The Development of a Viable Low-Energy Alternative to Air Conditioning

Submitting Institution

University of NottinghamUnit of Assessment

Architecture, Built Environment and PlanningSummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Interdisciplinary Engineering

Summary of the impact

Research at the University of Nottingham into the use of phase- change

materials as a means for heating and cooling buildings has resulted in the

development of COOL-PHASE®, a product which is sold by Monodraught ltd.

The system was launched in 2008 and has been installed in 136 buildings in

the UK. COOL-PHASE® underpins the long-term growth strategy for the

company and Monodraught has invested in employing 3 new staff and £250k in

capital expenditure to make the unit suitable for mass production.

Underpinning research

Global warming has brought an increased dependence on air-conditioning

and a growing demand for high-efficiency, lower-energy cooling systems. A

simple way to satisfy these would be to incorporate concrete beams within

a structure, exploiting the effect of night cooling to discharge heat

stored in the thermal mass during the day. However, this solution is

unsuitable for retrofit in existing buildings, which is where the greatest

energy saving potential lies.

In the late 1990s, recognising the need for alternatives to conventional

air conditioning, researchers at the University of Nottingham (UoN) began

work to reduce energy consumption and avoid the use of refrigerant

chemicals in potential systems. Dr David Etheridge (Associate Professor,

University of Nottingham, 1997 - 2010) performed the original research on

natural ventilation [2.1, 2.2] and led the team, with other key members

including Visiting Professor David Reay (appointed honorary professor,

University of Nottingham, 1994 — present) and Professor Saffa Riffat

(Chair in Sustainable Energy, University of Nottingham, 1992 — present) to

investigate the potential for combining natural ventilation with

phase-change materials (PCM) within a retrofittable unit to increase the

effective thermal mass of a building (EPSRC GR/R21639/01).

PCMs store energy in the form of latent heat and are more efficient than

concrete, typically achieving the same heat storage with just four per

cent of the mass. During the day heat is transferred to the PCM, "melting"

it and reducing the temperature of the room; whilst at night heat is

extracted from the PCM, "solidifying it".

Researchers faced several challenges in the process of developing the

system, which was supported through the use of a new theoretical model

[2.3]. The initial idea was to use PCM in conjunction with heat pipes and

a fan to make the system more effective. Heat pipes have the advantage of

offering high heat transfer rates and are easy to maintain. The team also

needed to find a way of making them reversible, meaning they would operate

in a horizontal position.

Intelligent controls were designed to run this with minimal energy

consumption. To allow for the expansion and contraction that occurs during

the operating cycle, the system needed to be housed in a way that enabled

heat transfer with the air in the room but without it coming into direct

contact, which could result in air contamination. Lastly, the final

product needed to be suitable for manufacturing at a cost that would rival

or outperform conventional mass-produced air conditioning units [2.4].

Enthused by the potential of the technology, UoN liaised with industry to

gain commercial expertise in product design and manufacture, as well as

specialist input into how the research could be disseminated and marketed.

Extensive research and testing resulted in the production of a

demonstration system, using heat pipes embedded in a PCM with a fan to

provide the necessary air movement.

Taking place from 2002 to 2004, a second stage of development refined the

technology and developed two units for field trials. One was tested in the

David Wilson Eco-House on the UoN campus and the other was tested

externally. These trials demonstrated that the system could maintain a set

temperature with the same effectiveness as an air conditioning unit [2.5].

Following from this proof of fitness-for-purpose the team proceeded with

their commercial exploitation plans.

References to the research

References (Items marked with an asterisk indicate 3 most significant

papers):

2.1 Turnpenny, J.R., Etheridge, D.W. and Reay, D.A., 2000, Novel

Ventilation Cooling System for Reducing Air Conditioning in Buildings,

Part I: Testing and Theoretical Modelling, Applied Thermal

Engineering, vol. 20, pp1019-1037 DOI: 10.1016/S1359-4311(99)00068-X

2.2 Turnpenny, J.R., Etheridge, D.W. and Reay, D.A., 2001, Novel

Ventilation Cooling System for Reducing Air Conditioning in Buildings,

Part II: Testing of Prototype, Applied Thermal Engineering, vol.

21, pp1203-1217 DOI: 10.1016/S1359-4311(01)00003-5

2.3 *Thaicham, P., Gadi, M. B. and Riffat, S. B., 2004, An investigation

of microencapsulated phase change material slurry as a heat transfer fluid

in a closed loop system, Journal of the Energy Institute, vol. 77

no. 513, pp. 108-115. Accession Number: WOS:000228272900005

2.4 *Etheridge, D.W., Murphy, K. and Reay, D., 2006, A PCM/Heat Pipe

Cooling System for Reducing Air Conditioning in Buildings: Review of

Options and Report on Field Tests, Building Services Engineering

Research and Technology, vol. 27, no.1, pp27-39 DOI:

10.1191/0143624406bt142oa

2.5 *Khan, N., Su, Y., Hopper, N. and Riffat, S. B., 2011, Evaluation of

Natural Ventilation and Cooling Systems using Dynamic Simulation Methods,

International Journal of Ventilation, vol. 10, no.2 , pp.133-146.

DOI: 10.5555/2044-4044-10.2.133, copy available on request.

Grants:

EPSRC: GR/R21639/01, Strategic Research For Sustainable Energy Technology

In Buildings, 2001-2005 (£439k), (PI Riffat)

Details of the impact

UoN's innovative PCM alternative to conventional air conditioning has

delivered a range of economic and environmental benefits since its

successful commercialisation in 2008.

Backed by a patent application [4.1], the technology was licensed to

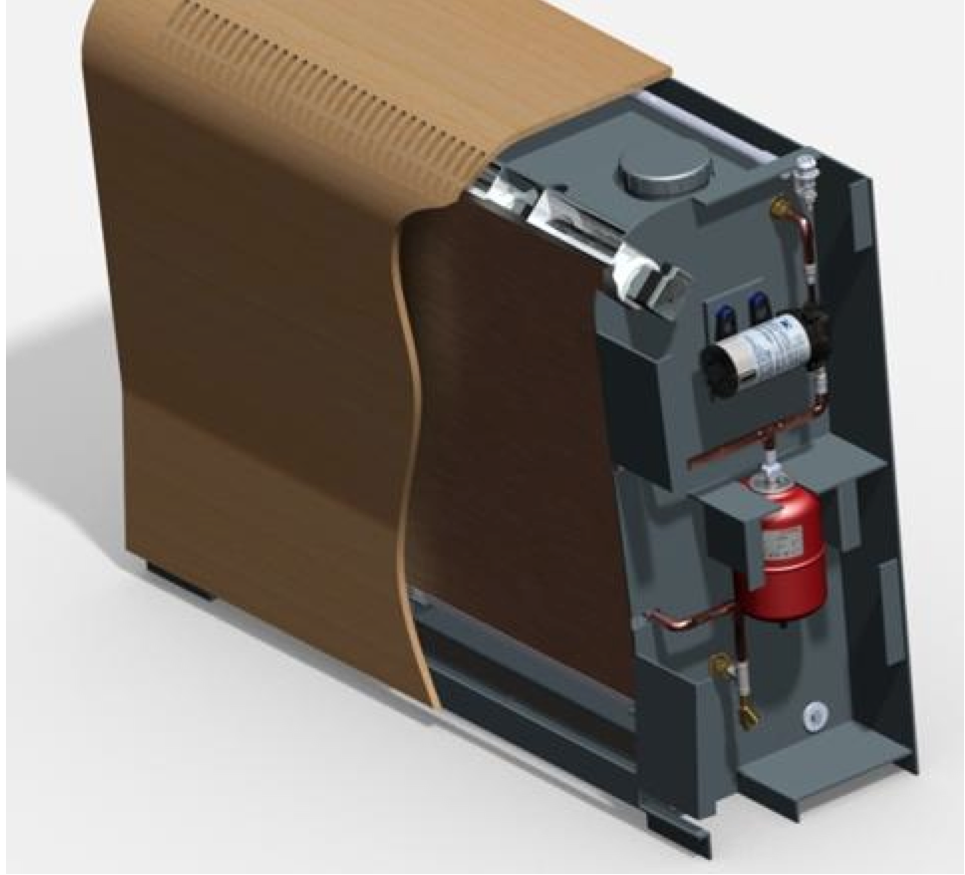

Monodraught Ltd, resulting in the launch of COOL-PHASE® (Figure 1). Having

already worked with UoN on the design and commercialisation of novel

daylighting and ventilation products, Monodraught was keen to add a

low-energy alternative to air conditioning to its range, and has since

benefited from being the first company worldwide to build such a system;

thus consolidating its position as a recognised market leader in

low-carbon, low-energy products.

"The novel science and technologies underpinning the COOL-PHASE® cooling

and ventilation system has elevated Monodraught's position in the industry

as innovators" [4.2]

COOL-PHASE® was officially launched at the annual building industry

exhibition, Interbuild, in October 2008. Although the industry is usually

notoriously slow in its uptake of new technologies, even without the added

pressure of an economic downturn, the system has enjoyed growth in sales

each year since commercialisation. The original COOL-PHASE® was

successfully installed at a total of 22 different commercial locations,

including schools, colleges and retail outlets throughout the UK; with an

average of six building installations at each location.

Further developments were undertaken by Monodraught in 2010 and 2011 to

redesign Cool-Phase, from its original wall-mounted system into one which

is now ceiling mounted. Sales of COOL-PHASE® are 11 units in 2011, 55 in

2012 and 48 up to June 2013; sales for 2013 are projected to total 150 by

the end of the calendar year. COOL-PHASE® underpins the major growth

strategy for the company, and the company's investment in appointing a

Business Development Manager to solely focus on expanding the sales

substantially over the coming years is evidence of the strategic

importance of the product. Another part of the business case for

COOL-PHASE® is exemplified by the investment of £250k over the past two

years to make the unit suitable for mass production. Consequently, two

additional production staff have been employed to achieve this — in total

three new jobs have been created at Monodraught as a direct result of

COOL-PHASE® [4.2].

Figure 1: Graphic illustration of Cool-Phase system

Figure 1: Graphic illustration of Cool-Phase system

Installations carried out between 2010 and 2011 include two serviced

offices in central London for Workspace plc; a refurbished IT classroom at

Scarborough Sixth-Form College; computer suites at the University of East

London's Stratford Campus; and a 70m2 school IT classroom,

where the system was required to overcome high internal heat gains through

IT equipment and glazing. Feedback has been extremely positive, with users

comparing the cooling effect favourably with that of conventional air

conditioning and noting that problems of discomfort associated with

conventional systems have been overcome. Customers commented that they

found the system to be "effective, sustainable and economically viable"

and delivering "a marked improvement in terms of temperature" [4.3].

Figure 2: Two Cool-Phase units mounted on the ceiling of an ICT suite in the University of East London

Figure 2: Two Cool-Phase units mounted on the ceiling of an ICT suite in the University of East London

Analysis of system performance in the 180m2 ICT suite shown in

Figure 2 was carried out by building simulation specialists. Results

indicated that the installation of just two COOL-PHASE® units in place of

conventional air conditioning would deliver financial savings of more than

26 per cent (approximately £10,000) and CO2 savings of 12.8

tonnes over the anticipated system lifespan of 20 years [4.3].

COOL-PHASE® was also installed in a particular "problem" room in the Owen

Building at Sheffield Hallam University — a 90-person teaching room on the

tenth floor that consistently exhibited poor air quality and high

temperatures. The room had no mechanical ventilation and was fitted with

opening windows to one side; but due to the height of the building these

were restricted to a 100mm maximum opening, limiting the effectiveness of

natural ventilation. In November 2009 the University's Estates Department

initiated environmental checks. The temperatures were consistently

recorded at 25ºC at a time when November's outside temperatures were

reaching only 5ºC. COOL-PHASE® was installed in March 2012 and Lee Allen,

Building Services Engineer in the Sheffield Hallam University Estate

Department said, "We monitored throughout the late March warm spell and

recorded a room temperature peak of 23ºC when outside temperatures were

hovering around 21ºC. We were very impressed with this performance

compared to the 25ºC internal room temperatures we were experiencing in

November". [4.4]

The contribution COOL-PHASE® has made to industry was recognised by the

Chartered Institution of Building Services Engineers (CIBSE), which named

the system 2012's Energy-Using Product of the Year [4.5]. CIBSE's awards

are widely acknowledged as among the most prestigious in the industry and

are presented at a high-profile ceremony traditionally attended by

hundreds of the sector's leading figures. Recently, COOL-PHASE® won an

IMPAX Ashden Award for Energy Innovation, which is a widely recognized

sustainability award, due to its low energy requirements. The product

consumes 90% less energy compared to alternatives on the market.

Commenting for Ashden, the awards judging panel remarks: "This is a

ground-breaking innovation from an established business that has built up

a reputation for its long term commitment to sustainable buildings in the

UK. It is no exaggeration to say this could potentially change the whole

ventilation and cooling market." [4.6]

Sources to corroborate the impact

4.1 Patent: EP2131112, Building Cooling Apparatus Using PCM for

Loading the Reservoir During Night-Time. Inventors: Hopper, N,

Butters, M, Hooley, A, and Etheridge, D Publication date: Jan 20, 2010;

Filing date: Jun 4, 2008; Priority date: Jun 4, 2008

4.2 Statement from Nick Hopper, Technical Director, Monodraught.

Available on file

4.3 Notre Dame School case study brochure, pdf available on file.

4.4 http://www.monodraught.com/news/6/monodraughts-cool-phase-system-is-specified-for-problem-room-at-sheffield-hallam-university/

4.5 http://www.cibseawards.org/2012-winners/

4.6 http://www.ashden.org/files/Monodraught2013winner.pdf