Electrostatic measurement of pulverised fuel flow

Submitting Institution

Teesside UniversityUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Chemical Engineering, Interdisciplinary Engineering

Summary of the impact

Coal fired power stations will be a major element of global power

generation for the foreseeable future. Measurement, and hence control, of

pulverised fuel flow is a vital technology for the efficient and green

operation of coal fired power stations. Balancing fuel delivery and

combustion stoichiometry increases boiler efficiency and reduces

emissions. Research in this area carried out at Teesside University was

adopted by ABB Ltd and led to the commercial development of new powder

flow measurement systems (PfMaster technology) installed in power stations

around the world. Quantifiable economic benefits of the installations

to date amount to >£3.4 M with concomitant environmental benefits

of significant reduction in CO2 and NOxemissions

and solid waste disposal burdens.

Underpinning research

The key research findings that underpin the impact are as follows.

1. Theoretical modelling of an electrostatic technique for Pulverised

Fuel (PF) flow measurement

Tests of electrostatic techniques for measuring pulverised coal flow in

the 1960s were unsuccessful due to the absence of a proper understanding

of the measurement theory. During 1994 to 1996, a team working at Teesside

University led by Professor John Coulthard, including two members of our

current staff, established the theoretical model underpinning the

mechanism of operation of a ring-shaped electrostatic sensor for the

measurement of solid-air flow. This describes the induced charge on the

sensor's electrode due to a single charged particle, from which the

spatial sensitivity and its frequency domain model for single particles

and homogenous flow were derived [1, 2]. The work continues and is being

further developed to the measurement of more complex solid materials,

particularly biofuels, by staff in our current Analytical Instrumentation,

Measurement and Control Engineering research theme within the University's

Technology Futures Institute.

2. Sensor power station trials

During 1996 to 1997, trials, funded by Scottish Power in collaboration

with ABB, were carried out by the Teesside team, led by Professor

Coulthard, at Methil Power station. Good system performance in real

industrial environments led to the commercialisation of this metering

system by ABB [3] (see opposite). The technique to compensate spatial

sensitivity using two electrodes of different widths was patented [4] and

led to the NPL Metrology for World Class Manufacturing Award (1998) for

the Teesside/ABB team.

3. Flow concentration and mass flow rate

In 1999, Zhang joined the research team at Teesside, and between 1999 and

2002, extended the previous theoretical model to accommodate an

inhomogeneous flow stream, and extended this to account for the

characteristics of the conditioning circuits, developing an improved

overall model of the electrostatic metering system [5]. Mathematical

models relating signal level to solids concentration and mass flow rate,

and compensating for the effect of particle velocity, were developed,

patented [6] and commercially implemented in the current ABB electrostatic

meter (see opposite. http://www.greenbankenergy.com/sub.php?main=4&id=11).

4. Spatial Sensitivity

The sensor's spatial sensitivity with respect to the radial distribution

of particles within the two-phase flow was studied by Cheng and Zhang at

Teesside during 1994 to 2002 [5] and led to the development of a technique

used as a rope-breaker (disrupting radial inhomogeneity in the flow,

increasing measurement accuracy). This was commercialised by Greenbank for

use with ABB electrostatic meters. (see opposite.

http://www.greenbankenergy.com/sub.php?main=4&id=12)

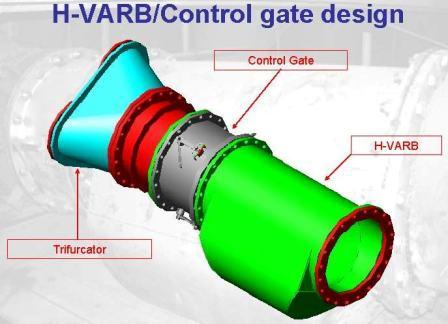

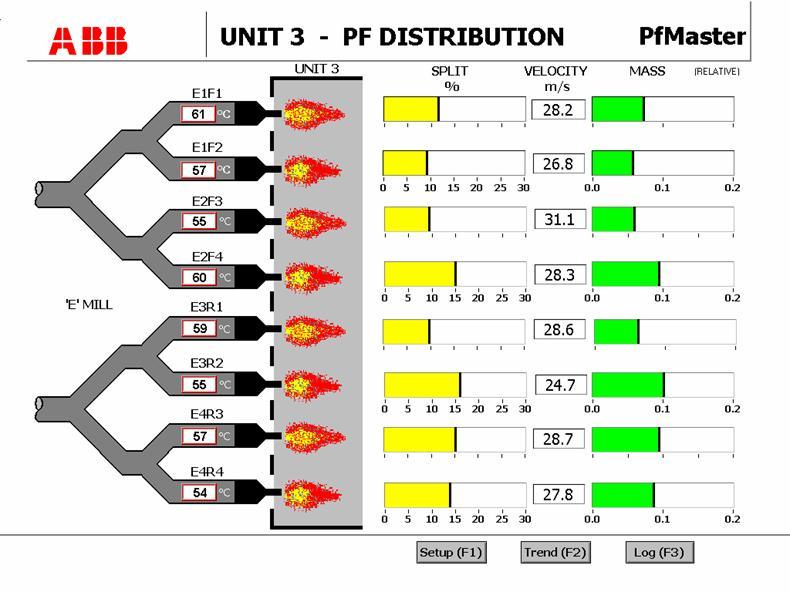

5. Using the meter for flow control

The applications of the technology were further developed in the

DTI-funded project, "Pulverised Fuel Meters — Split Control" (DTI/CC/102,

2000-2002), jointly carried out by ABB and the Teesside group. This work

demonstrated that the control of the distribution of pulverised coal

between two parallel pneumatic conveyors, fed from a single source via a

bifurcator, could be achieved. In this work, pulverised fuel meters

measured the mass flow rate in each line and provided feedback signals

used to actuate a flow control device based upon backpressure alterations,

allowing further improvements in combustion efficiency. An example of such

a control system is shown below.

ABB PfMaster control system for efficient balancing of split fuel flows

for power station boilers, based on original Teesside research.

References to the research

The three outputs that best indicate the quality of the underpinning

research are [1], [3] and [5].

[1] Cheng, R. (1996) "A study of electrostatic pulverised fuel meters."

PhD thesis. Teesside University. Due to commercial confidentiality

considerations the publication of this work was embargoed for five years.

[2] Coulthard, J and Cheng, R (1996) "Flow metering." US Patent number

6305231.

[3] Coulthard,

J., Cheng,

R., Kane,

P., Osborne,

J.T., Keech,

R.P. (1997) "Online

pulverised-fuel monitoring at Methil power station", Power

Engineering Journal 11 (1), 27-30. Coulthard and Cheng from Teesside

University and Dr. Ray Keech from ABB were awarded the NPL Metrology for

World Class Manufacturing Award in 1998 for their work on the Pulverised

Fuel Meter including this work.

[4] ABB Kent Taylor Ltd, Cheng, R., Coulthard, J. and Keech, R. (1998)

"Measurement using cross correlation." Patent number WO1998055839A1

[5] Zhang, J and Coulthard, J. (2005) "Theoretical and experimental

studies of the spatial sensitivity of an electrostatic pulverised fuel

meter", Journal of Electrostatics, Volume 63 (1), 1133-1149.

This work was part-funded by the EU project ECSC 7220 PR050: ECSC-COALRES

7C, (01/11/1998 to 31/10/2001; Principle Investigator: E.ON UK plc,

Power Technology Centre, Ratcliffe-On-Soar, NG11 0EE, Nottingham, United

Kingdom) "Measurement and control techniques for improving combustion

efficiency & reducing emissions from coal-fired plant", €2,051,496

(€318,011 to Teesside).

[6] Coulthard

J, Cheng,

R. and Asquith,

P. (2003) "Flow metering with flow velocity compensation." UK Patent

number GB

2388905-A; and Coulthard

J, Cheng,

R. and Asquith,

P. (2005) "Flow metering" US Patent number 6865495.

Details of the impact

The ABB electrostatic system based upon Teesside's research is currently

the most widely adopted commercial technology whereby PF flow can be

measured and PF flow distribution can be actively controlled. Since

demonstration of the technology and its commercialisation by ABB the

PfMaster flow measurement systems have been installed in many power

stations worldwide.

The development of this measurement technology at Teesside, in

conjunction with colleagues at ABB, has led to 5 UK, 3 USA and 1

European patents since 1993 [1].

Although the benefits of PF distribution control are highly site

specific, the techno-economic analyses undertaken in ECSC project 7220

PR050 [2] determine

-

NOx reduction of between 7.5% and 20%, depending on

the firing configuration of the plant.

-

Boiler efficiency gains of between 0.22% and 0.37%.

-

Payback periods between 3.5 and 7 years.

Assuming the boiler efficiency improvements to result in equivalent

reductions in carbon intensity of combustion, these estimates lead to:

-

Carbon emission reductions of between 5 and 8 kg CO2

per tonne of coal.

For illustration, Methil power station was a 60 MW facility. Assuming a

capacity factor of 75 % this equates to a constant output of 45 MW,

generating approximately 1 GWh each day. With a net calorific value for

coal of approximately 26 GJ/tonne, this equates to between 700 and 1,100

kg CO2 of emissions reduction per day.

ABB Ltd have, between January 2008 and July 2013, sold in excess of 148

units for installation in international markets including USA,

Europe and China [1], and have sold 510 in total since 2000.

The Greenbank Group UK are installers of the PfMaster technology and have

provided Teesside University with a report estimating the impact of

PfMaster installation [3]. During the period 2008 to 2013 their revenue

from PfMaster sales totalled £272,878. Greenbank state that

installation leads to improvements in coal distribution and particle

fineness consistency, leading to lower carbon-in- ash and improved power

station efficiency of 0.85% per fully installed unit. Greenbank estimate

that this has had an economic benefit on their customer stations of

£2.4m during 2009-2013, based on a typical £500,000 saving for a

typical 500 MW boiler and typical fuel process for the period.

Greenbank further estimate that, based upon increased unit output

achieved through lower dust emissions, the installed units will have

generated a saving of £160,000 per year over the period 2009 -

2013. Environmental benefits have been estimated by Greenbank to be valued

at £240,000 over the period due to reduced ash disposal and a

NOx reduction of ~ 100 mg m -3.

The development of the rope-breaker technology, underpinned by Teesside

research, contributed to Greenbank's receipt in 2007 of two Rushlight

Awards which support and promote clean technologies.

Research in this area and the collaboration with both ABB and Greenbank

is on-going and led by Dr Zhang as part of the Analytical Instrumentation,

Measurement and Control Engineering theme of Teesside University's

Technology Futures Institute.

Sources to corroborate the impact

[1] Director of Flow Development and Design, ABB Ltd., Oldends Lane,

Stonehouse Gloucestershire, GL10 3TA UK

[2] A.J. Minchener and J.T. McMullan, Clean Coal Technology R,D&D,

(2007) "Significant achievements of European coal and steel community

R&D programmes in the development of clean coal power generation

technology", available at http://www.iea-coal.org.uk/documents/81741/6388/Clean-coal-technology-R,D&D

[3] Greenbank Impact Statement, available upon request from Teesside

University or Greenbank (Managing Director, Hartshorne Road, Woodville,

Derbyshire, DE11 7GT, UK)