Improving Production and Logistics Operations in the Steel Industry

Submitting Institution

Loughborough UniversityUnit of Assessment

Business and Management StudiesSummary Impact Type

TechnologicalResearch Subject Area(s)

Mathematical Sciences: Applied Mathematics

Information and Computing Sciences: Artificial Intelligence and Image Processing

Engineering: Materials Engineering

Summary of the impact

Loughborough University research into Decision Support Systems (DSSs) has

been used to transform the production and logistics operations of the

Shanghai Baoshan Iron and Steel Corporation, China's largest steel

company. Implementing DSS has resulted in annual savings of around US$20m

and a reduction in CO2 emissions of 585,770 tons per year. The company

reports that the "tremendous benefits" of the research have extended to

improvements in efficiency, product quality, customer satisfaction and

management culture. The work won a Franz Edelman Finalist Award in 2013

for Achievement in the Practice of Operations Research and the Management

Sciences.

Underpinning research

Iron and steel production, an industry crucial to industrialised

economies, consists of a series of complex processes. These involve both

continuous and discrete material flows, high temperatures, heavy equipment

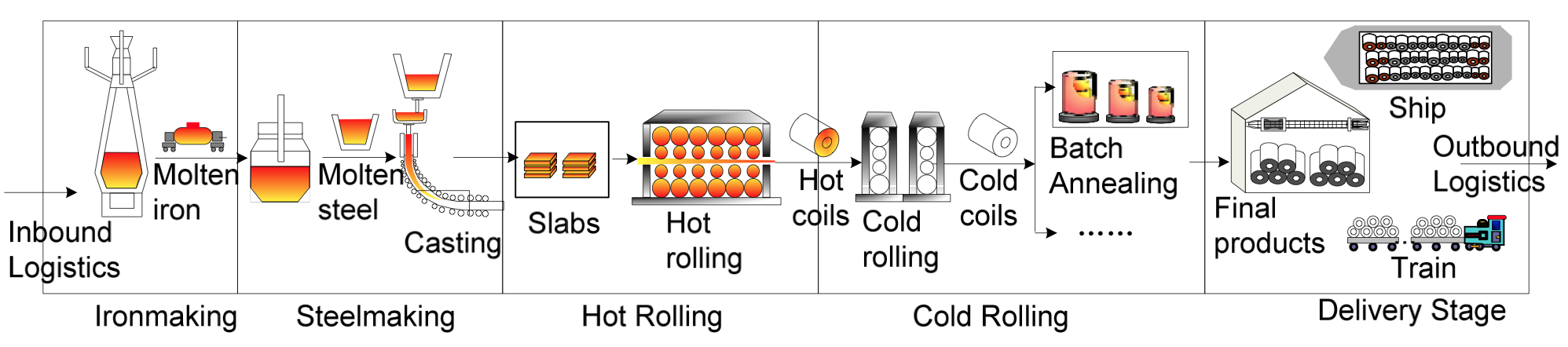

and the consumption of massive amounts of energy. As shown in figure 1,

there are several key stages in production — including iron-making,

steel-making, continuous casting, hot rolling, cold rolling and further

processing — as well as various logistics operations to support the

material/product flow inbound, outbound and between stages. Operations

planning and scheduling are critical to the efficient operation of the

production and logistics system.

Figure 1. Stages of steel production and logistics system

Figure 1. Stages of steel production and logistics system

Professor Jiyin Liu, who joined Loughborough University in 2004, has been

working with the steel industry for many years and has been involved in a

long-term research collaboration with Lixin Tang, one of his former

postdoc research associates and now a professor at Northeastern University

in China, in developing optimisation models and algorithms for operations

planning and scheduling in various stages of steel production and

logistics. After Liu joined Loughborough University the pair set up a

collaborative research team and received joint research grants from the

National Natural Research Foundation of China [G3.1] to further

their work in this field. Steel production, which provides materials for

manufacturing and construction, is particularly vital to a rapidly

emerging economy such as China.

The team, with Liu as a core member, studied decision problems in

different phases of steel production and logistics operation, including

scheduling of charges and casts in the steel-making and continuous casting

stage [3.1][3.5]; sequencing in the hot and cold rolling stages [3.2];

batching and crane scheduling for the batch annealing process in the cold

rolling stage [3.3][3.6]; and allocation of berths and scheduling

of unloading equipment for ships carrying inbound raw materials [3.4].

Optimisation models were formulated for these problems, taking into

account practical constraints and considering objectives such as reducing

costs and energy consumption, improving product quality and using

resources effectively.

The research considered not only academic rigor and novelty but also,

more importantly, the feasibility of real applications in practice. To

this end, the development of the models was based on analyses of the

production and logistics operations of steel companies and the decisions

involved. Data were collected from firms to assist in testing models and

algorithms. Among the companies that cooperated with the team was the

Shanghai Baoshan Iron and Steel Corporation, also known as Baosteel, the

largest steel company in China and one of the largest in the world.

The research team, one of the most active in its field, discovered that

some of the constraints experienced by steel companies were

problem-specific and others were of standard types similar to those in the

travelling salesman problem, knapsack problem and assignment problem. The

solutions to the issues identified during the course of the research

included deriving optimal properties and valid inequalities and applying

techniques such as Lagrangean relaxation and column generation.

Tailor-made heuristics and meta-heuristics, including genetic algorithms

and tabu search, were also developed. Most of the models involved both

integer and continuous variables.

References to the research

3.1. Tang, L, Wang, G, Liu, J (2007) A branch-and-price

algorithm to solve the molten iron allocation problem in iron and steel

industry, Computers & Operations Research, 34(10), 3001-3015,

ISSN: 0305-0548. DOI: 10.1016/j.cor.2005.11.010.

3.2. Tang, L, Wang, X, Liu, J (2008) Color-coating

production scheduling for coils in inventory in steel industry, IEEE

Transactions on Automation Science and Engineering, 5(3), 544-549,

ISSN: 1545-5955. DOI: 10.1109/TASE.2008.918126.

3.3. Tang, L, Xie, X, Liu, J (2009) Scheduling of a single

crane in batch annealing process, Computers & Operations Research,

36(10), 2853-2865, ISSN: 0305-0548. DOI: 10.1016/j.cor.2008.12.014.

3.4. Tang, L, Li, S, Liu, J (2009) Dynamically scheduling

ships to multiple continuous berth spaces in an iron and steel complex, International

Transactions in Operational Research, 16(1), 87-107, ISSN:

0969-6016. DOI: 10.1111/j.1475-3995.2009.00662.x.

3.5. Tang, L, Wang, G, Liu, J, Liu, J (2011) A combination

of Lagrangian relaxation and column generation for order batching in

steelmaking and continuous-casting production, Naval Research

Logistics, 58(4), 370-388, ISSN: 0894-069X. DOI: 10.1002/nav.20452.

3.6. Tang, L, Meng, Y, Liu, J (2011) An improved

Lagrangean relaxation algorithm for the dynamic batching decision problem,

International Journal of Production Research, 49(9), 2501-2517,

ISSN: 0020-7543. DOI: 10.1080/00207543.2010.532915.

The research was supported by two research grants from National Natural

Science Foundation of China. For one of them [G3.1], Liu is the principal

investigator:

G3.1. "Operations scheduling in production and logistics systems",

RMB400,000 (f0bb£40,000), National Natural Science Foundation of China

(Grant for collaborative research for overseas young scholars), PI: Liu,

J., CI: Tang, L., March 2007 — Dec 2009.

Evidence on the quality of the research

The research has made significant contributions and impact in the area of

production-logistics planning and scheduling. The results were published

in high level international journals and the publications have received a

considerable number of citations. For example, according to Google

Scholar, the example papers listed above have received 42 citations

collectively up to October 2013.

Details of the impact

Loughborough University's work in the field of Decision Support Systems

(DSSs) has transformed the production and logistics operations of

Baosteel, which, as China's largest and most advanced steel company,

employs more than 130,000 people around the globe and was ranked the

second most productive steel and iron enterprise worldwide in 2012.

The research team collaborated mainly with mid-level managers and

operations planners during the course of its investigative and

evidence-gathering work. It noted that Baosteel had advanced process

technology and information systems but had not used them to their full

potential in terms of scientific planning: instead planners still made

decisions based mainly on their experiences. The team's research

demonstrated to the company's management the potential of using

optimisation models and algorithms to make decisions, particularly at a

time when increased competition and raw material prices compelled the firm

to improve its operations management through better use of resources and

IT systems.

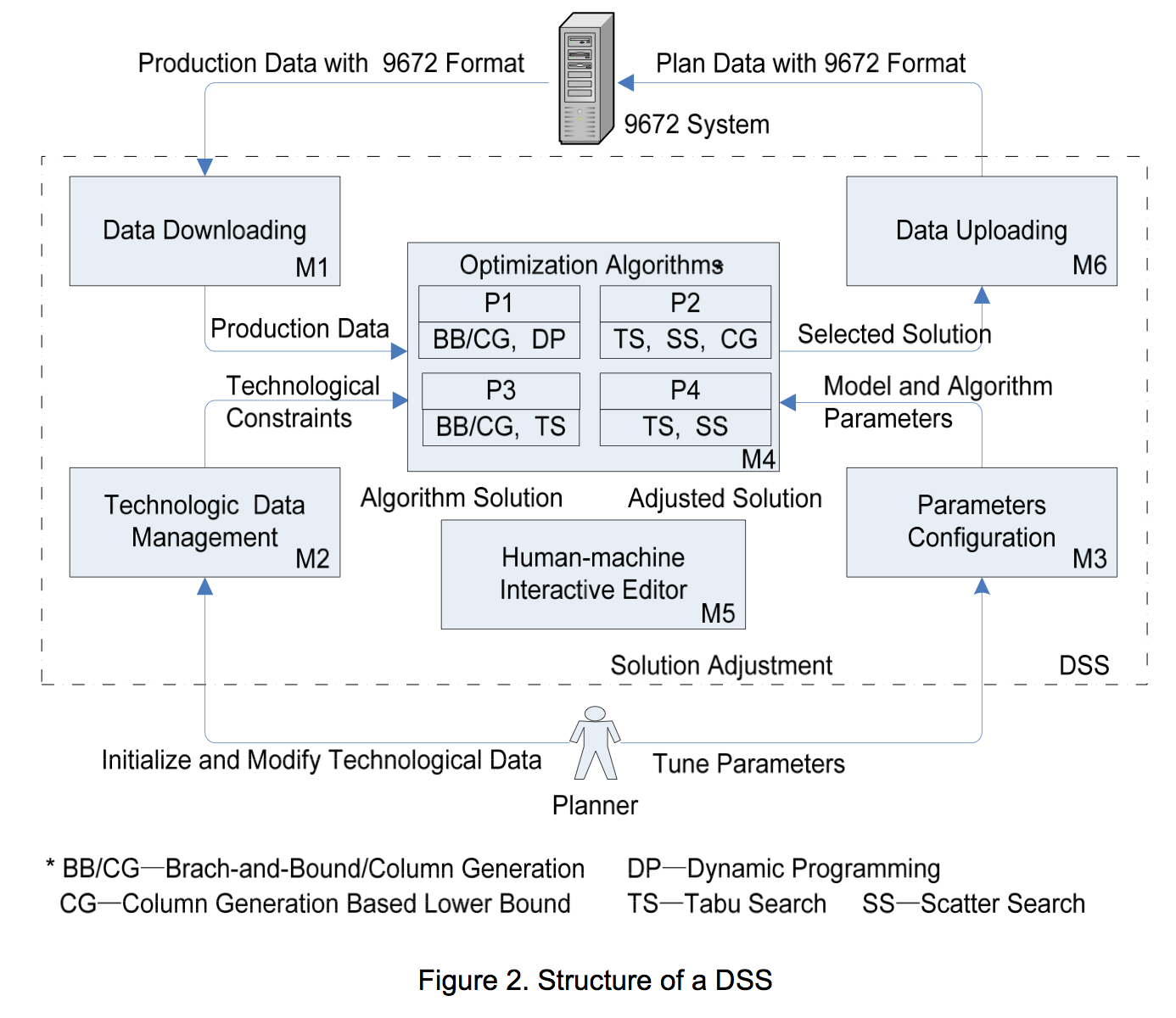

Managers went on to identify four bottleneck areas across the production

and logistics system and decided to improve them by applying the

optimisation techniques that emerged from the research. The company

collaborated with the research team in implementing the techniques and in

developing DSSs for each of the bottleneck areas:

- Integrated charge batching and casting width selection decisions in

the continuous casting operation of the steel-making stage

- Open-order slab allocation and slab reallocation decisions in the slab

yard of the hot-rolling stage

- Coil batching decisions in the batch annealing operation of the

cold-rolling stage

- Ship consolidation and ship stowage planning in the final product

delivery stage

The structure of each of these four DSSs (shown in figure 2) is similar.

Introduced at the company's Shanghai plant from 2006 to 2011, they have

delivered benefits that have been reflected in a series of key performance

measures throughout the impact period. For example, it has been estimated

that up to 2012 the use of the DSSs at the Shanghai plant resulted in a

total cumulative benefit of US$76.81m. It has also been estimated that

since 2011 the DSSs have together generated an annual economic benefit of

approximately US$20m. Other tangible benefits include an annual reduction

of energy consumption equivalent to 293,967 tons of standard coal, an

annual reduction in CO2 emission of 585,770 tons and a 9% reduction of

inventory. All of these figures have been calculated and/or corroborated

by Baosteel [5.1, 5.2, 5.3, 5.4].

The company's Executive President has credited the implementation of the

DSSs at the Shanghai plant with improving the productivity of Baosteel's

planners more than 30-fold and having a "huge impact" on strategy across

the organisation by promoting "the integration of informisation and

optimisation" and equipping staff with "invaluable" knowledge. He has

confirmed: "The use of DSSs has significantly increased production and

logistics efficiency, improved productivity, improved product quality, cut

down energy and resource consumption and reduced production and logistics

costs." Baosteel has championed the project as the first successful

example of the large-scale use of operational research in the Chinese

steel industry [5.3]. The company's Vice-President for Engineering

has highlighted further benefits, including greater customer satisfaction

and a shift "from experience-based decision-making to more scientific

decision-making" in Baosteel's management culture. The methods were

classed "five-star optimisation software" in the company's 2011 systems

review, and Baosteel has already made a commitment to implementing the

DSSs at its other plants [5.4]. As a major state-owned enterprise,

the company has also set a precedent for other Chinese firms and

industries through its pioneering use of operations research techniques —

particularly in light of the fact that China is now the largest steel

producer in the world, with its annual output accounting for some 45% of

the global total.

Baosteel and the research team jointly submitted the project to INFORMS

for the Franz Edelman Award. This is INFORMS' most prestigious award,

emphasising real applications of operations research and management

sciences and requiring savings and benefits verified by the users. The

project won a Franz Edelman Finalist Award at the INFORMS Conference on

Business Analytics and Operations Research in April 2013 [5.5].

Sources to corroborate the impact

The following sources of corroboration can be made available at request:

5.1. Abstracts and details of Edelman Award Presentations 2013,

INFORMS Video Learning Center.

(https://live.blueskybroadcast.com/bsb/client/CL_DEFAULT.asp?Client=569807&PCAT=623

3&CAT=6232).

5.2. Video of speech by the Executive President of Baosteel

confirming the benefits achieved and estimating future benefits when the

systems are applied to more plants of the company. (http://www.youtube.com/watch?v=4SJGZYLgb4E,

the speech is also in the Baosteel presentation on the webpage given in

[5.1]).

5.3. Franz Edelman Finalist Award winning paper "Operations

Research Transforms Baosteel's Operations", to be published in Interfaces

(Vol.44, No.1, 2014): http://pubsonline.informs.org/page/inte/forthcoming

5.4. Verification letter from Vice President for Engineering and

Technology, Baosteel.

5.5. Certificate of the Franz Edelman Finalist Award to Jiyin Liu.s