Multi-constraint and multi-dimensional visual coordination approaches and tools and their applications in the Architectural, Engineering and Construction (AEC) industry through industrial collaborations

Submitting Institution

Teesside UniversityUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Mathematical Sciences: Applied Mathematics

Information and Computing Sciences: Artificial Intelligence and Image Processing

Engineering: Civil Engineering

Summary of the impact

Research at Teesside University has enhanced sustainability and

productivity in construction and related sectors. Between 1998 and 2008,

Professor Dawood's research team developed a range of advanced

multi-constraint and multi-dimensional visual construction planning and

coordination approaches and tools. The global commercial application of

this work in Architectural, Engineering and Construction (AEC)

organisations has generated a substantial economic impact. For five

indicative organisations used as examples in this case study, the impact

amounts to more than £1,500,000 in the form of increased

turnover, cash injection from technology funds and a spin out company.

Underpinning research

Three main pieces of research underpinned the impact:

1. Establishment of a Uniclass approach for the integration of product

and process data:

Between 1998 and 2004, Professor Dawood's team developed a new

Uniclass-based approach enabling the development of a number of software

tools: ProVis [1], a 4D visualisation tool; the VIRCON (VIRtual

CONstruction, EPSRC GR/N00890/01) database; and nDCCIR, which combined

these into a single system.

The adoption of Uniclass, a standard classification system for the

construction industry, allowed the integration of previously disparate

information systems providing, for the first time, a medium for

integrating visual and project planning, product breakdown (e.g. elements

of the building) and work breakdown (e.g. construction operations)

structures [1]. Product and process modelling technologies were

dynamically linked to the VIRCON database to provide 4D (3D plus time)

simulations [1] allowing rehearsal of the building's construction to

identify potential clashes and pinch points.

The technology developed was tested with the involvement of experts from

major construction companies in the UK and Europe (Skanska Construction,

Balfour Beatty, AMEC, Ferguson McIIveen LLP, MotEngil, and VSS Civil

Engineers) [2]. The work was carried out within a 4-year collaborative

research programme with University College London, the University of

Manchester (UMIST) and the University of Wolverhampton, as part of the

EPSRC-Innovative Manufacturing Initiative. The development of the nDCCIR

tool was undertaken through KTP collaboration with Atkins FG (Partnership

Number 6486).

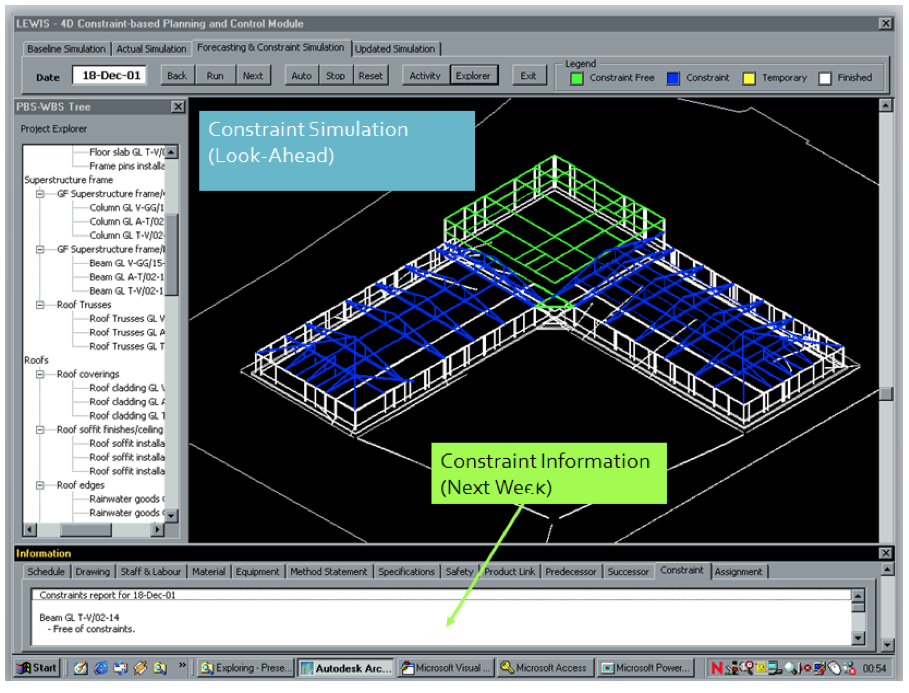

2.Development of Multi Constraint Planning Methodology for agile and

efficient construction site management: Between 2002 and 2005 the

research team developed the approach above into a multi-constraint

planning and control methodology bringing together all aspects of the

supply chain, ensuring "constraint-free execution" of site assignments.

The availability of all necessary elements at the correct time and place

substantially reduces wastes and delays on construction sites [3, 4 and

5]. This multi-constraint approach enhances the conventional 3 levels of

construction planning (i.e. baseline planning, look-ahead planning,

commitment planning) by integrating them with information management

systems, 3D models and management theories of optimisation and "Last

Planner". This work led to the development of an IT tool, "LEWIS — Lean

Enterprise Web-Based Information System", shown above, representing a new

generation of planning and control systems overcoming the limitations of

traditional project management theory and existing information

technologies [3].

3. Development of Key Performance Indicators (KPIs) to enable the

benefits accruing from these new approaches to be quantified and measured

in live projects. Between 2005 and 2009 quantifiable KPIs for the

different performance measures (e.g. time, communication efficiency,

planning efficiency, cost, productivity, etc.) were developed and used by

Prof Dawood's research team to estimate the benefits achievable from the

deployment of the multi-constraint planning approaches and tools. The

measured KPIs included schedule performance (KPI: "schedule hit rate" — a

measure used to identify deviations between actual and planned progress)

and communication performance (KPI: time and cost saved in meetings) which

were measured in three £multi-million construction projects (£236 million)

over a period of 2 years. The results showed a hit rate increase to 72%, a

17% increase compared to the average industry schedule hit rate (55%) and

a 30% reduction in the time spent on meetings [6].

References to the research

The three papers that best indicate the quality of the underpinning

research are [1], [2] and [4]. The work presented in these papers are

outputs resulting from EPSRC research project funding (VIRCON EPSRC —

GR/N00890/01, £500k total with £120k to Teesside), led by Dawood.

[1] Dawood N., Sriprasert, E., Mallassi, Z. (2002) Development of

an integrated information resource base for 4D/VR construction processes

simulation. Automation in Construction, Vol. 12, pp. 123-131.

[2] Dawood N., Scott, D., Sriprasert, E., Mallassi, Z. (2005) The

virtual construction site (VIRCON) tool: an industrial evaluation. The

Journal of Information Technology in Construction, Vol. 10, pp.

43-54.

The industrial validation of the VIRCON tool presented in this work was

supported by an EPSRC Networking grant (£70k to Teesside) led by Dawood.

[3] Sriprasert, E. and Dawood, N. (2003) Multi-constraint

information management and visualisation for collaborative planning and

control in construction. The Journal of Information Technology in

Construction, Vol. 8, pp. 341-366.

[4] Dawood N., Sriprasert, E. (2006) Construction scheduling using

multi-constraints and genetic algorithms approach. Construction

Management and Economics, Vol 24 (1), pp. 19-30.

[5] Dawood N. and Mallassi, Z. (2006) Construction workspace

planning: Assignment and Analysis Utilizing 4D visualisation technologies.

Computer Aided Civil and Infrastructure Engineering, Vol 21 (7),

pp. 498-513.

[6] Dawood, N. and Sikka, S. (2009) Development of 4D based

performance indicators in construction industry. Engineering,

Construction and Architectural Management, Vol. 16 (5), pp. 438-458.

Details of the impact

The significance of the research findings, their impact on the AEC

industry and their extensive dissemination in peer reviewed journals,

international conferences and workshops have led to the research outcomes

being adopted by a number of major industrial players. The work featured

on the UK Prime Minister's Website and in the media [1]. For the

organisations involved, the tools developed from the work produced

economic benefits, arising from shortened project timeframes, more

reliable planning and end dates and consequent minimisation of associated

penalties and equipment hire costs; whilst the improved communication

efficiency enables improved productivity through reductions in design lead

time and wastages associated with design changes. The details of the

impact on five organisations is summarised below.

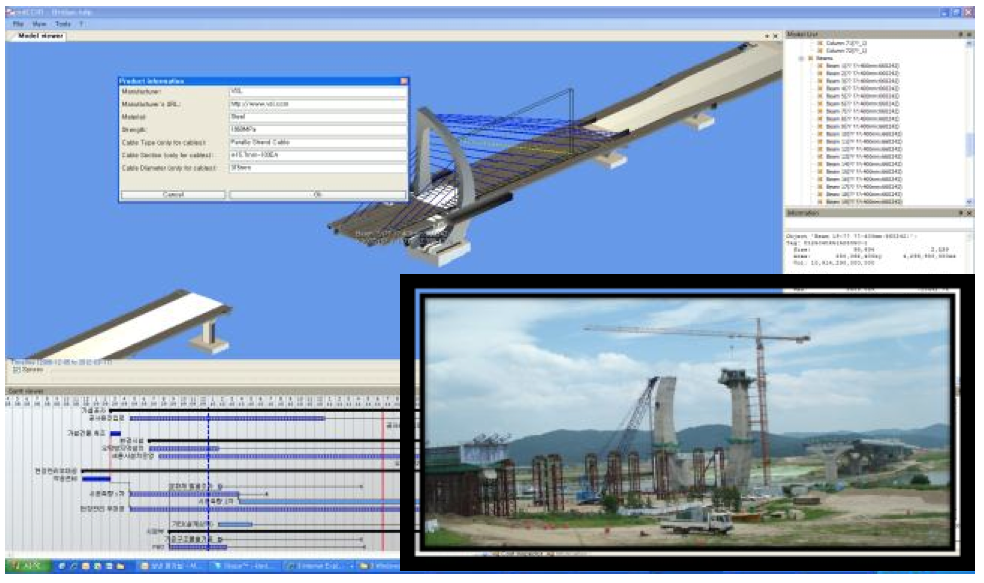

Dealim Industrial (South Korea), one of the largest

industrial conglomerates in South Korea, is using the nDCCIR package on

large infrastructure projects (e.g. the 2nd Geumgang Bridge-

see company's rehearsal of the bridge using nDCCIR, opposite). The company

has also adopted the KPI assessment tools developed by Prof. Dawood

enabling them to evaluate the impact. The company achieved a 95%

increase in schedule hit rate leading to decreased penalty

payments and equipment hire costs, 30% decrease in meeting time, and 5%

decrease in wastage related to reduced design changes and rework on

site, leading to a £178,500 increase in profit [2].

Ryder Architecture (UK) is a large architectural company.

Between 2009 and 2011 under a KTP project (Partnership Number 7304) the

company adopted the multi-constraint planning methodology to

facilitate improved coordination and management of their design processes.

As a result, Ryder achieved an increase of £249,500 in their

turnover, provided employment to 10 new staff members, and

established a new spin out company (BIM Academy) to provide new

consultancy services to the AEC industry [3].

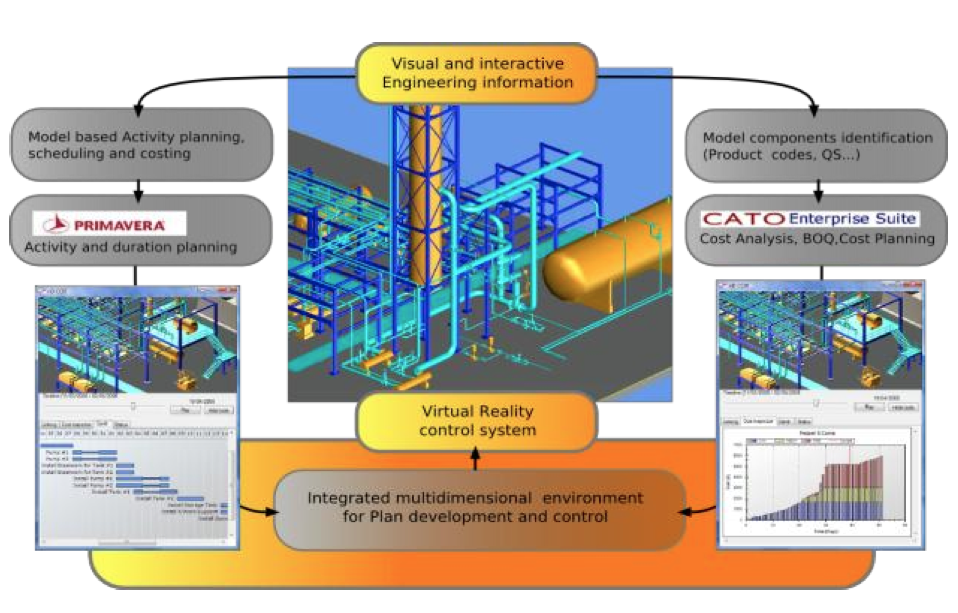

Datum360 (UK) has been collaborating since 2010 with CCIR

researchers under a 3-year KTP project (Partnership Number 8668). During

this collaboration the software tools were further developed to

incorporate asset management (using class libraries) and commercialised

for application in the oil and gas industry. Through the use of this tool,

significant business was won with major oil & gas companies such as

BP, Tullow, GDF Suez E&P UK Ltd, Chevron and Woodside. This work

resulted in increased turnover for Datum360 of £448,000 over 2012 and

2013 [4]. Additionally in 2012, as a result of this development, the

company received £500,000 in investment from the Finance for

Business North East Technology Fund managed by IP Group [5]. The reach of

the work in the oil and gas sector has been extended by collaborative work

with the management consultancy, Faithful+Gould, to develop a bespoke

visual 5D CAD tool (3D + time + cost) for the oil and gas industry (see

opposite) [6].

Deepdale Solutions Ltd (UK) utilised the multi-constraint

and visualisation tools for planning and site simulation of a prestigious

development in Stratford in 2011/2012 (M8 Hotel). The project was required

to deliver a completed building envelope in time to meet the constrained

Olympic timetable with the added constraint that simultaneous access to

complete the building of the ground and first floor shopping centre was

required. These tools enabled Deepdale to identify an alternative

installation methodology with prefabricated (unitised) panels for the

entire envelope. This led to an estimated reduction of 30% in site

time compared to their previous norms, and a saving of

£140,000 in time-related activities (i.e. reduction in the number of

site operatives; reduction of manual handling and its associated health

and safety implications; elimination of the need for external means of

access/scaffolding as well as managing the complex constraints operating

at the site). In addition, use of the planning tools reduced the number of

interfaces between dissimilar materials/technologies allowing improved quality

control on site, and improved product quality arising from

the maximisation of finished assemblies under factory controlled

conditions [7].

A planning expert and Vice President of WEN Qatar W.L.L. gave the

following testimonial: "Managing the numerous constraints posed by us

internally and by our interface with other stakeholders is an extremely

complex and challenging issue. We have identified the theories and

concepts for multi-constraint management developed by CCIR researchers

and are currently using them on most of our projects. We found these

concepts extremely effective and they contributed to increase

the efficiency of our projects' delivery; decrease wastages

on site, and integrate our operation with our projects' partners. There

are among the first and fewest concepts in Project

Management to provide a holistic and integrated management of the

multiple constraints involved in projects" [8].

Sources to corroborate the impact

[1] NE

Business web site

[2] Testimonial from a Senior Manager from Dealim Industrial

[3] Final Report of the Knowledge Transfer Partnership

[4] Testimonial from the Managing Director of Datum360 Ltd.

[5] NE

Business web site

[6] Faithful

and Gould Website

[7] Testimonial from the MD of Deepdale solutions Ltd.

[8] Factual statement from WEN Qatar W.L.L.