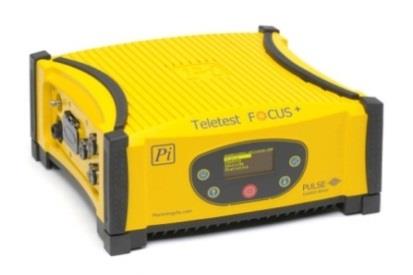

Teletest Focus, Non-Destructive Testing Device

Submitting Institution

Brunel UniversityUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Information and Computing Sciences: Artificial Intelligence and Image Processing

Engineering: Electrical and Electronic Engineering

Technology: Communications Technologies

Summary of the impact

In Europe, there are over a million kilometres of oil pipelines, nearly a

million kilometres of railway tracks, 600 offshore platforms and 300

suspension cable bridges. However, these assets are aging as they have

been in use for many years and operate under harsh conditions. Brunel

research team has advanced ultrasonic non-destructive testing (NDT) which

has the ability to inspect buried pipes in their original place without

removing the pipes or damaging their surrounding environment. In addition,

the research was pursued to improve the NDT of rail tracks, storage tanks,

flexible risers in offshore platforms and aircraft wires. The research has

been commercially exploited and incorporated into Teletest Focus System

Mark III by Plant Integrity Limited. The significant improvement has led

Plant Integrity to terminate the sale of Teletest Mark III and introduce a

new version, Teletest Focus System Mark IV, to the market in late 2010.

Since then, Plant Integrity has doubled its turnover from sales of

Teletest Focus System Mark IV from £1 million to £2 million in less than a

year.

Underpinning research

Professor Balachandran's research involves developing state-of-the-art

sensor technologies and advanced signal processing. Since 2003, Prof

Balachandran has been working in collaboration with The Welding Institute

in Great Abington in Cambridge by conducting research in ultrasonic guided

waves for long range non-destructive testing (NDT) of oil and gas pipes,

plates, rails, wind turbines and aircraft wires, with a view to improve

the performance of the Teletest Focus Mark III System. This product was

marketed by Plant Integrity Ltd, which is the commercial arm of The

Welding Institute.

Professor Balachandran and his research team embarked on addressing the

technical short comings of the Teletest Mark III by conducting fundamental

underpinning research in improving ultrasonic transducer design, new

advanced signal processing techniques, new monitoring methods and

significant improvements to the electronic hardware. This has resulted in

a new product, which has a competitive edge in the market.

The techniques of cross-correlation, wavelet de-noising and split

spectrum processing (SSP) have all been considered and SSP was found to be

the most promising technique for coated pipes, which improved the

signal-to-noise ratio (SNR) of received long range ultrasonic testing

signals, thereby improving the defect sensitivity and test range [1]. The

techniques were enhanced by incorporating robust hardware

pre-conditioning, guided wave focusing and advanced signal processing into

standard test procedures. Using these methods, a novel analytical model of

the interaction of flexural wave modes with circumferential groove-like

defects has been formulated, permitting a more accurate and comprehensive

representation [2].

In addition to the conventional PZT (Lead Zirconate Titanate)

transducers, fully coupled Macro Fiber Composite (MFC) transducers are

also used for inspection using longitudinal waves, whilst the adapted MFC

transducers are used with torsional waves. The research team developed a

novel method of adapting the MFC and determined its characteristics. These

improvements included the development of a robust calibration technique

and the use of Full Matrix Capture for data collection and improved

focusing results [3]. Using numerical modelling and experimental

investigations, Professor Balachandran has identified appropriate wave

modes and excitation/reception conditions needed to inspect different

sections of rails. The outcome of the research was used to investigate

defects such as in-plane and oblique defects for the twisted wire bundle

used in aircrafts. This facility was incorporated into Teletest Mark IV

where none existed before [4].

The research that has been pursued by Professor Balachandran and his

research team has enabled an enhancement of Ultrasonic Long Range Guided

Wave for NDT technology in general. These underpinning research findings

facilitated the hardware improvements needed to be implemented in the

electronic system. Brunel research team in collaboration with Plant

Integrity designed and implemented the new hardware. In this, an FPGA

(Field Programmable Gate Array) based soft core processor was used to

replace the previous stand-alone hardware microcontroller device to

control the memory and peripherals in the system. A novel design has been

developed for the multichannel transmitters with reduced size and

component count. An efficient and reliable multichannel receiver system

has also been designed and implemented in such a manner that fewer clock

cycles are required for completing data acquisition, which makes it

possible for meeting critical timing requirements for multichannel data

acquisition with real-time DSP (Digital Signal Processing) functions

[5&6].

References to the research

1) Mallett, R, Blakeley, B and Balachandran, W, "Automated Radiographic

Inspection of Flexible Risers: A Feasibility Study", Journal of the

British Institute of Non-Destructive Testing, Vol. 47, No. 12, pp.

752-755, December 2005.

http://dx.doi.org/10.1784/insi.2005.47.12.752

2) Catton P, Mudge P, Balachandran W, "Advances in Defect

Characterisation using Long-Range Ultrasonic Testing of Pipes", Journal

of the British Institute of Non-Destructive Testing, Vol. 50, Issue

9, (2008), pp 480-484 http://dx.doi.org/10.1784/insi.2008.50.9.480

3) Haig A G, Sanderson R M, Mudge P J, Balachandran W, 2013, "Macro-fibre

composite actuators for the transduction of Lamb and horizontal shear

ultrasonic guided waves", Journal of the British Institute of

Non-Destructive Testing, Volume 55, Issue 2, pp 72-77

http://dx.doi.org/10.1784/insi.2012.55.2.72

4) Gharaibeh Y, Sanderson R, Mudge P, Ennaceur C, Balachandran W,

"Investigation of the behaviour of selected ultrasonic guided wave modes

to inspect rails for long-range testing and monitoring", Proceedings of

the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid

Transit, V0l.225, (2011), pp 311-324 http://dx.doi.org/10.1243/09544097JRRT413

6) Parthipan T, Nilavalan R, Balachandran W, Mudge P J, "Design and

Analysis of an Ultrasonic NDT Instrumentation Through System Modelling,"

International Journal of Modern Engineering, volume 12, issue 1 (2011)

Details of the impact

Plant Integrity Limited is the commercial arm of The Welding Institute

and has been selling its trademarked Teletest Systems (I, II and III)

since 1998. Prof Balachandran's research identified that significant

improvement could be made to the then-current version Teletest System Mark

III. Teletest Mark III used an old communication protocol and the data

rate was limited to 5 Mbps. It had 24 transmitting but only 8 receiving

channels, which meant that the system had to be activated 3 times in order

to receive signals from all 24 channels. The ultrasonic transducers were

not properly matched, reducing its accuracy, and hence it often produced

unwanted mode conversions. Also, it was bulky and difficult to handle

during field tests.

Professor Balachandran and his team's research addressed these

limitations by advancing research in the field of ultrasonic

non-destructive testing. The Welding Institute commercially exploited his

research advancement so that it can be incorporated into their Teletest

System.

The improvement was so significant that Plant Integrity decided to

manufacture a new version of Teletest System Mark IV. The unit is sold at

£80,000. Since its introduction to the market in late 2010, 20 units per

year have been sold, doubling the market share of Teletest System Mark IV

from £1 million in 2010 to more than £2 million in 2013. Plant Integrity

no longer markets Teletest Mark III.

Teletest® FOCUS+ System Mark IV

Teletest® FOCUS+ System Mark IV

The improvements incorporated in Teletest Mark IV are listed below:

- The design of the ultrasonic transducers for transmitting and

receiving has been improved to achieve better focusing and to eliminate

unwanted dispersive modes

- The new system has 24 transmitting and receiving channels and they can

be activated simultaneously

- The gain of each channel can be independently controlled and

calibrated

- The use of FPGA has significantly reduced the requirements for

external components, ADC interpolation etc.

- Incorporates Ethernet protocol (100 Mbps) as opposed to 5 Mbps in

Teletest Mark III

- Operational speed is 7 times faster (2 minutes)

- The power electronics used is a hybrid of a number of custom made SMPS

topologies with overall efficiency in excess of 86%

- The size and weight of the battery has been reduced from 2.5 kg to 0.5

kg without compromising the system performance

- Teletest Mark IV is 45% lighter

- It can handle full matrix capture

- It incorporates WiFi and GPS

- It has better Electromagnetic Compatibility protection

- Significant reduction in physical size (33cm x 33 cm x14 cm)

- Four units can be interlinked and synchronised to the master clock and

the transmission distance is 100m

- Data link can be increased to 120 channels thereby extending

application to tanks

The Electronic system incorporated in Teletest Mark IV has the capability

to be used with high temperature ultrasonic transducers that have been

developed by Professor Balachandran and his research student for NDT in

nuclear and food manufacturing industries. Furthermore, it can also be

configured and used for NDT using Electromagnetic Acoustic Transducers

(EMAT), which has the advantage of being non-contact transducer and hence

not requiring air pressure for coupling to the target surface.

Teletest Mark IV has 10% domestic and 90% export market and has even

distribution globally (Europe, North America and Asia). Typical clients in

oil and gas industries are ConocoPhillips, Petrobras, Chevron, Shell etc.

Plant Integrity is intending to market the system to rail and aircraft

industries in the near future.

Sources to corroborate the impact

Contactable source: All information regarding sales and technical

improvement of Teletest Mark IV has been provided by the Manager at Plant

Integrity Limited, Cambridge, UK.