4. Low-Carbon Engine Design Through Integrated Computer Simulation-Validation

Submitting Institution

Cardiff UniversityUnit of Assessment

General EngineeringSummary Impact Type

EconomicResearch Subject Area(s)

Engineering: Automotive Engineering, Mechanical Engineering, Interdisciplinary Engineering

Summary of the impact

Cardiff University's research has provided quantitative characterisation

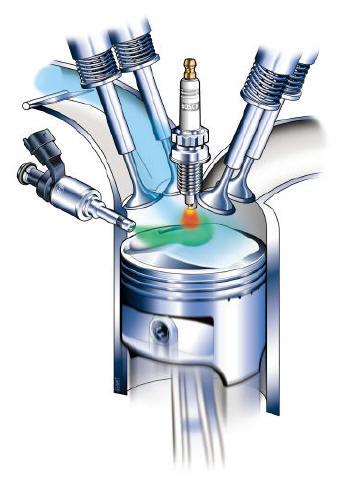

of transient fuel sprays under engine condition for the first time. This

has enabled integrated design optimisation of Gasoline Direct injection

(GDi) engines, through computer simulation validated by Cardiff's

experimental measurements. The method has been developed and used in

collaboration with Ricardo, a world-leading engine design consultancy, and

has resulted in:

Economic impact

- Ten contracts, generating Ricardo revenue of over £20M from major OEMs

worldwide (including Ford, GM, SAIC, Proton and Chrysler);

- An additional $7M Ricardo contract secured with a major US

manufacturer (2013);

- Increased licence sales (over £1M/year sales worldwide) for commercial

software `VECTIS';

- A novel tri-fuel Spray-Guided Direct Injection (SGDI) production

engine designed and developed on behalf of PETRONAS (Malaysia).

Environmental impact

There have been substantial reductions in global CO2

emissions. Prior to 2012, GDi engine production had resulted in over 20M

tonnes CO2 reduction globally, including 10M tonnes across

Europe. A global reduction of 10M tonnes/year is predicted by 2020.

Gasoline engines designed or developed by Ricardo in collaboration with

Cardiff have provided a considerable contribution to this reduction.

Cardiff's measurement techniques provided an essential step in designing

these engines. For example, the PETRONAS engine uses 20% less fuel and

produces 80% less NOx.

Improved Professional Engineering Practice

Cardiff's experimental validation methodology has enabled Ricardo to

design engines through simulation rather than step-wise empirical

development, significantly reducing lead time.

Underpinning research

Cardiff's Innovations in Optical Diagnostics for Industrial

Applications

Cardiff's expertise in this field dates back over 30 years to the

development of bespoke laser velocimetry systems for the UK-AEA.

Subsequently, Cardiff was first to develop and publish phase-resolved

laser-Doppler anemometry for the transient fluid-dynamic

`precessing vortex core' phenomenon in industrial burners and

cyclone-separators. This research was undertaken by Syred (then Professor)

and O'Doherty (then Lecturer), between 1993-95. This resulted in the

prestigious `Combustion Institute' Sugden award for best UK paper (1997)

and a Dyson contract for characterising dust separator prototypes

(O'Doherty, 1998). Syred was Dyson's invited expert witness (1998-2000) in

their successful `Dyson versus Hoover' legal case, utilising Cardiff's

pedigree and knowledge of transient swirling flows. Cardiff also won the

`NATO award for best international Collaboration' (with Russia and

Ukraine) for its related work on gas turbines (2002).

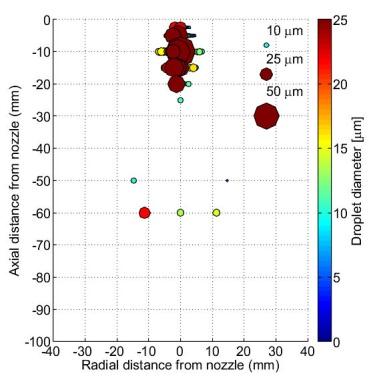

Cardiff's Temporally-Resolved Spray Characterisation Breakthrough

Bowen (then Lecturer, 1995-97) and Bates (Reader, 1995-97) developed

Cardiff's `phase-resolved' methodology to Phase Doppler Anemometry

(PDA), enabling enlightening time-resolved characterisation, for the

first time, of 2-phase/droplet, swirling, transient flows

(e.g. sprays). Traversing this methodology over a fine grid also enhanced

the 3D spatial resolution [3.1], as shown in Figure 1. This breakthrough

found application in the automotive sector, as these are precisely the

type of flows found within automotive engine fuel sprays, where conditions

are extremely challenging, namely: millisecond injection time-scales,

1-100 micron diameter droplets, 3D swirling flows with velocity magnitudes

over 100 m/s, coupled with the extreme in-cylinder environments of high

pressures and temperatures.

Cardiff-Ricardo Research Development, Communication and Strategic

Partnership

Ricardo offers globally-leading innovation in the automotive industry.

Through an EPSRC/Ricardo funded PhD studentship (Comer 1996-99), Ricardo

sponsored Cardiff's proposition to prove and develop phase-resolved

PDA for automotive injectors, and to develop its applicability to

engine conditions. The research enabled Ricardo to validate for the first

time its transient, 3-dimensional, 2-phase commercial spray models

(within its commercial code VECTIS). Moreover, this was done under

controlled, simulated engine conditions (with high pressures and

temperatures), enabled by a new optical spray-cell which was designed and

commissioned in Cardiff's laboratories.

VECTIS is an international, industry-standard software product, focused

on in-cylinder processes in the automotive sector, which is used by

leading international engine manufacturers such as [text removed for

publication]. The Cardiff technique established confidence in the VECTIS

spray modelling, provided by like-for-like validation (rather than

time/spatial integration), hence attracting a wide range of international

clients and delivering validated spray modelling for engine

design. The technique was presented first at a British Combustion

Institute meeting (Bowen, 1997). A Cardiff-Ricardo strategic partnership

was established to consolidate this on-going research and technology

breakthrough, and facilitate the application of the phase-resolved

technique to a wide range of global automotive clients. Cardiff has

effectively industrialised the spray characterisation process to the

extent of now carrying out all of Ricardo's spray characterisation

work for use in both research and customer programmes [5.1].

Complementary to this, Brighton University undertake Ricardo's

reciprocating optical engine R&D.

A continuous sequence of five EPSRC/Ricardo funded PhD studentships at

Cardiff over the past 15 years has enabled development of the spray

characterisation methodology (see Figure 1) for: fuel injection parameter

studies [3.2]; critical analysis of optical techniques [3.3];

Computational Fluid Dynamic (CFD) model validation [3.4]; injection into

high pressures/temperatures and impingement [3.5]; and novel injector

designs involving alternative fuels. The integrated simulation/validation

methodology now routinely practiced by the Cardiff-Ricardo partnership has

proven invaluable for optimal design of GDi engines. Cardiff's pipeline of

innovative optical diagnostic techniques has continued, most recently with

another new, laser-based technique which quantifies transient in-cylinder

liquid fuel films, utilising laser-induced fluorescence principles [3.6].

(a)

(b)

(c)

Figure 1. Examples of `instantaneous' characterisation of a

Pressure-Swirl GDi Spray

(a) `Wall-Guided' GDi Operation. (b) Fuel droplet size 0.75-1.0 ms after

injection. (c) Fuel droplet size 1.75-2.0 ms after injection.

References to the research

3.1 Comer M. A., Bowen P.J., Bates C.J., Sapsford

S.M. and Johns R.J.R. (1999) Transient 3D analysis of a DI gasoline engine

injector spray, Atomisation and Sprays, Vol. 9 No. 5 pp. 467-482,

ISSN 1044-5110

3.2 Comer M.A., Bowen P.J., Sapsford S.M. and Johns,

R.J.R. (1998) The transient effects of line pressure for pressure-swirl

gasoline injectors, ILASS-EUROPE `98, Proceedings of the 14th

International Conference on Liquid Atomisation and Spray Systems, July

1998, UMIST, Manchester, pp. 364-370

3.3 Comer M.A., Bowen P.J., Bates C.J. and

Sapsford S.M. (2001) Critical appraisal of current laser diagnostic

techniques for GDi Spray kinematics quantification, Journal of Optical

Diagnostics in Engineering, Vol 5. No. 1, ISSN 1364-4173 (online

journal)

3.4 Comer M.A., Bowen P. J., Sapsford S.M. and Kwon S.I.

(2004) A parametric sensitivity study of GDI spray characteristics using a

3-D transient model, International Journal of Automotive Technology,

Vol. 5 No. 3 pp. 145-153, ISSN 1229 9138

3.5 Kay P.J., Bowen P.J., Gold M.R. and Sapsford S.M. (2012)

Transient fuel spray impingement at atmospheric and elevated ambient

conditions, Experiments in Fluids, Vol. 53 No. 4 pp. 873-890, ISSN

0723-4864, 10.1007/s00348-012-1334-0

3.6 Alonso M., Kay P.J., Bowen P.J., Gilchrist R. and Sapsford

S.M. (2010) A laser induced fluorescence technique for quantifying

transient liquid fuel films utilising total internal reflection, Experiments

in Fluids, Vol. 48 No. 1 pp. 133-142, ISSN 0732-4864 10.1007/s00348-009-0720-8

Details of the impact

The crucial importance of Cardiff's research breakthrough to the success

of the new GDi engine designs is highlighted by Ricardo's Computer Aided

Engineering (CAE) Manager James Mullineux in `Ricardo Quarterly' [5.2]: `Validating

a detailed VECTIS spray model of the selected injector is

the first step in being able to simulate the operation of a new form of

combustion system'. He continues in [5.3]: `a significant

aspect of the achievement of the T-SGDI research project has been the

ability to produce validated VECTIS models of the combustion system

that can be used to provide a truly predictive assessment of the

engine under operation. Although the approach used on the

research project included a CFD correlation exercise both with the

(Cardiff) spray rig and an optically accessed engine, the latter would, as

Mullineux concludes, not be necessary as part of a production CAE

process.' Details of the major, wide-ranging impacts achieved as a

result of the spray characterisation methodology developed at Cardiff

University are described below.

Economic impact

Significant international business has been secured for Ricardo,

the industrial sponsor and global leader in automotive engine design.

The Cardiff-Ricardo methodology has been applied and disseminated through

Ricardo and their international clients. Ricardo have, for example, used

this integrated modelling-validation methodology, in partnership with

Cardiff, to develop bespoke gasoline engine designs and fuel-injection

operational strategies on behalf of a broad range of international

clients such as [text removed for publication]. These contracts

have generated over £20M revenue for Ricardo [5.1], and

significantly more revenue for Ricardo's OEM clients through revolutionary

performance improvements and resultant sales.

Recently [5.2] the Ricardo/Cardiff partnership used its methodology in

the design of a fuel-flexible SGDI engine for Malaysian-based

multi-national PETRONAS (a Fortune 100 global

company). This engine was designed to run efficiently and flexibly on

ethanol, methanol and gasoline fuel. Hence, not only does this engine

offer the efficiency gain associated with SGDI, but also the

significant additional environmental benefit of utilising sustainable

fuels. Cardiff worked very closely with both Ricardo and

PETRONAS, including regular PETRONAS research staff visits to Cardiff's

laboratories [5.1], to ensure effective understanding and implementation

of the integrated modelling/validation approach in the engine design

process.

This SGDI engine represents a step change in direct injection (DI)

combustion system design, reaching levels of fuel consumption for diesel

engines, but without the associated costs due to throttle-free operation.

SGDI is even more dependent upon accurate temporal/spatial spray

simulation than its predecessor, the `wall guided' GDi design, thus

further emphasising the crucial role of Cardiff's methodology. PETRONAS

has recently entered into agreements with far-eastern OEMs that will

see derivatives of this engine entering volume production from 2014,

rising to in excess of 100,000 units per year [5.1].

Ricardo's commercial code VECTIS, which Cardiff's research enabled

Ricardo to validate and hence which contributes to its market lead, generates

more than £1M in revenues per annum for this innovative,

high-tech UK multi-national company. It is used by global companies such

as [text removed for publication] for combustion system design and

development.

The integrated Cardiff-Ricardo methodology has enabled the design of GDi

engines more quickly and robustly, thereby gaining significant competitive

advantage. Ricardo continues to use the integrated methodology to secure

new orders in the growing GDi market. For example, it used the

Cardiff-Ricardo methodology to secure a further $7M contract with a

major US car manufacturer in 2013 [5.1].

Environmental impact

Bosch [5.4] state that GDi engines have increased market penetration from

2% (in 2002) to 22% (in 2012). The global market for road vehicles in 2012

was around 84 million [5.5]. When coupled with downsizing and boosting

(for which DI is a major enabler), GDi technology is estimated to reduce

CO2 emissions by over 20%. Hence, interpolating data between

1996-2012 shows that GDi engine technology has already been

responsible for a reduction in new car emissions of over 20M tonnes

globally, including 10M tonnes across Europe. As Ricardo is

the leading international consultancy in GDi engine design, having

undertaken GDi design projects with many of the major global OEMs since

1996, the Cardiff-Ricardo partnership has provided a considerable

contribution to this global CO2 reduction.

Furthermore, it is projected that around 26 million cars with GDi engines

will be produced per annum by 2020 [5.4]. This represents a reduction of

CO2 emissions from new cars of over 10M tonnes per annum

(by 2020) through the adoption of GDi technology, and integration with

usage of alternative fuels will result in further CO2

savings.

Impact on engineering practice

Ricardo claim that the PETRONAS project is one of their best

examples of successful modelling-led engine designs [5.1, 5.3],

where test-bed commissioning of the first prototype performed generally as

predicted. Validated spray modelling and integrated design

(enabled by Cardiff's research) is crucial to ensuring such a successful

result [5.2] and for promotion of the elusive goal of truly simulation-led

(rather than empirical) engine design and manufacture. Ricardo state, `The

(Cardiff) fuel spray rig will always be a crucial part of the CAE tool

chain ....... As such, we have a highly efficient and cost-effective

CAE methodology that can now be applied in the development of

production implementations of this type of advanced and highly

fuel-efficient combustion technology' [5.3]. Hence, it is

clear that the Cardiff-Ricardo methodology provides additional impact

through improving professional engineering practice.

In sum, Cardiff's research has revolutionised the design of modern

gasoline engines worldwide, with global economic and environmental impacts

of major significance.

Sources to corroborate the impact

5.1 Confirmation of economic benefits and impact of Cardiff-Ricardo

partnership: Steve Sapsford, Ricardo Global Market Sector Director, (steve.sapsford@ricardo.com)

5.2 Cardiff's contribution to improved GDi engine designs : Ricardo

Quarterly (pp. 19-22), 4th Quarter, 2012 http://www.ricardo.com/PageFiles/24669/RQ_Q4_2012.pdf

5.3 Cardiff validation of VECTIS spray model critical to computer-aided

engine design:

http://www.ricardo.com/PageFiles/24138/Software_CAE_issue_2_2012.pdf

5.4 Bosch data for GDi Market Penetration. http://www.bosch-presse.de/presseforum/details.htm?txtID=6406&tk_id=108

5.5 Data enabling evaluation of CO2 reduction through GDi:

International Organization of Motor Vehicle Manufacturers (OICA) http://www.oica.net/category/production-statistics/