1. Q Chip Ltd - Micro Technology for Injectable Therapeutics

Submitting Institution

Cardiff UniversityUnit of Assessment

General EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Chemical Sciences: Analytical Chemistry, Macromolecular and Materials Chemistry

Engineering: Interdisciplinary Engineering

Summary of the impact

Economic impact is claimed through the growth of the biopharmaceutical

spin-out company Q Chip Ltd. During the REF period, this has created 19

new jobs, £7.5M investment, a new Dutch subsidiary (Q Chip BV), and

staged-payment, six figure contract sales to four major international

pharmaceutical companies.

Q Chip has generated over £928K in contract sales from the pharmaceutical

industry from 2008-2012, with further sales of over £1M projected in

2013-14.

Originally established by Professor David Barrow in 2003 from his micro

technology research, Q Chip has developed new processes and miniaturised

equipment to encapsulate materials, including drugs, within uniform

polymeric microspheres as injectable therapeutics.

Underpinning research

Since 1995, Barrow has led the specialist research field of

microchip-based, multiphase-microfluidics, at Cardiff University, focused

on precision polymeric microsphere production. Specific research

undertaken by Barrow (Professor since 2000) and co-workers between

1998-2002 resulted in the development of a new manufacturing technology

that creates uniform microspheres within planar microfluidic ducts (Fig.

1). Two phases of grants from EPSRC (GR/M29634, July 1999, £105k;

GR/M73026, May 2000, £293k) and TSB (TI NCBT, 6/25 May 2002, £50k)

resulted in two patents, now assigned to Q Chip [3.1], [3.2]. The

co-workers were post-doctoral staff Dr. Nicola Harries and Dr. Kostas

Bouris, and PhD research associate Mr Tyrone Jones, all employed at

Cardiff University between 1998-2001.

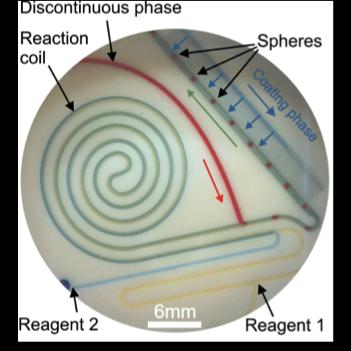

Figure 1: Microsphere production chip. Reagents 1 and 2

are precision delivered through flat capillaries, in which they are

incubated within a reaction coil. After this they are interfaced with an

immiscible discontinuous phase, thus causing the formation of droplet

microspheres, which are then coated.

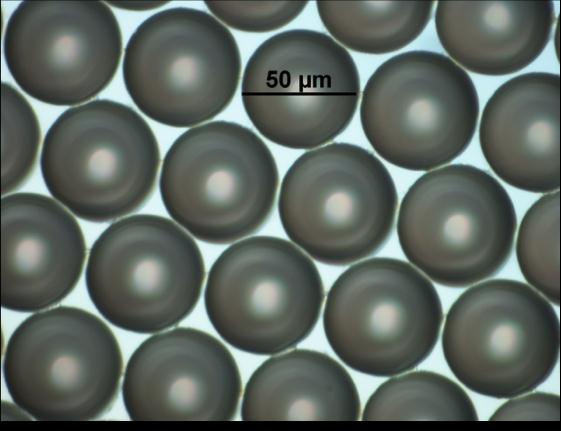

The first phase focused on the method of generating ideal fluid mixing

conditions required to produce uniform fluidic droplets (shown in Fig. 2),

initially by modelling [3.3] and then by experiment [3.4]. This research

discovered and characterised the many inter-related microfluidic

geometries for the generation of segmented flow streams, and their

manipulation to engineer uniform microspheres. A key advantage of this

particle manufacturing technique is the rapidity, purity, and uniformity

of products, the low-shear aseptic environment (thus preventing damage to

living cells), and the ability to undertake precision, serial chemical

operations on individual microspheres. It had not been possible to achieve

these features using traditional manufacturing techniques. At that time,

only a few other scientists were investigating similar phenomena. Since

then, the area of multiphase microfluidics using planar chip-based

substrates has developed rapidly and is now heavily researched and is used

in diverse applications. Subsequent related research by Barrow and new

co-workers has continued, with new inventions such as the liquid phase

separator [3.5].

Figure 2: Polymeric microspheres, with a highly uniform

diameter of 50 microns.

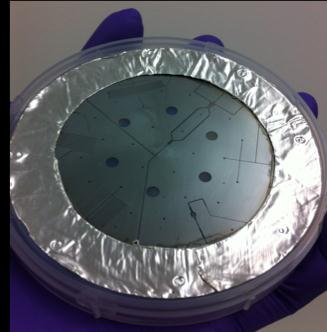

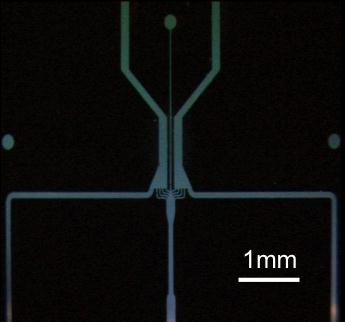

The second parallel phase of research identified combined manufacturing

mechanisms and materials required to create the microfluidic chips for

fluidic processing [3.1]. The mechanism involved novel, deep

plasma-etching of microfluidic structures on bioinert, solvent-resistant,

fluoropolymer substrates (shown in Fig. 3). This enabled highly-regular

microparticle formation, without the undesired use of surfactants, some of

which are toxic. This novel wafer-processing method favoured

solvent-resistant polymers and is compatible with processing equipment

already used in industry for silicon (like silicon-based,

high-aspect-ratio structures; for example, airbag sensors and

accelerometers).

Figure 3: A four inch PTFE wafer, with a metal mask,

showing deep-etched microfluidic ducts (top). Fine detail of the

microfluidic duct system on this wafer is also shown (bottom).

Pilot manufacturing studies, initiated by Barrow in 2001, established a

desk-top manufacturing microPlant for the production of microspheres

[3.6]. This has been employed for payload delivery in multiple industries,

such as biopharmaceuticals, neutroceuticals, cosmetics and smart paints.

An independent commercialisation report from Biolauncher Ltd. (contact

Rowan Gardener, Biolauncher Ltd., www.Biolauncher.com)

proposed that significant revenues would be obtained by focusing product

development on high-value, low-volume markets (including pharmaceuticals

delivery) and this strategy has since been followed.

With initial Welsh Assembly Government support (Q Chip exploitation roadmap, Education and Learning Wales Ref. 112; 01/08/02), and working with Entegris

and Victrex corporations, Barrow produced a platform [3.6]

for bespoke microsphere production to demonstrate the technology to

potential investors and supply chain partners.

The market potential for the Cardiff University research was supported by

Barrow, as inventor, patent author, pre-seed development leader, Q Chip

co-founder, and Q Chip Chief Scientific Officer. He exemplified the

initial prospects through exploratory work from 1999-2000, for Unilever

UK, by demonstrating pectin fibre production for hair-care products (Hugh.Clare@liv.ac.uk,

at Liverpool University, previously at Unilever).

Q Chip Ltd. was founded in 2003 by Prof. Barrow, Mr Mark Barry and Dr Jo

Daniels (Dr Nick Bourne, Cardiff University, Bourne@cf.ac.uk,

and documents kept therein). The company secured first round funding from

the E-Synergy investor syndicate (lead investor John Moulton), with a

corresponding second closing IP-equity swap with Cardiff University.

References to the research

3.2 Barrow D.A., Harries N., Jones T.G. and Bouris K.

(2004) Microfluidic device and methods for construction and application, Patent

Numbers: UK GB2395196B, Worldwide CA2545205, UK0226691.4, filing

date 11/11/2002.

http://www.google.com/patents/US7802591

3.3 Barrow D.A., Harries N., Burns J.and Ramshaw C. (2003) A

numerical model for segmented flow in a microreactor, International

Journal of Heat and Mass Transfer, Vol. 46 No. 17 pp. 3313-3322, http://dx.doi.org/10.1016/S0017-9310(03)00120-0

3.4 Ahmed B., Barrow D.A. and Wirth T. (2006) Enhancement

of reaction rates by segmented fluid flow in capillary scale reactors, Advances

in Synthesis and Catalysis, Vol. 348 No. 9 pp. 1043-1050, ISSN

1615-4150 10.1002/adsc.200505480

3.5 Castell O.K., Allender C.J. and Barrow D.A. (2009)

Liquid-liquid phase separation: characterisation of a novel device capable

of separating particle carrying multiphase flows, Lab Chip, Vol. 9

pp. 388-96, 10.1039/b806946h

(this is output Barrow 3)

3.6 Velten T., Ruf H.H., Barrow D.A., Aspragathos N., Lazarou P.,

Jung E., Malek C.K., Richter M., Kruckow J. and Wackerle M. (2005)

Packaging of bio-MEMS: strategies, technologies and applications, IEEE

Transactions on Integration and Packaging, Vol. 28 No. 4 pp.

533-546,10.1109/TADVP.2005.858427

Details of the impact

Impact summary: During the REF period, employee numbers at Q Chip

increased from 10 to 29 (up 180%), there were 5 patent filings and there

was £7.5M of new investment (75% of the total company investment) over 6

funding rounds [5.1],[5.2]. Access to new miniaturised industrial

bioprocessing equipment and new drug delivery techniques (currently under

trials) were sold to top pharmaceutical companies for improved quality of

life through cancer treatment. Revenues from four, staged payment,

six-figure value contracts [5.1],[5.2] have risen from £17k in 2010, £297k

in 2011 to £578k in 2012.

Company growth: During the REF period Q Chip has developed a

bio-encapsulation and drug delivery platform that enables companies to

extend product life cycles and deliver complex bio-therapeutics [5.3]. It

currently manufactures drug-loaded microspheres, mainly for pharmaceutical

industries. Q Chip aims to improve patient compliance and experience, and

improve therapeutic performance through the development of long-acting,

injectable therapeutics using its proprietary platform, Q-SpheraTM [5.3].

This breakthrough microsphere manufacturing and formulation system is

compatible with small molecules, peptides and complex biologicals.

With its commercial client partners, and with guidance from its

scientific advisory board (on which Barrow sits), Q Chip is developing

point-of-care clinical data with three different molecules encapsulated

within drug-eluting, polymeric microspheres. Q Chip is licensing the

microsphere production and sale via these client partners who, through

their own existing global marketplace presence, are taking the products to

market. Q Chip has five injectable, encapsulated drug formulations in its

therapeutics pipeline, including Q-Goserelin and Q-Leuprolide for the

treatment of breast and prostate cancer, Q-Insulin for diabetes therapy,

Q-Octreotide for acromegaly, and a new formulation of monoclonal

antibodies for a confidential application [5.1]. All have substantial

existing markets. For instance, Leuprolide and Octreotide products

achieved annual sales of around $1800M and $1200M in 2010; this is out of

a total global market for injectable therapeutics of $49B. During 2011, Q

Chip signed four separate multi-year R&D deals with international

pharmaceutical companies [5.1]. Two of these contracts are with those in

the top five global pharmaceutical industries. Q Chip has developed a

contractual relationship with leading biotechnology/pharmaceutical

company, ARTES Biotechnology GmbH [5.4], for the sustained release of

therapeutic protein interferon alpha 2 (using microspheres) to treat

chronic hepatitis B and C. A third contract is with a UK pharmaceutical

company, a fourth with a mid-sized European pharmaceutical company [5.1]

(contractually, other company names cannot be disclosed).

Further technical development: During the REF period Barrow has

continued to be instrumental in determining the on-going evolution of the

technology developed through the underlying research into Q Chip's

expanding range of products. He has also supported the company as chair

and co-chair of Q Chip's Scientific Advisory Board. His involvement has

enabled access to his TSB funded metaFAB facility for HPLC-MS and

femtosecond laser micromachining, and has enabled additional two-way

development contracts between the University (Professor Steve Dunnet, Dr.

Peter Kille) and Q Chip. The latter contracts developed cell-encapsulation

capabilities for the company, using its core microsphere production

technology.

Since Q Chip's inception, there has been significant process development

and intellectual property protection, through five patents, based on its

collaborative research programme. Microspheres are produced using a hybrid

of the original IP with new geometries and sub-systems. This happens at a

greater rate, with less solvent waste, using automated, industry-ready

bespoke equipment, also manufactured by Q Chip. The Q-Sphera manufacturing

process leads to environmental improvements and is now much `greener' than

current methods because (i) it operates without Class II

halogenated/hazardous solvents (e.g. dichloromethane/chloroform), (ii) it

uses >80% aqueous solvents (so waste may be recycled to remove Class

III solvents such as DMSO, alcohols), (iii) it is far more efficient than

current methods since there is no need for size-fractionation (no wastage

of intermediary product since there is none), and (iv) the unique, highly

miniaturised, production-on-demand processing equipment (manufactured by Q

Chip) sits on a desk, rather than occupying a building [5.1]. In 2011,

through a £3.6M external investor round, the Q Chip BV European

manufacturing subsidiary was founded as a cGMP sterile pharmaceutical

production facility at Geleen, near Maastricht, with initially three FTE

staff [5.5]. In 2012, the company was awarded a TSB grant of £250k towards

the cost of developing its innovative, scaled-up, sustained-release

pharmaceutical manufacturing process and production equipment [5.1].

Company investment: To provide context to the company investments

during the REF period, it is valuable to know that before the

REF period, the business secured first round funding from the

E-Synergy investor syndicate in 2004 (lead investor John Moulton), with a

corresponding second closing IP-equity swap with Cardiff University, which

now holds about 3% equity. Since its incorporation in 2003, Q Chip has

attracted investment of £10.4M over 12 funding rounds from angel and

institutional investors, has over 57 shareholders, with 29 FTE staff who

have contributed to employment in Wales [5.6].

During 2011-12, existing shareholders, including Disruptive Capital

Finance and Finance Wales, were joined by venture capitalist Jon Moulton

(founder of Better Capital) [5.7] and industrial entrepreneur Sir Harry

Solomon, in two £5.6M Series C financing rounds led by Limburg Ventures

and Nedermaas Hightech Ventures [5.7],[5.8]. Q Chip uses these funds to

increase production by scaling-up manufacturing development of

encapsulated drugs for prostate cancer and acromegaly.

Finally, in 2011-12 EPSRC undertook a healthcare economic IMPACT Study on

Q Chip, since its origins were based on EPSRC-funded research (IMPACT

summarised in [5.9] and [5.10]).

Sources to corroborate the impact

5.1 Confirmation of employment generated, investment and contracts

achieved and that Q-Chip developed 5 injectable microsphere formulations

on company contracts from Chief Operating Officer Q Chip Ltd.

5.2 Confirmation of turnover from audited (Ernst & Young) annual

company reports (Companies House Company No. 04929486).

5.3 Confirmation of Q Chip's specialist drug delivery mechanisms and

their benefits at

http://www.q-chip.com/downloads/0723_Inside_Technology_article.pdf.

5.4 Confirmation of a contractual relationship with leading

biotechnology/pharmaceutical company, ARTES Biotechnology GmbH http://www.artes-biotechnology.com/news.jsp.

Article on 29.04.2010.

5.5 Confirmation of investment and establishment of Dutch manufacturing

subsidiary http://www.growthbusiness.co.uk/news-and-market-deals/fundraising-deals/1625353/jon-

moulton-backs-q-chips-series-c-financing-round.thtml.

5.6 Confirmation from the (then) Welsh Assembly Government Minister, Mr

Andrew Davies, of economic (including employment) impact of Q Chip.

5.7 Confirmation of £3.6M investment raised http://www.walesonline.co.uk/business-in-

wales/business-news/2011/06/14/q-chip-raises-3-6m-more-to-expand-91466-28871341/

5.8 Confirmation of £2M funding from external investors in 2012 http://www.insidermedia.com/insider/wales/81880-2m-funding-q-chip/index.html.

5.9 Confirmation of original EPSRC funding from: "EPSRC Pioneering

Healthcare Technologies for the UK Life Science Sector", [No 3 on page 5].

One of four IMPACT case studies selected for this EPSRC publication.

5.10 Confirmation of economic impact from `EPSRC Research Performance and

Economic Impact Report 2011/12' [Page 13 ] at: (paste hyperlink into

google address bar on macs): http://www.epsrc.ac.uk/SiteCollectionDocuments/Publications/corporate/ResearchPerforman

ceAndEconomicImpactReport2011-12.pdf.