Controlling uncertainty with cost engineering tools

Submitting Institution

Cranfield UniversityUnit of Assessment

Aeronautical, Mechanical, Chemical and Manufacturing EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Information and Computing Sciences: Artificial Intelligence and Image Processing, Information Systems

Engineering: Manufacturing Engineering

Summary of the impact

Substantial savings have been made using Cranfield's Cost Engineering

software tools and techniques. These are used in BAE Systems, Airbus,

Rolls-Royce, GE Aviation, Ford Motor Company and increasingly in the UK

defence industry through the MoD. DTZ (Debenham Tie Leung Ltd) estimates

£213 million per annum financial benefit for BAE Systems and MoD alone,

with an additional £200 million per annum for other companies.

Cranfield's team has significantly influenced the national and

international policy of The Association of Cost Engineers and

manufacturing companies in methods and procedures. Cranfield has trained

over 700 engineers from over 50 companies in cost engineering based on our

research.

Underpinning research

Cranfield University started research on cost engineering to understand

the extant basis of cost prediction in the design, manufacture and service

of components and industry's understanding of affordability, in the late

1990s. The goal was to understand the science and engineering behind

current industrial practice so that cost engineering could become more

scientific and systematic in the future. Our studies established the best

practice in true cost prediction, and have developed software tools and

training, which have improved the competitiveness of UK manufacturing

companies. We studied how cost engineers think, and modelled the cognitive

processes behind the engineering judgement necessary for the cost

prediction [G1, 3, P1]. The study involved analysing the reasoning process

followed during cost estimating by both experts and novices. Research into

this cognitive process became the foundation for our cost engineering

training, which has been developed for industry since 2003.

The Cranfield team progressed to research best practice in predicting the

cost of new technologies, based on analogy, in collaboration with the

automotive industry [P2]. Then the team focused on predicting cost of

design, manufacturing and assembly at the conceptual design stage for

complex engineering systems, e.g. for aircraft wings and hydraulic

systems. The scope of this prediction covered the design effort, including

both the thinking time and the Computer Aided Design model development

time, based on the complexity of the product [G2-4, P3]. The research

included both mechanical and electronic components design and testing.

Novel techniques (e.g. function based cost estimating for automotive

components) were developed which can predict more realistic cost at the

conceptual design stage, in the absence of data of good quality and

quantity [P4].

Our research focused on predicting the cost of in-service issues,

especially within performance based contracts. The key challenges

addressed in the research are:

— predicting the cost of the resolution of component and material

obsolescence, based on a probabilistic approach [G5, P5];

— modelling service uncertainty within the cost estimates using an analogy

based approach [G5, P6].

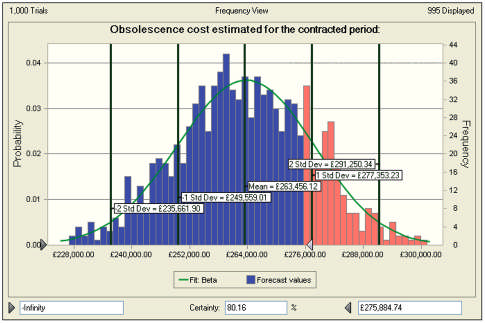

The probabilistic cost estimation approach identified the relationships

between component complexity and obsolescence resolution profile. We

identified that the cost efficiency achieved by organisations in relation

to obsolescence correlates with how proactive they are in managing the

problem. Understanding of this has informed the design of new tools for

predicting the non-recurring engineering effort/cost for obsolescence

resolution [P5].

The analogy and uncertainty based cost estimating technique identifies the

new challenges related to availability contracts, and enables a systematic

approach that reflects the impact of uncertainties on the cost drivers [P6].

The research identifies a cost distribution for the service provision using

a stochastic simulation. The research also allows us to understand the

enduring cost profile across a product/system/service life cycle and is

fundamental to improving UK capability in cost modelling for large and

complex projects in industry and the public sector.

| Key Researchers |

Post details* |

Dates involved |

Research |

| Dr. P Baguley |

Research

Fellow |

2006 – to date |

Artificial intelligence application for cost

estimation, parametric cost estimating |

| Dr. Y Xu |

Lecturer |

2008 – to date |

Design for cost, detailed cost estimation |

| Dr. E Shehab |

Reader |

2004 – to date |

Cost of obsolescence, Cost of information

preservation |

| Dr. C Wainwright |

Senior

Lecturer |

2001 – 2008 |

Parametric cost estimation, CADCO project |

| Prof R Roy |

Professor |

1997 – to date |

All the above, plus uncertainty- and

analogy-based service and qualitative cost

estimation |

* highest grade in period given

References to the research

Evidence of quality — peer-reviewed journal papers

P1* Rush, C and Roy, R, "Expert judgement in cost estimating: modelling

the reasoning process", Concurrent Engineering: Research and

Applications (CERA), 9, (4), pp. 271-284, 2001. DOI:

10.1177/1063293X0100900404.

P2 Roy, R., Colmer, S.a and Griggs, T.a,

"Estimating cost of a new technology intensive product: a case study

approach", International Journal of Production Economics, 97,

pp. 210-226, 2005. DOI: http://dx.doi.org/10.1016/j.ijpe.2004.08.003.

P3 Oduguwa, P., Roy, R. and Sackett, P. J., "Cost impact analysis of

requirement changes in the automotive industry: a case study", Journal

of Engineering Manufacture, Part B, 220, Number B9, pp.

1509-25, 2006. DOI: 10.1243/09544054JEM275.

P4* Roy, R., Souchoroukov, P. and Griggs, T.a, "Function-based

cost estimating", International Journal of Production Research, 46,

(10), pp. 2621-50, 2008. DOI: 10.1080/00207540601094440.

P5* Romero, Rojo F.J., Roy, R., Shehab, E., Cheruvu, K. and Mason, P.b,

"A cost estimating framework for electronic, electrical and

electromechanical (EEE) components obsolescence within the use oriented

product-service systems contracts", Journal of Engineering

Manufacture, Part B, 226, (1), pp. 154-166, 2012.

DOI:10.1177/0954405411406774.

P6 Erkoyuncu, J. A., Durugbo, C., Shehab, E., Roy, R., Parkerb,

R., Gath, A.b and Howell, D.c, "Uncertainty driven

service cost estimation for decision support at the bidding stage", International

Journal of Production Research, 51, pp. 5771-5788, 2013.

DOI: 10.1080/00207543.2013.794318.

* 3 identified references that best indicate the quality of the research.

Key

a Ford Motor Company, UK

b BAE Systems, UK

c GE Aviation, UK

Further evidence of quality — underpinning research grants

G1 EPSRC (GR/N21321). Developing an Integrated Costing Approach for

Conceptual Design Evaluation (ICOST), £275,000 (total: £575,000 including

cash and kind contribution from industry partners), 2000-2003, PI Roy.

Partners: BAe, MA&A, Ford and XR Associates..

G2 Cranfield IMRC (EPSRC) sub project. Integrated Requirements Management

for Digital Product Development (e-RM), £317,000 (total: £907,000

including contribution from industry partners), 2002-2005. Industry

Partners: Nissan Technology Centre Europe, JCA, EDS and SMMT. PI Roy.

G3 Cranfield IMRC (EPSRC) sub project + Four TSB/KTP with Airbus.

Formalisation of Expert Judgement in Cost Engineering and Integration

(CostExpert), £621,700 (total: £1,205,000 including cash and kind

contribution from industry), 2002-2006, PI Roy (CI on the KTPs) and CI

Wainwright (PI on the KTPs). Industry Partners: Airbus UK, Galorath UK and

Smiths Group.

G4 EU FP6 SSA, Virtual Cost Engineering Studio, £304,500, 2004-2006, PI

Roy. Partners: Centro Ricerche FIAT, PRICE Systems, DAS and IZET.

G5 Cranfield IMRC (EPSRC) sub project: Whole Life Cost Modelling for

Product-Service Systems (PSS-Cost), £380,000 (total: £630,000 including

cash and kind contribution from industry partners), 2007-2010. Industry

partners: BAE Systems, GE Aviation, Lockheed Martin (Insys), MoD, Rolls

Royce, Galorath, APMP, SBAC. PI Roy and CI Shehab.

Details of the impact

Cranfield developed a best practice process and software tool to predict

the obsolescence resolution cost for electronic components and materials

(figure 1). The tool helps to reduce the UK defence costs in two ways:

— the contingency sums that defence contractors would have incorporated

into availability contracts to resolve obsolescence issues will be lower

because the tool enables the costs to be predicted with greater accuracy

and confidence

— defence contractors will have a greater incentive to design equipment

with a view to minimising obsolescence issues.

A DTZ estimate shows £213 million per annum financial benefit for the

sectors (BAE Systems and MoD only) [C1, 2]. Cranfield's software tool is

disseminated to other defence companies by MoD through a support contract

[C3].

The research in cost engineering helped BAE Systems and MoD

systematically to identify uncertainties in cost estimation, and the tool

developed is used within BAE Systems to prepare bids [C4]. The research

has also significantly influenced the national and international policy of

the Association of Cost Engineers (ACostE), and promoted the need for a

scientific approach to cost engineering in industry and government

organisations [C5]. In addition, the Cranfield team developed cost models

that were used within Airbus as part of the "CADCO" project toolbox to

evaluate conceptual designs of new aircrafts [C6]. This enables Airbus to

understand better the costs in the early phases of new projects, with

calculated uncertainty. The team helped Airbus to implement the CADCO tool

set across Europe and provided extensive training.

Figure 1: Predicted cost of obsolescence resolution with uncertainties

Figure 1: Predicted cost of obsolescence resolution with uncertainties

Cost Engineering at Cranfield has developed novel approaches and tools

to predict the true whole life cost of complex engineering systems [C7,

C8]. Cranfield has provided cost engineering training for over 12 years

and has trained over 700 engineers in over 50 companies with an

indicative financial impact of £12 million per annum. Cranfield's effort

in improving the cost engineering practice across defence, aerospace,

automotive, railway, oil and gas companies has resulted in more

recognition of cost as a design driver and has helped in improving the

competitiveness. The indicative financial benefit from cost engineering

software developed at Cranfield (figure 1) is over £400 million per

annum [C2], and the UK MoD is disseminating the software to more

companies such that and the financial impact will be further increased

significantly.

To estimate savings, we consider that the UK civil aerospace sector

alone has revenue of £12 billion per annum [C9]. The training delivered

by the Cranfield team is estimated to help British aerospace companies

to gain at least an additional 0.01% of this market, which is an

additional £12 million per annum new business.

Cranfield developed cost engineering training and education programmes,

based on this research, with BAE Systems, Airbus, Ford Motor Company,

Rolls-Royce, Bombardier Transportation and the Ministry of Defence (MoD)

since 2001 [G1]. The initial training programme at BAE Systems focused on

bridging the gap between the technical/ engineering functions and finance.

The training improved the communication between the two groups and

therefore improved the cost estimating practice and policy, encouraging

the company to establish "cost engineering" as a distinct function. Once

the cognitive model for the cost engineers was captured, the team

developed detailed cost engineering training for the automotive industry

with Ford Motor Company and for the MoD in 2003, which is used to reduce

the learning curve of the novice. The training also included a `cost

awareness development programme' across Airbus (within Europe) and BAE

Systems. The training supported design engineers, manufacturing engineers

and procurement team members to improve their cost awareness. Since 2006,

the Cranfield team has delivered an online cost engineering course on

`Principles of Cost Engineering'. UK and international manufacturing

(aerospace, automotive, railway, oil and gas) and defence companies use

the course regularly. The face-to-face and online training courses have

supported companies like Airbus, Rolls-Royce, and BAE Systems to become

more competitive and manage their costs better, [C3,4,5,6].

Sources to corroborate the impact

C1 Contact: Consultant Engineer, Ex BAE Systems, now AIG Synergies

Limited.

C2 Contact: Consultant, DTZ.

C3 Contact: Obsolescence Management Lead, MoD.

C4 Contact: ILS Manager, BAE Systems.

C5 Contact: President of the Association of Cost Engineers

C6 Contact: Systems Engineer, Airbus.

C7 Services to Estimating Award from Industry. 2008. URL:

http://www.galorath.com/index.php/news/ukconference2008 (last accessed November 2013)

C8 Contact: Vice President — Europe and RoW, PRICE Systems Ltd.

C9 KPMG report on the future of UK civil aerospace industry. 2013. URL:

https://www.adsgroup.org.uk/articles/35553 (last accessed November 2013)