Optimal design of flow handling systems using computational fluid dynamics

Submitting Institution

University of HuddersfieldUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Information and Computing Sciences: Artificial Intelligence and Image Processing

Engineering: Interdisciplinary Engineering

Summary of the impact

University of Huddersfield research into the optimal design of

flow-handling systems has been credited with "transforming" the

development strategies and global market sales of an industrial partner.

Weir Valves and Control Ltd has enjoyed a 75% saving in design lead time

and a 1,800% increase in annual sales - from several thousand before its

collaboration to millions in 2013 - through the structured integration of

researchers' computational fluid dynamics expertise in its design process.

The success of this collaboration, which has been described as an exemplar

of a Knowledge Transfer Partnership, has also led to further research

contracts.

Underpinning research

The innovative design of fluid systems is an important area of work for

the University of Huddersfield's Energy, Emissions and the Environment

Research Group (EEERG) which is a part of the Centre of Efficiency and

Performance Engineering. Novel methods in this field can have a number of

different yet related applications for a range of end-users. Professor

Rakesh Mishra (Senior Lecturer, 2004-2009; Reader, 2009-2011; Professor of

Engineering, 2011-present) has led EEERG's studies into flow through

complex geometries, including research carried out on various

fluid-handling systems.

In 2005, as part of an EPSRC New Academic CASE award in collaboration

with Bentley Motors, Mishra began research to develop an inverse design

code for brake discs for optimum flow and heat transfer characteristics.

These discs have embedded pin and aerofoil-shaped structures within the

flow passage to modify flow patterns and minimise judder and undesirable

vibrations. A systematic computational fluid dynamic (CFD) analysis and

experimental study resulted in the development of design equations

correlating flow characteristics with the geometry of the disc. These

equations were then embedded in the design methodology to develop an

inverse design code. This work resulted in several publications, including

two in the Proceedings of the Institute of Mechanical Engineers, Part D:

Automobile Engineering [1, 2].

Weir Valves and Controls Ltd, which uses similar features in control

valve applications, approached Mishra after becoming aware of his research

through these publications. This resulted in a three-year Knowledge

Transfer Partnership programme, approved by the Technology Strategy Board

and EPSRC, to address the company's need to embed complex flow knowledge

into its design, operation and sales teams. This research involved the

following objectives:

- Improved scientific understanding of flow geometry of valve bodies in

order to enhance valve performance and comply with IEC 60534 Part 2

sizing calculation standards

- Improved understanding of valve performance under compressible versus

incompressible flows

- Understanding the effects of multiphase flow (e.g. oil/water,

water/solids, oil/water/gas) and entrained solids on valve performance

- Understanding the effects of specific trim designs on flow

recirculation, vortex shedding and cavitation.

The work involved detailed CFD and experimental studies on the standard

valve trim to validate the CFD models. The strategy for CFD was based on

the published works [1, 2] and resulted in accurate estimates of design

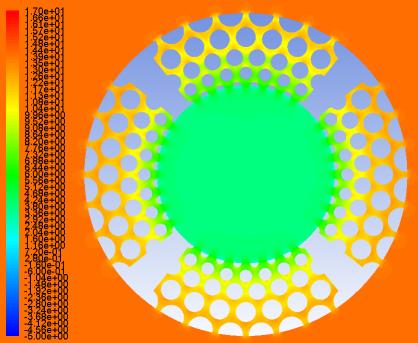

parameters CV and K. It was apparent that the front-row cylinders were

responsible for the majority of the pressure loss. Areas of negative

pressure zone that were susceptible to cavitation were also identified

(Figure 1).

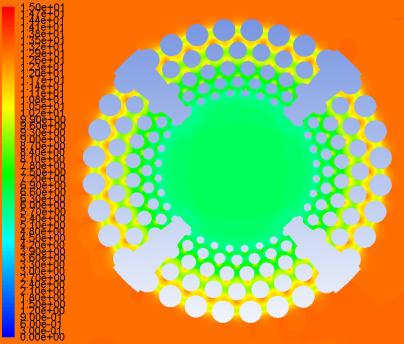

By manipulating the geometry it was possible to achieve controlled

reduction in pressure drop and minimise cavitation. The results obtained

through CFD tests were matched with a purpose-built valve test rig at the

University, and excellent matching between the two was observed. Outcomes

from CFD were then embedded in the design process, and a new strategy was

adopted (Figure 2). The work also included the development of special

software to simplify design and analysis.

Figure 1: Effect of geometry modification on Pressure

Figure 1: Effect of geometry modification on Pressure

Figure 2: Modified design strategy

Figure 2: Modified design strategy

References to the research

Publications:

1. E Palmer, R Mishra and J Fieldhouse (2008): `A Computational

Analysis on the Effect of Front-Row Pin Geometry on the Aero-Thermodynamic

Properties of a Pin-Vented Brake Disc', IMechE Journal Part D,

Volume 222, 1231-1245. DOI: 10.1243/09544070JAUTO755 (Downloaded 60 times

from the University Repository by users in 19 countries http://eprints.hud.ac.uk/4395/).

2. E Palmer, R Mishra and J Fieldhouse (2009): `An Optimisation

Study of a Multiple-Row Pin-Vented Brake Disc to Promote Brake Cooling

Using CFD', IMechE Journal Part D, Volume 223, Number 7, 865-875.

DOI: 10.1243/09544070JAUTO1053 (Downloaded 76 times from the University

Repository by users in 20 countries http://eprints.hud.ac.uk/4392/)

Grants:

EPSRC CASE award for New Academics, University of Huddersfield and

Bentley Motors, September 2005 to September 2009 - £78,000. PI Rakesh

Mishra.

Technology Strategy Board/EPSRC KTP award to University of Huddersfield

in association with Weir Valves and Controls Ltd, January 2011 to January

2014 - £120,000. PI Rakesh Mishra.

Details of the impact

EEERG's innovative work on fluid systems has been credited with

"transforming" the design, operating and sales strategies of one of the

University of Huddersfield's industrial partners. The successful

application of research, which has resulted in 18-fold increase in sales

for the company and further contracts for the University, has been

described as an exemplar of a Knowledge Transfer Partnership.

The inverse design methodology that was first developed for Bentley

Motors led to immediate success when incorporated into Weir Valves and

Controls Ltd's X-Stream valve trim. In its product literature the company,

based in Elland, West Yorkshire, describes X-Stream as "the first [valve]

of its kind to provide complete 3D-flow control", adding: "The result of

an extensive research programme, this method of design uses a combination

of proven computational fluid dynamics (CFD) and actual flow visualisation

techniques to eliminate local areas of excessive turbulence and velocity

(the main source of noise and erosion problems) and areas of recirculating

flow (a significant cause of cavitation)." [a] Modifications in design

strategy brought about by EEERG's research resulted in an immediate

improvement in design lead times - specifically, a reduction of 75% - and

led to growth in demand for and sales of X-Stream. In addition, enhanced

knowledge of the pressure field and the velocity field inside valve

internals enabled the company's design and sales employees to handle

clients' queries far more efficiently. [b, c]

The resulting success of this collaboration has led to more investment in

the company's R&D and sales strategies, including the establishing of

a team specifically tasked with handling X-Stream matters. The industrial

supervisor of the KTP was given responsibility for leading further

research and development in this area, with Mishra's team and the

University's facilities remaining integral to the work. The growth in

sales since the partnership was first established is reflected in the

figures below.

| Year: |

2010 |

2011 |

2012 |

2013 |

| Sales:* |

£X |

£4X |

£ 11 X |

£ 18 X |

(Actual numbers cannot be given because of confidentiality)

This progression shows how embedding the knowledge through the KTP

programme, along with initiatives taken by the company to fully utilise

the support available, has resulted in a 18-fold increase in sales in the

space of less than four years. [c] The figure for 2012-2013 is expected to

show a 25 fold increase by the end of this year. Weir's Senior Design

Engineer has remarked: "The impact of embedding outcomes of computational

fluid dynamics into the design strategy, as well as operation and sales,

transformed the market for X-Stream worldwide." [c] Speaking at a local

management committee meeting in September 2013, the KTP adviser described

the programme as an example of an ideal Knowledge Transfer Partnership in

which academic expertise had been embedded through a structured process in

the company's work system to deliver benefits to all parties. [d]

The strengthening of the partnership between the University and Weir as a

result of the success of EEERG's research has delivered further

advantages. In the past two years four graduates have been employed by the

company as full-time engineers, and every year Weir has employed two

placement students, which has further contributed to the partnership's

sustainability. Although the current KTP is due to end in January 2014,

both parties have already agreed to extend collaboration via another KTP -

one focused on extending the work carried out so far to develop the design

of wear-resistive valves for application in the oil and gas industry.

The influence of the research conducted with both Bentley and Weir has

also been be evidenced by the securing of further contracts by Mishra and

his team. Two PhD studentships are being sponsored by Blackhall

Engineering Ltd, of Brighouse, West Yorkshire, to embed the team's

knowledge base into the company's design and development activities in

order to optimise Blackhall's product range. [e]

Sources to corroborate the impact

a. Product description of X-Stream, Weir Valves and Controls Ltd

http://www.weirpowerindustrial.com/products__services/valve_products/control_valves/severe_service_control_valve-1.aspx

b. Support letter from Managing Director, Weir Valves and Controls Ltd

c. Support letter from Research and Development Lead Engineer, Weir

Valves and Controls Ltd

d. Support letter from the KTP Adviser, Technology Strategy Board

e. Studentship agreements signed by Managing Director, Blackhall

Engineering Ltd