Novel laser products open up new markets for spin-out company Intense

Submitting Institution

University of GlasgowUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Physical Sciences: Atomic, Molecular, Nuclear, Particle and Plasma Physics, Other Physical Sciences

Technology: Communications Technologies

Summary of the impact

High-power lasers developed at the University of Glasgow now lie at the

heart of state-of-the-art technologies in the commercial printing, medical

and defence markets. University of Glasgow spin-out company Intense has

introduced more than 10 new diode laser products with superior brightness,

longer lifetimes and increased reliability to these markets since 2008.

[text removed for publication.] In 2011 Intense was bought by ORIX USA

Corporate Finance Group for an undisclosed sum.

Underpinning research

Between 1995 and 2002, Professor John Marsh (Lecturer 1986-96, Professor

1996-present) and colleagues at the University of Glasgow, developed a

significant body of published work and patents that led to the formation

of Intense Ltd in 2000.

The demand for improved optical communications systems, optical sensing

applications and optical data processing drove a requirement for increased

functionality from optoelectronic devices and research to improve

manufacturing processes for optical integrated systems. These devices and

systems integrated multiple photonic functions, analogous to electronic

integrated circuits, typically operating in the visible spectrum or near

infrared.

Marsh secured a series of EPSRC-funded rolling grants from 1995 to 2002

(GR/K45968/01, GR/L75467/01) entitled `Multi-Giga-Hertz Integrated

Optoelectronics Systems'. These grants led to major developments in

Quantum Well Intermixing (QWI) technology resulting in improvements both

in device and system performance and manufacturing processes.

The QWI process [1] is a powerful tool used to integrate multiple

semiconductor components into complex, monolithic photonic systems. QWI

allows the local bandgap of regions of a wafer to be modified after

growth; multiple bandgaps are also possible [2]. The process enables the

manufacture of arrays of diode lasers with very high yield, superior

brightness, longer lifetimes and increased reliability. The resulting

small form-factor, cost effective and extremely versatile optical systems

are superior to the worldwide competing products. QWI enables the

integration of passive regions at the facets of laser diode emitters,

arrays and bars, giving excellent performance, enhanced reliability and

leading to superior manufacturing yield.

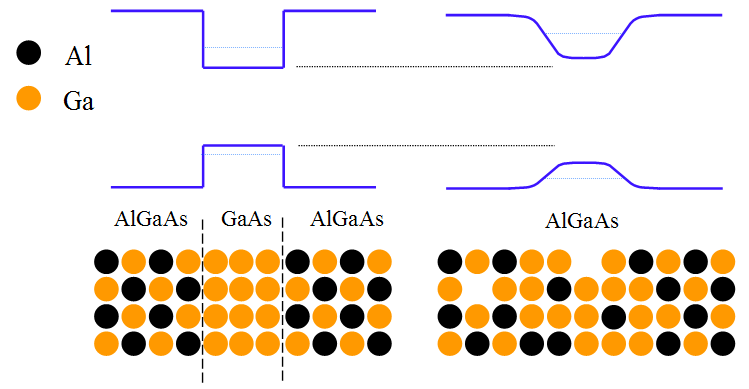

Figure: Illustration of band-structure and layer structure of a non-processed (left) vs. a QWI processed quantum well (right)

Figure: Illustration of band-structure and layer structure of a non-processed (left) vs. a QWI processed quantum well (right)

The research by Marsh was in collaboration with colleagues from the

School of Engineering: J. M. Arnold (Lecturer 1985-94, Professor

1994-2012), J. S. Aitchison (Lecturer 1990-99, Professor 1999-2001), A. C.

Bryce (Research Assistant 1985-1993, Research Technologist 1993-97, Senior

Research Fellow 1997-2007, Professor 2007-11) Professor, 1985-2011), R. M.

De La Rue (Professor, 1986-present), C. N. Ironside, (Lecturer 1984-92,

Senior Lecturer 1992-94, Reader 1994-99, Professor 1999-present), P. J. R.

Laybourn (Professor 1985-2007), Prof C. R. Stanley (Professor,

1972-present), Prof C. D. W. Wilkinson (Professor, 1992-2005) and Dr Craig

Hamilton (Research Assistant, 1995-2000). This was undertaken in two main

phases funded by £3 million in EPSRC grants (GR/K45968 and GR/L75467).

During phase 1 (1995 to 1997) QWI was a key technology in demonstrating

new devices for controlling guided wave optical systems over the frequency

range from DC up to the frequency of the optical carrier itself. QWI

enabled fully-integrated optoelectronic sub-systems on a single wafer

including Q-switched lasers, mode-locked lasers [3] and grating-based

devices.

In parallel to phase 1, Marsh secured additional funding from EPSRC for

`Compact High Power Visible Laser Diode Arrays', which focused on red

lasers (1995 to 1997, GR/K61098/01). The research utilised novel

multi-mode interference (MMI) coupling schemes to fabricate lasers with

high power and good beam quality. Integrated couplers were designed so

that multiple input laser beams could be imaged into a single output. A

laser array of multiple elements was fabricated and monolithically

integrated with the MMI coupler region. To minimise losses and

catastrophic optical damage, the coupler section was bandgap widened using

QWI. A robust QWI process for red lasers was developed [4] representing a

significant breakthrough and the MMI technologies were patented, licensed

to the University spin-out Intense Ltd and used in the development of

Intense products.

Phase 2 (1997 to 2002) developed QWI technologies for fabrication of

gratings, with specific focus on developing the technology for the

manufacture of diode lasers. Seven patents (including patents P1, P2) were

filed during 2000-2001 as a direct result of the significant developments

achieved during this programme of research. The inventions within the

patents mitigated a number of problems inherent in QWI manufacturing

methods including: losses caused by residual diffusion or implantation

dopants [5]; catastrophic optical mirror damage due to heat build up; poor

beam quality; low brightness; and limited power. The patents were also

licensed to Intense Ltd.

References to the research

[1] J. H. Marsh, `Quantum well intermixing', Semiconductor Science

and Technology, 8, 1136-1155, 1993 doi: 10.1088/0268-1242/8/6/022

*

[2] X. F. Liu, B. C. Qiu, M. L. Ke, A. C. Bryce, J. H. Marsh, `Control of

multiple bandgap shifts in InGaAs-AlInGaAs multiple-quantum-well material

using different thicknesses of PECVD SiO2 protection layers', IEEE

Photonics Technology Letters, 12: (9), pp1141-1143, Sep 2000. doi: 10.1109/68.874215

[3] A. C. Bryce, F. Camacho, P. Cusumano and J. H. Marsh, `CW and mode

locked integrated extended cavity lasers fabricated using impurity free

vacancy disordering', IEEE Journal of Selected Topics in Quantum

Electronics, 3, 885 892, 1997. doi: 10.1109/2944.640642*

[4] C. J. Hamilton, O. P. Kowalski, K. McIlvaney, A. C. Bryce, J. H.

Marsh and C. C. Button, 'Bandgap tuning of visible laser material', Electronics

Letters, 34, 665-666, 1998. doi: 10.1049/el:19980434

[5] S. D. McDougall, O. P. Kowalski, C. J. Hamilton, F. Camacho, B. C.

Qiu, M. L. Ke, R. M. De La Rue, A. C. Bryce, J. H. Marsh, `Monolithic

integration via a universal damage enhanced quantum well intermixing

technique', IEEE Journal of Selected Topics in Quantum Electronics,

4, 636-646, 1998 doi: 10.1109/2944.720474*

Key Patents:

[P1] J. H. Marsh and C. J. Hamilton, `Semiconductor Lasers', US Patent

6,717,971 (priority GB 0101641 Filed 23/1/2001 by University of Glasgow)

[P2] J. H. Marsh and C. J. Hamilton, `Optical Devices', US Patent

6,671,300 (priority GB 0101640 Filed 23/1/2001 by University of Glasgow)

[P3] J. H. Marsh, C. J. Hamilton, O. P. Kowalski, S. D. McDougall, X.

Liu, B. Qiu, `Method of manufacturing optical devices and related

improvements', US Patent 6,719,884 (priority GB 0122182 Filed 13/9/2001 by

both University of Glasgow and Intense Photonics Ltd)

* best indicators of research

Details of the impact

Professor John Marsh's research on Quantum Well Intermixing (QWI) has

underpinned more than 10 new diode laser products and upgrades developed

by the spin-out company Intense since 2008. The world-leading,

individually addressable laser arrays have in turn enabled new product

developments in high-speed colour printing of the highest commercial

quality with significant increases in cost effectiveness and productivity.

QWI has also been used in devices for the medical, industrial and defence

markets.

Developing new and improved diode laser products

Intense Ltd was formed in 2000 by Professor John Marsh and Research

Assistant Dr Craig Hamilton based on the University's patented portfolio

of QWI and related technologies. Marsh was seconded as Chief Technical

Officer on a 0.9 FTE basis to Intense from 2001 until 2009. Several

EPSRC-supported Research Assistants and research students joined the

company at or shortly after its foundation, including Dr Olek Kowalski, Dr

Stewart McDougall, Dr Bocang Qiu, Dr Xuefeng Li, Dr Valentin Loyo and Dr

Dan Yanson. In 2011 Intense Ltd was sold to ORIX USA Corporate Finance

Group for an undisclosed sum and continues to develop, manufacture and

sell its products based on University of Glasgow QWI IP under the Intense

name.

The Intense CEO has verified that

"Since 2008, the impact of research at the University of Glasgow,

particularly research on Quantum Well Intermixing, on products

manufactured by Intense Inc can be demonstrated by the following:

- Intense has released 10-12 new products

- Intense has a further 4-6 products in development

- These products have been sold to 10-12 new customers and 10-12

existing customers

- We have been able to launch 8-10 unique products into the

printing/defence/medical market sectors

- QWI has enabled us to develop higher performance products in terms

of the combination of output power and wavelength than our competitors

- We have grown our sales in the Defence, Print and Medical markets

by 10-25%

- The value of sales from QWI enabled products since 2008 is $12-15M

- Market opportunities have opened up in China, Europe and North

America

Intense is a living example of how the research and technology

development being conducted at the University of Glasgow can be used to

help tech start ups develop cutting edge, state of the art products

which provide those start ups the solid foundation and industry traction

upon which to build a successful and sustainable business model with

solid growth prospects."

Underpinning advances in the printing industry

The QWI process enabled array technology developed by Intense has had a

particularly profound influence on the printing industry as the processes

have played a major role in enabling wide arrays of lasers to be

manufactured. The Intense INSlam individually addressable arrays have been

responsible for major developments in next generation colour laser

printers [text removed for publication.] INSlam multi-beam systems allow

up to 64 multiple lines to be scanned in parallel from a single

semiconductor chip. The INSlam technology reduced the cost of modules and

increased print productivity by increasing scanning speed; this in turn

enabled further significant improvements in cost effectiveness and

productivity for high-speed, high-quality colour printing.

[text removed for publication.]

Sources to corroborate the impact

Corroborating impact on Intense products and markets

Corroborating contributing to print industry products

- [text removed for publication.]

- [text removed for publication.]

- [text removed for publication.]

- [text removed for publication.]