Revolutionising design planning and management

Submitting Institution

Loughborough UniversityUnit of Assessment

Architecture, Built Environment and PlanningSummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Civil Engineering

Built Environment and Design: Design Practice and Management

Economics: Applied Economics

Summary of the impact

Between 1992 and 2002, Loughborough University invented an award-winning

approach to

planning complex, highly interdependent development projects. Since 2008

the Analytical Design

Planning Technique (ADePT) method has resulted in:

- A sustainable spin-out business (Adept Management Ltd) employing 10

staff with a £6.2 million

turnover, providing ADePT services to the majority of the UK's top

construction contractors —

the business is run by four ex-researchers who were integral to the

development of ADePT at

Loughborough University;

- Formation of an Adept Management Ltd technology arm in 2008 providing

a state-of-the-art

commercial design planning software package incorporating enhancements

to the method;

- Establishment of a US office in 2009 and growth in the number of

international clients in

Europe, the US, the Middle East and Africa; and as a result

- Application on projects valuing £11 billion since 2008, with higher

levels of cost and time

certainty, fewer delays and less waste due to improved design

management.

Underpinning research

In the early 1990s Professor Simon Austin (1984-present) and Professor

Andrew Baldwin (1989-

2003, 2007-2011) identified a major problem with design planning and

management on complex

construction projects: inadequate methods were creating significant delays

and costly rework in

most projects [G1]. Research suggested that over 40% of design was

late and more than 35%

over-budget. Such projects often involve many thousands of activities and

the interfaces between

them — typically information exchanges — often number tens of thousands.

Company or geographic

boundaries increase the complexity and inevitable rework. This is often

overlooked when planning

design due to the lack of a method of analysis (hamstrung by all software

being based on the

Critical Path Method, which cannot deal with iteration). The potential

efficiency benefits are

significant given that design organisations typically estimate levels of

rework at 20-40%.

In response the academics, primarily assisted by PhD students Andrew

Newton and Paul Waskett,

developed ADePT, the Analytical Design Planning Technique,

a novel approach to mapping and

optimising iterative design processes, analogous to, but a fundamental

advancement upon, the

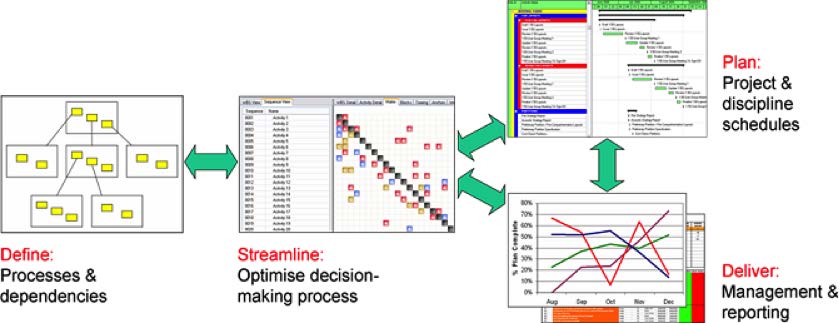

sequential critical path method. Its four steps involve (Figure 1):

modelling the process as tasks

and information flows; finding optimum sequences that minimise iteration;

creating a design

schedule and integrating the design schedule with the

construction/manufacturing schedule; and

monitoring and controlling design activity against the plan.

Figure 1: Overview of the ADePT method

Figure 1: Overview of the ADePT method

ADePT enables shared decision-making within a multi-disciplinary team to

agree design

compromises, reduce risk, create a sophisticated design plan integrated

with

construction/manufacturing and hence enable measurable and auditable

control of any complex

project, such as those faced in engineering industries.

ADePT was developed in three phases through a series of government- and

industry-funded

research projects at Loughborough University between 1992 and 2002:

-

Phase 1 (1993-1996) identified the design management problem as

an outcome of an SERC

project [G2] and found a new approach to planning complex

iterative processes, the basic

technique being invented in Andrew Newton's doctoral research,

supervised by Austin (1992-

95). This showed that a robust process model of design tasks and their

information flows could

be analysed by a dependency structure matrix to predict the coordination

challenges

experienced on projects [R1].

-

Phase 2 (1996-1999) explored ADePT's scalability, viability and

suitability in various design

stages, using case studies of construction and engineering projects, to

produce robust

integrated design plans. It was undertaken through two EPSRC grants [G3,

G4] and Austin's

PhD students Paul Waskett [R2], Tarek Hassan [R3], John

Steele [R4] and Martin Pendlebury.

-

Phase 3 (1998-2001) refined the technique in collaborative

design chains through EPSRC/DTI

projects, which included collaboration with the University of

California, Berkeley. This resulted

in DePlan [R5], in which ADePT was integrated with control

techniques to improve the active

management of design activities against the improved plans, and hence

achieve the benefits.

This research also produced a handbook for practitioners through the

ICE's publishing arm [R6] as well as a complimentary values/value management

approach (VALiD) later licensed to

Adept Management Ltd.

By 2001, this body of Loughborough University research had developed and

tested the ADePT

method to give the industrial research collaborators the confidence that

it could be applied robustly

in industry settings and the belief that the method could be encapsulated

in commercially viable

software. There was also growing evidence that other sectors involving

complex, multi-disciplinary

projects faced challenges on a similar scale to construction; more

significantly the ADePT

approach was equally suited creating further opportunities for

exploitation and impact.

References to the research

ADePT-related research has been reported in 15 peer-reviewed journals

since 1988, including the

5 journal papers cited below to evidence the quality of the underlying

research.

R1 Austin, S., Baldwin, A. and Newton, A. (1996) "A data flow

model to plan and manage the

building design process", Journal of Engineering Design, 7(1), pp.

3-25. DOI:

10.1080/09544829608907924 [impact factor 0.928; 83 citations]

R2 Austin, S., Baldwin, A., Li, B. and Waskett, P. (2000)

"Analytical Design Planning Technique

(ADePT): a dependency structure matrix tool to schedule the building

design process",

Construction Management and Economics, 18(2), pp. 173-182. DOI:

10.1080/014461900370807 [SCImago Journal Rank 0.64; 111 citations]

R3 Baldwin, A. N., Austin, S. A., Hassan, T. M., and Thorpe, A.

(1999) "Modelling information flow

during the conceptual and schematic stages of building design", Construction

Management

and Economics, 17(2), pp. 155-167. DOI: 10.1080/014461999371655

[SCImago Journal Rank

0.64; 64 citations]

R4 Austin, S., Steele, J., Macmillan, S., Kirby, P. and Spence, R.

(2001) "Mapping the conceptual

design activity of interdisciplinary teams", Design Studies,

22(3), pp. 211-232. DOI:

10.1016/S0142-694X(00)00026-0 [impact factor 0.969 (5 year 1.481); 79

citations]

R5 Choo, H., Hammond, J., Tommelein, I., Austin, S. and Ballard,

G. (2004) "DePlan: A tool for

integrated design management", Automation in Construction, 13(3),

pp. 313-326. DOI:

10.1016/j.autcon.2003.09.012 [impact factor 1.500 (5 year 1.702); 52

citations]

R6 Austin, S., Baldwin, A., Hammond, J., Murray, M., Root, D.,

Thomson, D. and Thorpe, A.

(2001) Design Chains — a handbook for Integrated Collaborative Design,

Thomas Telford,

London, 231pp, ISBN 978-0727730398 [43 citations]

Grants

G1 Austin, Baldwin and Thorpe, Cost control in design and

build & HVAC computer simulation,

SERC/DTI/IDC Ltd (Teaching Company), Jan 1988 - Dec 1990, £266,000

G2 Austin, Baldwin and Thorpe, Improving information transfer

within a design & build

environment by modelling and simulation, SERC/Industry, Mar 1993 -

Mar 1996, £88,863 +

£63,200 industry

G3 Austin and Baldwin, Design methodology and tools for

detailed building design management,

IMI/EPSRC/DoE/Industry, June 1996 - Sept 1998, £105,828 + £105,828

industry

G4 Austin and Baldwin, ADePT Technology Transfer Project,

EPSRC/Industry (grant), Jan 1999 -

Dec 1999, £45,339 + £69,850 industry

G5 Austin, Baldwin and Thorpe, Integrated Collaborative Design,

IMI/EPSRC/DETR/Industry, Oct

1998 - July 2001, £427,117 + £465,104 industry

G6 Austin, Baldwin and Thorpe, ICD: RAIS for Process and Value

Management, EPSRC (grant),

Jan 2000 - June 2001, £55,156 + £33,705 industry

G7 Austin, Baldwin and Thorpe, ICD: RAIS for Integrating and

Streamlining the Supply Chain,

EPSRC (grant), July 2000 - June 2001, £31,910 + £14,364 industry

Details of the impact

The ADePT method attracted widespread interest from its launch at the

Institution of Civil

Engineers in 1999, with 130 senior industrialists attending an evening

meeting to learn about `An

Innovative Approach to Design Management'. This coincided with an industry

awaking to the

challenge of design management and ADePT won the DETR Quality in

Construction innovation

award with AMEC. Such was the response that Professor Austin and four of

his ex-researchers

(Andrew Newton, Paul Waskett, John Steele and Jamie Hammond) set up a

university spin-out

company Adept Management Ltd (AML) in 2001 largely with `Business Angel'

funding and personal

investment. The ADePT method was patented and licensed to a third party

software developer, and

AML provide a combination of consultancy, software and training services

to many leading clients,

contractors and consultants.

In 2008 the company made strategic decisions to open an international

office and to develop its

own software through a technology business financed from retained profits

and a second tranche

of private investment. The following four impacts of the underpinning

research have occurred in the

REF period.

1. Sustainable spin-out company

The underpinning research [R1-R6] has contributed directly to the

growth of Adept Management

Ltd [www.adeptmanagement.com,

C1]. The knowhow and IP (patent and process models) together

with staffing by Simon Austin and his four ex-researchers have created a

sustained business

success (despite the global economic downturn) generating £6.75 million in

turnover (2008-2012)

[C2] with 10 employees; the ADePT approach remains at the heart of

the company's business

model [C3], as do the four ex-researchers who have remained at the

helm of the company.

Reach and significance are evidenced by ADePT being adopted by many top

companies [C4] in

the construction sector (e.g. seven of the contractors rated the UK's top

10 by turnover in the

annual league table published by Building Magazine in July 2012),

including Balfour Beatty,

Skanska and Carillion [C5]. One Head of Design described how: "We

have been so impressed

with the methodology, we have bought software licenses and are training

design managers/co-

ordinators to manage the process in-house". The technique has also

been adopted by design and

project management consultancies (e.g. Arup, Atkins, Capita Symonds,

Ryder) and property

developers (e.g. Westfield, Dart Realty Ltd). The construction sectors

impacted include healthcare,

education, commercial offices, residential, highways, bridges, rail and

energy [C6].

The reach has extended beyond construction to other sectors such as

manufacturing, ship building

and aerospace, including organisations such as Dart, BAE Systems,

Rolls-Royce and Boeing. The

significance is underlined by ADePT winning a BAE Chairman's award in 2010

for shipbuilding

work (on the Type 26 frigate). Since, 2008 ADePT has been used on 94

commissions (60

individual projects), 81 of which were from repeat customers. For

instance, Skanska has used

ADePT on eleven occasions, John Sisk, ten times and Costain, nine times.

As one client explained

"A recommendation was given that ADePT should be used on all future

suitable projects, both in

the pre-tender stage and also during the project itself" [C6].

2. New technology business and products

Adept Management has invested over £1.1 million to develop the ADePT

Design Software Suite,

launched in 2008. In doing so, it made the transition from a service

provider to also a technology

provider. By becoming partners of Microsoft and Oracle, the `Builder'

software interfaces directly

with conventional scheduling software used globally for project management

and specifically

construction/manufacturing phase planning, enabling integrated design and

construction planning,

as conceived by the research [R2]. The `Manager' software

encapsulates the planning and control

functions first described as DePlan [R5], critical to maximising

the benefits of the method. Sales of

software licences (including support and training) totalling £540,000 [C2]

have been made,

including non-construction businesses such as Boeing and BAE Systems.

Adept Management also

delivered bespoke training courses on the ADePT approach to companies such

as Balfour Beatty,

Morgan Sindall, Kier, BAE Systems, CDM Smith in Boston MA, RQ Construction

in San Diego,

BNIM architects in Kansas City and the Westfield Group [C3].

3. US Office and international clients

Adept Management established an office in California in 2009 (trading as

AML Technologies) to

expand into the lucrative North American market. ADePT has been used on

£11 billion worth of

projects since 2008, in countries including the UK, US, Australia, Cayman

Islands, Sweden,

Nigeria, Saudi Arabia, the United Arab Emirates and Morocco (evidencing

reach). Examples of

significant projects include the King Abdulaziz International Airport

development in Jeddah, the

New Karolinska Hospital in Stockholm and Westfield Stratford City

Development in London [C4].

4. More efficient projects through better design management

The research team have run 14 three-day "Managing the design process"

training courses (since

2008) on the ADePT approach on behalf of Thomas Telford Training, to over

150 delegates from

companies including Transport for London, Qatar Petroleum, Anglian Water

Services, Toyota and

BP further evidencing reach [C7]. The ADePT approach is also

taught at various UK universities,

including Reading, Northumbria and Coventry.

Feedback from users of ADePT has highlighted its positive impact on the

planning and

management of design on complex projects. The impact was described in

terms of improvements

to the design process and project outcomes. Users of ADePT explained how

the technique had

resulted in "appropriate resource allocation", "lower design

costs" and "less problems on site".

Using ADePT had enabled them to "minimise reiteration", "reduce

the risk", "avoid delays", "see

how the design team is performing" and "demonstrate rapidly and

scientifically [to clients] the

impact of variations and their late decisions". ADePT was considered

to be "much quicker than the

traditional way of planning design" and consequently "saved me

time and money" and "made the

whole design and construction process much more transparent". In

terms of project outcomes,

these process improvements were seen to have resulted in "increased

time certainty" and

"improved cost certainties" [C6].

Sources to corroborate the impact

The following sources of corroboration can be made available at request.

C1 Adept Management Ltd website, www.adeptmanagement.com

(describes services offered and

sectors served)

C2 Adept Management Ltd annual company accounts

C3 Interview with a Director of Adept Management Ltd

C4 Adept Management Ltd client list (which differentiates ADePT

work from other consultancy)

C5 Building Magazine's list of "Top 75 Contractors 2012", 27 July

2012 (http://bit.ly/H0egD3)

C6 Client testimonials supplied by Adept Management Ltd

C7 Delegate lists sourced from Thomas Telford Training Ltd