Robust assessment of fire toxicity leading to safer products and less loss of life and injury from fires

Submitting Institution

University of Central LancashireUnit of Assessment

Electrical and Electronic Engineering, Metallurgy and MaterialsSummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Interdisciplinary Engineering

Medical and Health Sciences: Pharmacology and Pharmaceutical Sciences, Public Health and Health Services

Summary of the impact

The Steady State Tube Furnace (ISO/FDIS 19700) allows fire toxicity to be

quantified in real fire conditions. This has led to the introduction of

"acidity classification" for cables in the European Construction Products

Directive/Regulation (2008/2013) (as a surrogate for fire toxicity) to

promote the use of safer, low smoke, zero halogen (LSZH) alternatives to

PVC cables. Additionally, architects and building specifiers can use our

data to avoid the most toxic foam insulation materials in low energy

buildings. The biggest impact of our work, the global reduction in loss of

life in fire is probably the most difficult to quantify, as too many other

factors influence the fire statistics.

Underpinning research

From 1955-1980 the number of deaths and injuries from fire increased

steadily. While deaths and injuries from burns (80% of total in 1955)

showed a modest increase, deaths and particularly injuries from inhaling

toxic smoke increased rapidly, and continued to rise until 2000 (over 50%

of total in 2011). Eventually, the rise was attributed to the increased

use of synthetic polymers, especially polyurethane foam furnishings.

Although much work was undertaken from 1980-1995, the difficulty of

replicating this toxicity on a bench-scale meant that investigation of

fire toxicity could only be achieved using large scale fire tests

(prohibitively expensive). Instead, efforts in fire safety focussed on

reductions in ignitability and heat release, rather than the toxicity of

effluent. Moreover, as coroners require evidence that fire was not used to

cover-up murder, and that the victims of fire were breathing at the time

of the fire, they quantify carbon monoxide inhalation as blood

carboxyhaemoglobin concentration. Unfortunately, this data has been used

to support the erroneous conclusion that carbon monoxide (which forms

carboxyhaemoglobin) is the only significant toxicant present in

fire effluents1

As a fire grows, it becomes ventilation controlled and the yields of

toxic products (especially carbon monoxide and hydrogen cyanide) increase

by factors of between 10 and 50. Most bench-scale fire apparatuses cannot

replicate these under-ventilated fires as too much radiant heat from the

flame is lost to the surroundings and the test fire is extinguished when

the oxygen concentration falls. The steady state tube furnace was designed

specifically to replicate each stage of fire growth in order to quantify

fire effluent toxicity under all conditions, including the most toxic

under-ventilated conditions, by surrounding the flames in a high

temperature, high radiant flux environment.

From the initial concept, by UCLan's visiting Prof Purser, (then based at

the UK's Fire Research Station, now BRE Fire and Security), the

development of the steady state tube furnace (SSTF) was led by Prof Hull,

based at UCLan from September 2007. In October 2007, Dr Stec was

appointed to a Lectureship, then Readership at UCLan, to lead the

development of the fire toxicity research. In addition to the SSTF

development, she quantified the fire toxicity of many important materials;

recognised the importance of particulates in toxicity; identified the need

to obtain more large-scale validation data to correlate against behaviour

observed in the steady state tube furnace; and set-up the Large

Instrumented Fire Enclosure (LIFE) facility to achieve this, at Lancashire

Fire and Rescue Service's Washington Hall Training Centre. This led to

further funding from EPSRC (£125k) to understand the problems of fire

toxicity in real fires.

The first breakthrough came when the group rationalised the toxic product

yields from burning polymers as a function of stoichiometric equivalence

ratio. They then developed the realistic bench scale measurement of fire

toxicity, from bespoke research equipment to international standard. They

have over 60 publications on the subject. In May 20102

their book, "Fire Toxicity" was recognised as the "best currently

available understanding and application of fire toxicity"3

by the editor of the Journal of Fire Sciences.

This research has:

- Developed, and characterised a method for replicating large scale fire

behaviour on a bench scale.

- Established relationships between fire effluent toxicity, material

composition, temperature and ventilation conditions for a wide variety

of materials.

- Investigated the effect of fire retardants and nanofillers on fire

effluent toxicity.

- Developed a methodology for separation and analysis of soot particles

from fire effluents.

- Established a unique (LIFE) facility at Lancashire Fire and Rescue

Service's Washington Hall Training Centre, for investigation of large

scale fire behaviour.

- Demonstrated the validity of the approach by monitoring effluent

toxicity from the real fires in domestic houses (prior to scheduled

demolition).

References to the research

*Best indication of quality of research

*A.A.Stec, T.R.Hull, J.A. Purser, D.A. Purser, Comparison of Toxic

Product Yields from Bench-Scale to ISO Room, Fire Safety Journal 44,

62-70, 2009. (Shows validity of the test method from bench to large

scale).

*A A Stec, T R Hull and K Lebek, Characterisation of the steady state

tube furnace (ISO TS 19700) for fire toxicity assessment, Polymer

Degradation and Stability, 93, 2058-2065 (2008). (Describes a number of

experimental studies to understand and characterise the SSTF apparatus).

Anna A Stec and T Richard Hull, Assessment of the fire toxicity of

building insulation materials, Energy and Buildings 43, 498-506,

(2011). (Uses the SSTF apparatus to measure fire toxicity of insulation

materials).

*A.A.Stec, T.R.Hull, K.Lebek, J.A.Purser, D. A. Purser, The Effect of

Temperature and Ventilation Condition on the Toxic Product Yields from

Burning Polymers, Fire and Materials 32, 49-60, (2008).

(Rationalises fire toxicity as a function of temperature and ventilation

condition for a range of common materials).

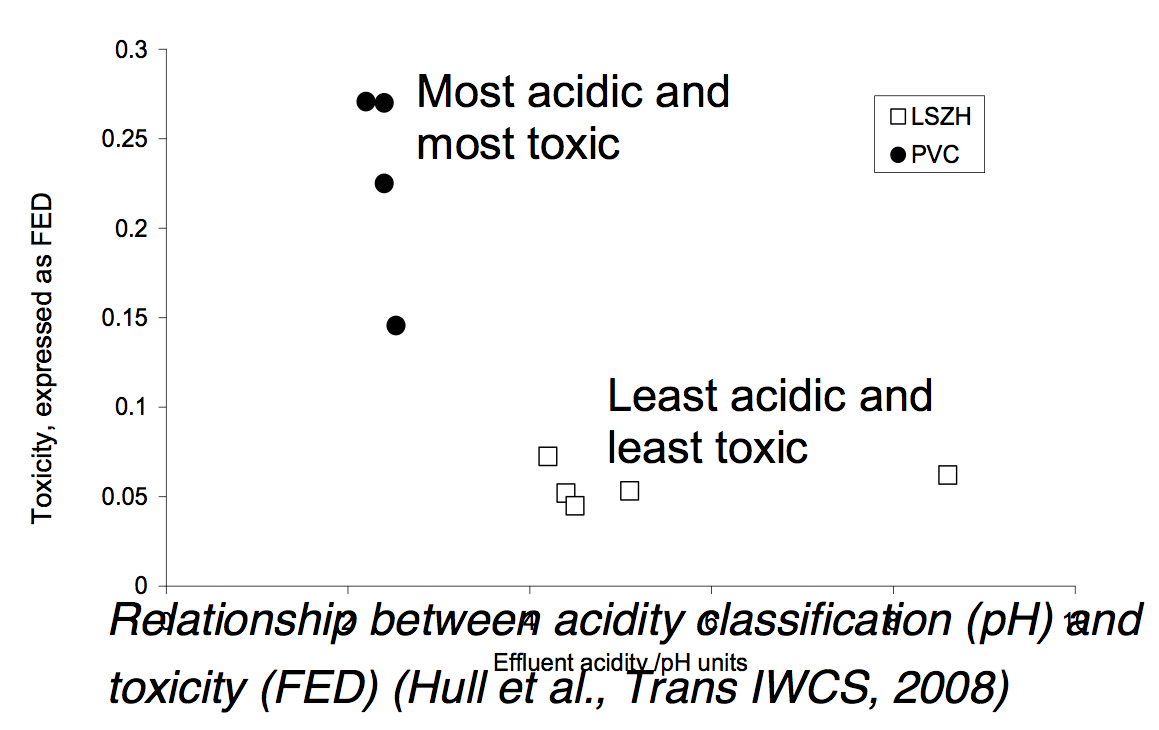

T.R. Hull, K. Lebek, and J.E. Robinson, Acidity, toxicity and

European cable regulation, Transactions of the International Wire

and Cable Symposium (Trans IWCS), 1, 111-117, (2008). (Shows the

relationship between acidity and fire toxicity for 10 typical cable

formulations; used to support the acidity classification in the EU

Construction Product Regulations).

J. A. Purser, D. A. Purser, A. A. Stec, C. Moffatt, T. R. Hull, J. Z. Su,

M. Bijloos, and P. Blomqvist Repeatability and reproducibility of the

ISO/TS 19700 steady state tube furnace Fire Safety Journal 55,

22-34, (2013). (Reports an investigation of interlaboratory

reproducibility of the SSTF, needed for acceptance by standardisation

bodies).

Funding

| Feb '05 – Dec `08 |

EU Framework 6: PredfireNano project –

Prediction of the fire behaviour (flammability and fire toxicity) of

polymer nanocomposites (€300k) |

| Oct '06 – Sept `09 |

PhD studentship “Comparison of Toxicity data from

Bench and Large Scale tests” from the European Association of

Producers of Flame Retarded Olefinic Cable Compounds (FROCC) (£61k)

(T R Hull) |

| Oct '07 – Sept `09 |

Borealis: “Development of Tube Furnace Toxicity

Standard” (£14k) (A A Stec) |

| Jan '11 - Dec 13 |

Rockwool International: research into the fire

toxicity of building materials (T R Hull and A A Stec) (£90k). |

| Jan '12 - Dec `13 |

EPSRC: Investigation of Fire Toxicity and Scale-Up of

Fire Behaviour £125k (A A Stec) |

| Dec '12 – Nov '15 |

EU Framework 7: Deroca – Assessing the fire safety (flammability,

fire toxicity and particulate releases) of replacements for

brominated flame retardants (€ 535k). |

Details of the impact

Overall, our work has demonstrated that fire toxicity can be replicated

on a bench scale, using the steady state tube furnace apparatus (SSTF).

This method was adopted by ISO as a technical specification in 2007 (ISO

TS 19700); Prof Hull has been ISO Project Leader since 2004. This

is a publicly available document and, now the interlaboratory

reproducibility has been demonstrated, is currently (2013) published as

ISO/FDIS 19700 (final draft international standard) due to be published as

ISO 19700 in 2014. This provides the first robust framework for the

realistic bench-scale quantification of fire effluent toxicity as a

function of fire condition. As the major killer, and major source of

injury in fires, this provides the vital tool for improving fire safety.

Some industries (for example the glass and mineral wool insulation, and

electric cable industries) have recognised the importance of fire

toxicity, supported our research, and are using it to market products of

greater fire safety. Recently, we have used the SSTF to show that

phosphorus based fire retardants are much safer than the brominated

materials they replace4, of great

interest to their manufacturer, Clariant, and the environmental groups

concerned about brominated flame retardants.

The adoption of performance based design by fire regulators, as an

adaptable strategy to free designers from the inappropriateness of

specific regulations that have no significant fire safety benefit,

includes a requirement to estimate the available safe escape time. This is

the time between detection of a fire and the safe evacuation of occupants.

The toxic product concentration along the escape route must be low enough

not to hinder or prevent escape. This requires prediction using robust

data on toxic product yields as a function of fire condition, and so far

the SSTF has proved the only apparatus capable of providing such data. In

addition, the SSTF provides regulators with a tool to quantify hazards,

and if necessary to restrict the use of the most dangerous materials in

the highest risk applications (e.g. mass transport, high rise buildings,

electrical and electronic components etc.)

Closer regulation of fire toxicity has saved lives, and forced industry

to replace dangerous products with safer materials; the progressive

switch-over from PVC to "zero-halogen" cables across Europe is the

clearest example. Meanwhile, for many years, the older products will

remain installed and sometimes in use, making it very difficult to

quantify the benefit in terms of reduced fire deaths and injuries. Thus,

while there is a clear societal benefit to reducing the toxicity of fires,

the short term cost has to be offset against the longer term benefits of

better designed materials and products (from which there is generally

greater profit) as well as improved fire safety. Industries already

manufacturing fire safe products, such as the zero-halogen cable and

mineral and glass wool insulation industries have been the immediate

beneficiaries in terms of increased sales.

One of the most tangible current outcomes has been the introduction of

the acidity classification in the European Construction Products

Regulation (305/2011/EU — CPR) — requiring all cables in Euroclasses B, C

and D to be classified according to the hazardous properties of gases

developed in the event of fire, which "compromise the ability of the

persons exposed to them to take effective action to accomplish escape",

allowing users to discriminate between high toxicity (PVC) and low

smoke/zero halogen (LSZH), low fire toxicity cables. This is illustrated

below, showing the acidity of the effluent as 0.15 measured by the EN

50267-2-3 regulatory test (a lower pH value means greater least toxic

acidity; cables with pH<4.3 do not meet the 0.05 low hazard "acidity

classification"), against the toxicity (quantified using ISO 19700

expressed as Fractional Effective Dose — the higher the value, the greater

the toxicity). This clearly shows the relationship between the acidity

classification and the toxicity, was presented in the IWCS paper, and was

used to persuade the regulators of the need to introduce such as

classification in the Construction Products Regulation (2011), which came

into force across Europe in 2013. This has driven the switchover from PVC

to LSZH cables in the non-domestic sector over the last 5 years. Our

industrial contacts have helped to ensure that ISO 19700 is a usable tool,

that our supporting publications are relevant to current industrial

practice, and have participated in our "Hazards from Fire" short course.

We have been proactive on national and international standardisation

bodies. Dr Stec represents the Society for Chemical Industry on

the British Standards Hazard to Life from Fire Technical Committee

(FSH/16), and is designated the UK's principal expert on Fire Chemistry,

playing a key role in ISO Fire Threat to People and the Environment

sub-committee (TC 92 SC3), while Prof Hull represents the Royal

Society of Chemistry on the same committee and is the Principal expert on

Fire Models, and leads the UK delegation to TC92 SC3 , the premier

international body on fire toxicity, where he is project leader for the

ISO 19700 steady state tube furnace.

Key dates:

| 2010 |

“Fire Toxicity” published by Woodhead publishing,

raising the profile of fire toxicity amongst the fire safety

community |

| 2011 |

ISO “Official” Interlaboratory Reproducibility Exercise completed |

| 2011 |

Acidity regulation requirement introduced across Europe

(305/2011/EU – CPD now CPR) |

| 2012 |

Detailed publication of correlations of various bench scale

methods with large scale. |

| 2013 |

Ballot approves circulation of ISO/FDIS 19700, prior to adoption

as a ful international standard. |

Sources to corroborate the impact

CONTACT 1: [text removed for publication]

CONTACT 2: [text removed for publication]

CONTACT 3: [text removed for publication]

CONTACT 4: [text removed for publication],

1 Nelson, G.L. Carbon monoxide and fire

toxicity, (1998) Fire

Technology, 34 (1), pp. 39-58.

2 A.A. Stec, T.R.Hull, Fire

Toxicity, CRC Press/Woodhead Publishing, Cambridge, UK 2010

3 G.Hartzell, Book Review, FIRE TOXICITY, Journal

of Fire Sciences, Vol.

29, pp. 489-490, 2010

4 S Molyneux, A A Stec, T R Hull,

The

effect of gas phase flame retardants on fire effluent toxicity

Polymer Degradation and Stability (in Press) 2013

doi:

10.1016/j.polymdegradstab.2013.09.013