Improvements to the Environment by means of Broad Band Sound Attenuating Devices

Submitting Institution

Loughborough UniversityUnit of Assessment

PhysicsSummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Interdisciplinary Engineering

Medical and Health Sciences: Neurosciences

Summary of the impact

Sound pollution, which harms quality of life and health

(e.g. hearing loss, hypertension and heart disease), is a subject of

public concern and legislation. Research at Loughborough University has

led to the design and production of a new generation of sound

barrier for a wide range of industrial and business partners,

a number of them leaders in their field. These sound barriers provide

improved environmental benefit and reduced cost

in compliance with EU Regulations. A spin-out

company (Sonobex) has been established to test and market these designs

and products. Outreach by Sonobex through the media and at the Houses of

Commons has led to a contribution to the understanding of science

and engineering to both the public and to policy

makers.

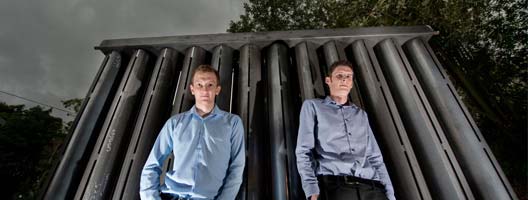

Image: Drs Chalmers and Elford with the first commercial prototype.

Image: Drs Chalmers and Elford with the first commercial prototype.

Underpinning research

Noise barriers are used to reduce noise disturbance from industrial

plant, roads, railways etc. Traditionally outdoor noise barriers are

constructed from solid structures (concrete walls etc.) which act both to

absorb the sound and also, by reflection, to deflect it away from the

areas that require protection. Whilst these traditional methods can be

very effective they generally suffer from the major disadvantage of

preventing the free flow of air and light through the barrier. Recent

years have seen a growing interest in the potential for use of sonic

crystals — arrays of cylindrical rods — as noise barriers. An advantage of

sonic crystals (SCs) is that by varying the distance between the rods it

is possible to attain peaks of attenuation in a selected range of

frequencies.

A further advantage of an SC barrier in comparison to more traditional

sound barriers are its ability to allow light to pass and, uniquely, that

it does not present an obstruction to the free flow of air. However,

barriers using `conventional' SCs suffer from the major disadvantage of

providing attenuation only over a rather narrow frequency band (and

harmonics thereof) and are therefore unsuitable as barriers to broad band

sound.

The concept of using Locally Resonant Sonic Crystals (LRSC) in which the

cylinders in the array act individually as resonators whose frequency

differs from that of the array helps to alleviate this problem but broad

band attenuation is still not achieved. Experimental and modelling work

carried out in the Loughborough University Physics Department by research

students and latterly postdoctoral researchers Dan Elford and Luke

Chalmers (2007-2013) under the joint supervision of Prof. Kusmartsev (Head

of Department, staff member 1990 to date) and Dr. Swallowe (Senior

Lecturer, staff member 1984 to date) [3.1, 3.2] in which the use

of multiple active Helmholtz resonators as scattering elements was

investigated has shown that carefully designed LRSCs can provide

attenuation well in excess of that provided by normal `mass law'

attenuators and in broader frequency ranges than conventional LRSCs.

The key aspects of the research outcomes and the potential impact are

that with LRSC systems attenuation is as good as with conventional

barriers but

1) In all situations a flow of air and light is possible — thus systems

such as industrial compressors can be acoustically shielded without being

enclosed. This is a major advantage since air flow is required to provide

cooling [3.1, 3.2]

2) LRSCs can be manufactured from a very wide range of materials and can

be used to architecturally enhance the appearance of a building while

providing (when used as a window covering) shade from direct sunlight and

attenuation of exterior sound along with a free flow of cool air [3.1,

3.2]

3) Conventional sound barriers for outdoor use (e.g. along motorways in

residential areas) are intermittently subjected to very considerable wind

loading resulting in the need for massive supports. The wind permeability

of LRSC barriers considerably alleviates this requirement [3.1, 3.2]

4) Barriers can attenuate at low acoustic frequencies without the need to

satisfy the mass law. [3.1, 3.2]

The work is protected by GB and international patents [3.3, 3.4, 3.5,

3.6]

References to the research

Because of the commercial implications journal publications are limited

but it is worth noting that the Journal of the Acoustical Society of

America is one of the most highly regarded and has the highest `H-index'

of any acoustics journal as well as being rated A* confirming the quality

of the underlying research. Since 2010 over £350k has been invested in

commercialising the technology.

3.1. Chalmers, L., Elford, D., Kusmartsev, F. and Swallowe, G.M.,

Acoustic band gap formation in two-dimensional locally resonant sonic

crystals comprised of Helmholtz resonators, International Journal of

Modern Physics B, 23, 4234-4243 (2009), DOI:

10.1142/S0217979209063390 — B ranked journal in ERA 2010 journal

rankings H-index 49

3.2. D. Elford, L. Chalmers, F. V. Kusmartsev, and G. M. Swallowe,

Matryoshka locally resonant sonic crystal, Journal of the Acoustical

Society of America, 130(5), 2746-2755 (2011), DOI:

10.1121/1.3643818 — A* ranked journal in ERA

2010 journal rankings. H-index 105

3.3. GB patent application GB0901982.9 (Feb 2009), Attenuators,

arrangements of attenuators, acoustic barriers and methods for

constructing acoustic barriers; G.M. Swallowe, D. Elford, L.

Chalmers, F. Kusmartsev

3.4. International patent application PCT/EP2010/051370 (Feb.

2010); Attenuators, arrangements of attenuators, acoustic barriers and

methods for constructing acoustic barriers; G.M. Swallowe, D.

Elford, L. Chalmers, F. Kusmartsev

3.5. European Patent Application No. 10704128.7 (2012); Attenuators,

arrangements of attenuators, acoustic barriers and methods for

constructing acoustic barriers; G.M. Swallowe, D. Elford, L.

Chalmers, F. Kusmartsev

3.6. US patent application No. 13/148020 (2012); Attenuators,

arrangements of attenuators, acoustic barriers and methods for

constructing acoustic barriers; G.M. Swallowe, D. Elford, L.

Chalmers, F. Kusmartsev

Research Grants Obtained:

EMDA Innovation Fellowship: PI Dr. G. Swallowe, CI Prof F. Kusmartsev.

£15,948 from October 2010 for 8 months "Sound Blocking Technology"

EPSRC EP/I029001/1: PI Prof. F. Kusmartsev, CI Dr. G. Swallowe. Value

£167,750 from January 2011 for 12 months "Practical Sound Attenuation

using Broad Band Sound Attenuating Devices"

KTA Funding: 1st Feb 2012-30th Sept 2012: Dr D.

Elford £61,000 "Novel Noise Barrier Technology"

Royal Academy of Engineering Enterprise Fellowship: Dr D Elford £83,000

from 30th March 2012 for 12 months to turn research into a

viable operating spin out company.

Details of the impact

We now provide evidence to show that the research findings that we have

cited in 3.1 and 3.2 have resulted in two major impacts:

(1) the design and production of a new generation of sound barrier for a

wide range of industrial and business partners, a number of them leaders

in their field. These sound barriers not only provide commercial and

operational benefit for these companies but they additionally provide

improved environmental benefit (reduced sound transmission) and reduced

cost in compliance with EU Regulations. A spin-out company (Sonobex) has

been established to test and market these designs and products

(2) a contribution to the understanding of science and engineering to

both the public and to policy makers, via Sonobex.

Impact 1

The outcome from the research is in the commercialisation stage and the

research grants listed in section 3 have been awarded in order to develop

commercial products based on the academic research carried out in

2007-2012 [3.1, 3.2]. A spin-out company Sonobex

Ltd. was formed in May 2013 and prototype sound barriers have been

successfully tested. The list of project partners given below is evidence

that Sonobex Ltd has established its visibility and is set

to realise its potential in both UK and international markets. Because of

the damaging effects of noise on public health and

the environment, European Legislation [The European

Parliament and The Council of The European Union, Directive

2002/49/18.7.2002.] for noise has required each member state to prepare

noise maps of larger towns and cities and to publish action plans that

identify noise standards and set out programmes to reduce levels to these

standards. The first UK round of noise mapping has been completed (2011)

and the second round of noise mapping is taking place. A follow on

regulation to the Environment Noise (England) regulations, 2006 will

require reductions in noise limits to take effect from 2016. The noise

which is predominately of concern is airborne sound and the Loughborough

University research and development of air sound barriers with their

advantages as outlined in Section 2 has led to interest from a wide

variety of major construction firms. As such the solutions provided by

Sonobex Ltd, based on the research conducted within the Unit, is

contributing to the implementation of public policy and improved

public services.

Current business partners, attracted to the technology because of its

potential for improved public health and quality

of life, include:

- Alkane Energy (Methane Extraction — prototype installed) [5.1]

- East Midland Trains (prototype installed) [5.5]

- British Gypsum (prototype designed) [5.2]

- Tarmac Building Products [5.3]

- Cherwell District Council design for first ever acoustically designed

sheltered housing for autism sufferers [5.4]; their application

for sheltered housing incorporating Sonobex attenuators has won

the Department of Health Care and Support Specialist Housing Fund

design competition and will commence construction in

2014.

- A leading European power infrastructure company (non-disclosure

agreement in place) have placed an initial order for a trial

instillation for power station use in Brazil.

- Colas rail (France) who are evaluating the SonoBex designs with a view

to a roll out in the French rail transport infrastructure.

The range of designs and products include:

- Production of enclosures for use around noisy machinery in factories,

air conditioning systems, road drills etc.- the Alkane Energy prototype

and the "Major Power Infrastructure Company" order are of this type [5.1,

5.2].

- Sound barriers for use along motorways and railways with reduced wind

loading, improved drainage and visual impact — East Midlands Trains

prototype is in this area as are the Colas rail designs [5.3, 5.5].

- Prevention of sound barriers forming a physical barrier to small

animal movement.

- Bespoke barriers for special needs — Cherwell District Council

sheltered housing application [5.4].

Impact 2

Loughborough's spin out, Sonobex has featured on national radio (BBC

Radio 4's PM show) and newspaper (The Times, Innovation & Growth

supplement) as well as in more specialist outlets (The Engineer magazine

and a cover article in Innovation & Research Focus). Sonobex and the

BBC have agreed production of a feature in the The One Show for 2014. This

provides further evidence of an on-going commitment to public engagement.

In addition, for his work on sound barrier technology, Elford won a Bronze

award from the Parliamentary & Scientific Committee at the Houses of

Commons research competition — SET for Britain. Sonobex has

therefore made a contribution to the understanding of science and

engineering to both the public and to policy

makers.

Sources to corroborate the impact

Full commercial products are not yet available but trials have been

successful and we expect that commercial products and consequent full

impact on society will take place in late 2013. Support letters from

Tarmac, British Gypsum, Lindhurst/Alkene Energy, Cherwell District Council

and East Midlands trains have been provided.

The following sources of corroboration can be made available at request:

5.1. Letter from Managing Director, Lindhurst Engineering Ltd.

Midland Road, Sutton-in-Ashfield, Notts., NG17 5HG

5.2. Letter from Project Leader, Project Engineering Dept.,

British Gypsum, East Leake, LE12 6JU

5.3. Letter from Chief Executive Officer, Tarmac Building

Products, Tunstead Road, Buxton, SK17 8TG

5.4. Letter from, Delivery Team, Regeneration and Housing,

Cherwell District Council, Bodicote House, Bodicote, OX15 4AA

5.5. Manager, East Midlands Trains Etches Park Depot, Deadman's

Lane, Derby, DE24 8WE