Commercialisation of Ferroelectric Liquid Crystal over Silicon Microdisplays

Submitting Institutions

University of St Andrews,

University of EdinburghUnit of Assessment

PhysicsSummary Impact Type

TechnologicalResearch Subject Area(s)

Physical Sciences: Other Physical Sciences

Engineering: Materials Engineering

Technology: Communications Technologies

Summary of the impact

Impact: Economic gains

PHYESTA research has led to the setting up of a company now known as

ForthDD. Since 2008 it has increased its annual revenue by more than 25%

to around US $5M, and its global workforce from 25 to 35. It has released

new products directly underpinned by PHYESTA research as recently as

October 2012.

Significance:

A consortium involving PHYESTA staff in collaboration with Edinburgh's

School of Engineering and five industrial partners realised the world's

first high-resolution ferroelectric liquid crystal over silicon (FLCOS)

microdisplay. This digital display attracted investment from the UK,

Taiwan, and USA of over $40m, and was taken forward to production by

MicroPix, MicroVue, and Forth Dimension Displays.

Reach:

ForthDD now has offices in Valencia, USA, and Berlin, Germany. The

company designs, develops and manufactures single chip microdisplays used

in the demanding near to eye (NTE) training and simulation systems, HD

video camera viewfinders, medical imaging systems and virtual reality and

head-mounted displays.

Beneficiaries:

ForthDD, its customers and business partners (e.g. in the medical imaging

sector).

Attribution: This work was led within PHYESTA by Professor David

Vass involving PHYESTA and done in collaboration with Edinburgh's School

of Engineering.

Underpinning research

The Applied Optics Group at the University of Edinburgh was a

cross-departmental research unit involving the Schools of Physics (now

PHYESTA) and Engineering (now ERPE — the Edinburgh Research Partnership in

Engineering). The Group operated under the direction of Professor David

Vass (PHYESTA), who was working on liquid crystal over silicon (LCOS)

devices with initial interest in their use for optical correlators, beam

steerers, and beam shapers. The ferroelectric class of liquid crystals

offered response times an order of magnitude faster than nematic crystals,

and could be operated in a binary mode suited to driving digital

applications. However, ferroelectric liquid crystal devices posed severe

design and manufacturing challenges, as the thickness of the required cell

was much thinner than conventional nematic liquid crystal based devices.

Typically a sub-micron thickness is required and flatness, cell

parallelism and uniformity are also needed to make these devices viable.

At first commercial manufacturers of silicon wafers regarded such tight

tolerances as unattainable using conventional processing and polishing

methods. Vass, Hossack (PHYESTA) and collaborators in the School of

Engineering developed designs, pulsed illumination methods, polishing

techniques and silicon planarization (removal of excess curvature that can

reduce optical coherence and lead to colour artefacts), which produced

cells of excellent flatness and high reflectivity sufficient for coherent

optical applications [R1, R2]. This work was undertaken with a SERC SCIOS

rolling grant, SERC/DTI Link grant SASLM and EU ESPRIT grant HICPOBS over

the period 1993-1995 for which Vass was Principal Investigator.

Further refinements in the device design led to the realisation of smart

pixel structures including light blocking layers and robust backplane

electronics enabling a fast digital FLCOS Spatial Light Modulator [R3],

which was able to operate under intense illumination. This led to

applications in routers for telecoms, holographic projectors, and optical

tweezers. The smart algorithms, binary phase holograms, and fast device

operation were critical in realising real time full speed operation in

these application areas. The realisation of the FLCOS based holographic

optical tweezers, permitted for the first time multiple trapping and

real-time capture of freely moving microbes, as described in a well cited

paper [R4].

While more generally applicable these advances directly addressed

requirements of the emerging technology of microdisplays, which demanded

improved manufacturing methods to enhance image quality and colour

fidelity above threshold levels for a practical display. To the basic

spatial light modulator device we added fast image processing algorithms

in collaboration with GEC, STC, Admit Design, and Davin Optronics, thereby

producing the world's first high resolution, video speed, full colour

FLCOS digital microdisplay. This device was first showcased at the 6th

International Conference on Ferroelectric Devices hosted by ENST and

subsequently published in the leading journal for ferroelectric technology

[R5,R6]. This prototype device was a key development bringing together

VLSI design, surface planarisation, light blocking layers, fast electronic

interface and ferroelectric liquid crystals in a fully operational FLCOS

device. This work was undertaken over the period 1995-1998.

Personnel:

The key PHYESTA researchers involved were Professor David Vass

(1993-2004; category A in 2001 RAE return), Dr Will Hossack (Academic

staff, 1993-present), Professor Jason Crain (1993-present) and Dr Jochen

Arlt (Senior PDRA and COSMIC laboratory manager).

References to the research

The quality of the underpinning research is best illustrated by R1, R2

and R3. [Number of citations]

| [R1] |

A. O’Hara, J.R. Hannah, D.C. Burns, I. Underwood ,

D.G. Vass, R.J. Holwill, ‘Mirror

quality and efficiency improvements of reflective spatial light

modulators by use of dielectric coatings and chemical-mechanical

polishing’, Applied Optics, 32,

p. 5549, (1993), DOI: 10.1364/AO.32.005549, URL: tinyurl.com/mhydpes,

[14]

|

| >[R2] |

I. Underwood, D.G.Vass, A. O’Hara, et al., ‘Improving

the performance of liquid crystal-over-silicon spatial light

modulators – issues and achievements’, Applied Optics,33,

p. 2768, (1994), DOI: 10.1364/AO.33.002768, URL: tinyurl.com/n7tpurb,

[18]

|

| [R3] |

D. Burns, J. Gourlay, A. O’Hara, I. Underwood, D.G.Vass, ‘A

256x256 SRAM-XOR pixel ferroelectric liquid crystal over silicon

spatial light modulator’, Optics Communications, 119,

p. 623, (1995), DOI: 10.1016/0030-4018(95)00414-4, URL: tinyurl.com/knsfftm,

[11]

|

| [R4] |

W.J. Hossack, E. Theofanidou, J. Crain, K. Heggarty, M. Birch, ‘High-speed

holographic optical tweezers using a ferroelectric liquid crystal

microdisplay’, Optics Express, 11,

p.2053, (2003), DOI: 10.1364/OE.11.002053, URL: tinyurl.com/llgftlt,

[58]

|

| [R5] |

I.D. Rankin, I. Underwood, D.G. Vass, and M.R. Worboys, ‘Full

colour miniature display’, Proc SPIE on "Liquid Crystal

Materials, Devices and Applications”, 2651,

p.16, (1996), DOI: 10.1117/12.235358, URL: tinyurl.com/mclqaef,

[1]

|

| [R6] |

D. Vass et al., ‘A high

resolution full colour head mounted ferroelectric liquid

crystal-over-silicon display’, Ferroelectrics, 213,

p.209 - 218, (1998), DOI: 10.1080/00150199808016486, URL: tinyurl.com/mpsn54d

|

Details of the impact

The Applied Optics group formed a consortium with Thorn, GEC, BNR, Davin

Optronics, STC, and ENST, to perform research and development of FLCOS

devices with DTI funding. The local Scottish company, ADMIT Design, used

the FLCOS demonstrator to attract interest and investment. ADMIT was then

bought by Central Research Laboratories of Thorn EMI, forming MicroPix

Technologies Ltd in 1998. They developed the FLCOS microdisplay technology

into a commercial product. Subsequently in 1995, in a joint venture with

PicVue Electronics a pilot production company, Microvue, was created in

Scotland, and an investment of £20m was raised to build a volume

production plant in Taiwan.

ForthDD [S1], is the successor company of MicroPix and MicroVue, founded

in 2005, and based in Dalgety Bay, Fife. They succeeded in bringing the

technology to production demonstrating that FLCOS microdisplays could be

made to adequate standard in wafer scale production. Since its formation,

and over the period of the REF impact window, it has raised in excess of

US $33M in investment including the 2011 injection of US $14M by the

leading US microdisplay company, Kopin Corporation [S2]. ForthDD designs,

develops and manufactures single chip micro-displays used in the most

demanding segments of markets such as training and simulation systems, HD

video camera viewfinders, medical imaging systems and virtual-reality and

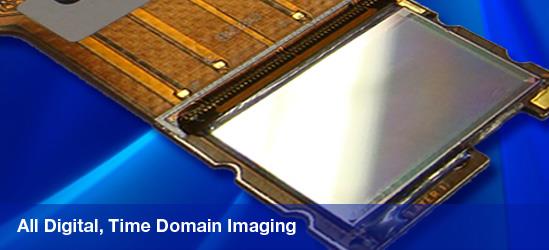

head-mounted displays. Entirely digital, providing 24-bit full colour

images, and capable of handling high-speed motion with no visible

artefacts, Forth DD's single chip imagers are especially well-matched to

the new solid state LED and laser diode light sources and provide very

high native resolution. In late 2012, ForthDD reaffirmed its position as

the world's leading supplier of advanced microdisplays when it released

the world's highest resolution full colour microdisplay. ForthDD employs

over 35 staff, many in posts requiring undergraduate and post-graduate

qualifications. It has annual revenues in excess of £3M, with exports

accounting for 95% of its sales. "A key selling point for Forth

Dimension Displays is our ability to produce high quality images in

applications where competing technologies do not quite make the grade.

Underpinning this image quality are product features enabled by

technical specifications such as high pixel aperture ratio and accurate

liquid crystal alignment, that were first established through the

PHYESTA research on backplane surface quality improvement. The backplane

surface quality improvement techniques described by the PHYESTA research

have been adopted by CMOS foundries, such as those from which ForthDD

obtains the substrates for its current product range."

Director of Product Design, ForthDD [F1].

The improvements particularly in surface planarity and pixel fill factor

achieved by PHYESTA researchers were critical enablers in FLCoS

microdisplay technology, allowing them to exceed the threshold of image

quality necessary to satisfy customers. The underlying manufacturing

processes were made available to ForthDD's commercial CMOS foundry

supplier, through publication and direct transfer, and thus were

incorporated into product manufacture. The CMOS foundry has continued to

refine these. Thus the manufacturability, image quality and optical

efficiency of the current product range and the newly released product

range rely upon PHYESTA's underlying research into manufacturing

techniques. Improvements in active device surface planarity and pixel

filling factors achieved by PHYESTA and collaborators were key

translational steps. With the exception of the liquid crystal materials

themselves and aspects of the drive circuitry, the entire ForthDD product

line is substantially and directly underpinned by PHYESTA innovations in

optical sciences and materials processing. The collaboration with ForthDD

remains active with Hossack and other staff continuing to consult and work

with them.

PHYESTA/ERPE research [R6], was quickly incorporated into early products

and has been continually developed and refined within the company to

encompass higher colour depth, higher frame rates and higher definition. "Thus

every Forth Dimension Displays product, including the most recent

product range, the QXGA (2048 x 1536 pixel) microdisplay launched in

October 2012, has used and continues to use pulsed RGB LED illumination

based upon the original ERPE scheme that was published [R2, R3] as an

outcome of the foundational ERPE research." CEO of ForthDD [F2].

Sources to corroborate the impact