Dynamic Extractions: New Platform Liquid-Liquid Continuous Flow Technology for the Purification and Manufacture of Drugs for Industry

Submitting Institution

Brunel UniversityUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Chemical Sciences: Analytical Chemistry

Engineering: Chemical Engineering, Manufacturing Engineering

Summary of the impact

In recognising the challenges facing a competitive, globalised

pharmaceutical industry, the Advanced Bioprocessing Centre team at Brunel

University have pioneered the technology and a methodology for speeding up

the R&D, purification and manufacture of new drugs.

Already being adopted by market leading pharmaceutical companies, the

High Performance Counter-current Chromatography presents a new

technological platform to generate significant reductions in development

costs; an increase in yield and a greener waste process.

The research supported by eight Research Councils grants totalling

£3,557,168 led to establishing a spin-out company, Dynamic

Extractions, which today operates a commercial enterprise with £1M

turnover in partnership with Brunel.

Underpinning research

The manufacture of high value pharmaceutical products is critical to

underpin industry longevity. R&D into new drugs to tackle increasingly

complex conditions is capital intensive, leading `big pharma' to outsource

the complex and time consuming process.

Building on 20-year experience in the field, Sutherland and his team

pioneered Counter-current Chromatography (CCC) in the UK; producing the

capability of using a two-phase liquid stream to obtain unprecedented

yield and solubility with no loss of product. In proving the technology to

be reliable, scalable and significantly faster (separation processes in

minutes rather than hours), the process has been adopted by some of the

world's leading global pharmaceutical brands. [Publications 5 and 6 and

Source 5].

First developed in the US in the 1960s, CCC lay dormant until Sutherland

and his team improved the performance, reliability and visibility of the

technology via establishing the first international conference series in

2000 followed by a spin-out company, Dynamic Extractions (DE), in 2003

under the auspices of the then Brunel Enterprise Centre (BEC). Re-named

High Performance Counter-current Chromatography (HPCCC) the process

enables efficient commercialisation of the instruments at various scales

with a potential 10% penetration into the $1 billion preparative

extraction/chromatography market.

A number of grants from the Research Councils have been awarded with

notable outcomes: the feasibility of scale up of the technology with a

BBSRC/DTI LINK Award with leading industries (Grant 1); the feasibility of

scale-down and linking to Mass Spectroscopy (G2); the realisation of

process scale-up (G3); the feasibility of further scale-up to industrial

scale via an BBSRC-SBRI Grant with Dynamic Extractions (G4)[P1]; the

equipping of the new Advanced Bioprocessing Centre (G5) and the building a

new 18 L prototype pilot instrument (G5) [P2].

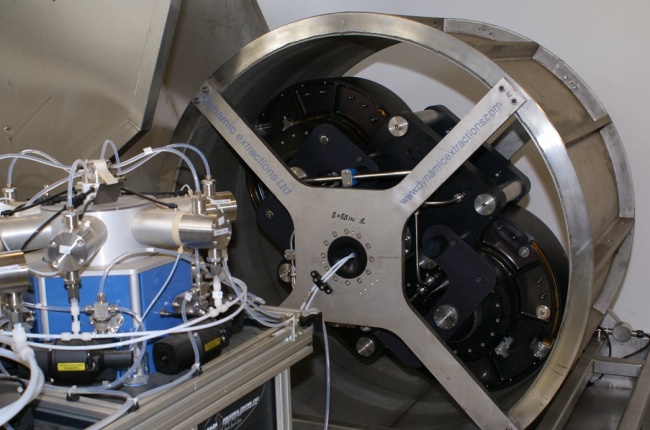

Running from 1998-2006, the equipment development phase culminated in the

University investing £1M SRIF money in a new Advanced Bioprocessing Centre

(ABC)opened in April 2006, housing large scale hazards and applications

laboratories with pilot scale prototypes of 4.6L and 18L capacity (the

largest in the world at that time; see opposite).

When DE moved to Slough in 2005, two of the four founder shareholders

(Janaway and Wood) moved with them, Hawes retired and Sutherland formed a

new team with Ignatova, Hewitson, Garrard and Fisher covering chemistry,

natural products and biochemistry.

While the company focused on instrument development/sales, production and

commercial separations, the ABC addressed new technology for the

purification of biologics such as proteins [G6, G7, P3], rapid method

development and continuous processing.

A feasibility study for the purification of glucosilonates such as

glucoraphanin from Broccolis seeds was commissioned by the National Cancer

Institute (NCI-P4). The success of the study led to DE being commissioned

to manufacture 1kg and 2kg of pure glucoraphanin for clinical trials as an

anti-cancer agent.

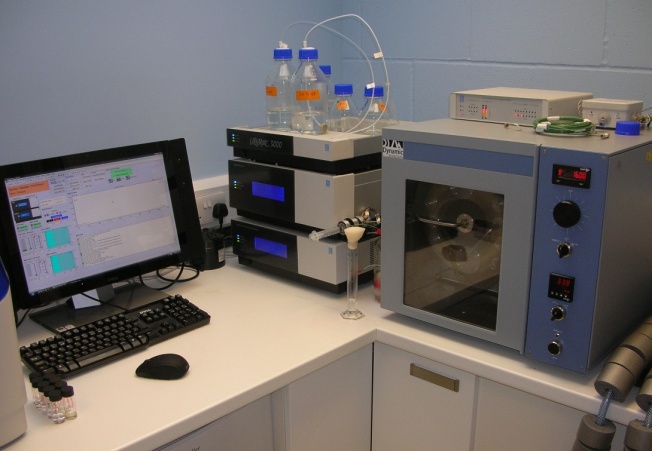

Taking academic research and turning it into industrial reality [P5,P6]

the TSB High Value Manufacturing research programme (G8) funded "Scalable

Technology for the Extraction of Pharmaceuticals (STEP)" with GSK and

Pfizer as end users and DE as the supply company. In 2012 DE established a

laboratory-based robust preparative device capable of 1 kg/day throughput

of crude extract. (see opposite — new 24x7 laboratory based automated

instrument at Dynamic Extractions Ltd in Slough).

References to the research

Publications referred to in underpinning research and impact sections

[1]. Ignatova, S., Wood, P., Hawes, D., Janaway, L., Keay, D., and

Sutherland, I.A. (2007) Feasibility of scaling from pilot to process

scale, J. Chromatog. A., 1151 (1-2), 20-24

http://dx.doi.org/10.1016/j.chroma.2007.02.084

[3]. Sutherland, I.A., Hewitson, P. Sieber, R., van den Heuvel, R.,

Arbenz, L., Kinkel J. and Fisher, D. (2011) Scale-up of protein

purifications using aqueous two-phase systems: comparing multilayer

toroidal coil chromatography with centrifugal partition chromatography, J.

Chromatogr. A., 1218, 5527-5530. http://dx.doi.org/10.1016/j.chroma.2011.04.013

[4]. Fisher, D., Garrard, I.J., van den Heuvel, R., Chou, F.E., Fahey,

J.W. and Sutherland, I.A. (2005) The Technology Transfer and Scale-up of a

Potential Cancer-preventative Plant Secondary Metabolite — Glucoraphanin,

J. Liquid Chromatog. & Rel. Tech., 28 (12-13), 1913-1922 http://dx.doi.org/10.1081/JLC-200063563

[5]. DeAmicis, C., Edwards, N., Giles, M.B., Harris, G.H., Hewitson, P.,

Janaway, L. and Ignatova, S. (2011) Comparison of preparative reversed

phase liquid chromatography and countercurrent chromatography for the

kilogram scale purification of crude spinetoram insecticide, J.

Chromatogr. A, 1218, 6122-6127 http://dx.doi.org/10.1016/j.chroma.2011.06.073

[6]. Sutherland, I.A., Thickitt, C., Douillet, N., Freebairn, K., Johns,

D., Mountain, C., Wood, P., Edwards, N., Rooke, D., Harris, G., Keay, D.,

Mathews, B., Brown, R., Garrard, I., Hewitson, P., Ignatova, S. (2013)

Scalable Technology for the Extraction of Pharmaceutics (STEP): Outcomes

from a 3 year collaborative industry/academia research programme, J.

Chromatogr. A., 1282, 84-94 http://dx.doi.org/10.1016/j.chroma.2013.01.049

Grants referred to in underpinning research:

1. The Industrial Scale up of Countercurrent Chromatography. BBSRC/DTI

LINK Award Ref: 100/BCE08803, PI Ian Sutherland, Feb 98 — Jan 00

(£322,668)

2. EPSRC Instrument Development Grant No GR/M48345, "A New Rapid

Centrifugal Liquid-Liquid Chromatography Separation and Detection System

for Multiple High-Resolution Purification without Sample Loss or

Degradation" PI Ian Sutherland, Apr 99 - Mar 02 (£623,244 with Dai Games

co-I, Swansea University)

3. EPSRC IMI Responsive Processing, Grant Ref GR/R03143/01, "Realisation

of Process Scale Countercurrent Chromatography" PI Ian Sutherland with

Gary Lye co-I UCL, Dec 2000 - Aug 2003 (£392,175)

4. BBSRC-SBRI Grant 192/SBRI9675 for Dynamic Extractions Ltd, "Industrial

Scale up of Countercurrent Chromatography (CCC): the feasibility of

scaling from pilot to process scale", PIs Philip Wood, Svetlana Ignatova

& Ian Sutherland Aug 2003 - July 2005 (£125,000)

5. BBSRC Research Equipment Initiative, "Dynamic Rapid Extraction And

Manufacture of Pharmaceuticals (DREAM-Pharma)", PI Ian Sutherland, co-I

Ian Garrard,, Ref BBD524583/1 (£198,499)

6. BBSRC Grant Ref BB/C506364/1, "An innovative dynamic

extraction/chromatography manufacturing process for purifying bioactive

proteins (DEM-PRO)" PI Ian Sutherland, co-I Derek Fisher, Sept 2004 - Aug

2007 (£333,129)

7. BBSRC-Tools and Resources Programme Grant Ref. No. BB/E012949/1- "A

New Dynamic Extraction Centrifuge with Independent Control of Mixing and

Settling Suitable for Separations Involving Viscous Fluids of Similar

Densities", PI David Hawes, co-Is Svetlana Ignatova and Ian Sutherland

(£83,419) Feb-Oct 2007.

8. Technology Strategy Board High Value Manufacturing Competition,

Scalable Technology for the Extraction of Pharmaceuticals (STEP), August

2009 - July 2012 (£1.46m with GSK (lead Keith Freebairn — £503k); Pfizer

(£75k), Dynamic Extractions (£438k) with £441k coming to Brunel — PI Ian

Sutherland; co-PIs Peter Hewitson and Svetlana Ignatova). Grant No:

TP14/HVM/6/I/BD506K — Sept 2009 - Aug 2012

Details of the impact

This impact case study demonstrates a pioneering approach to simplifying

the process and thus reducing the cost of bringing new drugs to market. A

spin-out company, Dynamic

Extractions was established in 2003: its business is split

approximately 50:50 between instrument sales and contract separation work

for industry. With the instrument sales it is developing a global market

with 30% of sales in Europe, 20% in North America and 50% in the rest of

the world. The company has been operating profitably for 10 years now with

7 staff and a turnover approaching £1m today. 60% of all sales of the new

technology are directly to industry, of these 83% are semi-preparative and

preparative and being used for preparation of materials for clinical

trials and toxicity studies. In an unprecedented move by industry, Dow

(USA) recently published a comparison between preparative column

chromatography (HPLC) and HPCCC [P5]. The HPCCC process produced a

two-fold higher throughput and consumed approximately 70% less solvent

than preparative scale RP-HPLC. They were so pleased with the technology

they returned a number of times for repeat kg scale separations (Dr

David Rooke).

Interest from industry and academia has been marked; Professor

Joachim Kinkel (Source 6), when commenting on Brunel's work,

as chairman of the scientific committee at the Symposium on Preparative

and Industrial Chromatography and Allied Techniques (SPICA) said that

"liquid-liquid chromatography will be the future new technology for the

pharmaceutical industry with its ease of integration in production lines,

ideal clean-up of systems and efficient method development". Professor

Lijuan Chen of Sichuan University, when commenting on

developments from our early Honokiol work, reported: "In the past two

years, we signed a cooperation agreement to develop one novel drug using

HPCCC combined with HPLC for treating lung cancer with Chengdu Jiye Bio-Tech Co. Ltd. An agreement has recently been made to develop an

anti-cancer drug sharing similar mechanism to taxol in collaboration with

Yangtze River Pharmaceutical Group. Honokiol has now passed the on-site

verification for drug registration and applied to conduct a clinical trial

in China". "They are producing the bulk of the Honokiol drug using two

MIDI-CCCs — turning the hope behind our original paper (Chen et al, The

Rapid Purification and Scale-up of Honokiol and Magnolol using HPCCC,

J,Chromatogr.A., 1142 (2007) 115-122) into reality". (Professor Lijuan

Chen — Source 4). From Sutherland's research with GSK there are four new

business case studies currently being developed: pharmaceutical and

clinical development; virgin manufacture of API; toll refining of API from

crystallisation liquors and the use of telescope processing for the

manufacture of early development materials (Dr Keith Freebairn, source 5

and Michael Carroll, source 7).

There is a thriving Chinese industry building the traditional CCC

instruments with long separation times, but six key laboratories in

Chinese Universities are bucking the trend; investing in the new HPCCC

technology (China-25% of DE sales). High quality publications on the

fractionation of new compounds from ginsenosides are being published by

Tsinghua University, new analogues as new anti-cancer drugs from Honokiol,

new anti-tumour agents from Sichuan University and new compounds as

anti-depressant drugs from Changchun Normal University.

Dissemination - Training workshops on the use of the

technology are being rolled out and an outreach programme placing

instruments for collaborative research in the Universities of Geneva,

Barcelona, Lyon and Rio de Janiero and also Sichuan University in China

where Sutherland has a visiting professorship.

Pivotal to the outreach impact has been establishing a conference series

on counter-current chromatography (CCC). The 1st International

Conference on Counter-current Chromatography (CCC2000) was launched at

Brunel in 2000 and has been hosted in Beijing, Tokyo, Bethesda (USA), Rio

de Janiero, Lyon and Hangzhou, also in China. It will return to Brunel in

2014. The technology has also had an impact on the Symposium for

Preparative Chromatography and Allied Techniques (SPICA) where talks in

2010 resulted in a special liquid-liquid extraction session and workshop

in 2012.

Environmental Benefits - Waste and its disposal continue to

be economically and environmentally challenging issues across the

pharmaceutical industry. New, greener, business opportunities are arising

from the recovery of product from waste streams (up to 15%) making the

waste stream more economical to dispose of (Keith Freebairn, GSK-see

above)

Awards for the research - highest cited paper in JCA in

2009 ("role of counter-current chromatography in the modernisation of

Chinese herbal medicines" -JCA1216(2009) 740-753) and SPICA2012 prize for

"API recovery from pharmaceutical waste streams" (2012)

Sources to corroborate the impact

- Dynamic Extractions http://www.dynamicextractions.com

- The Advanced Bioprocessing Centre:

http://www.brunel.ac.uk/bib/bioprocess-engineering/abc

- The Chairman of Dynamic Extractions (UK) can be contacted for the

impact of the research on the establishment of a spin-out company,

Dynamic Extractions; all sale information has been provided by the

contact.

- Letter received from Vice Director, State Key Laboratory of Biotherapy

and Cancer Center, West China Hospital, West China Medical School,

Sichuan University, Chengdu, China: The contact confirmed how Sichuan

University and Chengdu Jiye Bio-Tech have developed a novel drug for

treating lung cancer, using HPCCC.

- Director, Second Generation Process Department, GSK Research &

Development, Stevenage, UK: The contact can corroborate 4 new business

case studies in development and the environmental benefits of HPCCC.

- Chairman of SPICA Scientific Committee and Faculty of Applied

Sciences, Georg Simon Ohm University of Applied Sciences, Nuremberg,

Germany

- TSB Final report from the TSB High Value Manufacturing Research

Programme, "Scalable Technology for the Extraction of Pharmaceutical",

TSB project monitor, available from Brunel.