'Gorman, Room-Temperature Operation of Discrete-Mode

InGaAs-AlAsSb Quantum-Cascade Laser With Emission at 3.3microns, IEEE

Photonics Technology Letters, 22(17), 1273-1275, 2010.

doi: 10.1109/LPT.2010.2053529

[5] D. Dhirhe, T.J. Slight, C.C. Nshii and C.N. Ironside, A tunable

single-mode double-ring quantum-cascade laser, (Invited paper),

Semicond. Sci. Technol. 27, 094007, 2012. doi: 10.1088/0268-1242/27/9/094007

*

[6] D. Dhirhe, T. J. Slight, B. M. Holmes, D. C. Hutchings, and C. N.

Ironside, Quantum cascade lasers with an integrated polarization mode

converter, Optics Express, 20(23), pp. 25711-25717, 2012. doi: 10.1364/OE.20.025711

* best indicators of research quality

Details of the impact

Professor Charles Ironside's research on Quantum Cascade Lasers (QCLs)

has created commercial impact through two SMEs — Compound Semiconductor

Technologies Global (CSTG) and Cascade Technologies — and the development

of new products and processes for gas sensing, safety and security and

military applications.

CSTG supplies advanced semiconductor optoelectronic devices to a range of

markets including counterterrorism, homeland security, and oil and gas.

For example, devices that sense minute quantities of explosive gases are

used for the stand-off detection of explosive devices including IEDs, and

the detection of hydrogen peroxide is used in combination with infrared

counter measures to dazzle heat-seeking missiles. The company serves both

fabless and vertically integrated customers in the UK, US, Europe and

Japan. In excess of 70% of the company revenues are derived from

high-value product exports. CSTG is now recognised as a global leader in

QCL fabrication as a direct result of the collaboration with the

University of Glasgow and achieved an increase in turnover of ~40% from

2010 to 2012.

Building on his world-leading research, Ironside, together with CSTG,

secured a KTP project in 2009 which has had a remarkable impact on CSTG's

profitability. This has been achieved through the creation of a

manufacturing toolbox, a generic QCL process library that can be used to

produce a wide variety of chip designs, hence establishing the company's

reputation in new applications and markets. The company has achieved world

firsts, in manufacturing QCLs for systems that detect explosives at a safe

distance and for countering heat-seeking missile attacks on aircraft.

This project integrated Ironside's knowledge of the design and optical

characterisation of QCLs into CSTG business, allowing the company to

harness the commercial potential of QCLs as an emerging mid-infrared laser

technology. This resulted in CSTG adding a new high-value laser device and

manufacturing process to their product range. The project also yielded new

fabrication processes and novel laser chip designs, enabling CSTG to

address a market need for innovative semiconductor foundry processes for

the manufacture of compact, mid-infrared micro-chip laser sources. The

Commercial Director at CSTG has stated that at least 60% of the company's

increase in turnover (between 2010 and 2012) could be attributed to these

mid-infrared products. CSTG's ability to access markets and clients

through the introduction of a QCL foundry service has resulted in new

contracts, customers, and the recruitment by the company, via a KTP, of

Thomas Slight from Ironside's research group. The impact of this

collaboration in terms of business profitability and expansion was

recognised by the award of Best KTP in Scotland in 2012.

In addition to the impact through CSTG, Ironside's QCLs were used to tune

a new intra-pulse spectroscopy technique. This led to a series of

successful gas phase molecular fingerprinting experiments. Cascade

Technologies was established in 2003 to capitalise on this novel

technique. The intra-pulse technology is now used within the spectroscopic

systems developed, manufactured and marketed by Cascade Technologies.

Their QCL based gas emission monitoring systems and gas analysers are used

for industrial emissions monitoring, process optimisation, analytical

chemistry and trace level applications. The systems are installed on the

production lines of products where integrity is critical, e.g. in the

manufacture of aerosol cans and inhalers, guaranteeing their integrity by

scanning to sense for escaping gases.

Sources to corroborate the impact