Use of biomechanical modelling to develop and commercialise an artificial spinal implant

Submitting Institution

University of NottinghamUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Medical and Health Sciences: Clinical Sciences, Neurosciences

Summary of the impact

Research into the biomechanics of intervertebral discs at the University

of Nottingham has made a

significant contribution to the development of two medical implants

(Cadisc®- L and Cadisc®-C) by

Ranier Technology Ltd. 226 patients (90% outside the UK) have had this

treatment, which has

outperformed the alternatives by 34% in measured outcomes of reducing

patient disability (ODI),

pain and quality of life (QALY). Consequently, Cadisc® now accounts for

all of Ranier's business.

The company has expanded its workforce to 35 people and has attracted

external investment of

£13M to perform clinical trials and manufacture the product.

Underpinning research

The discs of the lumbar and cervical spine are subject to degenerative

changes caused by ageing

and the stresses of day-to-day life. The resulting loss in disc height and

flexibility and reduced

ability to absorb shock can lead to pain or even tearing or rupturing of

the disc. As one of the most

common causes of back pain, the Chartered Society of Physiotherapy

estimates that: disc

degeneration is estimated to cost the UK economy alone over £12Bn a year;

nearly 2 million

people worldwide are treated for spinal disc defects annually and 50%

require some structure to be

inserted or implanted; over 7 million work days were lost in the UK from

back pain related illness in

2011 and; back pain is the second most common cause of illness and time

off work [4.1].

It is in this area that Dr Donal McNally (Reader in Bioengineering,

University of Nottingham, 2001-current) has focused an important part of

his research. His work has primarily investigated the

internal mechanical behaviour of the intervertebral disc and load transfer

between it and the

adjacent vertebrae.

Between 2002 and 2009 McNally and his team studied the mechanics of the

intervertebral disc

(including the permeability of the cartilage end plate) and variations of

load patterns in the vertebra

after disc implantation. This was done by developing finite element models

of natural and artificial

discs [2.1, 2.4]. The researchers observed an altered stress pattern in

the vertebrae adjacent to

implanted segments and found that the use of smaller-size implants and

presence of voids at the

interface caused localised stress concentration in the endplate and

adjacent spongy bone. The

research [2.4] supported the hypothesis that conventional implants fail to

restore normal loading

patters in the vertebral body and that localised high-stress regions could

be a source of pain and

the reason for the low success rate of traditional total disc

replacements. Other studies [2.2]

focused on examining and quantifying the loading and load transfer between

the intervertebral

discs and the adjacent vertebrae.

Work on Cadisc® began in 2002, when medical device development company

Ranier Technology

began sponsoring three PhD students and a postdoctoral researcher at the

University of

Nottingham, who — led by McNally — have contributed key research to

Cadisc®'s development. An

in vitro investigation of the effect of implantation of Cadisc®-L

(for the lumbar spine), using frozen

human lumbar spines, showed a reduction in axial stiffness while

maintaining disc height and

flexion stiffness — all conducive to preserving the biomechanics of an

implanted spinal motion

segment [2.3]. The research also contributed to the development of Cadisc®

by: investigating the

design and performance of surgical instrumentation; validating the

manufacturing process;

modelling the performance of Cadisc®-C for the cervical spine [2.5];

analysis of load transmission

from vertebrae to implant [6]; and confirmation of the biofidelic

performance of the device.

The work is highly multidisciplinary and has involved collaboration with:

spine surgeons (Arun,

Freeman and Mullholland at Nottingham, Fairbank and Meir at Oxford) to

understand better the

surgical needs specific to spine surgery and ease of operation;

orthopaedic surgeon (Scammel at

Nottingham), to appreciate the general surgical situation; physicists

(Gowland and Cox at

Nottingham) to aid with imaging and measurement techniques to evaluate the

pre and post-surgery

conditions; physiologists (Jones and Urban at Oxford) to understand the

human physiology

aspects.

The award of the International Society for the Study of the Lumbar Spine

(ISSLS) Prize — one of

the most prestigious awards in spinal research — in two of three

categories in 2009 demonstrates

the internationally leading quality of the research produced by McNally

and his group [2.5, 2.6].

References to the research

References (Items marked with an asterisk indicate 3 most significant

papers);

2.1. Riches, P.E. and McNally, D.S., 2005, A one-dimensional theoretical

prediction of the effect of

reduced end-plate permeability on the mechanics of the invertebral disc, Proceedings

of the

Institute of Mechanical Engineers, Part H — Journal of Engineering in

Medicine, 219(H5), 329-335 DOI: 10.1243/095441105X34365

2.2. McNally, D.S., 2002, The objectives for the mechanical evaluation of

spinal instrumentation

have changed, European Spine Journal, 11, 179-185 DOI:

10.1007/s00586-002-0435-5

2.3. McNally, D., Naylor, J. and Johnson, S., 2012, An in vitro

biomechanical comparison of

Cadisc®-L with natural lumbar discs in axial compression and sagittal

flexion, European Spine

Journal, 21(5) 612-617 DOI: 10.1007/s00586-012-2249-4

2.4. *Palissery, V., Mulholland, R.C.M. and McNally, D.S., 2009, The

implications of stress patterns

in the vertebral body under axial support of an artificial implant, Medical

Engineering and

Physics, 31, 833-837 DOI: 10.1016/j.medengphy.2009.03.010

2.5. *Meir, A., Fairbank, J.C.T., Jones, D.A., McNally, D.S. and Urban

J.P.G., 2007, High

pressures and asymmetrical stresses in the scoliotic disc in the absence

of muscle loading,

Scoliosis, 2 (4) DOI: 10.1186/1748-7161-2-4

2.6.*Arun, R., Freeman, B.J.C., Scammel, B.E., McNally, D.S., Cox, E. and

Gowland, P., 2009,

What influence does sustained mechanical load have on diffusion in the

human intervertebral

discs? An in-vivo study using serial post-contrast magnetic resonance

imaging, Spine, 34(21),

2324-2337 (2009 ISSLS Prize winner) DOI: 10.1097/BRS.0b013e3181b4df92,

copy available

on request.

Details of the impact

The underpinning research validates the biomedical function of the

Cadisc® implants, which

underwent clinical trials on 30 patients from October 2009 to June 2010

[4.2] and has since led to

the impacts described below.

Patient health benefits

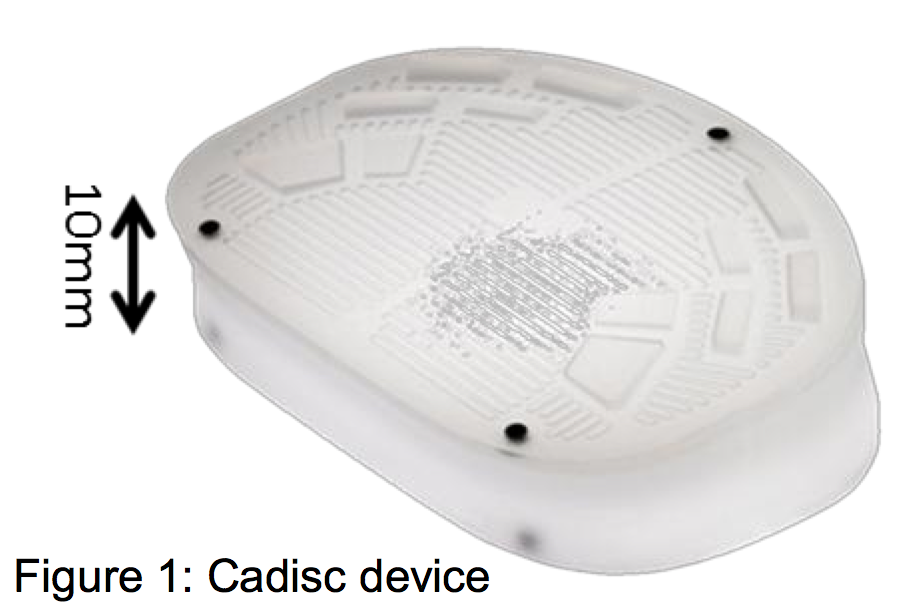

The research has led to the development of two products that are

specifically designed to treat

patients suffering from degenerative disc disease — Cadisc®-L, which

mimics the biomechanical

properties of the natural lumbar disc, and

Cadisc®-C, which does the same for the natural

cervical disc. Based on the research insights

into the mechanical loading on spinal discs and

the transfer of fluid, Cadisc® (see Figure 1) is

designed to replicate the behaviour of a real

spinal disc and hence give better results in

terms of pain relief, mobility and quality of life to

patients soon after surgery. It is unique in that it

does not have a metal endplate and therefore

conforms to vertebral anatomy better than conventional implants [4.3].

The graph below left shows the improvement in Quality Adjusted Life Years

(QALY, a standard

measure of disease burden including both quality and quantity of life) in

the 24 months after

patients received the product, in comparison to alternative treatments

available. QALY accrual rate

for Cadisc® is 0.7 over 12 months, which is approximately twice that of

conventional disc

replacements and three times that of spinal fusion, the current "Gold

Standard" of care [4.4].

In the UK the National Institute for Health and Care Excellence (NICE)

values 1 QALY at £20k to

£30k [4.4]. Using this methodology, the intervention already brings a

value of around £30k to £45k

over the first two years after the intervention per patient.

![Figure 2: Performance of Cadisc® against competition against QALY’s and ODI over time [4.4, 4.6] Figure 2: Performance of Cadisc® against competition against QALY’s and ODI over time [4.4, 4.6]](getImage.aspx?ID=308) Figure 2: Performance of Cadisc® against competition against QALY’s and ODI over time [4.4, 4.6]

Figure 2: Performance of Cadisc® against competition against QALY’s and ODI over time [4.4, 4.6]

Under the Oswestry Disability Index (ODI), one of the principal

condition-specific outcome

measures used in the management of spinal disorders, Cadisc® has shown a

33% performance

improvement compared to competitor products and treatments (see Figure 2

right) [4.5, 4.6].

Between October 2009 and the end of July 2013, 226 patients received

these implants; the

operative success rate was 100% [4.3].

In 2011, after the clinical trials for Cadisc®-L, Dick Zeilstra, the

trial's principal investigator,

highlighted the enormous significance of the discs for patient well-being:

"Over 80% of patients

experienced a clinically significant improvement in Oswestry Disability

Index (ODI) scores and

there was an average improvement in ODI scores of 63% at 12 months; this

compares with an

average improvement of 47% in studies of other disc prostheses. Patients

also experienced

remarkable improvement in quality of life, with Cadisc®-L patients

accruing 0.7 of a Quality

Adjusted Life Year (QALY) at 12 months. In recently published trials,

competitor products

demonstrated a mean accrual of 0.14 of a QALY at 12 months and 0.41 at 24

months." [4.5]

The biomechanical advantages of Cadisc® and its ability to mimic the

natural disc, informed by

UoN research, have been commended by Dr. Hamid Afshar, one of the leading

surgeons

specialising in this area: "The Cadisc® concept is very unique — a single

block disc with no metal

components which offers biomechanics similar to the natural disc.

Conceptually, it's the ideal

solution for the spine. Aside from the biomechanical advantages, the

Cadisc® also offers MR and

CT imaging compatibility which allows clear visualisation of the adjacent

skeletal anatomy and

neural tissues. Having nearly 10 years of product development and testing

provides surgeons the

reassurance that the device will meet the mechanical and functional

demands of the spine. The

Cadisc® technology has helped patients become pain free and enable them to

return to work. In

particular, It gives young patients (20-50 years) the opportunity to

return to a more active, pain-free

lifestyle" [4.7].

Commercial benefits

The research directly contributed to the development and sales of

Ranier's two flagship products,

Cadisc®-L and Cadisc®-C. £8M of third-party investment was secured (from

Alliance Trust Equity

Partners (ATEP) and First Ventures) to fund the clinical testing and

European launch in February

2008 [4.8] followed by a further injection of £5M in 2010 by the same

companies [4.3, 4.9]. Both

products, along with their associated surgical instruments, have been

successful in gaining CE

marks and have been sold commercially throughout Europe since 2009. An

application for an IDE

clinical study was submitted to the US Food and Drug Administration (FDA)

on June 27th 2011

with a view to marketing the devices in the USA and is pursuing further

funding to enable full scale

clinical trials to obtain full FDA approval. Distribution contracts were

signed in early 2013 to cover

the supply of products to the surgical community in South Africa,

Australia and New Zealand [4.10

a&b].

The research has transformed Cambridge-based Ranier Technology from a

small medical device

development company into the only UK manufacturer of total disc

replacements. Cadisc® now

accounts for all of the company's business. It has gained international

reach, exporting 90% of its

production, mainly to Germany. Since 2008 its workforce has grown to 35,

and its turnover has

increased by more than 80% between 2008 and 2013 [4.3].

Sources to corroborate the impact

4.1 http://www.csp.org.uk/documents/impact-nhs-reforms-musculoskeletal-physiotherapy-health-social-care-bill-lords-report-stag

pdf available on file.

4.2 http://clinicaltrials.gov/ct2/show/NCT00949936?term=Cadisc®+Ranier&rank=1

4.3 Dr Geoffrey Andrews, Director, Ranier Technologies Ltd. (letter dated

22nd August 2013)

4.4 Ian Quirk, Cadisc®™ EU Clinical Trials Current Status, Presentation

to the scientific advisory

board of Ranier Technologies, January 2013. Copy available on request.

4.5 http://www.cambridgenetwork.co.uk/news/ranier-announces-results-of-its-Cadisc®-l-lumbar-disc/

4.6 Quirk, I, Bertagnoli, R, Conix, B, Freeman, BJC, Hes, R, and

McConichie, A: Clinical

performance and quality of life following Cadisc®-L total disc

replacement: a prospective, non-randomised, multi-centre trial with 12

months follow-up, ISASS Meeting, Barcelona, 2012

4.7 Mr. Dr. Hamid Afshar, statement available on request. Statement

received via Scott Johnson,

Technical Director, Ranier Technologies Ltd.

4.8 http://www.prnewswire.com/news-releases/ranier-technology-secures-gbp8m-funding-for-its-Cadisc®-replacement-spinal-discs-56961057.html

4.9 https://www.orthoworld.com/knowent/ranier_091010.pdf

4.10a http://www.ranier.co.uk/index.php?public/news-and-events/news/view/ranier-technology-announces-approval-for-reimbursement-in-south-africa-for-Cadisc®-c-compliant-elastomeric-artificial-disc

4.10b http://www.ranier.co.uk/index.php?public/news-and-events/news/view/ranier-signs-with-distribution-partner-asdm-in-australia-for-lumbar-and-cervical-discs