16. Introduction of stone deflector in the design of the Airbus A400M Aircraft

Submitting Institution

Imperial College LondonUnit of Assessment

Aeronautical, Mechanical, Chemical and Manufacturing EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Aerospace Engineering, Interdisciplinary Engineering

Summary of the impact

Runway stones thrown up by aircraft undercarriage wheels can cause

considerable damage to the

aircraft structure. A model of runway debris lofting developed at Imperial

College has been used for

the new A400M military transport aircraft, which Airbus reported was

`absolutely needed' during the

successful development of a nose wheel debris deflector [5. A]. This

deflector dramatically reduces

the incidence and severity of the runway debris impacts and the associated

maintenance costs and

downtime of the new aircraft. Airbus has received 174 orders to date for

the A400M. An indication

of the cost savings comes from the Hercules C130K, the predecessor of the

A400M, which

incurred costs of up to £1M for each aircraft on active service in

Afghanistan for the repair of

runway debris damage. This cost is now eliminated for the Airbus A400M

aircraft.

Underpinning research

The underpinning research responsible for this impact was led by Dr

Greenhalgh from October

2006 to 2010 at the Aeronautics Department of Imperial College London. It

was funded through a

DSTL EPSRC CASE studentship. Before work started, there had been no

realistic, reliable means

of predicting the impact threat from runway stones hitting the

undercarriage of the aircraft. Using

information on runway debris characteristics, aircraft and tyre geometry

for take-off and landing

profiles, a model was devised to predict the likelihood of a tyre/debris

encounter. This model was

published as part of Reference 1. The next stage in the research was to

model the mechanisms by

which the debris, tyre and runway surface interacted to cause lofting and

to determine the initial

direction and speed of the projected debris. Initially, finite element

(FE) models using contact

mechanics were developed which captured the physics of the interactions

between the hard stone,

the ground and the compliant rubber tyre. The first models assumed solid,

cylindrical tyres [2, 3],

and these were extended to more realistic configurations, which, using

data from indentation

testing on aircraft tyres [4], included the inflation pressure and

detailed tyre geometries [1]. All

these models were validated against bespoke drop-weight experiments,

monitored with high speed

video, which reproduced key aspects of the contact conditions between the

stones, tyres and

ground. The understanding gained during the FE and experimental

investigations, enabled the

development of a physically-based analytical model [5] which was the first

to provide an insight into

the critical parameters which dictated the severity of the stone lofting

processes, such as tyre

geometry, stone mass and shape, and aircraft speed, and predicted the

direction and initial speed,

which included a significant spin component [1]. The kinetic energy

associated with spin could be

as much as 50% of the translational component. During a second research

project funded directly

by Airbus the models were further refined to incorporate the effect of the

multiple interactions that

occur when a wheel encounters a group of runway stones and to include the

geometry of the tyres

used on the Airbus A400M. Sang Nguyen received his PhD from the department

of Aeronautics

Imperial College for this work.

Having established a reliable model for the initial state of the lofted

stone at the start of its

projected motion, the next stage of research investigated the subsequent

motion of the debris to

enable prediction of the severity of any resulting impact on the aircraft.

This work was funded

directly by Airbus during 2011 and was led by Dr. Emile Greenhalgh with

Dr. Nguyen as a

postdoctoral researcher. Aerodynamic models were developed for the

interaction between the

spinning lofted stone and the airflow in the wake of the undercarriage

wheels and beneath the

fuselage [6]. The research focussed on the relative interaction between

the different aerodynamic

flows (such as tyre wake, aircraft boundary layer, ground effects and

turbulence) and the rapidly

spinning stones and culminated in the production of 'threat maps' which

identify the sites on the

aircraft lower fuselage that are exposed to the most severe impact

conditions.

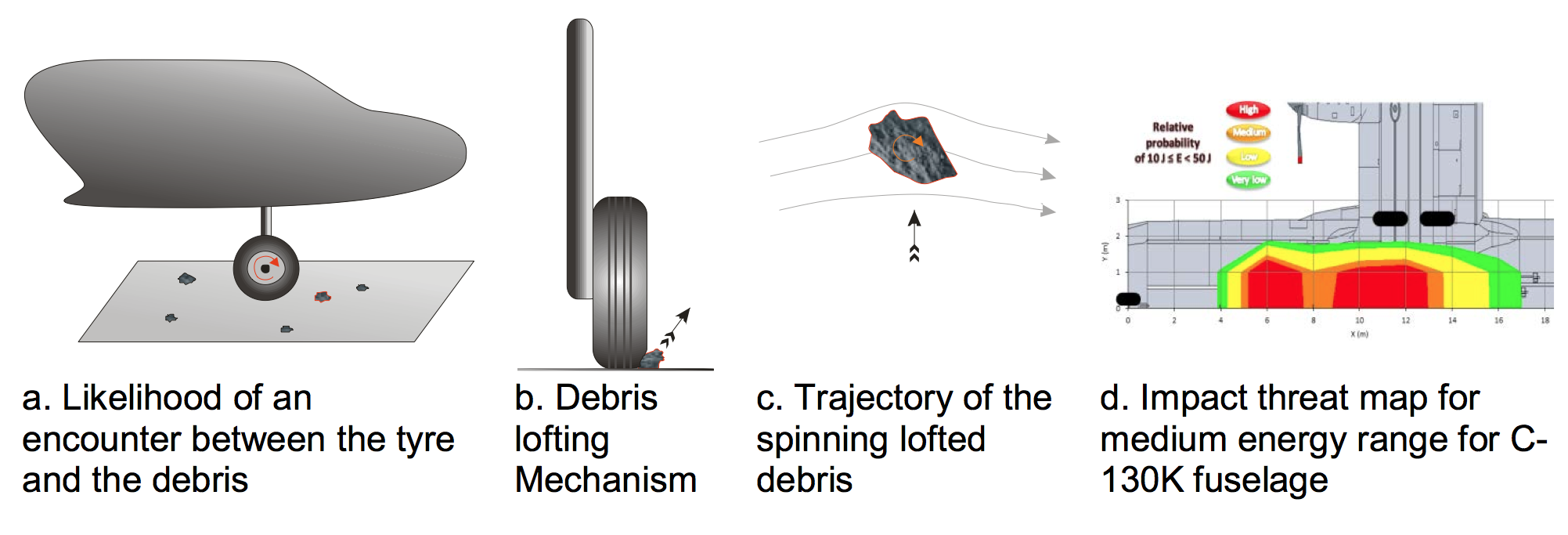

Figure 1: Overview of key research that led to impact

Figure 1: Overview of key research that led to impact

This is a unique capability that allows designers to optimise the damage

tolerance of

aerostructures exposed to such impact threats (i.e. undercarriage

components and lower

fuselage). The location and severity of debris damage predicted by the

model has been shown to

be in good agreement with that observed on aircraft such as C130K

Hercules.

References to the research

* References that best indicate quality of underpinning research.

[1] S.N. Nguyen, E.S. Greenhalgh, R. Olsson, L. Iannucci, P.T. Curtis,

"Improved Models for

Runway Debris Lofting Simulations", The Aeronautical Journal, Vol 113,

Issue 1148, pp. 669-681,

(2009)

This paper was the first model to quantify stone encounters for

realistic runway debris distributions

which was an essential step towards accurate assessment of the threat

posed by runway debris.

*[2] S.N. Nguyen, E.S. Greenhalgh, R. Olsson, L. Iannucci, P.T. Curtis,

"Modelling the Lofting of

Runway Debris by Aircraft Tyres", AIAA International Journal of Aircraft,

Vol 45, Issue 5, pp. 1701-1714,

(2008) DOI: 10.2514/1.35564

This was the first instance of a computational model to simulate the

stone lofting mechanism and,

together with the experimental validation, produced vital information on

the mechanism by which

spin is imparted to the debris.

*[3] S.N. Nguyen, E.S. Greenhalgh, R. Olsson, L. Iannucci, P.T. Curtis,

"Parametric Analysis of

Runway Stone Lofting Mechanisms", International Journal of Impact

Engineering, Vol 37, Issue 5,

pp. 502-514, (2010) DOI: 10.1016/j.ijimpeng.2009.11.006

*[4] S.N. Nguyen, E.S. Greenhalgh, R. Olsson, L. Iannucci, P.T. Curtis,

S. Longstaff, "Experimental

Characterisation of Tire Indentation by Simulated Runway Debris", Strain:

An International Journal

for Experimental Mechanics, Vol 47, Issue 4, pp. 343-350, (2011) DOI:

10.1111/j.1475-1305.2009.00704.x

[5] S.N. Nguyen, E.S. Greenhalgh, R. Olsson, "Analytical Modelling of

Runway Stone Lofting",

AIAA International Journal of Aircraft, Vol 48, Issue 4, pp. 1412-1421,

(2011) DOI:

10.2514/1.C031306

This paper described a physically-based analytical model which was the

first to provide an insight

into the critical parameters which dictated the severity of the stone

lofting processes, such as tyre

geometry, stone mass and shape, and aircraft speed.

[6] S.N. Nguyen, E.S. Greenhalgh, J.M.R. Graham, A. Francis, R. Olsson,

"Methodology for

Predicting the Threat of Runway Debris Impact to Large Transport Aircraft"

53rd

AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials

Conference,

Honolulu, 23-26, (April 2012) Paper no: AIAA 2012-1377.

Details of the impact

Military aircraft encounter a significant problem caused by damage from

debris or stones lofted by

the aircraft wheels onto the aircraft structure (see Figure 1 below). The

conventional approach to

designing against this threat is to essentially make an assumption about

the worst impact energy

(typically 50J) likely to occur during the lifetime of the aircraft. The

structure would then be

designed to tolerate any damage produced from such an impact when exposed

to the most severe

mechanical loading anticipated during its lifetime (i.e. design ultimate

load). However, such an

approach is not rigorous, and makes several assumptions regarding the type

of impact conditions

and the resulting damage. With weight being critical for aerospace design,

overdesign of a

structure imparts a considerable penalty; but if the

perceived level of threat is underestimated, this could

lead to parts of the aircraft being susceptible to

damage during service, with potentially catastrophic or

very costly implications. The latter is the case for the

Lockheed C130K Hercules transport aircraft which the

RAF have been using in the Gulf and Afghanistan and

for which repair of runway debris damage is up to £1M

per aircraft (source: verbal discussions with MoD and

DSTL staff [A]).

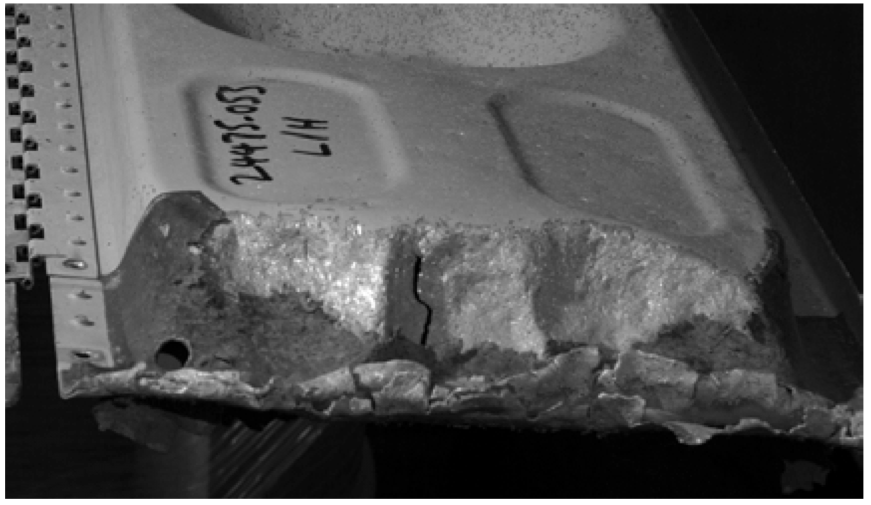

Fig 1 Runway debris damage to the leading edge of an undercarridge door of a transport aircraft

Fig 1 Runway debris damage to the leading edge of an undercarridge door of a transport aircraft

During initial work investigating the physics of the

interactions between the hard stone, the ground and the compliant rubber

tyre, the Head of

Landing Gear Structures in Airbus Military (Spain) approached Dr

Greenhalgh. He was interested

in further developing the understanding of lofted debris and provided

support for this work as

outlined in section 2.

This research then had an immediate pathway for significant impact and

has been relied upon by

Airbus during the 2011 in designing the Airbus A400M Aircraft. The

research allowed Airbus to

quantify the severity of the threat to aircraft from runway debris and so

enabled engineers to

reliably design efficient aircraft structures to tolerate this threat [A].

The debris lofting model was

able to predict the potential damage to the lower fuselage of the A400M

aircraft from lofted runway

debris. This was used in the design of a deflector plate for the nose

landing gear (NLG) which

would protect the lower fuselage from lofted stone damage. In particular,

the models developed at

Imperial were used to optimise the shape and exact position of the

deflector plate [A].

In May 2012, The Head of Landing Gear Structures at Airbus commented that

the research

undertaken by Imperial College was "absolutely needed, because landing on

unprepared runways

was a new concept inside the Airbus Aircraft Family" and went on to state

"The model identified the

most critical parts on the fuselage, predicting in a reliable way the

probable trajectories for a stone

lofted by the NLG tyres and making it possible to start developing

protections and devices that help

to minimize the effect of such impacts during the operation on unprepared

fields" The results of the

Imperial model "confirmed the need of a stone deflector to help protect

the belly of the A400M" and

allowed Airbus "to improve the efficiency of such a stone deflector in the

series design". The results

of the model developed have subsequently been shared inside the Airbus

Community, and have

raised interest from other areas as such as Power Plant and Dynamic

Analysis [B].

As has been demonstrated above, the research has had a direct impact on

the design of the new

Airbus A400M. This has enabled one of the features of the plane to be

reduced operational costs

compared to its predecessor the Hercules C130K. The A400M has had

successful test flights and

is now being manufactured with over 174 orders in place as at 30th June

2013 [C]. The results of

tests undertaken in the summer of 2013 on an unsurfaced runway covered

with gravel of different

sizes confirmed predictions made by the model and the efficacy of the

deflector plate [B].

Sources to corroborate the impact

A. Flight lieutenant, Hercules IPT - Confirmation of the runway debris

repair costs of £1M for

a Hercules C130K

B. Head of Landing Gear Structures, Airbus Military - Corroboration of

the impact of the

research on Airbus design and results of subsequent full scale test

landing on the prototype

aircraft.

C. Airbus Military "Orders, Deliveries, In Operation aircraft by country-

Worldwide" pg. 3

(2013)

http://www.airbusmilitary.com/Portals/0/Images/Aircraft/OrdersAndDeliveries/AMOrdersDeliveries.pdf

Archived here

on 17/09/2013.Corroboration of 174 orders for the Heavy Transport

Aircraft Airbus A400M.