Reduction of non-degradable waste from used plastic food packaging materials

Submitting Institution

Brunel UniversityUnit of Assessment

Mathematical SciencesSummary Impact Type

TechnologicalResearch Subject Area(s)

Chemical Sciences: Macromolecular and Materials Chemistry

Engineering: Materials Engineering

Summary of the impact

The production of plastic (polymer) waste and the difficulties associated

with its disposal is a major

environmental challenge. Many polymer food packaging structures are made

using thermoforming

processes in which hot thin oil-based polymer sheets are forced under

pressure into moulds and

then cooled to become thin-walled packaging structures. These structures

are not eco-friendly and

do not degrade after use. Thus unless they are recycled, which is a

complicated process and

mostly does not happen, these structures cause major environmental

problems worldwide.

Researchers in Brunel Institute of Computational Mathematics (BICOM) have

undertaken

extensive computational modelling of the thermoforming of packaging

structures made from bio-materials

(thermoplastics). This computational work, together with the necessary

laboratory

experiments which were executed by Brunel engineers, has contributed to a

far better

understanding of the behaviour of starch-based biodegradable food

packaging. In turn, the

availability of such knowledge has contributed to the steady move by food

packagers and food

retailers towards the adoption of such packaging which is helping to

reduce the amount of long

term non-biodegradable waste produced.

Underpinning research

Since 1993 Professor J R Whiteman, Drs S Shaw and M K Warby, and research

students in

BICOM have undertaken research into the computational modelling of

thermoforming processes

for thin polymeric sheets. Initially for oil-based materials, the research

covered the large

deformation of hot polymeric sheets into moulds in order to form

thin-walled packaging structures.

New applications were treated and numerical techniques based on the

theoretical work [1] were

proposed. These computational models required knowledge both of the

viscoelastic/elasto-plastic

behaviour and of the material properties of the oil-based polymeric

materials. Design tools, based

on finite element models of forming processes, were delivered to the

British companies: CMB

Technology (CarnaudMetalBox plc); Autotype International Ltd; John

McGavigan Ltd [2]-[4]; and to

the US Army Research Laboratory, Langley. The state was reached whereby,

for many relevant

packaging shapes, the wall thicknesses of the structures could be

predicted for a range of

polymeric materials such as Bayfol® and Polypropolene.

Over the past two decades it has become increasingly clear that oil-based

polymer packaging is

creating much non-biodegradable waste, which typically ends up at landfill

sites. With this in mind,

Whiteman and Warby collaborated with Professor J Song (Department of

Mechanical Engineering,

Brunel) on a project applying computational modelling and experimental

analysis to thermoforming

processes for bio-degradable thermoplastic starch sheets. This work,

funded by the Department

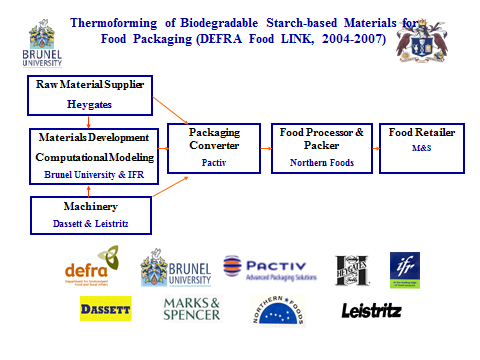

for Environment, Food and Rural Affairs from 2004 to 2008, brought

together the industrial

partners: Dassett Process Engineering Ltd; Marks and Spencer Plc; Heygates

Ltd; Leistritz

Extruders; Institute of Food Research; Pactiv Ltd and Northern Foods Plc.

At the time thermoplastic bio-materials were relatively new and, unlike

oil-based materials, their

material properties were not well understood. In particular, the behaviour

of starch-based bio-materials

during thermoforming is affected by their moisture content. The

researchers at BICOM

developed new computational models for the deformation of a bio-plastic

membrane during

thermoforming, under temperature and moisture content variation. The

parameters required for

these models were determined experimentally by Song and co-workers using a

thermoplastic

material sourced by Plantic plc. This research [5]-[8] provides an insight

into how different

parameters (including temperature and moisture content) affect the wall

thickness and other

properties (such as strength and stiffness) of a structure during

thermoforming. Such information is

essential for the design of moulds and processing of raw material while

manufacturing starch-based

bio-degradable food packaging.

References to the research

Papers in International Journals:

1. I. Babuska, J.R. Whiteman, T.Strouboulis. Finite Elements; An

Introduction to the Method

and Error Estimation. Oxford University Press, (2011).

2. M.K. Warby, J.R. Whiteman, W-G Jiang, P. Warwick, T. Wright. Finite

element simulation of

thermoforming process for polymer sheets. Maths and Computers in

Simulation, 61, 209-218,

(2003).

3. W-G Jiang, M.K. Warby, J.R. Whiteman, S. Abbott, W. Shorter, P.

Warwick ,T. Wright, A.

Munro, B. Munro. Finite element modelling of high air pressure forming

processes for

polymer sheets. Computational Mechanics 31, 163-172, (2003).

4. M. Karamanou, M.K. Warby, J.R. Whiteman. Computational modelling of

thermoforming

processes in the case of finite viscoelastic materials. Computer Methods

in Applied

Mechanics and Engineering 195, 5220-5238, (2006).

5. D. Szegda, J. Song, M.K. Warby, J.R. Whiteman. Computational Modelling

of a

Thermoforming Process for Thermoplastic Starch. American Institute of

Physics,

Proceedings 908, 35 - 47, (2007).

6. D Szegda, Experimental Investigation and Computational modelling of

the Thermoforming

Process of Thermoplastic Starch. PhD Thesis, School of Engineering, Brunel

University,

(2009). http://bura.brunel.ac.uk/handle/2438/3445

7. S. Shaw, M.K. Warby, J.R. Whiteman. Discretization and modelling error

in the context of

the rapid inflation of hyperelastic membranes. IMA Journal of Numerical

Analysis, 30 302-333, (2010).

8. S. Shaw, M.K. Warby, J.R. Whiteman. Computational Modelling of Some

Problems of

Elasticity and Viscoelasticity with Applications to thermoforming

Projects. IJNAM 3, 320-329,

(2012). http://bura.brunel.ac.uk/handle/2438/6699

Background Research Grants and Contracts, with Outcomes

• From European Community, 750,000 EU, Jan 1994 — Dec 1996, Numerical and

Physical

Study of Material Forming Processes (Collaboration with Univs of Paris,

Stuttgart, Aachen,

Twente, Eindhoven, Palermo, Swansea) & companies from the European

polymer industry,

particularly Elf-Atochem AG and Centre de Mise en Forme des Matériaux,

Sophia Anlipolis,

France. Outcome: Reports on thermo- forming processes produced for the

network and

associated companies.

• From EPSRC, £176,000, Sept 1999-Aug 2003, Computational Modelling of

Thermoforming

and In-Mould-Decoration Processes. Collaboration with Autotype

International Ltd and John

McGavigan plc, who contributed an additional £90,000. Grant under the

EPSRC Material

Processing for Eng Applics programme. Outcome: Design tools produced based

on finite

element models of forming process for transforming thin polymer sheets

(primarily

BAYFOL®) into thin-walled structures. Results and software for associated

In-Mould-Decoration

processes delivered to companies. PI Whiteman.

• From United States Army Research Office, Durham, NC, $223,433, Aug

2000-Nov 2003,

Adaptive Space-Time Finite Element Methods for Dynamic Viscoelastic

Problems.

Outcome: Numerical schemes produced and tested in collaboration with US

Army

Research Laboratory, Langley, Virginia. PI Whiteman.

• From EPSRC, £39,341, Jan 2001-July 2004, Nonlinear Modelling and

Computational

Simulation in Applied Polymer Viscoelasticity. Grant under the Engineering

International

Collaboration Programme. Outcome: Numerical schemes produced in

collaboration with

colleagues from the US Army and ICES, University of Texas at Austin. PI

Whiteman.

• From United States Army Research Office, Durham, North Carolina,

$249,287, Aug 2004 — July 2007,

Development of Multi-adaptive Simulation Technologies for Nonlinear Solid

Polymer Viscoelasticity. Outcome: Numerical schemes produced in

collaboration with US

Army Research Laboratory, NASA Langley, Virginia, and reports and code

delivered. PI

Whiteman.

• From DEFRA Food LINK Programme, 2004 - 2008, Thermoforming of

Biodegradable

Starch-Based Materials for Food Packaging. Biodegradable Starch

Mano-Composites for

Thermoformable Film Packaging for Food Products (AFM 200) - FT1505. PI

Song.

Details of the impact

Packaging structures based on thermoplastic bio-materials are being

increasingly used by food

retailers with the result that, as they are bio-degradable and/or

compostable, the amount of waste

which is being produced is being significantly reduced. This research has

contributed to the

steady increase worldwide in the use of biodegradable plant based

materials in food packaging

structures. This uptake is, in turn, generating a demand for further

knowledge of the material

properties and behaviour of thermoplastic bio-materials.

The thesis [6] and all the computational results on the forming processes

for thermoplastic food

packaging containers were delivered to the company Plantic plc, (http://www.plantic.com.au), the

world's largest manufacturer of starch based materials for packaging, who

sourced the materials.

In response, Plantic stated that `the company is pleased to receive the

outcomes of the project

which will be included on our website and which will provide technical

information for our clients,

many of which are multinational firms.' Furthermore, Pactiv plc (http://www.pactiv.com), one of the

largest suppliers in the world of food containers for packaging (e.g. to

Marks & Spencer plc),

similarly confirmed that `the outcomes from the project will help us to

modify our designs and

processing facilities for packages produced from new eco-materials.'

There is strong motivation from governments worldwide for the adoption of

biodegradable

materials in food packaging, both to reduce the amount of non-degradable

waste that litters the

world and also to avoid the use of oil-based products in the packaging

arena.

The research described above has been disseminated through presentations

made at a number of

major international conferences including:

i) NUMIFORM 2007, 5-day international conference on Materials Processing

and Design:

Modeling, Simulation and Applications, University of Porto, Portugal (see

[5]).

ii) CMMSE 2010, 4-day international conference on Computational and

Mathematical Methods in

Science and Engineering with approximately 130 presentations, Almeria,

Spain. (Proceedings,

Volume 3, p 849-852, ISBN13: 978-84-613-5510-5).

http://gsii.usal.es/~CMMSE/images/stories/congreso/volumen1_10.pdf

In addition, the work is cited by engineers/mathematicians world-wide,

for example:

i) Thongwichean, T., Pahlakormkule, C., Chaikittiratana, A. Finite

element analysis for

thermoforming process of starch/biodegradable polyester blend. AIJSTPME

5(2), 33-37, (2012).

ii) Saedpanah, F. A posteriori error analysis for a continuous space-time

finite element method for

a hyperbolic integro-differential equation. BIT Numer Math (2013)

53:689-716 (2013).

Sources to corroborate the impact

Pactiv plc was closely involved in the DEFRA funded project. Since the

end of the funding period

Pactiv plc has been taken over by the Pregis Corporation. The contact is

now with Pregis.

Contactable:

D and D Manager, Pregis (formerly Pactiv).

General Manager — Technology, Plantic Technologies Ltd.