Chemtrix - Scalable Flow Chemistry

Submitting Institution

University of HullUnit of Assessment

ChemistrySummary Impact Type

TechnologicalResearch Subject Area(s)

Chemical Sciences: Inorganic Chemistry

Engineering: Chemical Engineering, Interdisciplinary Engineering

Summary of the impact

Chemtrix Ltd. was established in February 2006 as a 50-50 joint venture

between the University of

Hull and Lionix Ltd. In 2008 the company attracted investment from Limburg

Ventures BV,

Panthera, Technostartersfund, Microfix BV and Hugo Delissen (€2 million)

that led to the creation

of Chemtrix BV. In 2009 the Company launched Chemtrix USA and a second

investment round

followed with investors Particon BV. In 2012 ESK Ceramics GmbH & Co.

KG, acquired a minority

interest (30%) in Chemtrix BV based on a valuation of €5.3 million.

The three products developed and marketed by Chemtix, Labtrix®,

KiloFlow® and Plantrix®, are

differentiated from competitor products as they offer `scalable flow

chemistry', such that optimised

reaction conditions can be easily scaled from R&D to production. In

addition to the employees and

investors in Chemtrix the main non-academic beneficiaries of the research

have been industrial

customers such as Janssen Pharmaceutica NV, Edward Air Force Base, Iolitec

GmbH and DSM.

Underpinning research

In the early 1990s a small number of researchers (7-8 academics) mainly

from Europe, the USA

and Japan started to develop microfluidic based methodology which built on

techniques drawn

from the semiconductor industry (in particular photolithography and wet

etching) in an attempt to

produce so called micro total analytical systems. Professor Haswell, one

of these pioneers,

published the first micron-scale flow injection analysis system in 1995

and started to develop micro

reactor technology.1 This activity became instrumental in

securing a prestigious multi

university/industry £5 million Foresight LINK grant in 1999 that in turn

was used by the DTI (now

TSB) to establish a strategic national focus for the micro- and

nano-technology. The research of

Professor Haswell since 1993 has lead to over 180 peer reviewed

publications and 10 patents in

the field which have focused on establishing the fundamental design and

operational parameters of

flow reactors which gives the methodology significant advantages in the

fields of synthetic and

analytical chemistry.2-6 These advantages can be attributed to

the unique operating conditions

associated with meso/micro flow-reactor devices in which the spatial and

temporal control of

reagents is achieved under a non-turbulent, diffusion limited mixing

regime. Within such systems

the control of hydrostatic and other pressure gradients, the

immobilization of catalysts (Pd, Pt,

sulphated zirconia, zeolites and enzymes) and the monitoring of reactants

and products have

featured strongly. A range of chemical reaction types have been carried

out to demonstrate the

advantages meso/micro flow-reactors offer in terms of stereoselective

product control, multi-step

synthesis and in-situ separations. In addition, mathematical

models of reactions in meso/micro

flow-reactors under electrokinetic and hydrodynamic control have been

successfully constructed

and validated using in-situ measurements of spatially and

temporally resolved concentration

profiles.

In 2002 a previous postdoctoral fellow of Professor Haswell, Dr Paul

Watts (Lecturer, University of

Hull; 2002 to 2013) and a former PhD student and postdoctoral researcher

Dr Charlotte Wiles

(PhD Student, University of Hull; 2000 to 2003 and post doctoral

researcher, University of Hull;

2003 to 2005) seized the opportunity to commercially develop the

underpinning research carried

out at Hull, focusing in particular on the up-scaling (volume increase) of

micro-reactor methodology

whilst retaining the inherent operational advantages of excellent reaction

control and efficiency. In

partnership with the University of Hull and Lionix, Chemtrix BV was

established to develop micro-reactor

based operating systems for industrial applications of flow chemistry.

Charlotte Wiles is

now the Chief Executive Officer with Chemtrix BV. The research carried out

at Hull in the field of

micro-reactors has therefore been instrumental in establishing the core

technology on which

Chemtrix has now developed innovative products that have lead to a

significant growth and

internationalisation of the business; with industrial customers in Europe,

UK, USA, Israel, India,

Taiwan, Korea, China and Australia.

References to the research

(1) Development of a micro flow injection manifold for the determination

of orthophosphate,

R.N.C. Daykin and S.J. Haswell, Analytica Chimica Acta, 1995, 313,

155-159.

(2) Theoretical investigation into the rates of chemical reactions in

micro-total analytical systems

(µTAS) operating under electroosmotic and electrophoretic control,

P.D.I. Fletcher, S.J. Haswell and V.N. Paunov, Analyst, 1999, 124,

1273-1282.

(3) The use of novel microreactors for high throughput continuous flow

organic synthesis, G.M.

Greenway, S.J. Haswell, D.O. Morgan, V. Skelton and P. Styring, Sensors

and Actuators B,

2000, 63, 153-158.

(4) Micro reactors: principles and applications in organic synthesis,

P.D.I. Fletcher, S.J. Haswell,

E. Pombo-Villar, B.H. Warrington, P. Watts, S.Y.F. Wong and X.L. Zhang, Tetrahedron,

2002, 58, 4735-4757.

(5) Electrokinetic control of a chemical reaction in a lab-on-a- chip

micro-reactor: measurement

and quantitative modelling, P.D.I. Fletcher, S.J. Haswell and X.L. Zhang,

Lab on a Chip,

2002, 2, 102-112.

(6) Pressure-driven and electroosmotic flows and electrical currents in

Lab-on-a-chip micro

reactor devices, I. Broadwell, P.D.I. Fletcher, S.J. Haswell, X.L. Zhang,

R.W.K. Allen, J.M.

MacInnes and X. Du, Trends in Physical Chemistry, 2004, 10,

117-133.

Details of the impact

Key impacts have been:

- 2 new businesses (Chemtrix BV and ChemtrixUSA).

- 13 jobs created including 4 PhDs, 3 MScs and 4 engineers.

- The development of 3 innovative products (Labtrix®□

KiloFlow® and Plantrix®) with a growing

international industrial and academic customer base.

New businesses: After receiving substantial investment from Dutch

investors, the Headquarters of

Chemtrix was established in Geleen (Netherlands) in April 2008; and

product development and

sales actively commenced. Chemtrix Ltd.[A] remains the holding

company trading under the name

`Chemtrix BV'. In 2009 Chemtrix USA was registered to facilitate sales in

North America and

Canada whilst management and product development/engineering remains in

the Netherlands and

R&D at The University of Hull where 2 full-time employees (Drs Wiles

and Ngamsom, previous Hull

postdoctoral workers) develop customer-initiated processes/products

related to process

optimisation. In total Chemtrix BV employs 11 full time staff (split

between the Netherlands and UK)

and Chemtrix USA has 2 employees. In addition Chemtrix has sales

representatives in Europe,

Taiwan, India, Israel, Korea and China; and is actively investigating

other worldwide market

opportunities with the Asian market developing rapidly.

Instrumental in securing initial investment were two patent families

licensed from the University of

Hull and two patents licensed from Lionix, BV. Since then, Chemtrix has

applied for two patents

[B,C] with two more patent applications are in progress, IP generation

remains key to the on-going

technical development of the Company.

New innovative products: Based on early research conducted at

Hull, the commercial advantages

of micro-reactor technology, as it relates to organic synthesis under flow

conditions, has underpinned

the development of new products which now meet previously unfulfilled

industry needs [D] (Figures 1-3).

Competitor analysis reveals that other micro-reactor companies either

specialise in small scale

screening equipment (e.g. Syrris, Mikroglas, Future Chemistry) or

large scale production systems

(e.g. Corning, Alfa Lafal) and it is not facile to directly

translate research from one system to another.

Chemtrix believes that it is the only Company currently developing

equipment to directly link both

markets; specifically using the slogan `scalable flow chemistry'.

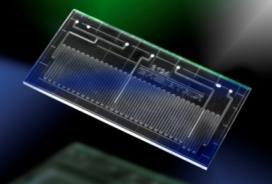

The first product launched was Labtrix® (2009), a fully

automated flow reactor platform (Figure 1a)

containing a glass micro-reactor (Figure 1b) (volume 1-20 µL), allowing

processes to be optimized

using minute quantities of reagent (200 experiments day-1 using

10's mg of material[C]).

Furthermore, the equipment enables researchers to conduct organic

synthesis more safely[D] as

well as generating less chemical waste. Independent evidence is reported

by Ley.[E] In addition,

Chemtrix is the only micro-reactor supplier to manufacture a reactor

(Figure 1c) that enables the

incorporation of heterogeneous catalysts.[D]

Figure 1. (a) Labtrix® system (launched 2009) and (b/c)

micro reactors.

Figure 1. (a) Labtrix® system (launched 2009) and (b/c)

micro reactors.

Through discussions with industry it was identified that although process

chemists are content

using fully automated computer controlled equipment, many bench chemists

prefer manual

equipment. Consequently, reacting to market demand, Chemtrix in 2010

launched Labtrix® Start

(Figure 2). Sales of this product have been particularly high, both within

academia and industry

(independent evidence reported by Kappe[F]) with more than 40

units of this type sold to date ~

40:60 academic to industrial end users.

Figure 2 Labtrix® Start (launched 2010).

Figure 2 Labtrix® Start (launched 2010).

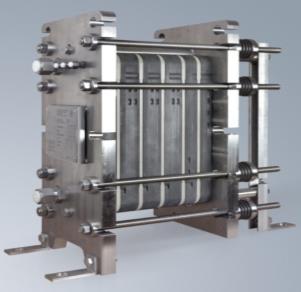

Scale up production from Labtrix®using `meso' scale reactors

(KiloFlow® launched 2011, 3 installed and 2 in production)

which consists of mm-size channels (Figure 3a). Through

carrying out detailed ongoing research into available static

mixer technology, the Company has developed the ability to

translate the reaction conditions identified in micro-channels to

meso-channels, where combination of these modules (Figure

4b) affords access to production-scale quantities (g-kg's) within

a standard laboratory fume cupboard.[G,H] A partnership with

ESK has enabled Chemtrix to develop silicon carbide reactors

capable of achieving production rates at the tonne-scale (Figure

3b) which will service a growing industrial market estimated to

be € 50million.[I] This partnership was strategic in giving

Chemtrix access to larger production units and ESK access to

the continuous flow reaction knowledge of Chemtrix.

Figure 3. (a) KiloFlow® system (launched 2011) and (b)

Plantrix® system.

Figure 3. (a) KiloFlow® system (launched 2011) and (b)

Plantrix® system.

Chemtrix is working closely with major international pharmaceutical and

fine chemical companies

(under CDAs and NDAs), with publicised examples including Sanofi-Aventis

(Hungary),[J] DSM

Pharmaceutical Products (NL), Janssen Phamaceutica NV (Belgium) and

Iolitec GmbH (Germany)

who presented results at a Symposia held at CPhI 2011 and Flow Chemistry

Europe, Munich,

2011. The work focuses on access to new processing conditions (higher

temperatures & pressure)

with simplified synthetic processes that can be transferred from R&D

to production. In one

example, a new route for an API was identified at the lab-scale, resulting

in an increase in product

purity which upon transfer to the production plant led to significant cost

savings due to a reduction

in the complexity of the downstream separation process. In addition to the

publicised work,

Chemtrix are currently working on multiple projects with industrial

partners focussing on the

translation of batch processes to continuous flow, with the aim of

developing sustainable, cost

effective production processes. Chemtrix maintains its links to the

University of Hull, collaborating

in the development of new chemical processes beyond those initially

identified as having

commercial interest; this includes for example the synthesis of inorganic

nanoparticles with Dr

Grazia Francesconi.[K]

Sources to corroborate the impact

[A] www.chemtrix.com/company-profile

(corroboration of the establishment of Chemtrix BV and ChemtrixUSA)

[B] Patent Application - `A microfluidic system and the use thereof'

EP2010/002777.

[C] Patent Application — `A new design microfluidic device, a kit of

parts comprising such

microfluidic devices and a modular system comprising such microfluidic

devices'

EP10008784.0.

[D] Microreactors as tools for high-throughput synthesis, C. Wiles and P.

Watts,

Speciality Chemicals Magazine, 2009, 40-41.; The evaluation of the

heterogeneously

catalysed Strecker reaction conducted under continuous flow, C. Wiles and

P. Watts,

Eur. J. Orgc. Chem., 2008, 5597-5613.

[E] The flow synthesis of heterocycles for natural product and medicinal

chemistry, M. Baumann,

I. R. Baxendale and S. V. Ley, Mol. Divers., 2011, 5,

613-630.

[F] The microwave to flow paradigm: Translating high-temperature batch

microwave chemistry

to scalable continuous flow processes, T. Glasnov and C.O. Kappe, Chem.

Eur. J., 2011, 17,

11956-11968.

[G] Chemtrix' KiloFlow: The turn-key kilo-lab in your fume hood, C.

Wiles,

Chem. Today, 2011, 29, 32-33.

[H] Flexible Durchflussreaktoren für das schnelle Scale-up von

Produktionsprozessen, C. Wiles

and M. Seipel, Process, 2012, 1, 42-44.

[I] Innovative solutions to fulfill the flow chemistry potentials in

Europe, L. Pichon, 4th

Symposium on continuous flow reactor technology for industrial

applications, 2012, Lisbon.

[J] Formation of aromatic amidoximes with hydroxylamine using

microreactor technology',

Voros, Z. Baan, P. Mizsey and Z. Finta, Org. Proc. Res. Dev.,

2012, 16, 1717-1726.

[K] The preparation of magnetic iron oxide nanoparticles in

microreactors, M. Simmons, C.

Wiles, V. Rocher, M. G. Francesconi and P. Watts, J. Flow Chem.,

2013, 3, 7-10.