Automatic measurement of difficult solid objects in unstructured and challenging environments

Submitting Institution

University of the West of England, BristolUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Information and Computing Sciences: Artificial Intelligence and Image Processing

Medical and Health Sciences: Neurosciences

Summary of the impact

Companies in the manufacturing, construction, courier, freight and

airline industries have made use of Photometric Stereo based imaging

technology, developed by the Centre for Machine Vision (CMV) at UWE

Bristol, to capture 2D and 3D data simultaneously. This has enabled them

to develop new products for large volumetric measurement, characterisation

of aggregates, tile quality control and automotive wheel alignment. These

examples have addressed hitherto challenging tasks or have extended

functionality to new or poorly structured environments, for instance: (i)

the robust capture of accurate 3D data from postal packages exhibiting

complex shape and coloration; and (ii) a new capability for distinction

between printing and moulding defects during fast moving tile quality

control — previously impossible. In all cases ultra-low-cost equipment is

used — underlining the attractiveness of the techniques developed by the

CMV.

Underpinning research

Research at UWE's Centre for Machine Vision (CMV) has developed

photometric stereo (PS) imaging techniques that can be used in

unstructured, real-world environments, away from the ordered and

controlled environment of the laboratory. Three key advances of the

underpinning research are as follows:

- CMV has developed techniques to extract a "bump map" from objects — a

3D texture that can be "peeled off" a surface, allowing the colour, 3D

texture and underlying surface to be isolated and inspected from any

angle;

- PS techniques from elsewhere can only image in a static way, whereas

CMV's approach was the first to succeed in doing this for a moving

object or one with non-ridged surfaces; and

- others have worked in a lab setting with idealised illumination, i.e.

a small specialist lighting source at a distance, whereas CMV's method

has worked with cheap off-the-shelf lights placed close by.

The following people were involved: Prof Melvyn Smith (Director

of the CMV); Dr Lyndon Smith (Co-director of the CMV); Dr Gary

Atkinson (Senior Lecturer, CMV); Dr Abdul Farooq (Senior

Lecturer, CMV); and Dr Jiuai Sun (Lecturer, CMV).

Photometric stereo (PS) for practical surface metrology, inspection and

analysis was pioneered at UWE's CMV (formerly named the Machine Vision

Laboratory) in the 1990s (R1). Before this, no practical means existed to

capture detailed 3D topography at sub-pixel resolution to identify

objects, textures or defects while camouflaged by complex surface

reflectance/colour patterns, which obscure topography.

Prior work had tended to concentrate on the `reverse engineering' of 3D

objects, for which the application of conventional PS per se was

problematic. Early research insight at CMV by M. Smith in 1999

identified PS as advantageous for the capture of fine 3D surface features

at sub-pixel resolution from predominantly planar surfaces. A key

development by M. Smith, L. Smith and Farooq in

2005, Dynamic PS, served to extend the technique from static to moving

scenes. M. Smith and Farooq established techniques from

2000 to 2006 that could isolate concomitant 3D and 2D surface features for

inspection of fast moving decorative ceramic tiles (R2) and other natural

materials, such as polished stone (R3).

In 2003 M. Smith and L. Smith also identified PS as

offering a useful synergy with other established 3D imaging techniques,

such as laser and stereo triangulation, where novel hybrids offered new

functionality by combining the excellent high-resolution but poor

low-resolution performance of PS with the complementary attributes of

conventional 3D imaging. In addition, because PS allowed the appearance of

surface colour to be depressed, while isolating and amplifying 3D shape

attributes, the technique was identified as potentially useful in

simplifying a wide range of conventionally difficult unstructured imaging

tasks.

CMV was able to overcome a major obstacle to the practical application of

PS: the step from a static to moving imaging technology (M. Smith

in 2005), together with a number of other limiting practical issues. The

solution was realised by allowing PS to operate in unconstrained moving,

cluttered, changing or confined environments and to integrate the

technology with existing techniques. This was first achieved by M.

Smith, L. Smith and Farooq between 2000 and 2005 by

introducing a patented multiplexing approach — either space, frequency or

temporally based — to realise a new dynamic form of PS.

By 2005, the investigation of novel hybrid PS methods and advanced

modelling by M. Smith and L. Smith culminated in a

practical dynamic or moving PS demonstrator (R5). In 2007, this research

established the minimum number of illuminates (six) to allow any convex

object to be fully recovered, and later (by Sun and M. Smith

in 2007) to new models allowing use of practical low-cost hardware, such

as non-specialist illumination (R4). These findings were particularly

important in widening application and in realising practical commercial

applications of PS able to address conventionally challenging imaging

tasks, such as the segmentation, characterisation and metrology of

embedded 3D objects in complex scenes and in using PS at close range (1mm)

or at a large stand-off (50m and more).

More recently, the outcomes of this earlier research in using PS to

robustly capture 3D data in industrial application for metrology and

complex shape characterisation have opened up new avenues at CMV exploring

further advanced forms of PS and analysis methods in unstructured

environments. These have been investigated in applications such as: (i) 3D

facial recognition by M. Smith and Atkinson (2007 to

date), where PS-derived surface normals have been shown to offer the most

effective face biometric data; (ii) skin analysis and respiratory

assessment by L. Smith (2008 to date); and (iii) facial expression

and emotion analysis (M. Smith in 2012-13), where high- resolution

3D micro-expressions have been captured for the first time.

References to the research

Publications

R1 Smith, M. L. (2001). Surface Inspection Techniques — Using the

integration of innovative machine vision and graphical modelling

techniques. John Wiley & Sons Ltd, 256 pages. ISBN 1-86058-

292-3.

R4 Sun, J., Smith, M. L., Smith, L. N., Midha, S. and Bamber, J. (2007).

Object surface recovery using a multi-light photometric stereo technique

for non-Lambertian surfaces subject to shadows and specularities. Image

and Vision Computing, 25 (7) — Special Issue on Computer Vision

Applications, 1050-1057. http://dx.doi.org/10.1016/j.imavis.2006.04.025

Grants (reverse chronological order and showing total grant

values)

Shape and outline amplification using 2.5D and 3D imaging. A new tool

for covert surveillance aimed at real threat identification such as left

object detection, M. Smith, DSTL, 2012, £60k

Intelligent Advertising Proof of Concept, M. Smith, TSB Smart

award, 2012-13, £100k

Research and develop new 3D metrology equipment within the automotive

sector, commercial, M Smith, 2011-12, £100k

Intelligent Video Surveillance KTP, A Farooq, 2010-13, £215k

Skin Reflectance and Face Shape Estimation Using Photometric Stereo

(PhotoSkin), G Atkinson, EPSRC, 2010-13, £127k

Novel non-invasive assessment of respiratory function (NORM), L

Smith, NIHR i4i Stream 1, 2008-10, £125k

Use of 3D Facial Asymmetry in Better Diagnosis and Treatment of

Plagiocephaly, M Smith, MRC, 2008-9, £120k

Innovative Technology for the Quality Control of Specular Ceramic

Materials using a Specular Photometric Stereo Sensor, M Smith, Great

Western Research and Surface Inspection Ltd, 2007-10, £75k

Face Recognition using photometric Stereo (PhotoFace), M Smith,

EPSRC, 2007-10, £672k

Application of Photometric Stereo in Dermatology (PhotoDerm), M

Smith, 2007-10, DTI, £647k

Stealthy Object Detection and Recognition, M Smith, 2007-8, MOD,

£154k

Visual inspection of polished stone, M Smith, EU 5th Framework,

2003-5, €1.3 million

Petroscope: visual 3D characterisation of aggregate materials, M

Smith, DTI Eureka Initiative, 2002-4, €1.43m

Photometric stereo for tile inspection, M Smith, EPSRC and Surface

Inspection Ltd, 2000-4, £169k

Irregular object metrology, M Smith, Commercial, multiple projects

2000-13, £119k

Details of the impact

The research developments that took place at CMV attracted much interest

from companies in the manufacturing and construction sector. This led to a

range of commercial applications in: (i) ceramic tile manufacture

inspection; (ii) polished stone defect inspection; and (iii) 3D

characterisation of aggregate materials. All of these followed from CMV's

work on evolving static PS to dynamic PS. Further application has been in:

(iv) 3D automotive wheel alignment; and (v) the segmentation and

characterisation of large objects. Both these followed from CMV work in

isolating 2D and 3D data, as detailed below.

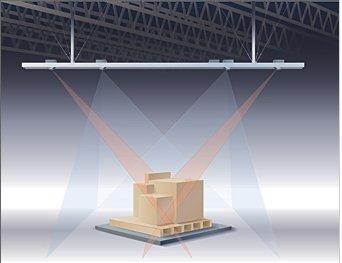

One of the companies that approached the CMV was Quantronix Inc,

an American company operating globally, specialising in object metrology

for freight forwarding. In 2000 the company funded the CMV to develop an

Overhead Dimensioning System (ODS — see right) able to rapidly acquire 3D

data from any object(s) of up to 3m x 3m in size. CMV researchers

developed the system using the PS method (hybrid) and in 2001 the

innovation was protected and a patent application filed by the company. In

2004, a full prototype ODS was realised with a commercial product, known

as the CubiScan 1000-VS, becoming available in 2009.

First sales were made to an international freight forwarder and, since

then, over 40 systems have been sold in the US and in other countries,

including ten to FedEx and one to our own MOD at $50k each, with a total

value of over $1m. A range of benefits were delivered to their customers,

through new capability and more efficient processes. For instance,

courier, freight handlers and airlines customers, including FedEx, have

used it to measure the sizes of packages automatically, enabling them to

achieve efficiency gains by reducing both time for measurement and

previous losses due to inaccurate manual measurement, offering an average

3-week payback (S1) and other benefits such as reduced fuel consumption,

pollution and packaging materials.

Government facilities (MOD) and retail customers have been able to

optimise the use of storage space, handling assets and processes, with one

customer reporting that "one of the CubiScan 1000-VS machines they

purchased... generated over $1 million additional revenue for the

company in one year" (S1). The impact of the ODS has been continuous

since its availability and has resulted in broadening Quantronix's

in-house knowledge base to include vision-based technology. The company

has now produced a business case for developing a countertop device based

on CMV PS vision technology (S1). For this, they returned to CMV in

2012/13 to undertake the necessary R&D incorporating some of the

latest hybrid PS approaches and a new system developed by CMV is now

scheduled for release this year.

CMV's leading research in 3D metrology attracted a new collaboration from

a company in India in 2011 — Precision Testing Machines Pvt Ltd

(PTM) — which operates in the automotive sector and is the lead supplier

of sophisticated automotive diagnostic and body shop equipment

manufactured in India. A non-contact optical measuring device for

automatic automotive wheel alignment was developed by CMV, minimising

subjectivity, operator error and allowing faster throughput. In 2012, the

demonstrator was handed over to PTM engineers to develop the system to

commercial requirements. [text removed for publication]

Another application has been that of the Dynamic PS prototype developed

by CMV in 2005 for Surface Inspection Ltd, a global company which

specialises in machine vision systems and automation equipment for the

ceramic tile industry. The system developed was used to detect, isolate

and characterise concomitant 2D printing (including colour and glossiness)

and 3D moulding defects on complex surfaces with deeply relieved

topographic features and is currently in use for quality control in

ceramic tile manufacturing worldwide (S3). [text removed for publication]

The final application has been the Petroscope system developed by CMV for

Petromodel, a knowledge-based company based in Iceland, providing

software and high-technology testing instruments for quality and process

control in the aggregates industry. The Petroscope replaces labour

intensive techniques and is shaping the inspection methodology used by the

construction mineral industry (S4). A patent for this work was filed in

2004 and granted in USA and Eurasia in 2012 and in China in 2013. This

system has been demonstrated in a commercial environment for petrographic

analysis, including the characterisation of the complex 3D morphology of

aggregate particles using techniques developed as part of CMV's earlier

work in 3D face recognition, with use in the construction sector and

benefiting companies producing gravel and crushed rock for asphalt,

concrete, and railways. The system is currently being marketed and a new

version including composition (PETROSCOPE 4D) has been under test by the

Austrian railways (Jan — Aug 2013) (S4).

Sources to corroborate the impact

Testimonials listed below are available from UWE, Bristol, and

numbered on REF system in same order as below.

S1 Testimonial from CEO of Quantronix Inc, USA. Large object metrology —

corroborates customers' benefits and device sales to date, including use

by courier, freight handlers and airlines

S2 Testimonial from Managing Director of Precision Testing Machines Pvt

Ltd, India. Corroborates benefits and sales of device developed by CMV,

UWE, that automatically measures the alignment of car wheels.

S3 Testimonial from Chief Technical Officer of Surface Inspection Ltd,

UK. Corroborates benefits in surface analysis for tile inspection.

S4 Testimonial from Founder and Managing Director of Petromodel, Iceland.

Morphology of particles in petrographic analysis — corroborates benefit in

new technology for petrographic analysis.