Passively safe street furniture

Submitting Institution

University of NottinghamUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Aerospace Engineering, Civil Engineering, Materials Engineering

Summary of the impact

Dr Richard Brooks and his team at the University of Nottingham have been

investigating the high strain rate behaviour of composite materials since

2003. This has led to the development of two products that are being

installed in streets in the UK and Ireland by East Midlands SME Frangible

Safety Posts Ltd. The direct benefits to the company have been: the

installation of 900 products in the UK and Ireland; saving of £17k capital

cost and 2 months in terms of time to market per product developed and;

raising of £1.8M investment to bring the products to market At least one

life has already been saved in the Shetland Islands as a direct

consequence of the product behaving in the way it was designed to.

Underpinning research

Dr Richard Brooks (Associate Professor, University of Nottingham, 2003 -

present) and Dr Kevin Brown (Research Associate, University of Nottingham,

2003-2013) have been investigating the impact behaviour of composites at

the University of Nottingham since 2003. This was developed to cover the

strain rate sensitivity [2.1] where the time dependent damage nature was

identified as having significant effects on the behaviour of the composite

material.

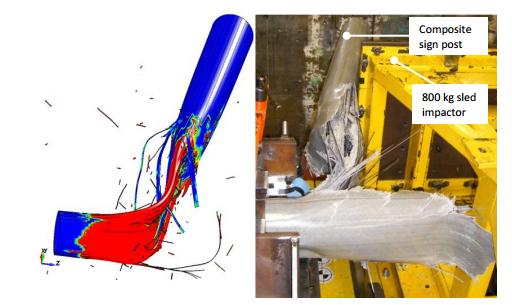

Figure 1: Finite element model showing material behaviour of sign post

under crash conditions (left); Physical crash test of same material

performed at UoN labs (right). Note: excellent replication of model by

physical test.

Figure 1: Finite element model showing material behaviour of sign post

under crash conditions (left); Physical crash test of same material

performed at UoN labs (right). Note: excellent replication of model by

physical test.

This led to further work in 2006 to predictively model the impact

response of more complex thermoplastic composite sandwich structures [2.2]

where three point bending tests of composite sandwich structures

(fibre-reinforced thermoplastic skins and a polymer foam core made from

the same thermoplastic material) were performed and numerical schemes were

developed and implemented using finite element code (see Figure 1, left).

This work was validated on several prototype components including a novel

wind turbine blade and a safety critical rail component. The work was

developed further in 2008 to investigate the microscopic damage and relate

this to observed meso-scale (lab) and macro-scale (field) phenomena [2.3].

The research presented related to strain rate behaviour of thermoplastic

and thermoset composites mapped directly to the behaviour of structures

when subjected to impact such as when vehicles crash into composite

structures. This translated into a collaborative piece of work, funded

through the East Midlands Development Agency's Transport iNet scheme, to

develop the next generation of passively safe composite posts with

Frangible Safety Posts Ltd. This project (CompSafe) centred on using the

High Performance Computing (HPC) facilities at the University of

Nottingham to simulate the impact behaviour of different composite

material compositions to find the best solution using the MAT 162 model

(see below) in LS-DYNA-explicit Finite Element Analysis software.

MAT162 is an advanced elastic-damage model capable of simulating complex

multi-modal failure in both unidirectional and plain weave composites. It

requires a total of 34 materials properties and numerical modelling

parameters. Complexity is added from the nature of the hybrid structure

because each constituent has its own set of properties which require

definition. Over 100 input parameters were required to model the hybrid

structure. A calibration method developed by Brown [4] was used to obtain

appropriate values for these parameters.

The validated full scale crash model, as shown in Figure 2, provided the

platform to develop a design guide for passively safe hybrid composite

posts. The design guide aims to enable evaluation of the feasibility of

variations in the design of the composite post against the European

Standard EN12767 limits for ASI (Acceleration Severity Index) and THIV

(Theoretical Impact Velocity). The design parameters investigated

included: Number of carbon tows; Layup variation; Wall thickness

variation; Post diameter; Foundation type (granular sub base, sand,

concrete).

Figure 2: Finite element simulation of whole car crashing against sign

post

Figure 2: Finite element simulation of whole car crashing against sign

post

Simulations of the validated crash model were made for each design

option. The ASI and THIV results were plotted for each design alteration.

This analysis indicated that the level of hybridisation within the

composite profile can have a significant effect on the impact performance

characteristic and that the designer can use this parameter when

considering products for alternative energy absorption categories.

As a result of working on CompSafe with the University of Nottingham,

Frangible Safety Posts Ltd has adopted the design guides to develop the

products described in Section 4. Structural properties of the resulting

products were also tested at the University of Nottingham (see Figure1,

right).

References to the research

References (Items marked with an asterisk indicate 3 most significant

outputs):

2.1 *Brown, K., Brooks, R. and Warrior N. A., 2010, The static and high

strain rate behaviour of a commingled E-glass/polypropylene woven fabric

composite, Composites Science and Technology, 70, 272-283. DOI:

10.1016/j.compscitech.2009.10.018

2.2 *Brooks, R., Brown, K.A., Warrior, N.A. and Kulandaivel, P.P., 2010,

Predictive modelling of the impact response of thermoplastic composite

sandwich structures, Journal of Sandwich structures and materials,

12:449 (originally published online 10 June 2009) DOI:

10.1177/1099636209104537

2.3 *Lidgett, M., Brooks, R., Warrior, N. and Brown, K.A., 2011, Virtual

modelling of microscopic damage in polymer composite materials at high

rates of strain, Plastics, Rubber and Composites, 40(6/7),

324-332. DOI: 10.1179/1743289810Y.0000000007

2.4 Brown, K.A., 2007, Finite element modelling of the static and dynamic

impact behaviour of thermoplastic composite sandwich structures, PhD

thesis, University of Nottingham, copy available on request

Grants:

Brooks R, Competitive Design of Passively Safe Composite Profiles for

Transport Safety (CompSafe), Transport iNet, http://www.transport-inet.org.uk/portfolio/epl-composite-solutions-and-

frangible-sign-posts-ltd/

Details of the impact

The University of Nottingham's research into the high strain-rate

behaviour of composite metals has resulted in significant industry

engagement and adoption, economic benefits and — as already demonstrated

in a real-life setting — major improvements in safety. This has resulted

in faster and cheaper development of the 168mm and 219mm diameter sized

street posts [4.1], which were formally launched in June 2010. As of March

2013, 900 are installed in the UK and Ireland [4.2]

The University of Nottingham, through the involvement of Dr Brooks and Dr

Brown, has played a central role in the development of these two products,

providing numerical simulations of high strain rate behaviour that have

resulted in the specific material composition of the street posts. Sales

of these two products account for 60% of the company's revenues and 50% of

the profits. 6 jobs have been created to produce, sell and install these

products [4.2].

Key outcomes resulting from the underpinning research include [4.2]:

- Use of the pendulum testing methodology (the term used to describe the

virtual testing methodology, the development of which is described in

Section 2) to replace full vehicle crash testing. Pendulum testing

alone: estimated cost savings of up to 70% per result. Elapsed time

estimated savings of up to 83% per result.

- Use of the design guide to replace full vehicle testing within

iterative product development. Use of the design guide during product

development: estimated cost savings of up to 90% per result. Elapsed

time estimated savings of up to 93% per result.

- Use of the design guide and computer simulation to replace full

vehicle testing for product accreditation. Use of the design guide &

simulation for full product accreditation: estimated cost savings of up

to 72% per result. Elapsed time estimated savings of up to 62% per

result.

Savings in bringing the products to market as a result of the modelling

work done by the University of Nottingham amount to approximately £17k per

product through minimising the number of physical crash tests that had to

be performed and 2 months were saved in terms of the time to market. In

the future this could increase to £99.6k and 4 months saving if the

modelling fully replaces vehicular crash testing [4.2].

Figure 3: Picture of the real crash test simulated in Figure 2

Figure 3: Picture of the real crash test simulated in Figure 2

Furthermore, the research provided valuable data that was used to secure

an investment of £1.8m from Ahlstrom Capital (one of Finland's biggest

private equity investors, portfolio turnover exceeding €1Bn) to bring the

product to market [4.3].

In addition to the economic impacts, there has been at least one clear

example of the improvements in safety offered by these products: A vehicle

struck one post of a two post Frangible Safety Post installation and the

driver walked away unscathed. It is likely that, should the vehicle have

struck a traditional steel post installation, the driver would have

suffered significant injuries [4.4].

FSP had their posts installed throughout the Shetland Islands in 2010 and

2011 [4.5] and commenting on this accident Neil Hutcheson, Roads Engineer

at Shetland Island Council said:

"We recently renewed a large number of advanced direction signs and

took the opportunity to replace the existing steel posts with the

passive safety equivalent supplied by FSP. This incident has shown that

to be the correct decision. I have no doubt that the vehicles occupant

would have been seriously injured if we had retained the steel posts. We

consider that these passive safety posts can play a significant part in

reducing casualty rates and making Shetland's roads safer" [4.4].

On the 4th December 2012 in icy conditions there was an accident on the

A970 on the Shetland Islands. A vehicle struck one post of a two post

Frangible Safety Post installation and the driver walked away unscathed.

It is likely that should the vehicle have struck a traditional steel post

installation the driver would have suffered significant injuries. The

Frangible Safety Post that was struck performed and reacted exactly as

intended through our patented design. [4.4]

Figure 4: Damaged post and car as result of Shetland Islands incident

Figure 4: Damaged post and car as result of Shetland Islands incident

Sources to corroborate the impact

4.1 http://www.fsp-ltd.com/docs/june2010/fsp_launch_new_products_10.06.10.pdf

4.2 Dr Nick Weatherby, Technical Director, EPL Composite Solutions Ltd

4.3 Ahlstrom annual report (page 21) available at

http://www.ahlstromcapital.com/PDF/ACOY_Annual%20Report%202012.pdf

4.4 http://www.therichworks.co.uk/more_info.asp?current_id=2155

— an independent, non-competitive site that provides everything you need

to know about construction and highways in the UK. Endorsed by the

Highways Agency and leading contractors such as URS.

4.5 Dr Gerry Boyce, Director, Frangible Safety Posts Ltd.