High Performance Simulation techniques to reduce industrial production and logistics costs through better management

Submitting Institution

Brunel UniversityUnit of Assessment

Computer Science and InformaticsSummary Impact Type

TechnologicalResearch Subject Area(s)

Information and Computing Sciences: Artificial Intelligence and Image Processing, Computer Software, Information Systems

Summary of the impact

The research has enabled industrial simulation users to investigate and

develop larger scale systems faster and cheaper and thus

to explore a wider variety of cost-saving options with more precision,

and industrial simulation providers to offer new high-performance

simulation (HPS) products and services. As a direct result of this work:

Ford has made £150,000 cost savings in consultancy and significant process

improvements to engine manufacture globally; Saker Solutions (UK SME) has

created the first ever HPS system for production and logistics; Sellafield

PLC has used this system to make significant process improvements and

savings in the management of nuclear waste reprocessing of around £200,000

per year; and Whole Systems Partnership (a UK SME) used a spin-off from

this research to generate a £200,000 per year revenue stream from

interoperable healthcare decision support systems. Globally, several other

companies are adopting the standardisation efforts and other outcomes of

the research as the foundation for future innovation.

Underpinning research

Discrete-event simulation is used to investigate and improve planned or

existing industrial production and logistics systems (e.g., car engine

manufacturing plants, nuclear waste disposal, etc.). However, the

state-of-the-art of simulation technology limits the size of system being

studied and the amount of investigation that can be done in a project.

Models are also costly to develop, so it is desirable to reuse models as

`building blocks' in analysing larger systems. For example, an engine

manufacturing system model might be composed of several reused

interoperable models that represent the production of engine blocks,

camshafts, assembly lines, etc. Reusing these models to compose a larger

model clearly saves costs as there is significant investment in each

individual model. There are, though, major barriers to such composability

and interoperability that limit the size of model that can be developed.

Simulations also take time to run (minutes to hours depending on

complexity/size), and a systematic investigation could require many

thousands of simulation runs (and therefore potentially thousands of

hours). In practice, projects have limited time and budgets, so only a

subset of simulation experiments can be carried out in a specific

project/context, limiting the quality of study outcomes as a result.

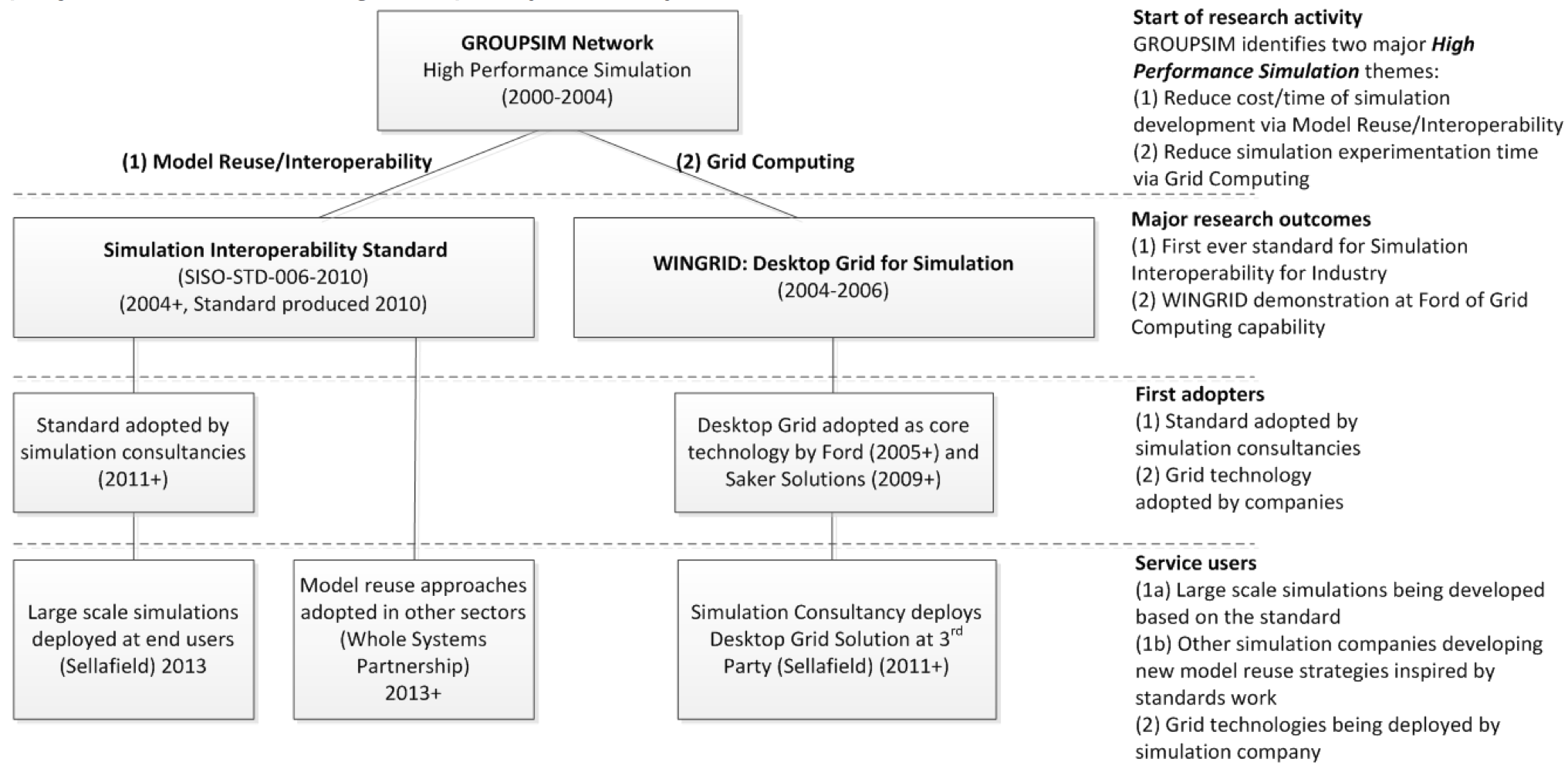

Figure 1: High Performance Simulation Impact Overview

Figure 1: High Performance Simulation Impact Overview

Solutions to the above problems were evident in other simulation domains,

but did not exist for industrial discrete-event simulation users. In 2000,

Taylor (a Senior Lecturer at Brunel at the time, now a Reader) led the

EPSRC Network GROUPSIM (EPSRC GR/N35304, 2000-2004) to investigate methods

to transfer these innovations into this industrial simulation sector to

make a step change in the state-of-the-art. These High Performance

Simulation techniques have two major complementary themes: (1) techniques

to reduce the cost and time of simulation development and (2) techniques

to reduce the time of simulation experimentation. The path to impact of

the research is shown in Figure 1.

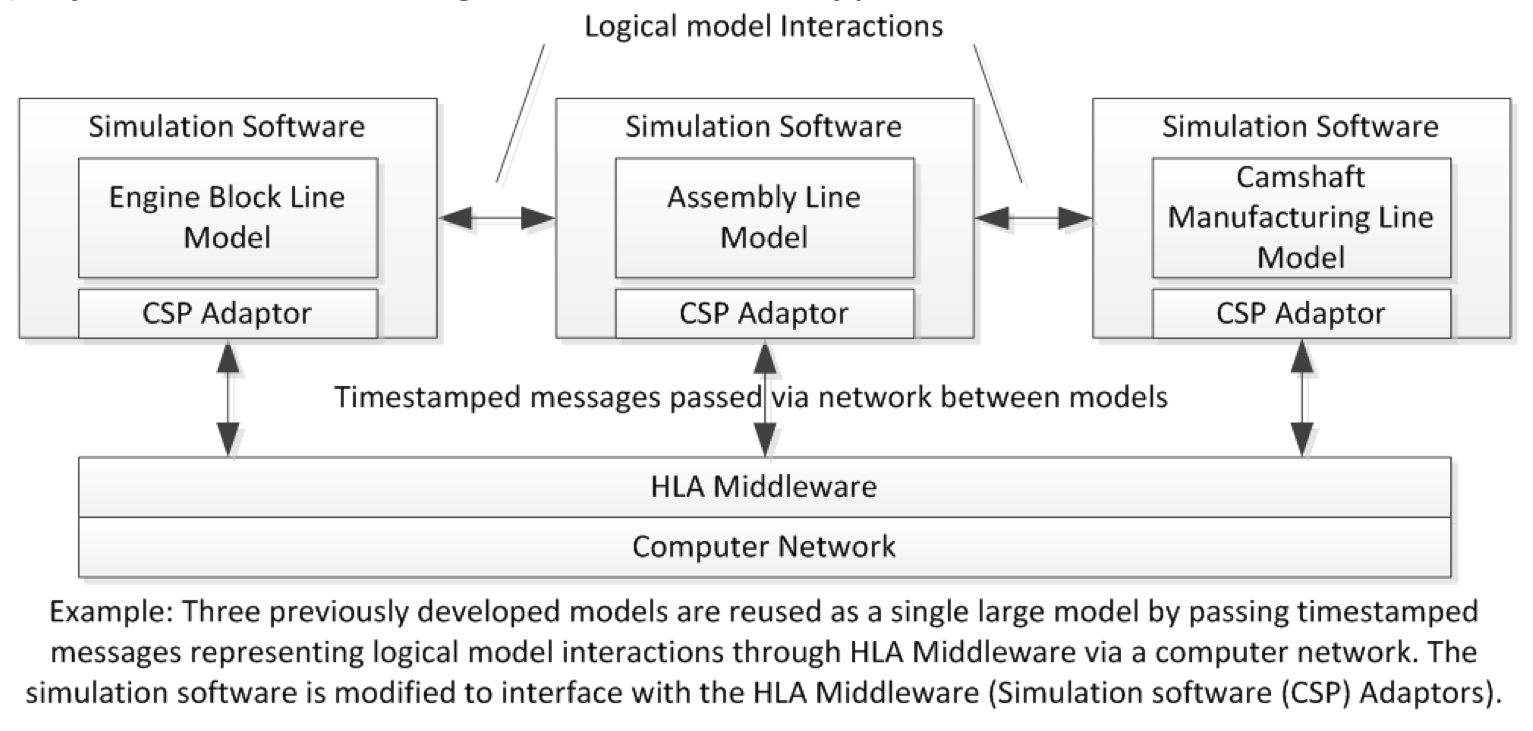

(1) The defence simulation sector had successfully created an

approach to model reuse that linked together (interoperated) models over a

computer network (Figure 2) and thus made major cost savings in model

development by reusing previously developed models. This was based around

the IEEE 1516 High Level Architecture (HLA) standard for simulation

interoperability. GROUPSIM identified that there were major barriers to

using the HLA and related software (middleware) for production and

logistics simulation and that further standardisation was needed. In 2004,

Taylor led this standardisation effort by creating the international COTS

Simulation Package Interoperability Standards Development Group under the

US-based Simulation Interoperability Standards Organization (SISO). In

2010, derived directly from concepts introduced by Taylor in GROUPSIM, he

developed the world's first standard in this area, the Standard for

COTS Simulation Package Interoperability Reference Models

(SISO-STD-006-2010) (validated by SISO standards development process

following repeated community balloting). This is being used, for example,

to underpin large-scale simulation of nuclear waste management at

Sellafield (developed by Saker Solutions) and has been adopted by several

companies (e.g., AEGIS Technologies (USA), PITCH (Sweden), Simul8 (UK) and

D-SIMLAB (Singapore)). To demonstrate the approach and to avoid

proprietary model and data issues, a generic healthcare-based production

and logistics simulation was also created with related software developed

to support simulation interoperability by Taylor and Mustafee (PhD

Student, then Research Fellow, at Brunel 2004-9; now a lecturer at the

University of Exeter) (e.g., simulation software adaptors developed for

the well-known Simul8 software). A novel model reuse strategy has also

been developed with Whole Systems Partnership under a Knowledge Transfer

Programme (Taylor as lead academic) for Systems Dynamics Decision Support

in Healthcare (KTP008757) (Manpower capability planning) (currently

deployed at Trent Strategic Health Authority).

Figure 2: Model Reuse Via Simulation Interoperability

Figure 2: Model Reuse Via Simulation Interoperability

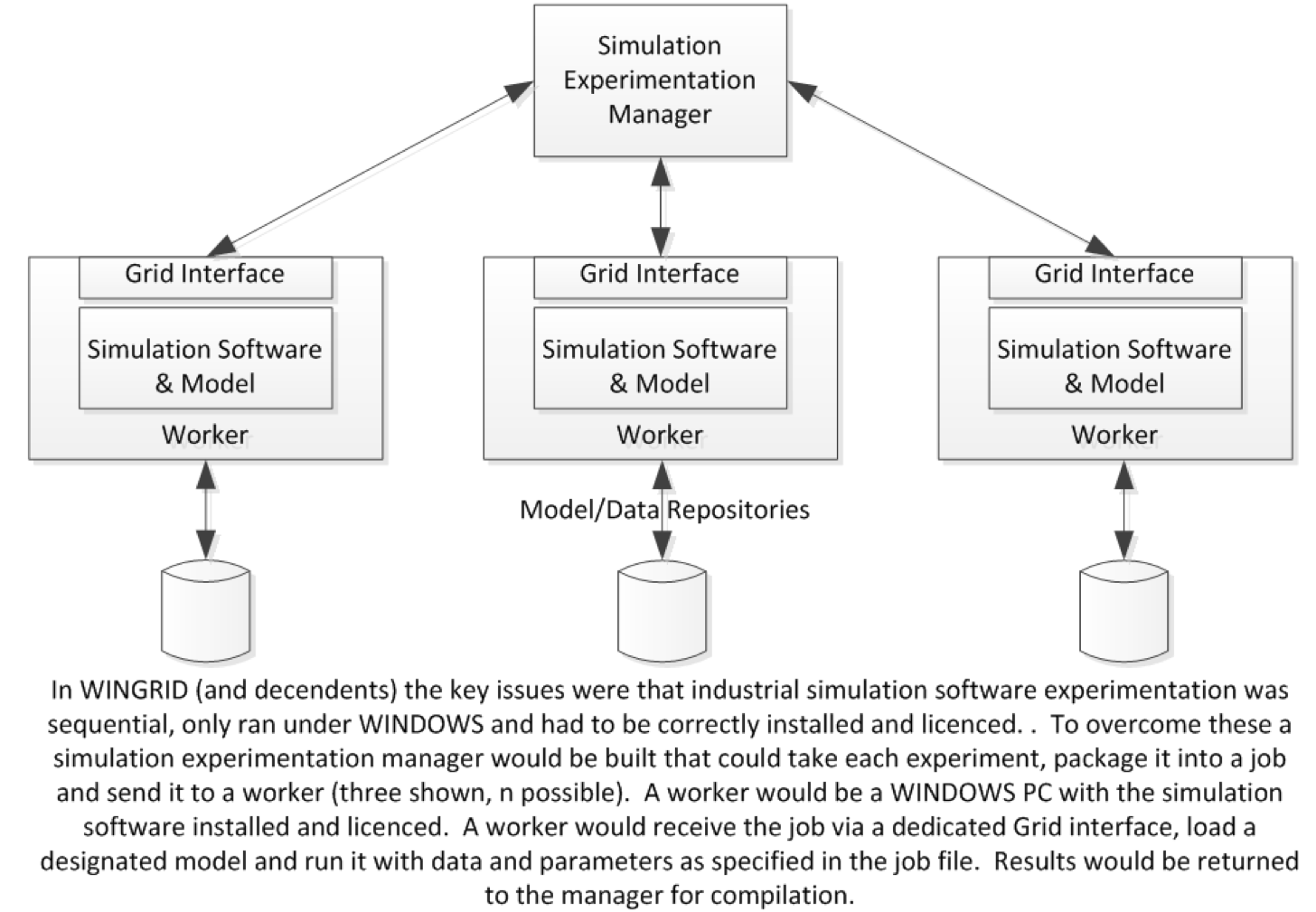

(2) In other areas, Grid Computing (the use of multiple computers

to speed up applications) has had a major impact. However, at the time,

Grid Computing technologies could not be easily utilised by most

simulation software used for production and logistics simulation. To

demonstrate how Grid Computing could be used in this area, Taylor with

Mustafee developed WINGRID (2004-2006) — the WINDOWS-based Desktop Grid

for Simulation (Figure 3). This was successfully deployed at the Ford

Motor Company's Dunton Engineering Centre (Brentwood, Essex) to

investigate engine system manufacturing worldwide. At Ford this system has

evolved and is now a core simulation technology. Experience from this work

led to the development of SAKERGRID which supports high speed simulation

at Saker Solutions, a UK simulation consultancy with a wide range of

production and logistics projects. SakerGrid has, in turn, been deployed

at Sellafield to support the high speed simulation of nuclear waste

management.

Figure 3: WINGRID Desktop Grid Architecture

Figure 3: WINGRID Desktop Grid Architecture

References to the research

[1] Taylor, S.J.E., Turner, S.J. and Strassburger, S. (2010). Standard

for COTS Simulation Package Interoperability Reference Models

(SISO-STD-006-2010), Simulation Interoperability Standards Organization,

Orlando, Florida, USA.

[2] Taylor, S.J.E. Developing Strategies and Infrastructure for

Collaborative Simulation Modelling (GROUPSIM). EPSRC (GR/N35304).

Publications

[3] Taylor, S.J.E., Turner, S.J., Strassburger, S. and Mustafee, N.

(2012). Bridging The Gap: A Standards-Based Approach to OR/MS Distributed

Simulation. ACM Transactions on Modeling and Computer Simulation.

22(4). Article 18. http://dx.doi.org/10.1145/2379810.2379811

[4] Mustafee, N., Taylor, S.J.E., Katsaliaki, K., Dwivedi, Y.K. and

Williams, M. D. (2012). Motivations and Barriers in using Distributed

Supply Chain Simulation. International Transactions in Operational

Research. 19(5): 733-751. http://dx.doi.org/10.1111/j.1475-3995.2011.00838.x

[5] Mustafee, N. and Taylor, S.J.E. (2009) Speeding up simulation

applications using WinGrid. Concurrency and Computation: Practice and

Experience, 21 (11), 1504-1523. http://dx.doi.org/10.1002/cpe.1401

[6] Katsaliaki, K., Mustafee, N., Taylor, S.J.E and Brailsford, S.

(2009). Comparing Conventional and Distributed Approaches to Simulation in

a Complex Supply-Chain Health System. Journal of the Operational

Research Society.60, pp. 43-51. http://dx.doi.org/10.1057/palgrave.jors.2602531

Details of the impact

The GROUPSIM Network began work that has led to major innovations in High

Performance Simulation for industrial discrete-event simulation users and

is facilitating the investigation and development of larger scale systems

faster and cheaper and now allows a wider variety

of cost-saving options to be explored with more precision. It also

has made it possible for industrial simulation providers to offer new

high-performance simulation (HPS) products and services. As shown

in Figure 1, these innovations have two major complementary themes: (1)

techniques to reduce the cost and time of simulation development (Model

Reuse and Interoperability) and (2) techniques to reduce the time of

simulation experimentation (Grid Computing). The impact of each theme is

detailed below.

The standardisation efforts involved in (1) began in 2004 with the

formation of the standards development group (CSPI PDG) at SISO and

produced the first standard in 2010. The standard is now being gradually

adopted by the international practitioner community and is being used to

guide the development of large-scale manufacturing simulations. Saker

Solutions was involved in the development of the standard and is now using

the standard to create a large-scale simulation of nuclear waste

reprocessing at Sellafield PLC which has led to "major cost savings" (see

corroborating source S1). This is the first time that Sellafield has been

able to comprehensively study the major elements of waste management as a

whole system and is a direct output of both the standard and the

standardisation process. Examples of practitioners adopting the standard

internationally are: AEGIS Technologies (a USA SME specialising in defence

simulation), PITCH (an SME based in Sweden that develops large scale

simulations), Simul8 (a UK SME that sells one of the most well-known

simulation software) and D-SIMLAB (a Singapore SME specialising in

aircraft maintenance logistics). (Corroborating source S2 from Mark Elder,

Chairman of Simul8, is representative of this adoption, "Without this

we and the whole simulation industry would still be operating in an

isolated way").

The Grid Computing development work in (2) has been adopted by several

simulation users. At the Ford Motor Company's Dunton Engineering Centre

(Brentwood, Essex) simulation is used to design engine manufacturing

facilities worldwide and for process improvement in day-to-day operations

by studying different machine configurations, buffer capacities,

changeover Schemes, etc. Brunel and Ford developed various High

Performance Simulation solutions for implementation in Ford's Power Train

Manufacturing simulation team. Ford has adopted and built new high

performance simulation systems in conjunction with Lanner Group (a

simulation consultancy SME). Ford now uses significantly more simulation

in this area and has saved an estimated £150,000 in consultancy cost

during the REF period and, according to Ford's Technical specialist, a

significant undisclosable sum due to process improvements as a result of

that extra experimentation (see corroborating source S3). Dunton leads

simulation activities in this area worldwide and this work has therefore

affected production teams at Ford's engine manufacturing facilities across

the world (UK, USA, Mexico, Spain, South Africa and Brazil) (see

corroborating source S3).

Experiences from this enabled Taylor to lead the development of SAKERGRID

(in 2010) with Saker Solutions (one of around 10 UK SMEs specialising in

simulation), Grid Computing software supporting high speed experimentation

and test/build development. Saker Solutions employs 12 people (annual

turnover £1 to £2 million) in the UK and works with many UK companies

using simulation to study a wide range of manufacturing, production and

logistic problems. SAKERGRID has been used to significantly improve the

quality of Saker's simulation projects and is saving around £20,000 per

annum in terms of project time saved at Saker (£80,000 over 4 years) (see

corroborating source S1). Saker Solutions has now implemented SAKERGRID

(in 2011) within the Sellafield Ltd Operational Research Group (around 25

members) where the tool has been used since to support over 10 major

projects in the last year. The expected direct savings in this financial

year at Sellafield Ltd are approximately £200,000 with substantial

additional savings expected in subsequent years. Of course, in addition

there are unquantified savings arising from the reduced turnaround time of

experimentation enabled by the use of SAKERGRID which both reduces project

lead time and increases the number of scenarios which can be examined (see

corroborating source S4).

In terms of products and services, Saker Solutions is now able to offer

new high-speed products and services based on this work. Saker Solutions

is the first to offer these in a comprehensive manner. This has had a

`ripple effect' in the community and has led to at least one further

innovation due to the impact of these advanced in simulation technology

state of the art. This took the form of a Knowledge Transfer Partnership

(KTP) between Whole Systems Partnership and Brunel University (Taylor).

Whole Systems Partnership is a small consultancy with a £300,000 per year

turnover that develops healthcare decision support solutions. The results

of the KTP are a (from 2013 onward) £200,000 per year revenue stream using

reusable Systems Dynamics models for decision support in manpower

capability planning in the NHS (see corroborating source S5).

Sources to corroborate the impact

S1 - Letter received from Managing Director, Saker Solutions

S2 - Letter received from Founder and Non-executing Chair, Simul8

Corporation

S3 - Letter received from Simulation Technical Expert, Ford Motor Company

Ltd.

S4 - Letter received from Project Leader, Sellafield Operational Research

Group

S5 - Letter received from Managing Director, The Whole Systems

Partnership