18. Improving survivability of protective structures through novel design and modelling

Submitting Institution

Imperial College LondonUnit of Assessment

Aeronautical, Mechanical, Chemical and Manufacturing EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Aerospace Engineering, Civil Engineering, Materials Engineering

Summary of the impact

The vulnerability of both military and civilian infrastructure to the

threat of terrorist activity has highlighted the need to improve its

survivability, and this poses a significant design challenge to engineers.

Research work at Imperial has led to the development of novel constitutive

relationships for polymeric materials coupled to novel analysis

procedures; software algorithms for effective simulations of blast and

impact events; and enhanced experimental testing methods allowing a

fundamental understanding of the structures. According to Dstl, this body

of research has `unquestionably improved the security and effectiveness

of the UK armed forces operating in hostile environments abroad as well

as the safety of citizens using metropolitan infrastructure within the

UK'. The techniques have been applied to vehicles and UK

infrastructure, including for high profile events, such as the 2012

Olympics.

Underpinning research

Research projects funded by the EPSRC, European Union, TSB and MoD (Dstl)

over the past ten years have contributed to the development of this

research area. The overall aim of this research activity has been to

develop sophisticated modelling techniques that are capable of simulating

the complex phenomena associated with the deformation of polymeric armour

materials under high velocity impact loadings [C, F]. The research has

also contributed to the development of sophisticated meso-scale modelling

methods for advanced materials and structures, which have been implemented

into bespoke and (protected) commercially-available numerical simulation

software [E,D,F]. The clearer insight into the dynamic response mechanisms

of the current protective materials has also provided a strong foundation

for the micro-scale design of significantly better systems in the near

future [B], Figure 1 and 2.

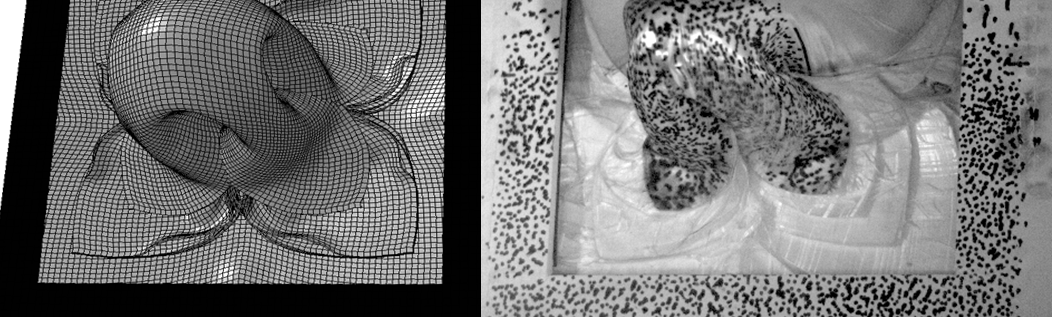

Figure 1: Ballistic impact into Dyneema armour panels at 1km/s with

60g copper projectile. Left: Improved numerical predictions; Right:

Experimental test (from Figure 2 test).

Figure 1: Ballistic impact into Dyneema armour panels at 1km/s with

60g copper projectile. Left: Improved numerical predictions; Right:

Experimental test (from Figure 2 test).

The evolution of the modelling approaches for high performance composites

can be divided into the development of delamination failure modelling and

in-plane failure modelling techniques.

Delamination failure modelling (using the cohesive element approach) was

originally developed for implicit finite element codes within the

Aeronautics Department by Professor Mike Crisfield [97-02] and later

adopted for use in commercially available explicit finite element codes.

In parallel with the original cohesive element approach a number of

in-plane composite failure models were developed specifically for impact

and blast and implemented into finite element codes [2, 3]. In recent

years new advanced fracture-based failure models for in-plane failure were

devised and these have been key in the development of new impact modelling

approaches [3, 5]. In parallel with the modelling developments a number of

novel testing and examination procedures [6] have been developed to

understand the physical processes which occur during severe loadings and

to measure key material parameters[1, A]. The resulting two- and

three-dimensional numerical modelling of composite materials, validated

with extensive experimental studies, has greatly improved the

phenomenological understanding in this field and enabled a much more

accurate response prediction of protective structures when exposed to

blast and ballistic loading [5, B, F]. Most recently these modelling

techniques have been applied to the development of techniques to improve

the design of polymer armours and polymer composites [4, B] subject to

severe loadings. This deeper understanding has also led to the development

of fundamentally new armour concepts based on recycled and micro-braided

materials [F].

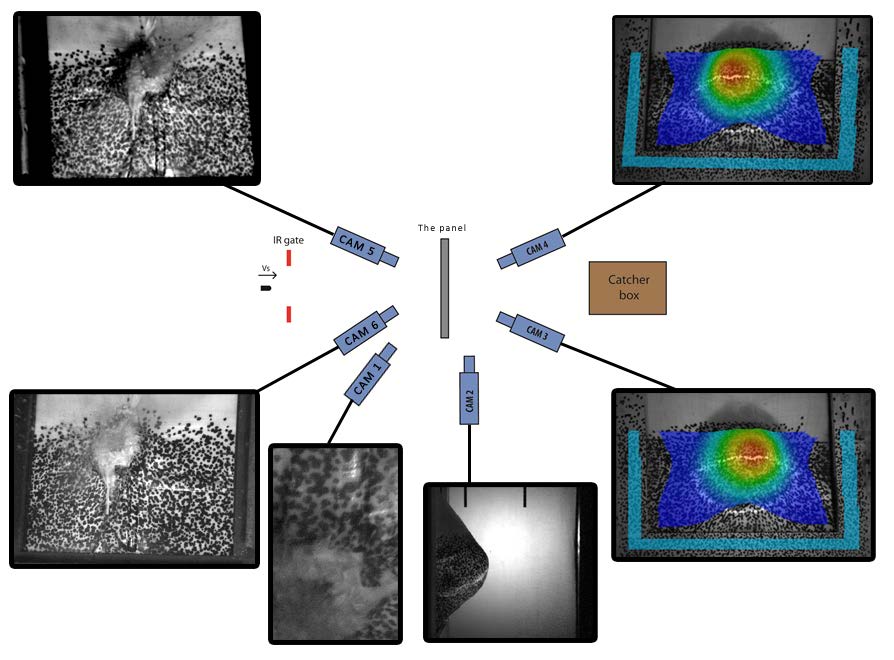

Figure 2: Enhanced ballistic testing of high performance composites

Figure 2: Enhanced ballistic testing of high performance composites

References to the research

* References that best indicate quality of underpinning research.

*[1] S.T. Pinho, P. Robinson, L. Iannucci, "Fracture toughness of the

tensile and compressive fibre failure modes in laminated composites",

Composites Science and Technology, Vol 66, pp. 2069-2079, (2006), DOI:

10.1016/j.compscitch.2005.12.023.

This original publication presents procedures to determine the

intralaminar fracture toughness of composites which led to the

successful award of the Dstl/EPSRC (C) project and has been incorporated

into models used by Dstl for impact and blast and for AIRBUS

vulnerability airframe design (F).

*[2] L. Iannucci, M.L. Willows, "An energy based damage mechanics

approach to modelling impact onto woven composite materials - Part I:

Numerical models", Composites Part A - Applied Science and Manufacturing,

Vol 37, pp. 2041-2056, (2006), DOI: 10.1016/j.compositesa.2005.12.013

The initial development work which led to the 3D constitutive model for

high performance fibres. This was key background knowledge for the award

of the Dstl/EPSRC (C) and MAAXIMUS (D) grants.

*[3] M.V. Donadon, L. Iannucci, B.G. Falzon, J.M. Hodgkinson, S.F.M. de

Almeida, "A progressive failure model for composite laminates subjected to

low velocity impact damage", Computers & Structures, Vol 86, pp.

1232-1252, (2008), DOI: 10.1016/j.compstruc.2007.11.004

The paper provides an original implementation into ls-dyna of an impact

constitutive model with mesh objectivity for composites. This approach

was used to successfully win the CEC MAAXIMUS (D) and the DTI IPSoFACTo

(E) projects. The approach has also been used to support AIRBUS on their

vulnerability studies, AIRBUS projects (F).

[4] L. Iannucci, D. Pope, "High velocity impact and armour design",

eXPRESS Polymer Letters, Vol 5, No 3, pp. 262-272, (2011), DOI:

10.3144/expresspolymlett.2011.26

The original approach in this paper resulted in the award of the

RAEng/Dstl chair (B) on multiscale armour design, and provided an

outline procedure to develop the 3D modelling approaches (F).

[5] L. Raimondo, L. Iannucci, P. Robinson, P.T. Curtis, "Modelling of

strain rate effects on matrix dominated elastic and failure properties of

unidirectional fibre-reinforced polymer-matrix composites", Composites

Science and Technology, Vol 72, pp. 819-827, (2012), DOI:

10.1016/j.compscitech.2012.02.011

This paper presents a fundamental output of the TSB IPSoFACTo (E) and

Dstl/EPSRC (C) grants on impact, and has led to a new US-UK government

collaboration on high velocity impacts, via grants (A) and (B).

[6] E.S.

Greenhalgh, V.M.

Bloodworth, L.

Iannucci, D.

Pope, "Fractographic observations on Dyneema® composites under

ballistic impact", Composites Part A: Applied Science and Manufacturing,

Vol 44, pp. 51-62, (2013), DOI: 10.1016/j.compositesa.2012.08.012

This paper presented a detailed examination of a polymer armour panel.

This led to the award of the MAST polymeric armour project (March 13,

£480k) and the multiscale polymer design grant (B). The insight also

allowed the successful award of Dstl PhD CASE award (F) and CDE award

(F) on novel recycled approaches to armour.

3.1 Grants supporting the research

[A] Dstl, Development of improved of improved modelling and materials

for protective/armour systems, 24 months, July 2012, £200k,

L Iannucci(PI).

[B] RAEng/Dstl, Chair: Multiscale Armour Design, 60 months, April

2011, £455k, L Iannucci(PI).

[C] EPSRC/Dstl, Development of improved of improved modelling and

materials for protective/armour systems, 36 months, Oct 2009, £1275k,

L Iannucci(PI), L Louca, P Robinson.

[D] CEC, MAAXIMUS: more affordable aircraft through extended

integrated and mature numerical sizing, 36 months, Nov. 2008, £230k,

L Iannucci(PI).

[E] DTI/TSB, IPSoFACTo, Shock and impact for hostile

environments, 36 months, April 2006, £336k, L Iannucci(PI),

P Robinson.

[F] Approximately £800k of further funding via projects from

Dstl, EPSRC, AIRBUS, and EU.

Details of the impact

Improving the survivability of vital infrastructure is vitally important

to the development of military technology, and, due to the increased

threat of terrorist activity, to civilian installations. Research at

Imperial between 1993-2013 led to a major advance in the ability to

virtually design a range of protective components, which are often very

expensive or impractical to test, and provided improved performance and

significant cost savings to the UK between 2008 and 2013. New blast,

impact and ballistic modelling techniques developed at Imperial were

applied in the military sector to investigate improved materials and

designs for protective components. As a result Dstl has been able to

develop lighter, more effective armour for both military vehicles and the

dismounted soldier, providing personnel with better protection and

superior operational performance. These improvements were achieved with

significant cost savings and, more importantly, have ultimately

contributed to the saving of many lives during expeditionary operations.

Within the UK MOD the development and procurement of military vehicles

represents a significant portion of the annual defence budget. A typical

development cost for a single vehicle is £500M. A critical part of this

process is to ensure that the occupants of the vehicles are properly

protected against potential explosive and penetrative threats present in

the current theatres of operation. While initial financial outlay for the

protection of a vehicle would typically amount to £10M, the total cost for

protection development over the lifetime of each vehicle will be

significantly higher due to the need for system retrofitting as new

threats or operational requirements emerge. [a]

The research findings have also been used to address the emerging and

increasingly severe threat of terrorist activity, which has highlighted

the vulnerability of vital infrastructure. Testing undertaken at Imperial

to characterise the structural components of civilian aircraft has enabled

Government scientists to better simulate the failure mechanisms associated

with internal explosive detonations, and therefore identify and mitigate

potentially critical terrorist scenarios. This capability has been used to

assess the explosive performance of a wide range civil aircraft structures

manufactured by Airbus and Boeing. Quick-running algorithms developed by

Imperial to predict blast effects for operational analysis have been

integrated within the Government-developed HIP (Human Injury Prediction)

code. This is now being used by security analysts both within the UK and

in friendly nations abroad to implement appropriate security measures

within transport infrastructure and high-profile public events (such as

the London Olympics[a]).

Dstl has summarised the benefits of this research activity as follows:

`The Department of Aeronautical Engineering at Imperial College London

have provided key expertise to Dstl in the field of physical protection

for many years. Although it is difficult to place a financial value on

these state of the art, technical advancements, their contributions have

unquestionably improved the security and effectiveness of the UK armed

forces operating in hostile environments abroad as well as the safety of

citizens using metropolitan infrastructure within the UK.'

The resulting improvement in model fidelity has led to a vast reduction

in the number of expensive tests required to confirm the veracity of a

particular amour variant. A typical purely experimental trial to assess an

armour design against one of the many potential threats costs over £100K.

Conservative estimates indicate that the cost of undertaking the same

design exercise but replacing all but the key experiments with numerical

simulation are one third of this amount.

Sources to corroborate the impact

[a] Capability leader, Structural Dynamics, Dstl Porton Down, Physical

Protection Group & Material and Structures Group. (for

corroboration of the Dstl statements regarding the impact of this

research)