UOA10-01: Computational fluid dynamics: the Rolls-Royce HYDRA code for jet engine design

Submitting Institution

University of OxfordUnit of Assessment

Mathematical SciencesSummary Impact Type

TechnologicalResearch Subject Area(s)

Mathematical Sciences: Applied Mathematics, Numerical and Computational Mathematics

Information and Computing Sciences: Computation Theory and Mathematics

Summary of the impact

Rolls-Royce uses the HYDRA computational fluid dynamics (CFD) code for

the design of all of its

new gas turbine engines. The HYDRA CFD package, including the mathematical

theory behind it,

was developed by Professor Mike Giles and his research team in the period

1998-2004 at the

University of Oxford, and subsequently transferred to Rolls-Royce, forming

the basis of the RR

corporate CFD strategy with an investment of over 100 person years in

development.

Since 2009, HYDRA has become the standard aerodynamic design tool across

Rolls-Royce, and

has been used to design Rolls-Royce's Trent 1000 engine and the newer

Trent XWB. HYDRA has

enabled Rolls-Royce to save over [text removed for publication] in

test rig expenses, provides

superior accuracy compared to its competitors such as FLUENT, and has

contributed to increases

in engine efficiency of up to [text removed for publication],

which in turn has led to higher sales

and increased revenue for Rolls-Royce.

Underpinning research

In 1993, Professor Mike Giles of the University of Oxford established the

Rolls-Royce University

Technology Centre (UTC) in Computational Fluid Dynamics. Part of the

Numerical Analysis Group,

it was created to investigate and develop mathematical and computational

techniques for use in

the analysis and design of turbo-machinery.

The development of HYDRA, a programme of work at the University of Oxford

running from 1998

to 2004, was led by Professor Mike Giles and was sponsored by Rolls Royce

with supporting

funding from EPSRC. Based on identified Rolls Royce requirements, Giles

set four key goals for

his team: that they should use efficient multi-grid iterative solvers on

complex unstructured grids to

model problems with complex engine geometries; that they should enable the

efficient computation

of linear and nonlinear unsteadiness due to blade flutter and forced

response; that they should use

adjoint design techniques to improve the speed of design optimisation; and

that the whole

computation should execute very efficiently on distributed-memory parallel

clusters.

Turbomachinery flows have hydrodynamic shocks which can be modelled

mathematically as

discontinuities in the flow properties. In prior work, Giles was the first

to show that linear

perturbation methods could be used to analyse the effect of shock

oscillations in inviscid flows.

This was an important background result for the development of HYDRA at

the University of

Oxford, but new research was required to develop efficient multi-grid

solvers for linear unsteady

viscous flows [3].

Giles and his team also developed new adjoint techniques [2,4] to improve

the efficiency of

optimisation calculations. The team moved away from existing adjoint

techniques, instead

developing their own so-called "discrete" approach in which the nonlinear

discretisation is

linearised and then the transposed matrix defines the discrete adjoint

equations. While other

research groups were also working on the subject, HYDRA research pioneered

many of the

developments in the area, including the use of Automatic Differentiation

software to construct

discrete adjoint equations.

Taken as a whole, these advances were combined by Giles' team into a

complete CFD package

called HYDRA which offered:

- use of complex unstructured grids composed of a mix of different

element types, to give

maximum geometric flexibility to handle complex turbomachinery

geometries, including tip

gaps, disk cavities, cooling slots, and internal cooling passages;

- an efficient multigrid solver for time-averaged steady flow

calculation, and for solving the

implicit nonlinear system of equations which comes from approximating

nonlinear unsteady

flow calculations;

- the ability to analyse linearised harmonic unsteady flow perturbations

for both forced

response and flutter analysis;

- an "adjoint" design capability to efficiently compute the sensitivity

of output quantities, such

as engine efficiency, to changes in any one of possibly hundreds of

design variables.

The parallelisation aspects were handled by building on preparatory

research undertaken between

1993 and 1998. This made it possible to hide the parallelism, from both

the HYDRA CFD users

and crucially the HYDRA developers in Oxford, allowing them to concentrate

their efforts on

developing new features within HYDRA [1]. This was a forerunner of modern

high-level abstraction

techniques which are an active research topic today in computer science

addressing the

challenges of many-core computing.

Key researchers from the University of Oxford:

Mike Giles: Reader (1992-1997), Professor (1997-present); Paul Crumpton:

PDRA (1993-1997);

Niles Pierce: PDRA (1997-1998); Mihai Duta: PDRA (2002-2005); Jens Muller:

PDRA (1997-2002)

References to the research

[1] P.I. Crumpton and M.B. Giles. `Multigrid aircraft computations using

the OPlus parallel

library'. pp.339-346 in Parallel Computational Fluid Dynamics:

Implementations and Results

Using Parallel Computers, A. Ecer, J. Periaux, N. Satofuka, and S. Taylor,

editors, North-Holland, 1996. DOI: 10.1.1.48.9819.

Key paper on OPlus parallel framework on which HYDRA is built.

* [2] M.B. Giles, M.C. Duta, J.-D. Muller and N.A. Pierce. `Algorithm

developments for discrete

adjoint methods'. AIAA Journal, 41(2):198-205, 2003. DOI: 10.1.1.10.262.

Key paper, in international journal, on adjoint algorithms in HYDRA;59

Citations (Web of

Science), 108 citations (Google Scholar).

* [3] M.S. Campobasso and M.B. Giles. `Stabilization of a linear flow

solver for turbomachinery

aeroelasticity by means of the recursive projection method', AIAA Journal,

42(9) 1765-1774,

2004. DOI: 10.1007/978-3-540-74460-3_24.

Key paper, in international journal, on linearisation problem; 13

citations (Web of Science),

23 citations (Google Scholar).

* [4] M.B. Giles and NA Pierce. `An introduction to the adjoint approach

to design', Flow,

Turbulence and Combustion, 65(3-4):393-415, 2000. DOI: 10.1.1.135.6053.

Overview paper in international journal; 130 citations (Web of

Science), 280 citations

(Google Scholar).

The three asterisked outputs best indicate the quality of the

underpinning research. All these

papers report research performed exclusively at the University of Oxford.

Details of the impact

The impact is economic: enhanced design capabilities based on the

research have resulted in a

superior product and substantial time and cost savings. The beneficiary is

Rolls-Royce, a world

leader in the design and manufacture of gas turbine engines for aircraft,

ships, power generation

and other applications. Rolls-Royce has been hailed as a star of the

manufacturing sector by the

UK Government, bucking the trend of many of its peers by achieving a total

revenue of over £12.2

bn and record profits of £1.4 bn in 2012 [A], with 85% of its sales abroad

[B] bringing valuable

income to the country, as well as providing employment for almost 20,000

in the UK alone [C].

From research to impact. Rolls-Royce uses CFD codes to simulate

the flow of fluids in and

around all products, including the flow of air through all components of

diesel or gas turbine

engines and their installations [D]. In 2004, Rolls-Royce received from

Oxford the first production

version of the HYDRA CFD code for testing. In 2006 it was established as

the company's

compressor design tool, and by 2009 it had become the design tool for

multiple businesses across

Rolls-Royce — including gas turbines, air and thermal systems, and power

generation [E]. It is one

of the few codes that the company uses for CFD [D].

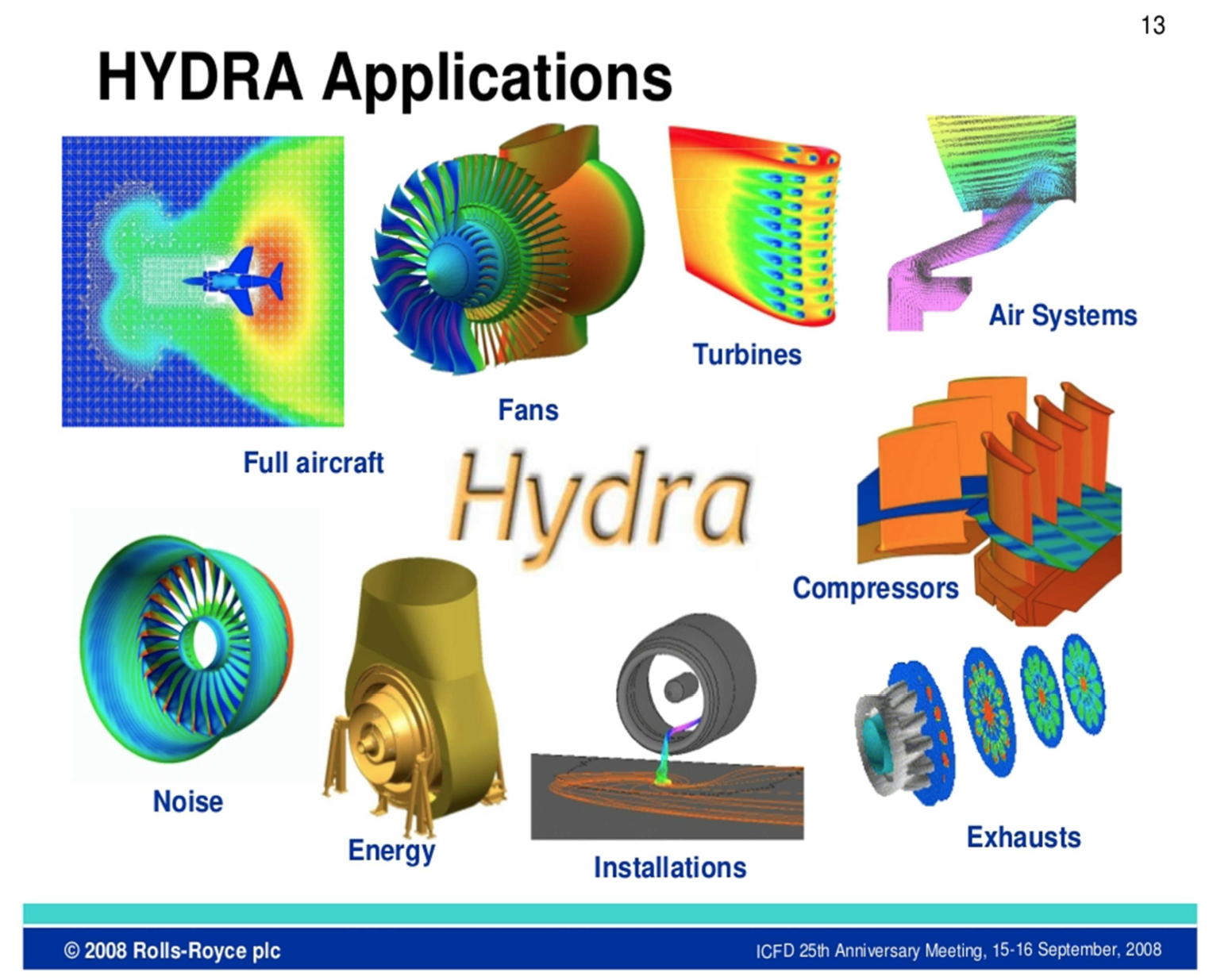

The many uses of HYDRA within Rolls Royce are illustrated in this

diagram, taken from [F] and

used with permission.

The ability to simulate the flow of air through the engines is crucial to

Rolls-Royce's design

capability, as engines are now designed almost exclusively through

computer simulation with

experimental testing carried out afterwards to verify the performance of

the final design. Rolls-Royce uses HYDRA in various ways: to assess the

aerodynamic efficiency of a design; to assess

the unsteady aerodynamic forces acting on blades due to the passing of

neighbouring blade rows;

to assess the possibility of self-induced vibrations; and to quantify the

heat transfer from the very

hot gases coming out of the combustor into the high pressure turbine

blades [F].

HYDRA offers Rolls-Royce unprecedented accuracy because of its ability to

deal with shocks, and

the company reports that it is now able to rank designs to better than 1%

efficiency, consistently

more impressive than rival packages such as FLUENT. As an example, it

reports that calculated

loss coefficients for industrial exhaust systems now differ from measured

values by just 0.02%,

compared to 0.16% when calculated using FLUENT [E].

Nature and extent of the impact. Of the many impacts of HYDRA to

Rolls-Royce, the greatest

has been on the design of its gas turbine engines for aircraft. The

`soaring demand for more fuel-efficient engines for planes' [G] helped the

civil aerospace arm of the company deliver a 16%

increase in annual revenue to over £6.4 billion in 2012 [A, G] and with

Trent engines, which are

designed using HYDRA, making up around 75% of all orders [A]. Furthermore,

`Rolls-Royce's

order book rose 4% to £60.1bn thanks to strong demand for its Trent

aircraft engines' [B].

HYDRA has given Rolls-Royce a single tool for aerodynamic, aero-acoustic

and aero-elastic

applications. Its novel multi-grid solvers allows the company to

efficiently analyse complex engine

shapes which were previously difficult to assess. Furthermore, the

parallelisation of the software

has cut analysis time, and Rolls-Royce attributes the decrease in design

time for an intermediate

turbine test rig, from [text removed for publication], to the use

of HYDRA's adjoint CFD code [E].

In total, the code has helped save Rolls-Royce at least [text removed

for publication], in test rig

expenses [E]. Rolls-Royce technological development webpage openly credits

HYDRA as one of

the key pieces of technology that make up The Rolls-Royce Engineering

System [D]; for example,

"HYDRA has been used extensively in the design of recent RR products such

as the Trent 1000."

The code was used to design Rolls-Royce's Trent 1000 series of engines,

which power Boeing 787

aeroplanes. By way of illustration of the benefits of improved accuracy

and design capability,

improvements to the latest iteration of the Trent 1000, unveiled in 2012,

over its predecessors

include: [text removed for publication] more efficient

intermediate pressure compressor; [text

removed for publication] more efficient intermediate pressure

turbine; shortened Boeing flight

testbed schedule thanks to design being ahead of time; and a fan assessed

as having "world class

performance" in a Boeing Audit [E]. The Trent 1000 is also the quietest

mode of powering the 787

— some 6 dB quieter than its competitors [C].

The newer Trent XWB, announced in 2007 and then first flown in 2012,

powers the new Airbus

A350 XWB and was also designed using HYDRA. As of May 2012, it was

Rolls-Royce's fastest-selling engine to date, having achieved 1,100 orders

from 34 customers worldwide [C]. Once

again, HYDRA contributed to the improvement of its design, with its high

pressure compressor

seeing an improvement in efficiency of [text removed for publication],

and its intermediate

pressure compressor seeing a [text removed for publication]

improvement, both over the Trent

1000. All told, the Trent XWB is [text removed for publication]

more efficient than the first

generation Trent engines of 1995, making it the most efficient Trent

engine to date.

Sources to corroborate the impact

[A] http://www.rolls-royce.com/investors/financial_reporting/financial_results/index.jsp

[B] http://www.guardian.co.uk/business/2011/nov/11/rolls-royce-engine-recovery-economy

[C] http://www.rolls-royce.com/Images/RR_full_AR_2011_tcm92-34435.pdf

[D] http://www.rolls-royce.com/about/technology/systems_tech/design_systems_tools.jsp

[E] A Brief History of HYDRA, Rolls-Royce internal presentation, supplied

by Chief Design

Systems Architect at Rolls-Royce (who can be contacted), showing the

significance of the

impact of Hydra at Rolls-Royce. Copy held by Oxford University.

[F] Rolls-Royce presentation at ICFD meeting, reading University, 2008,

www.icfd.rdg.ac.uk/ICFD25/Talks/LLapworth.pdf

[G] http://uk.reuters.com/article/2013/02/14/uk-rolls-royce-idUKBRE91D0B720130214?feedType=RSS&feedName=businessNews

[C]-[F] give data about Hydra and its use at Rolls-Royce. [A], [B] &

[G] give evidence of the

economic success of Rolls-Royce engines designed using Hydra.