From the lab to wind turbines and beyond… the global commercial impact of Aston’s fibre Bragg grating research

Submitting Institution

Aston UniversityUnit of Assessment

Electrical and Electronic Engineering, Metallurgy and MaterialsSummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Electrical and Electronic Engineering, Materials Engineering

Technology: Communications Technologies

Summary of the impact

Aston's fibre Bragg grating research on optical sensing has had a global

commercial impact, in particular the development of low-cost fibre FBG

sensor interrogation methods. The work has been carried out with a diverse

range of companies (including BAE Systems, Airbus, Insensys, Schlumberger)

working across different sectors including oil and gas aerospace and

marine. Specific impacts include the acquisition of 70% of the stock of

Insensys Wind for US$15.7 million by Moog in 2009 and continuing

employment by Smart Fibres, Moog Insensys and Astasense.

Underpinning research

In the last 20 years fibre Bragg grating (FBG) sensing has moved from a

small research field involving a handful of researchers to a multimillion

dollar global industry. The UK has a significant commercial presence in

this area. Aston researchers have been working in the field since the

start of 1993 when the Group was founded by Professor Ian Bennion (Head of

Group, 1992-2010) and has since expanded to become the Aston Institute of

Photonics Technologies (AIPT). Much of the early work in the UK on FBG

sensors was funded by DTI collaborative programmes. The first projects

were GIFTS (Gratings In Fibre Transmission Systems), which employed Dr Lin

Zhang (1994-present, now Professor) as a research fellow, and a BNR Europe

PhD studentship, which sponsored Dr Kate Sugden (PhD student, 1992-96,

visiting researcher 1999-2003, re-joined Aston 2003 as academic staff

member). In these projects, the expertise in FBG fabrication was developed

at Aston and included some notable world firsts (summarised in [3.1]) for:

design and fabrication of chirped FBGs, dispersion compensation with FBGs

and FBG resonator cavities.

The highly successful MAST (Maritime Applications Of Smart Structures

Technology) project followed, alongside the associated Carbospars CASE

sponsorship of Lorna Everall (1995-1999), and centred around the

development of embedded FBG strain sensor arrays primarily for carbon

fibre composite yacht masts. The key outcomes were: a relatively compact

sensor interrogator (4U, 19 inch rack sized); advanced understanding of

the interrogation and fabrication requirements e.g. [3.2]; exploration of

broader applications e.g. [3.3]. This project led to the formation of a

new optical sensing company, Smart Fibres, in 1996. At the end of MAST,

Smart Fibres employed Dr Everall (1999-2001) on a Teaching Company scheme

with Aston to continue the research and facilitate technology transfer.

A consistent issue that the collaborative projects faced was the cost of

the optical interrogation systems. At the time, this was upwards of £30k

and posed a significant commercial hurdle. The cost came from a reliance

on expensive tunable laser of optical spectrum analyser technology. In

2001, Indigo Photonics (IP), an Aston photonics spin-out, and the

Photonics Group set up a small research team at Aston specifically to

research the area of low-cost interrogation systems This team included

Glyn Lloyd (IP employee / Aston PhD student (2001-2005), Dr Everall (IP),

Professor Bennion and Dr Sugden (then CTO of IP and visiting researcher at

Aston(1999-2004)).

The successful outcome of this research was a system design that utilised

emerging semiconductor optical amplifier (SOA) technology to create an

amplifying system that could lock onto an FBG located at a specific

distance away from the interrogation unit by matching the frequency of the

SOA to the time of flight of the light pulses. This enabled the wavelength

of the FBGs to be measured using a simple spectrometer since it was

possible to average the light received over time. This overcame a key

problem of time division multiplexed (TDM) systems, where the detection

system typically has to operate very quickly at the expense of sensitivity

and noise. Importantly the system contained no moving parts making it a

very reliable solution for vibration rich environments thereby offering

significant performance advantages over competing technologies. It

resulted in the resonant cavity sensor interrogation system [3.4-3.5]

widely used by Moog and Schlumberger today. This system could be sold for

<£5k, a significant decrease in cost. Moreover, its reliance on time

division meant that all of the sensors could be low reflectivity and the

same wavelength, further reducing the system cost.

The work on low-cost interrogation systems continues. A Framework 7

project PHOSFOS resulted in several low-cost interrogation systems

operating at 850nm for healthcare applications (<£1,500 volume price) —

especially those targeted at the embedded polymer sensors developed by Dr

David Webb (2002-, now Professor) working with photonics consultancy

Astasense [3.6].

References to the research

The references below are a small, indicative subset of a large body of

published work in this area spanning 20 years. Much of the research is in

(what were then) highly regarded journals and also includes book chapters

and patents (use references 1, 3 ,4 to evaluate research quality,

marked *).

The total value to Aston of grants cited is ~£940,000

1. * I Bennion, JAR Williams, L Zhang, K Sugden, NJ Doran, UV-written

in-fibre Bragg gratings, (1996) Optical and Quantum Electronics,

28 (2), pp.93-135, doi:10.1007/BF00278281. Cited 116 times, this paper

brought together all of the early work on Fibre Bragg gratings and was

widely used for a number of years as the `go to' paper for the background

information.

2. RW Fallon, L Zhang, LA Everall, JAR Williams and I Bennion, All-fibre

optical sensing system: Bragg grating sensor interrogated by a long-period

grating, (1998) Measurement Science and Technology, 9 (12), pp,1969,

doi:10.1088/0957-0233/9/12/007. Cited 83 times.

3. * Y-J Rao, DJ Webb, DA Jackson, L Zhang, I Bennion, In-fiber

Bragg-grating temperature sensor system for medical applications, (1997)

Journal of Lightwave Technology, 15 (5), pp. 779-785,

doi:10.1109/50.580812. Cited 102 times, this paper is indicative of the

breadth of research in different application areas.

4. * G Lloyd, L Everall, K Sugden, I Bennion, Resonant cavity

time-division-multiplexed fibre Bragg grating sensor interrogator, IEEE

Photonics Technology Letters, 16(10), October 2004, pp 2323-232.

Cited 21 times, this paper described the interrogation system which forms

the basis of the system used today by Moog and Schlumberger. DOI

10.1109/LPT.2004.834849

5. L Everall, G Lloyd, Optical interrogation system and sensor system,

Patent, published June 2004, EP1432149 (and US patent 7,046,349, 2006).

Cited 18 times, this is the patent that protects the IP relating to

reference 4.

6. B Van Hoe, GCB Lee, E Bosman, J Missinne, S Kalathimekkad, O Maskery,

DJ Webb, K Sugden, P Van Daele, G Van Steenberge, Ultra small integrated

optical fiber sensing system, Sensors, 2012, 12(9), 12052-12069,

doi:10.3390/s120912052. This paper demonstrates current work on new

compact interrogation systems, in this case for a medical application.

The main grants, awarded to Bennion that underpinned this research area

were :

EPSRC "Gratings In Fibre Transmission Systems Link" (GIFTS), DTI Link,

10/92-02/95, £70,086; PhD CASE award from BNR Europe, ~£15,000;

EPSRC "Maritime Applications Of Smart Structures Technology" (MAST), DTI

Link, 08/95-05/98, £200,947;

EPSRC "Structural Health Monitoring Using Distributed Optical Fibre

Sensors" (SHODOS), DTI LINK, 03/97 - 02/2000, £83,691;

EPSRC "Fibre Optic Sensor Technology For Respiratory Function Monitoring",

12/00-05/03, £116,081;

CASE Award Development of low cost interrogation techniques and sensors

for multiplexed optical sensing systems (with Indigo Photonics),

08/02-08/05, £59,700;

EPSRC "Embedded Photonic Infrastructure" (EMPIRE), DTI Link, 09/01-08/04,

£194,302;

FP7-ICT 224058 "Photonic Skins for Optical Sensing" (PHOSFOS),

Seventh Framework Programme FP7-ICT 224058, 04/08-08/11, Euro 2,489,235

Details of the impact

In summary, this study demonstrates the economic impact of Aston's

research on FBG sensing and low-cost fibre grating interrogation systems

through the generation and safeguarding of jobs in the UK at Smart Fibers,

Moog Insensys, Schlumberger Oil and Gas and Astasense. The research has

also had an environmental impact by making structures safer and more

efficient through the cost effect integration of smart technology.

To understand how this relates to Aston University, it is necessary to

look further back and, in doing so, highlight additional commercial

activities that have a connection to Aston research. Aston was pivotal in

the development of this technology in the UK through continued support of

companies seeking to explore commercial opportunities in this area. The

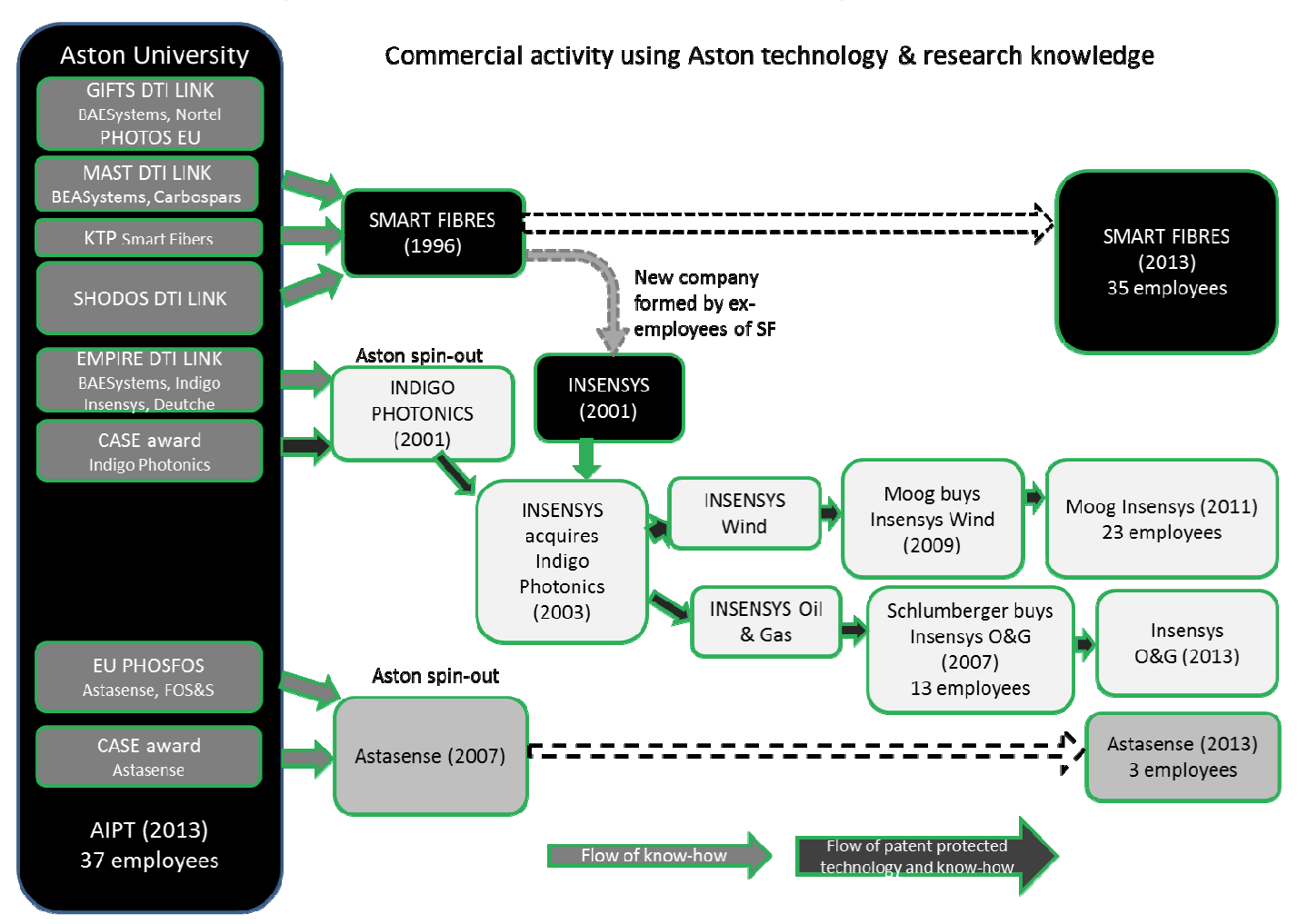

impact over the period of interest, shown on the right of the figure, is

as a result of a long period of working with a number of companies

enabling technology transfer in this area. It also results from previous

spin-outs and IP generation. A timeline charting some key events

surrounding this work is shown below:

Figure 1: schematic tracing the complex relationship between commercial activity in FBG sensing and Aston

research (the dates of company formations and key events are shown in brackets).

Figure 1: schematic tracing the complex relationship between commercial activity in FBG sensing and Aston

research (the dates of company formations and key events are shown in brackets).

Aston was one of the first universities in the world to work on FBG

sensing [1]. An early collaboration with Carbospars and BAE Systems

resulted in the formation of Smart Fibres [A]. The FBG technology

developed was featured on Tomorrow's World in 1999 raising the profile of

the technology and company and Smart Fibres has continued to build on this

FBG sensing expertise and is widely respected in the industry [A]. In

2012, this company employed 23 people in the UK and had a turnover of

£1.5 million. The company works in structural health monitoring in

areas such as oil and gas, marine, aerospace, civil engineering, medical

and sports. The technology enables the safe operation of equipment and

structures.

Indigo Photonics Ltd was formed as an Aston spin-out by Dr Sugden, along

with Professors Bennion and Zhang, in May 2001. Collaborative research

resulted in the filing of the key sensor interrogator patent in December

2002 [3.4, 3.5, 5B]. Following an intense period of collaborative work,

Insensys Ltd acquired Indigo Photonics in August 2003 [C] and continued to

develop and commercialise this sensor technology [D]. About the sale Mike

Sibson of 3i said "We co-founded Indigo Photonics with the management team

and Aston University, and we have been active in delivering the benefits

of our global network as it has grown and developed its technology. The

acquisition by Insensys will make a powerful combination..." [C]. The

technological advantages that the system had, allowing it to be used

effectively in vibrating structures such as wind turbines, gave the

company a significant technical advantage over competitors. Of the

technology Robert Brogue later said "this new technique allows sensor

costs to be reduced dramatically and also yields operational benefits"

[D]. Insensys was split into three business units — Oil & Gas, Wind

Energy [E] and Aerospace and two parts continue to be a significant UK

employer.

In May 2007, Schlumberger (the world's leading supplier of technology,

integrated project management and information solutions to customers

working in the oil and gas industry) announced the purchase for an

undisclosed amount of the Oil & Gas division of Insensys, recognising

the unique nature of its technology [F]. The technology is still in use

monitoring the structure integrity of oil risers.

This was followed by the acquisition of the Wind division of Insensys by

US company Moog (a worldwide designer, manufacturer, and integrator of

precision motion control products and systems) in November 2009 for

US$15.7 million [G]. Moog Insensys employs ~23 people in the UK working in

the wind turbine technology area (June 2013). The impact is therefore

in their continued business and employment. The technology developed

during Dr Lloyd's PhD is a key part of their product portfolio. It is

estimated that a significant proportion of the £30 million revenue that

the business has generated would have been unlikely to have happened

without the technology since it offers lower cost, greater flexibility and

inherent increased reliability than competitors [H]. Combined with the

commercial knowledge and composite expertise from the company it provided

a highly competitive offering. Moog was awarded the Queen's Award for

Enterprise in 2010 due to contributions to UK Export [J] after selling

over 800 interrogation systems in two years.

In this sector the technology [5] has an environmental impact, especially

in the safe running of large wind turbines where the health of the

structures can be monitored during operation and active pitch control of

the blades can be implemented. It enables the efficiency of the turbines

to be optimised and ensures they operate within given safety parameters

[I]. This work was enabled by the development of the compact sensor

interrogator since, unlike the competitors; the device was low cost, small

and contained no moving parts.

A further company, Astasense Ltd, was formed in 2007 by Dr Sugden and

Professors Webb, Zhang and Bennion. The company originally offered

consultancy services, but was invited to join an EU Framework 7 project

PHOSFOS. The company has generated further impact by employing a

total of 14 researchers since 2008, and in 2013 launching a fibre

interrogator system and polymer fibre FBGs based on the research at

Aston. This work was included in the British Science Festival exhibition

in 2012 bringing the technology to the public. Astasense (07/13)

employs 3 people full time in the UK working in product development in

optical sensing directly based on expertise derived from Aston University,

the oil and gas sector is the main end user for current development work.

Webb and Sugden are also active participants in EU COST Action TD1001:

Novel and Reliable Optical Fibre Sensor Systems for Future Security and

Safety Applications (OFSeSa) where one of the key aims is to further

support the commercial development of this technology.

Sources to corroborate the impact

(all available in pdf format if required)

A. http://www.smartfibres.com/?page=company

B. L Everall, G Lloyd, Optical interrogation system and sensor system,

EP02258640 & WO2004056017 (and US patent 7,046,349, 2006 (citations:

18)) (priority 12/2002)

C. http://www.lightreading.com/document.asp?doc_id=38364

D. Robert W. Bogue, (2005) "UK start-up poised to take the fibre optic

sensor market by storm", Sensor Review, Vol. 25 Iss: 1, pp.24 - 27, doi:

10.1108/02602280510577780

E. http://www.greentechfocus.com/index.php#state=CompanyDetail&id=1053

F. www.rigzone.com/news/oil_gas/a/45663/Schlumberger_Acquires_Insensys_Oil_Gas

G. http://www.moog.com/news/operating-group-news/2009/moog-acquires-wind-energy-firm-insensys/

H. Moog Insensys, CTO

I. Shawn Taylor (2012) "Cost Reduction Using Fiber Optics And Embedded

Intelligence"

http://proceedings.ewea.org/annual2012/allfiles2/1344_EWEA2012presentation.pdf

J. http://www.moog.co.uk/markets-overview/wind-energy/