UOA15-09: Compact, lightweight compressors for space applications

Submitting Institution

University of OxfordUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Physical Sciences: Other Physical Sciences

Information and Computing Sciences: Artificial Intelligence and Image Processing

Engineering: Interdisciplinary Engineering

Summary of the impact

Compressors developed at the Department of Engineering Science have

formed a key component of the cryocoolers used to cool the infra-red

sensors on satellites. Their low mass has trimmed almost $250k from the

cost of individual satellite missions. Sixty seven have been sold to date,

with sales totalling £2.8M between January 2008 and July 2013; three units

are currently in Earth orbit with another nine planned to follow in 2014.

A specialised version has been developed to achieve extremely low

temperatures, with prototypes already built for the Mid Infra-Red

Instrument (MIRI) that will form part of the James Webb Space Telescope.

Underpinning research

The development of Oxford compressors has been on-going for many years,

with its design being continuously re-evaluated, improved and refined.

This study relates to the impact of the current, third-generation device,

developed since 1995.

- The development of this technology began in 1978, when research was

initiated on the original `Oxford-style' compressor for use in long-life

Stirling cycle cryocoolers designed for orbiting satellites. Later, a

second-generation `integral cooler' was developed for lower-cost

Earth-based applications.

- Work on the third-generation compressor was triggered in 1995 by a

requirement from US-based firm TRW — now part of Northrop Grumman

Corporation (NGC) — for a small, high power density compressor

compatible with the envelope of an existing short-life cooler. The work

was led by Dr Mike Dadd, responsible mainly for scientific design, and

Paul Bailey, responsible mainly for engineering design (both joined the

Department in 1985 and are still in post). In 2005, Professor Richard

Stone, who joined the Department in 1993 as a University Lecturer and is

also still in post, took over from Dr Gordon Davey as academic lead on

the research.

- The resulting design, licensed to TRW in 1997, offered a higher power

density and thus a higher efficiency than existing devices [1]; and was

also easier to manufacture. The technology is partly protected by a US

Patent [2], with many other details proprietary.

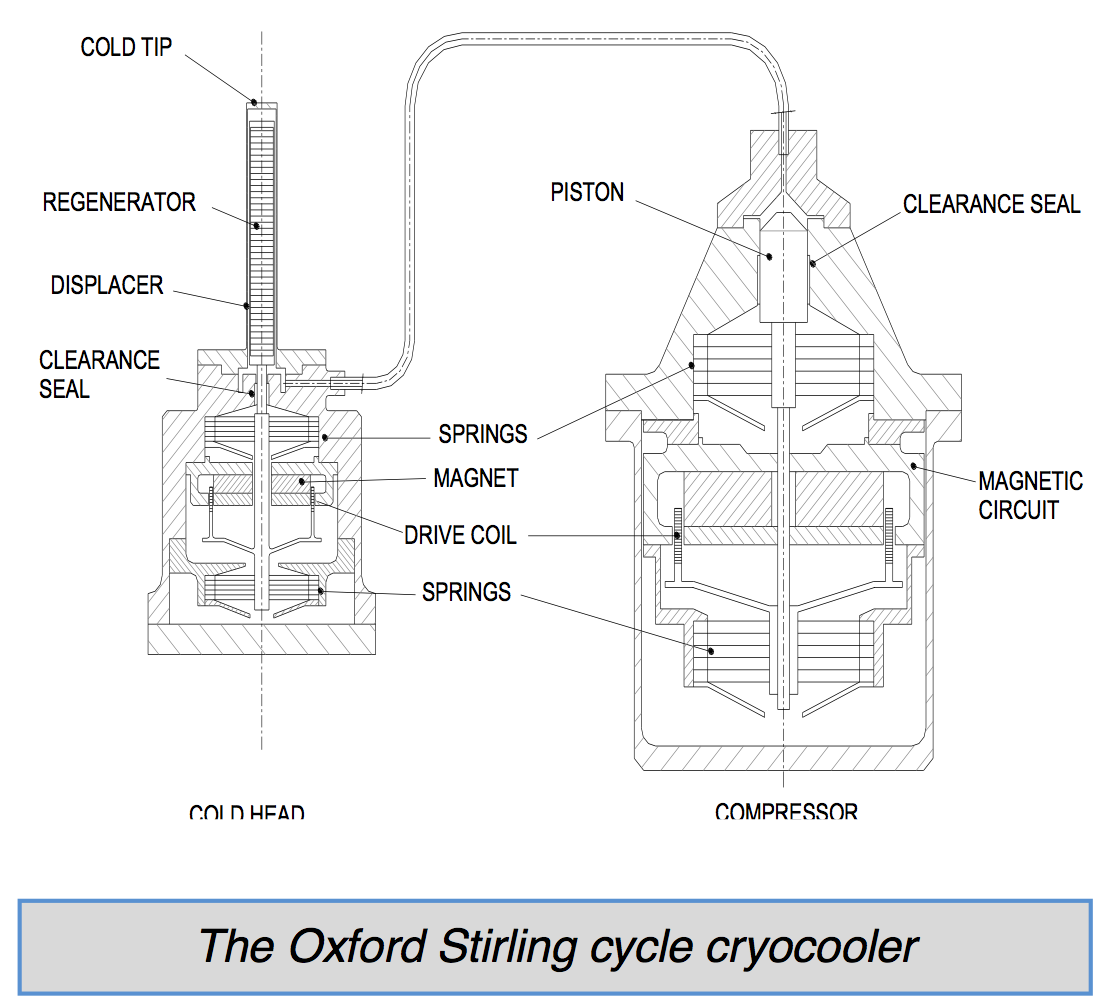

- Key features of these third-generation compressors include: a small

clearance (10-1603bcm radially) between the piston and cylinder,

ensuring that gas leakage is negligible; diaphragm springs that allow

axial, but not radial, piston movement; and a linear electromagnetic

drive with a moving coil (similar to a loudspeaker).

- The specific improvements that this design delivered were increased

magnetic flux density in the air gap, reduced overall motor size and a

reduction in the stray magnetic field around the compressor [3].

Electromagnetic, thermal, stress and thermodynamic modelling carried out

by Dadd and Bailey led to the manufacture of single compressors each

with a separate momentum balancer incorporated into the pressure vessel.

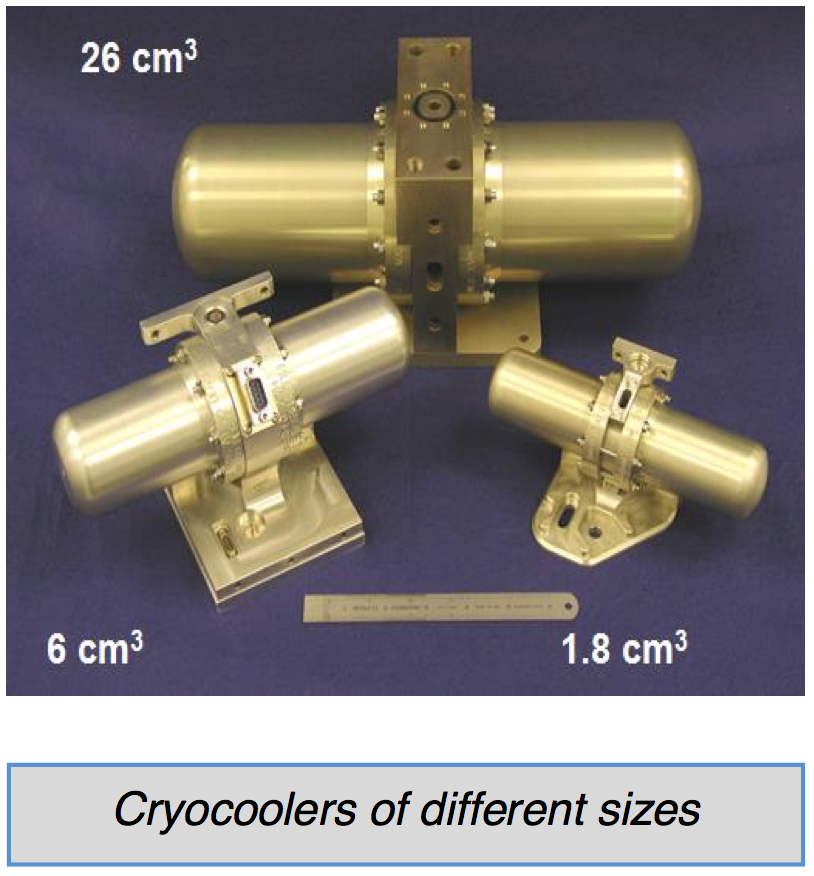

- TRW further requested the design and manufacture of `balanced pair'

compressors (see photo), building on the previous design [4] as part of

this development process. When combined with TRW pulse-tube cold heads,

the complete cryocooler was smaller and at least 16% more efficient than

anything else available.

Due to commercial sensitivity, many technical details about the

third-generation design remain unpublished; published papers are typically

limited to details of system performance. However, projects funded by the

US Air Force (USAF) and by TRW involved detailed investigation of:

- The reduction of vibration from the compressors as a result of

improved balancing. This is crucial in satellite applications, where

excessive vibration can harm optical measurements.

- The effect of geometrical factors on the linearity of piston motion in

the compressors [5].

In 2005, a paper summarising USAF-funded research conducted by the

research team, focusing on motor and thermodynamic losses, secured the

Russell B Scott Memorial Award for Best Paper at the Cryogenic Engineering

Conference in Keystone, Colorado [6].

References to the research

(best indicators of research quality are marked `Q')

1. Curran, D.G. et al. `Space Cryocooler Vendor Survey Update:

2007' (2008). Aerospace Report No. TOR-2008 (1033)-7691, Aerospace

Corporation, El Segundo, California.

(Confidential document held on file and available on request)

Survey of space cryocoolers, including data on mass per unit of

cooling power.

2. Dadd, M.W. Linear Compressor Motor. US Patent 6127750 (3/10/2000).

http://www.google.co.uk/patents/US6127750

4. Bailey, P.B., Dadd, M.W., Hill, N., Cheuk, C.F., Raab, J. and Tward,

E. `High Performance Flight Cryocooler Compressor' (2001). Cryocoolers,

11, pp 169-174. Kluwer Academic/Plenum Press, New York. http://www.hymatic.co.uk/stirling.cryocooler.tp1.htm

`Q'

Paper describing the performance of a cryocooler incorporating the

third-generation compressor.

5. Dadd, M.W., Bailey, P. B. and Davey, G. `The Linearity of Clearance

Seal Suspension Systems' (2003). Cryocoolers, 12, pp 255-264.

Kluwer Academic/Plenum Press, New York.

http://dx.doi.org/10.1007/0-306-47919-2_35

`Q'

Paper on factors affecting linearity of motion of a piston mounted on

diaphragm springs.

6. Reed, J., Bailey, P. B., Dadd, M.W. and Davis, T. `Motor and

Thermodynamic Losses in Linear Cryocooler Compressors' (2006). Advances

in Cryogenic Engineering, 51a, pp 361-368. AIP, New York. http://dx.doi.org/10.1063/1.2202436

`Q'

Grants in support of this research:

• Northrop Grumman, contracts totalling £1.73m, 1995-2013

• USAF, contracts totalling £300k, 1998-2011

• EPSRC (EP/E036899/1), £246k, 2007-2010

Details of the impact

In the space sector, demand is growing for cost-effective solutions to

the challenge of cooling satellite sensors. Infra-red sensors, in

particular, are used in a wide range of satellite applications such as

deep space astronomy, missile detection and measurement of ocean and land

surface temperatures. The compressors' proven ability to meet this need is

reflected by their total sales of £5.7M [7], estimate £2.8M between

January 2008 and July 2013. Satellite systems where they are currently

deployed include:

- JAMI (Japanese Advanced Meteorological Imager), launched in 2005 and

scheduled to remain in orbit till 2015, see http://www.wmo-sat.info/oscar/instruments/view/236.

- GOSAT (Greenhouse Gases Observing Satellite), launched in 2009. Seven

compressors are also currently in production. Other key developments

have included:

- Addition of valves to transform the device from a `pressure wave

generator' into a `conventional' compressor. One such unit is to be used

to drive a Joule-Thomson cryocooler that will provide the James Webb

Space Telescope's MIRI instrument with cooling to 6 Kelvin [8]. Two

prototypes have been produced and manufacture of the flight units is now

under way.

- Modification of the technology to provide the basis for a small engine

capable of generating electrical power for deep space and planetary

missions. Working with TRW and NASA, the team modified a 6cm3

compressor by increasing the piston and cylinder size to give a swept

volume of 21cm3; this device was then used as an expander in

a thermo-acoustic Stirling heat engine [9]. An electrical power output

of 40W was achieved with a thermal efficiency of 18%.

The research underpinning the compressors has achieved three key impacts,

with the benefits felt by the space industry and beyond:

Economic Impact 1 — savings in satellite launch costs:

Third-generation `Oxford-style' compressors deliver substantial cost

savings for satellite missions when combined with pulse-tube cold heads

manufactured by NGC. This is because the compressors' smaller size,

compared to rival technologies, leads to reduced satellite weight and

therefore a cut in launch costs. With the cryocooler weighing about 12kg

less than alternatives [10] and satellite launches costing around

US$20,000 per kg [11], the result is a saving of US$240,000 per mission.

The Cryocooler Systems Manager at NGC has confirmed that "The high

reliability, small size, low mass and efficiency of the compressors

incorporated into a pulse tube cooler has been a significant advantage to

us, ..." [12]. Moreover, due to the higher efficiency of cryocoolers

incorporating the compressors, smaller solar arrays are needed to power

them; the radiator area for heat rejection can also be reduced — further

reducing the mission cost.

Economic Impact 2 — cost savings for satellite missions:

Previously all compressors were uniquely developed for each system, which

had to bear the costs of the device development and qualification testing

for space flight (typically $5-10M). Oxford's third generation devices are

now available as off-the-shelf products which are "flight qualified".

This was achieved through close collaboration between Oxford University,

TRW and Hymatic (now Honeywell Hymatic, Redditch, UK) which aimed to

further develop the compressor after the successful creation of prototype

units. Hymatic successfully manufactured a `productionised' version

featuring enhanced in-process testing to verify the process [13]. Hymatic

subsequently manufactured families of `balanced pair' compressors

developed at Oxford, (Section 2) with displacements of 1.8cm3

(1998), 26cm3 (1999) [14], and even as small as 0.6cm3

(2003) [15]. Ease of manufacturing the compressor has led to a significant

cut in the cost of in-space cooling.

Economic Impact 3 — wider economic benefits and wealth creation:

Honeywell Hymatic sales for this product, manufactured in the UK, have

totalled £5.7M, with £2.8M generated from January 2008 to July 2013. The

company's Engineering Manager confirms that "this product line is a

significant part of our business, and we anticipate that it, and future

related products, will continue to be an increasing part of our strategic

business model for years to come" [7].

Income to the University through a

licensing agreement with TRW amounted to £99,640 (gross) between 2008 and

the end of 2012 [16]. The cryocoolers' success has resulted in NGC

securing a significant share of the US market, with devices based on the

licensed technology sold to major US aerospace companies, resulting in 16

out of the 19 long-life coolers currently in orbit being based on Oxford

designs [12]. Although these cryocoolers have largely been sold to US

firms, a collaborative project involving NGC, Systems Engineering &

Assessment Ltd (based in Bristol), Honeywell Hymatic and the UK Science

and Technology Facilities Council is currently adapting the compressor for

use with a Stirling cold head in a cryocooler for the European Space

Agency.

Sources to corroborate the impact

- Letter from the Engineering Manager, Honeywell Hymatic. Corroborates

their sales and that the product is significant in Honeywell's business.

- Petach, M. et al.. `MIRI Cooler System Design Update' (2011). Cryocoolers,

16, pp 9-12. ICC Press, Boulder, Colorado. http://hdl.handle.net/1853/38740

Paper describing the cooling system for the MIRI instrument.

- Petach, M., Tward, E. and Backhaus, S. `Design of a High Efficiency

Power Source (HEPS) Based on Thermoacoustic Technology' (2004). Final

Report for NASA GRC Contract NAS3-01103. http://www.lanl.gov/projects/thermoacoustics/Pubs/HEPSFinalDraftU.pdf

- Pettyjohn, E. `Cryocoolers for Microsatellite Military Applications'

(2011). Cryocoolers, 16, pp 709-713. ICC Press, Boulder,

Colorado

https://smartech.gatech.edu/bitstream/handle/1853/39788/086.pdf?sequence=1

Paper stating that "space cryocoolers usually weigh 22-25kg"; cf.

the total mass of a cryocooler incorporating the Oxford-style

compressor, which is 7.4kg [1]. The estimate of reduced mass is

conservative.

- Futron Corporation. `Space Transportation Costs: Trends in Price Per

Pound to Orbit 1990-2000' (2002).

http://www.futron.com/upload/wysiwyg/Resources/Whitepapers/Space_Transportation_Costs_Trends_0902.pdf

Gives launch costs as US$17,032 or US$6,967 per pound mass,

depending on launch vehicle, for geosynchronous orbit, interpreted

conservatively at 2013 prices as US$20,000/kg.

- Letter from Cryocooler Systems Manager, NGC. Corroborates the

minimised size/weight.

- Cheuk, C.F., Hill, N.G., Strauch, R., Bailey, P.B. and Raab, J.

`Producibility of Cryocooler Compressors' (2003). Cryocoolers,

12, pp 275-281. Kluwer Academic/Plenum Press, New York.

http://www.eng.ox.ac.uk/cryogenics/publications/abstracts/stirling.cryocooler.tp2.pdf/view

Paper describing some of the in-process testing.

- Jaco, C., Nguyen, T., Colbert, C., Pietrzak, T., Chan, C.K. and Tward,

E. `High Capacity Staged Pulse Tube Cooler' (2004). Advances in

Cryogenic Engineering: Transactions of the Cryogenic Engineering

Conference — CEC AIP Conference Proceedings, 710, pp 1263-1268.

http://dx.doi.org/10.1063/1.1774813

Paper describing the largest in this family of compressors, mated to

a multi-stage cold head.

- Petach, M., Waterman, M.C., Tward, E. and Bailey, P.B. `Pulse Tube

Microcooler for Space Applications' (2007). Cryocoolers, 14, pp

89-93. ICC Press, Boulder, Colorado.

http://minds.wisconsin.edu/handle/1793/21708

Paper describing the smallest in the family of compressors.

- Senior Technology Transfer Manager, Isis Innovation. Corroborates

income to the University.