Development of a novel carbon fibre manufacturing process for high performance automotive applications

Submitting Institution

University of NottinghamUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Aerospace Engineering, Manufacturing Engineering, Materials Engineering

Summary of the impact

Underpinned by research at the University of Nottingham, the development

of automated

discontinuous carbon fibre preforming (DCFP) technology has helped drive

more than half a billion

pounds in sales of Aston Martin's DBS sports car across 42 countries,

boosting the company's

brand worldwide. Recognising the potential of this process, Bentley Motors

invested £1.3M directly

to develop this technology for its next generation of models. The Royal

Academy of Engineering

acknowledged the body of research as an "outstanding" contribution to the

reputation of British

engineering through the award of a silver medal to Professor Warrior.

Underpinning research

Increasingly stringent emissions targets are pushing vehicle

manufacturers to find novel ways of

reducing vehicle mass. A fall in the cost of carbon fibre has increased

the viability of using carbon-

based body panel systems as a cost-effective, lightweight alternative to

steel in order to improve

fuel consumption. Research carried out at the University of Nottingham

(UoN) from 2003 set out to

demonstrate that carbon fibre composites are suitable materials for the

high-volume production of

vehicles.

The UoN team, headed by Nick Warrior (Professor of Mechanical

Engineering, 1989 - present) and

Chris Rudd (Professor of Mechanical Engineering and Pro Vice-Chancellor,

1989 - present), began

by investigating how the established Ford Programmable Preform Process

(F3P) — a process that

fabricates vehicle parts from lightweight and strong glass fibre

composites, could be translated to

carbon fibre preforms.

Using F3P, a robot sprays the glass fibres on to a screen. The material

is consolidated with an

upper screen to form a preform in the shape of the vehicle part. However,

this process was not

directly transferable to carbon fibre composites. Glass fibre preforming

is facilitated by a special

form of glass fibre roving that has characteristics that make it suitable

for automated processing.

Similar product forms are not available for carbon fibre, as the

production volumes do not warrant

costly fibre modifications. Various technical issues related to the fibre

handling and placement also

had to be solved to allow processing of off-the-shelf carbon fibres. In

addition, the modelling of the

manufactured carbon fibre parts posed major challenges, as there is

significant heterogeneity in

the fibre architecture.

Using experimental and numerical techniques, Warrior and Rudd carried out

a range of simulations

and analyses to develop scientific understanding in two key areas.

Firstly, work on benchmarking

carbon body panel systems, carried out from 2002 to 2008, focused on the

comparison of DCFP

with commercial body panel systems [2.1] and the design of an optimal body

panel system.

Secondly, from 2006 to 2009, processing studies were carried out to

support carbon DCFP

manufacture, including analysis of microstructural parameters [2.2], the

effects of fibre length [2.3]

and filamentisation [2.4], permeability and resin injection simulation

[2.5] and fibre alignment [2.6].

The research concluded that carbon fibre composite structures could make

mass-produced

vehicles up to 50% lighter while still maintaining crash-test performance.

From 2004 to 2012 the

team developed the carbon DCFP process and commissioned a DCFP machine at

UoN, the first of

its kind in Europe. A four-stage process was established, comprising

spraying, heating, cooling and

preform extraction. During spraying, carbon fibre yarns (tows) are chopped

and sprayed on to a

perforated tool where a vacuum holds the desired pattern and shape of

fibres.

The work at Nottingham moved on to property prediction of the DCFP and

developing an in-depth

understanding of the material and how different fibre architectures

perform. This succeeded in

aiding the design of new components and identifying improvements in the

overall design process,

which in turn led to the creation of an Aston Martin technology

demonstrator. It was subsequently

deployed at tier one supplier SOTIRA (now part of France-based SORA

Composites) and

ultimately allowed Aston Martin to apply carbon fibre technologies to the

door opening

reinforcement and the trunk lid surround components on its DBS sports car.

The DCFP technology is being developed further as part of the EPSRC

Centre for Innovative

Manufacturing in Composites at Nottingham.

References to the research

References (Items marked with an asterisk indicate 3 most significant

papers):

2.1 *Turner, T.A., Harper, L.T., Warrior, N.A. and Rudd, C.D., 2008,

Low-cost carbon-fibre-based

automotive body panel systems — a performance and manufacturing cost

comparison, Journal

of Automobile Engineering — Proceedings of the Institution of Mechanical

Engineers Part D,

Volume 222, Issue 1, 53-64 DOI: 10.1243/09544070JAUTO406:

2.2 *Harper, L.T., Turner, T.A., Warrior, N.A., Dahl, J.S. and Rudd,

C.D., 2006, Characterisation of

random carbon fibre composites from a directed fibre preforming process:

analysis of

microstructural parameters, Composites Part A: Applied Science and

Manufacturing, Volume

37, Issue 11, 2136-2147 DOI: 10.1016/j.compositesa.2005.11.014

• JS Dahl, Ford Motor Company, USA (owners of Aston Martin at that time)

2.3 *Harper, L.T., Turner, T.A., Warrior, N.A. and Rudd, C.D., 2006,

Characterisation of random

carbon fibre composites from a directed fibre preforming process: the

effect of fibre length,

Composites Part A: Applied Science and Manufacturing, Volume 37,

Issue 11, 1863-1878 DOI:

10.1016/j.compositesa.2005.12.028

2.4 Harper, L.T., Turner, T.A., Warrior, N.A. and Rudd, C.D., 2007,

Characterisation of random

carbon fibre composites from a directed fibre preforming process: the

effect of tow

filamentisation, Composites Part A: Applied Science and Manufacturing,

Volume 38, Issue 3,

755-770 DOI: 10.1016/j.compositesa.2006.09.008

2.5 Endruweit, A., Harper, L.T., Turner, T.A., Warrior, N.A. and Long,

A.C., 2008, Random

discontinuous carbon fibre preforms: permeability modelling and resin

injection simulation,

Composites Part A: Applied Science and Manufacturing, Volume 39,

Issue 10, 1660-1669 DOI:

10.1016/j.compositesa.2008.07.006, copy available on request.

2.6 Harper, L.T., Turner, T.A., Martin, J.R.B. and Warrior, N.A., 2009,

Fibre alignment in directed

carbon fibre preforms: a feasibility study, Journal of Composite

Materials, Volume 43, Issue 1,

57-74 DOI: 10.1177/0021998308098151

Grants:

• EPSRC CASE studentship on studying the durability of DCFP for high

performance structural

applications under severe conditions (extreme temperatures, fatigue etc)

(PI Warrior)

• Advanced Composites Truss Structures (ACTS), Feb 2008 - Sept 2011, TSB

project #100447,

Grant value £939k with Bentley Motors Limited (PI Long)

• Affordable Discontinuous Carbon Composites for Structural Automotive

Applications, Feb 2008

- July 2012, TSB project #100442, Grant value £1.8M with Aston Martin

Lagonda Ltd. (PI

Warrior)

• EPSRC Centre for Innovative Manufacturing in Composites, July 2011 -

June 2016,

EP/I033513/1, £5.9M (PI Long)

Research contracts and income from industry:

2.7 Directly sponsored project with Bentley Motors Ltd on Multiscale

Material Modelling of

discontinuous fibre composites (Total Value £698k), 2008-2011

Details of the impact

The discontinuous carbon fibre preforming process developed through

Warrior and Rudd's body of

underpinning research at UoN has made a significant contribution to the

economic competitiveness

of two of Britain's leading manufacturers of luxury vehicles, Aston Martin

Lagonda and Bentley

Motors, and in the process has showcased British engineering excellence.

Aston Martin employed the technique for the production of the door

opening reinforcement and the

trunk lid surround for its DBS, 12MY Virage, 13MY DB9 and new Vanquish

models [4.1]. For DBS

alone — since 2008 3,300 cars have been sold in 42 countries at around

£180,000 each, which

equates to sales revenue of £594M. In 2011 more than 80% of Aston Martin's

sales were to buyers

outside the UK [4.2]. This surpassed Aston Martin CEO Ulrich Bez's aim of

selling a third of the

company's cars in Europe and a third in America. By comparison, in 2000

the brand's annual sales

were 800 cars, of which 700 were sold in the UK [4.2].

The two carbon fibre parts are manufactured and supplied by Sora

Composites, which is based in

St Meloir, France. They represent a weight saving of 52% and 44%

respectively compared to the

alternative glass fibre materials. Over 23 tonnes of discontinuous carbon

fibre composite material

has reached the market through this process on the DBS alone. The

technology has been a key

enabler for reducing mass and therefore improving both performance and

economy — making the

car lighter, faster and stronger [4.1].

"The Discontinuous Carbon Fibre Preform (DCFP) work with the University

of Nottingham resulted

in the uptake of chopped carbon fibre composite technology into the Trunk

Lid Surround (TLS) and

Door Opening Reinforcement (DOR) panels of the DBS... These parts were

originally one of the

main differentiators between the top of the range DBS model and other

models in our range of

supercars... The technology has been a key enabler for reducing mass and

therefore improving

both performance and economy across our range of vehicles." Source: Roland

Snell, Aston Martin

[4.1]

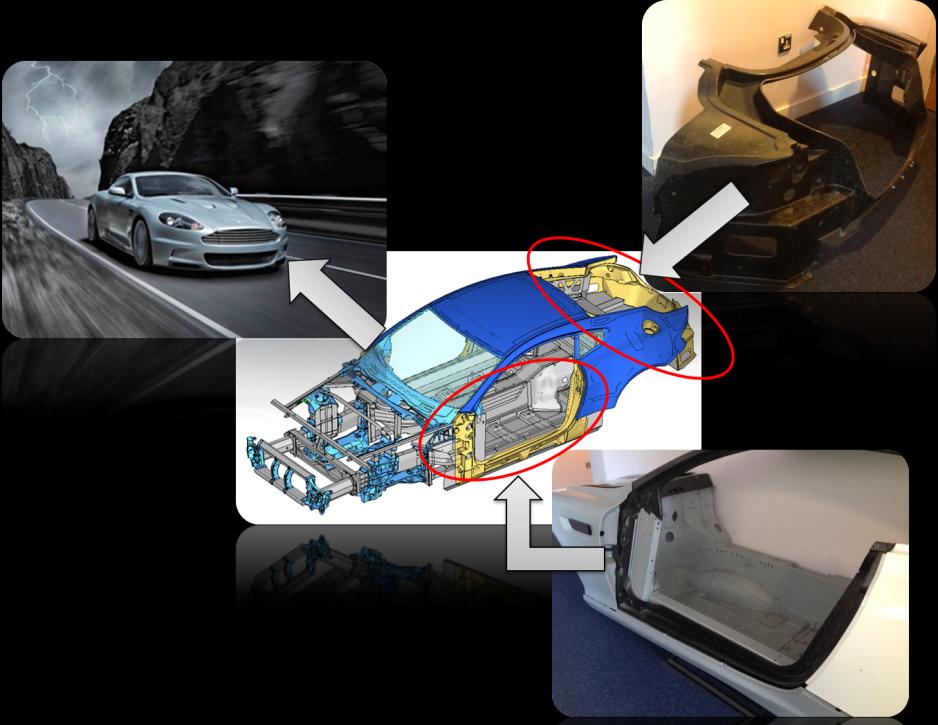

Figure 1: showing carbon fibre parts manufactured using DCFP and their

location on the automobile

Figure 1: showing carbon fibre parts manufactured using DCFP and their

location on the automobile

The successful development of DCFP by the University of Nottingham

convinced Bentley Motors

Ltd of the value of DCFP. A total investment of £800k ([2.7] and

contribution to studentships) was

made by Bentley Motors in developing an enhancement to the DCFP process —

in collaboration

with Warrior — that involved using carbon fibre in its least processed

form and spraying it with resin

into a mould, eliminating the need for heating and cooling [4.4].

UoN's work formed the basis of Bentley's RayCell technology, which

Bentley employed, through

investment of a further £500,000 in 2010, for the production of a

demonstration vehicle that

showcases the next generation of cars to be produced by the company [4.4].

The demonstration

vehicle specifically showed that it is possible for the carbon fibre

chassis rails to support the weight

of the vehicle [4.3].

"The Raycell technology developed at the University of Nottingham has

been used to develop the

composite elements for the demonstrator vehicle. The research has

indicated that it is feasible to

manufacture major structural elements in our next generation of cars using

carbon fibre in this

way." Source: Lee Bateup, Bentley Motors [4.4]

Figure 2: carbon fibre chassis rails manufactured using the Raycell

concept and its

location on the Bentley T35 demonstration vehicle

Figure 2: carbon fibre chassis rails manufactured using the Raycell

concept and its

location on the Bentley T35 demonstration vehicle

The underpinning research led to Warrior receiving the Royal Academy of

Engineering's

prestigious Silver Medal in July 2009 for his "outstanding personal

contribution to British

engineering" — further evidence of the positive impact of the research on

the reputation of the

British engineering industry. On presenting the award, the RAE said the

research into carbon fibre

composites had "shown that mass-produced vehicles can be up to 50% lighter

and still maintain

crash-test performance using lightweight carbon fibre composites". It

added: "High material costs

and labour-intensive manufacturing have restricted composites to motor

sports and supercars until

now... [Warrior] has demonstrated that composites are now a legitimate

material for use in high-

volume production (up to 20,000 vehicles a year)" [4.5].

Sources to corroborate the impact

4.1 Roland Snell, Principal Engineer — Body Structures, Aston Martin

Lagonda Ltd

4.2 Press article regarding Aston Martin sales growth

http://europe.autonews.com/apps/pbcs.dll/article?AID=/20120226/ANE/120229916/1131/aston-martin-plans-double-digit-sales-growth#axzz2M0S6ajyf

4.3 RayCell Technology

http://www.innovate10.co.uk/uploads/02%20-%20AD%20-%2012%20October%20GRAND%20CHALLENGE%20Slides%20-%20FINAL.pdf

4.4 Lee Bateup, New Technologies/Processes and Properties Manager,

Concept Engineering,

Bentley Motors Ltd

4.5 Press release regarding award of Royal Academy of Engineering Silver

Medal

http://www.raeng.org.uk/news/releases/shownews.htm?NewsID=509