1 Super-repellent surfaces by Plasmachemical techniques

Submitting Institution

University of DurhamUnit of Assessment

ChemistrySummary Impact Type

TechnologicalResearch Subject Area(s)

Physical Sciences: Atomic, Molecular, Nuclear, Particle and Plasma Physics

Chemical Sciences: Physical Chemistry (incl. Structural)

Engineering: Materials Engineering

Summary of the impact

Super-repellent surfaces created by plasmachemical techniques invented at

Durham University have been exploited by P2i as the Ion-mask™

and Adiron™ brands and used to protect the surfaces of millions

of products worldwide including: 3 million pairs of footwear (Timberland,

Hi- Tec); 8 million mobile phones (Nokia, Motorola, Alcatel); 60% of the

world's hearing aids (HLT, GN Resound); 55,000 feet of filter media

(Porvair); and 100 million pipette tips (Eppendorf). This has earned P2i

industry awards including the 2011 and 2012 International Business Award

for "Most Innovative Company in Europe" and the "Global Business

Excellence Award" 2012. The combined turnover of P2i since 2008 was ca.

£20M, it received external investment of £31.75M and has created 115 new

jobs. A DU IP-holding spin-out company, Surface Innovations, was purchased

by P2i in 2010, and further applications of DU plasmachemical

functionalization were commercialized by Dow Corning Plasma Solutions Ltd

and exploited in-period.

Underpinning research

Research focused on understanding and controlling chemical reaction

pathways at plasma-solid interfaces was led by Professor Jas Pal Badyal

(Durham staff, 1989-present).

Surface engineering and modification techniques are being used in all

sectors of the materials, engineering, electronics and health-care

industries to provide devices with specific functional properties such as

waterproofing, antifouling and corrosion-resistance properties. This

industry has an estimated value of $50 billion per annum and new

technologies to enhance surface properties of all types of materials are

highly valued.

The plasma state was discovered in 1879 by the English scientist William

Crookes and, despite being used for technological applications such as

lighting for over 100 years, very little progress had previously been made

in relation to achieving high chemical reaction pathway selectivities

within this 4th state of matter. Durham research has, however, developed

methods to use plasmachemical techniques to selectively functionalise the

surfaces of a wide range of different materials. Two particular areas of

research which underpin the impact described in Section 4 are:

(a) Synthon theory for plasmachemical surface functionalization:

this theory allows rational prediction of the surface functionalization of

polymers by electrical gas discharges. It uses a synthon approach to

correlate the reactivity of chemical groups located at a polymer substrate

surface with the impinging plasma species. In this way, desired

functionalities can be incorporated into a surface by the judicious choice

of electrical discharge and polymer substrate. Structure- behaviour

relationships were developed which explain the interfacial plasma-solid

chemical reaction pathways [1,2].

(b) Structurally well-defined functional nanofilms: Most

established surface treatment methods are substrate-specific and cannot be

easily adapted to different materials or geometries (making them no more

than an academic curiosity in many cases). Durham research showed that

plasmachemical deposition offers the potential to address this limitation

by exploiting the inherent substrate activation by the electrical

discharge prior to the onset of film growth. This allows

substrate-independent surface functionalization. Furthermore, this

approach is single-step, solventless, operates at ambient temperature, and

requires very low energy input. Two methods utilized by Durham have been

shown to achieve extremely high chemical selectivity at the plasma- solid

interface during functional nanolayer deposition:

-

Pulsed Plasmachemical Deposition (PPD): By pulsing the

electrical discharge on ms-03bcs timescales, two distinct reaction

regimes can be constructed: firstly activation of precursor molecules by

UV irradiation, ion, or electron collisions during the plasma duty cycle

on-period (typically 03bcs), and then conventional chemistry (e.g.

cyclisation or polymerisation) proceeding in the absence of any damaging

plasma species during a much longer off-period (typically ms). This has

been shown to lead to extremely high levels of surface functionality

[3,4].

-

Atomised Spray Plasma Deposition (ASPD):

Structurally well-defined functional nanofilms can also be obtained by

the nebulisation of precursor molecules into an electrical discharge.

Mechanistically, this proceeds by highly excited metastable atoms

possessing sufficient energies to activate precursor molecules (Penning

type reactions) which initiate conventional chemical reaction pathways

during the impact of the supersonically expanding atomised liquid

droplets onto the substrate surface [5]. It has also been shown that

well-defined nanocomposite films can be created by utilizing

nanoparticle slurries [6].

References to the research

[1] J. Hopkins and J. P. S. Badyal, "Nonequilibrium Glow Discharge

Fluorination of Polymer Surfaces", J. Phys. Chem., 1995, 99,

4261-4264. DOI: 10.1021/j100012a056 [60 citations]

[2] I. S. Woodward, W. C. E. Schofield, V. Roucoules and J. P. S. Badyal,

"Super-Hydrophobic Surfaces Produced by Plasma Fluorination of

Polybutadiene Films", Langmuir, 2003,19, 3432-3438. DOI:

10.1021/la020427e [203]

[3] M. E. Ryan, A. M. Hynes and J. P. S. Badyal, "Pulsed Plasma

Polymerization of Maleic Anhydride", Chem. Mater., 1996, 8,

37-42. DOI: 10.1021/cm9503691 [135]

[4] S. R. Coulson, I. S. Woodward, S. A. Brewer, C. Willis and J. P. S.

Badyal, "Ultra-Low Surface Energy Plasma Polymer Films", Chem. Mater.,

2000, 12, 2031-2038. DOI: 10.1021/cm000193p [141]

[5] L. J. Ward, W. C. E. Schofield, A. J. Goodwin, P. J. Merlin and J. P.

S. Badyal, "Atmospheric Pressure Plasma Deposition of Structurally

Well-Defined Polyacrylic Acid Films", Chem. Mater., 2003, 15,

1466-1469. DOI: 10.1021/cm020289e [82]

[6] L. J. Ward and J. P. S. Badyal, "Method and Apparatus for Forming a

Coating on a Substrate", Patent WO 2006/092614, 8 September 2006.

The quality of this research is evidenced by several major awards to

Badyal including: the Harrison Prize of the Royal Society of Chemistry;

the Burch Prize of the British Vacuum Council; and the International

Association of Advanced Materials Medal for "Outstanding and Notable

Contribution in the Field of Nanomaterials and Nanotechnology". He has

given 13 plenary/keynote and 12 invited lectures at overseas international

conferences since 2008 (in countries including Australia, Austria,

Belgium, Canada, Czech Republic, Denmark, France, Germany, Greece, India,

Italy, Luxembourg, Mexico, Netherlands, New Zealand, Poland, Portugal, and

USA). The surface science described in this study was funded by a variety

of research grants from several sources including EPSRC, British Gas, EU,

Mupor Ltd, DERA and Dow Corning.

Details of the impact

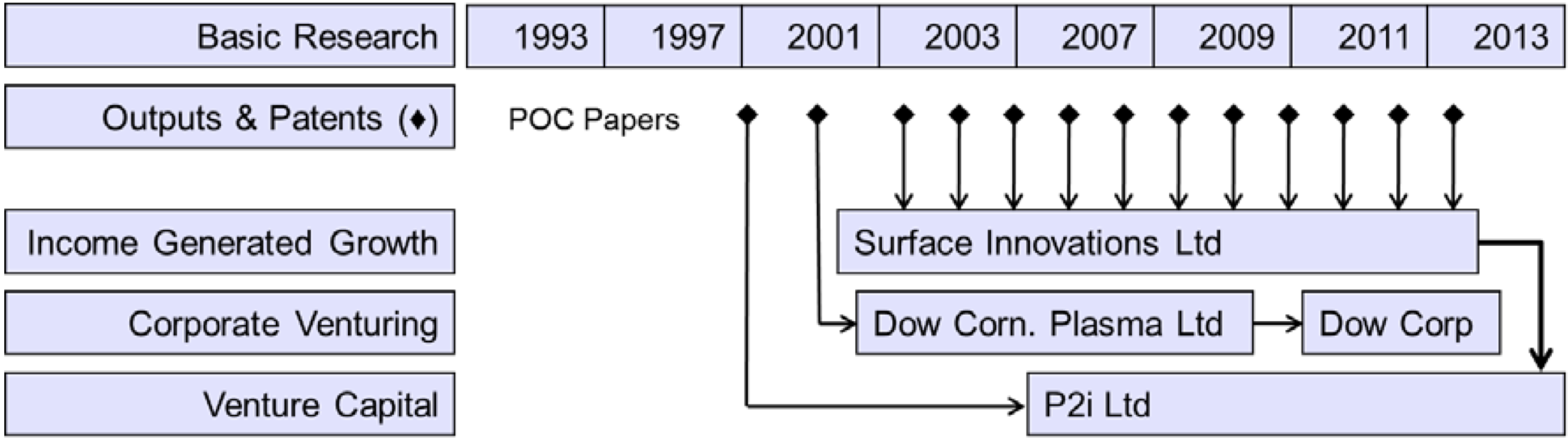

The Durham research described in Section 2 has been transferred to

industry through three different business models (income generated growth,

corporate venturing, and venture capital). The transfer methods are

summarized in the flow chart below and an example of impact generated

through each method is given in the following sections.

(a) Income Generated Growth (Surface Innovations Ltd, Durham, UK):

Atomized-Spray Plasma Deposition (ASPD) described in [6] is capable of

producing a wide variety of thin, high quality, functional coatings, at

throughputs attractive to a large number of markets. The approach allows

lost-cost substrates to exhibit the surface properties and performance of

far more expensive materials. To exploit this technology Badyal and Dr

Luke Ward (a former PhD student) founded the IP-ownership company Surface

Innovations Ltd. in 2001 [Im1]. Durham University agreed to assign

non-industrially sponsored intellectual property developed within the

Badyal group to the company in return for an equity stake. 14 core patent

families were filed during the period 2001-2010 on surface

functionalization for applications including: filtration; antifogging;

bioarrays; antibacterial; antifouling; high dielectric constant;

super-repellency; fog harvesting; and rewritability. The company was

funded by loans and income generated from prototype development amounting

to £824K for industrial partners including: Siemens (Germany); Arcelor

(Belgium); Procter & Gamble (USA); Sauflon (UK); Federal Moghul

(Luxembourg); Dow Corning (USA); IRD Fuel Cells (Denmark); Kimberly-Clark

(USA); Gillette (USA); Calgon (USA); Porvair (UK); and SMB Microfluidic

Devices (Denmark). The company had 5 employees when it was bought out by

P2i Ltd in July 2010 [Im2] for ca £737K (P2i 2010 Annual report

[Im8]). The Department's share of the income has been used to fund

undergraduate research internships in Durham and abroad to highlight

entrepreneurship opportunities and benefits to our students. Badyal has

utilized proceeds to help alleviate extreme child poverty in India and

Africa.

(b) Corporate Venturing (Dow Corning Plasma Ltd, Cork, Ireland):

The atomised spray plasmachemical deposition (ASPD) technique developed in

Durham [5] was patented in collaboration with Dow Corning and a start-up

company [Im3,Im4] was set up in Ireland with an initial investment of €3.3

million made by Dow Corning Corporation (USA). Its managing director was

Dr Alan Hynes (a former Badyal PhD student). Large scale (up to 2.8 m

width roll-to-roll) industrial manufacturing machines were built based

upon the Durham ASPD equipment design and sold for significant sums. The

company employed 28 people, and in 2008 the business became fully

integrated into Dow Corning Corporation. Current licensees of the ASPD

technology include Invexus (USA) which is supplying to the >£2 billion

global market for antibacterial surfaces.

(c) Venture Capital (P2i Ltd, Abingdon, UK): In 1996 Badyal was

approached by the UK MoD concerning the dehydration of British soldiers in

the desert during the 1990 conflict with Iraq. In particular, the military

wanted to reduce the number of layers of clothing that soldiers had to

wear in the battle field. Badyal proposed the utilization of pulsed

plasmachemical deposition (PPD) which led to the funding of a PhD student

(Stephen Coulson). The idea was successful, a patent for treating fabric

was filed (GB Pat Appl. 9712338.4, 1997) and the research published

[4,Im5,Im6]. Upon completion of his PhD, Stephen Coulson moved to the MoD

and in 2004 helped found P2i Ltd (UK Company 04814350), where he has

remained as Chief Technology Officer (CTO). P2i has raised £40 million

investment from Swarraton Partners, NAXOS Capital Partners, Porton Capital

Limited, Unilever Ventures, OMBU Group, and the Rainbow Seed Fund,

including £31.75M since 2008. The company headquarters are in Abingdon,

and it currently has offices in Savannah (USA), Oregon (USA), Singapore,

and an applications centre in China. In 2010, having undergone very rapid

growth, P2i purchased Surface Innovations from DU and Badyal in order to

broaden its portfolio of functional nanocoatings [Im2,8].

P2i has built its business by developing and commercialising the Durham

plasma deposited liquid repellent nanocoatings described in [4]. It has

commercialised treatments as the Ion Mask™ brand for footwear,

clothing and accessories, and as Aridion™ for electronics

applications [Im7]. These ultra-low surface energy nanocoatings impart

numerous benefits to consumer products. For footwear and filtration media,

treated products no longer absorb liquids but instead remain dry, clean

and lightweight. For complex three dimensional products such as

smartphones, and computer tablets, the low surface energy prevents liquids

from being drawn into the device by means of capillary action.

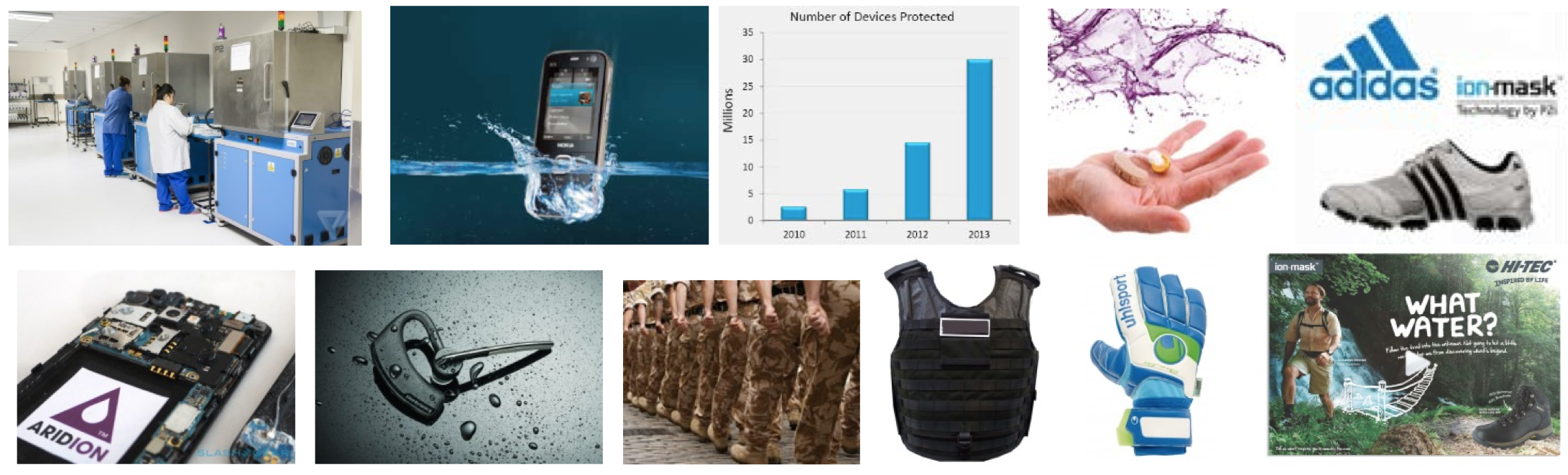

Figure: Some examples of product applications using Durham-derived plasma nanocoatings.

Figure: Some examples of product applications using Durham-derived plasma nanocoatings.

Over 150 commercial plasma coatings units based on the Durham design have

been manufactured by P2i and installed with customers in Argentina,

Australia, Brazil, China, Germany, India, Indonesia, Singapore, Spain,

Thailand, UK, and the USA for the surface treatment of products in the electronics, lifestyle,

life sciences, filtration,

energy, military,

and institutional sectors. Examples of the use of Ion Mask™

and Aridion™ technologies are given in the figure above and the

table below. This is sourced from Case Studies described in P2i open

literature [Im8] in July 2013, and is not a comprehensive list of

applications.

| Application |

Examples: Brand

(models) |

Notes |

| Phones |

Alcatel (ONE TOUCH 997 and 992D); Plantronics (Headsets Voyager

legend, Backbeat GO); Motorola (RAZR and Moto X smartphones and

Xyboard tablet) |

8 million units >£4M retail |

| Hearing Aids |

Hearing Lab Technology (HLT) – GN Resound 60% of the

world’s hearing aids |

6 million units >£3M retail |

| Footwear |

Hi-Tec (V-Lite Mach 4, V-Lite Infinity, Sierra Lite); Teva (Links

Mtb, Mush Frio Lace, Fuse-ion, Reforge-Ionmask); K-Swiss (Kwicky

Blade Light, California); Timberland (Tall Zip Boot, Desert Boot,

City 6IN Boot, Formentor Boot); Scott (Eride Icerunner); Van Dal

(suede shoe range); Mizuno (Weathers golf); MAGNUM (Sidewinder

Combat Desert Boot, Elite Force Boot); Nike; Adidas |

3 million pairs of shoes >£2M retail |

| Clothing |

Kangol Headwear (Tropic Jacquard 507, Zig Duke, Pole Stripe);

Trekmates (Mountain Lite Mitt); Global Armour (G Tech Vest) |

Potential market of >£1 billion |

| Filtration and Energy |

Porvair (filtration and separation equipment) Crowcon

(gas detection equipment, STAY-CLIR) Eppendorf (Pipette tips) |

55,000 ft of filter media

100 million pipette tips |

P2i company turnover has grown rapidly since 2008 (see table), exceeding

£8.8M in 2011-12 with 93% of revenues generated in geographic markets

outside of the UK, leading to the creation of >100 new jobs and the

establishment of wholly owned subsidiaries in China, Hong Kong, USA and

Singapore. P2i currently own a portfolio of over 60 patent families to

protect their core businesses.

|

2008 |

2009 |

2010 |

2011 |

2012 |

Totals* |

| VC raised (£M) |

2.0 |

6.1 |

5.5 |

11.4 |

6.75 |

31.75 |

| Turnover(£M) |

0.862 |

1.035 |

3.180 |

6.021 |

8.886 |

19.984 |

| Employees |

15 |

27 |

48 |

90 |

115 |

115 |

* Company report for January - July 2013 unavailable at time of writing

P2i is widely recognized as being the world leader in plasmachemical

deposited functional nanocoatings and has won numerous awards including:

International Business Award for "Most Innovative Company in Europe", 2011

and 2012; "Footwear Innovation" category at the 2009 Company Clothing

Awards, London, 2009; "Borderless Business" category, Management Today,

2011; "Best of Show" award, American Academy of Audiology, 2011; Global

Business Excellence Award 2012; and 27th fasted growing UK technology

company in the 2012 Sunday Times Tech Track 100 league table. The Durham

research has featured extensively in the media, including: the Sunday

Times newspaper; the national BBC Evening TV News; BBC Radio 4 Today

Programme; Channel 5's Gadget Show; and the Discovery Channel.

Sources to corroborate the impact

[Im1] Surface innovations: www.surface-innovations.com

and annual reports filed with Companies House 2008-2013.

[Im2] P2i acquisition of Surface Innovations: P2i Press Release, 13 July,

2010.

[Im3] Dow coatings: Dow Corning Plasma Solutions Application Note, 2005.

[Im4] Dow coatings: Chem. Eng. News, October 16, 2006, 84 (42), 18-20.

[Im5] Fabric coating: DSTL Annual Report and Accounts, 2004/2005, p17.

[Im6] Fabric coating: Sunday Times main section, 11th October 1998.

[Im7] P2i brands: Financial Times, March 4, 2012.

[Im8] P2i awards: www.p2i.com, P2i

Media Information Pack and Annual reports filed with Companies House

2008-2013.