Mercury Capture Technology for the Global Petroleum Industry

Submitting Institution

Queen's University BelfastUnit of Assessment

ChemistrySummary Impact Type

TechnologicalResearch Subject Area(s)

Chemical Sciences: Organic Chemistry, Physical Chemistry (incl. Structural), Other Chemical Sciences

Summary of the impact

Queen's University's Ionic Liquids Laboratory (QUILL) has developed an

ionic liquid technology for removing mercury, a toxic, corrosive

contaminant naturally present in hydrocarbon reserves, with the national

oil and gas company Petroliam Nasional Berhad (PETRONAS).The technology

has been successfully installed in 1-and 15-ton units in two PETRONAS gas

processing plants in Malaysia. The process, marketed as HycaPure Hg™,

captures all mercury species present in natural gas and has up to 3 times

higher capacity than competing state-of-the-art commercial alternatives.

This technology represents a significant improvement towards ensuring the

health and safety of workers, process plant and the environment.

Underpinning research

QUILL was the first research centre to focus on the development of ionic

liquids (liquid salts) and is now recognised as the world-leader in new

applications, notably in green chemistry. We drew on our expertise to

design an entirely new ionic liquid based approach to remove mercury from

natural gas supplies, a feat that has much broader applications. The

underpinning research has been performed since the formation of QUILL in

1999 to now. Over this period of time a significant understanding of the

controlling features of ionic liquids was determined from a fundamental

perspective. This included the phase behaviour of ionic liquids and the

effect of anion and cation structure as well as new synthetic methods for

the production of low cost ionic liquids and the effect of impurities

(halide and water, for example) on physicochemical properties of the

materials (references 1-5 in section 3). Due to the large number

of ionic liquid systems possible, predictive methods for the determination

of both chemical interactions and physical property determination were

also formulated (references 4 and 5 in section 3). Using this

understanding and a knowledge of the requirements of the challenge —

notably the need to extract inorganic, organic, and elemental forms of

mercury from natural gas streams on an industrial scale, and the need for

rapid capture kinetics in order to protect down-stream facilities from

spikes in mercury content, Seddon, Nockemann and Holbrey led the team

which targeted the design, synthesis and testing of ionic liquid materials

at laboratory scale. Following the initial screening, the Queen's team

successfully incorporated the active ionic liquids into porous solids

without leaching. Finally, the composition of the solid-supported ionic

liquid (SSIL) was optimised as a direct retrofit to existing mercury

scrubbers with no added investment required (reference 6 in section 3).

In partnership with PETRONAS, the optimised SSIL was scaled-up and

validated at pilot scale and subsequently scaled up to 15 tons of

adsorbent providing the first commercial charge to treat natural gas at an

on shore PETRONAS gas processing plant.

References to the research

* signify the references which best indicate the quality of the

underpinning research

Key references from the investigators, demonstrating the strength and

depth of fundamental research underpinning the design, understanding and

application of ionic liquid materials.

1. Influence of chloride, water, and organic solvents on the physical

properties of ionic liquids, KR Seddon, A Stark, MJ Torres, Pure Appl.

Chem., 2000, 72, 2275, DOI: 10.1351/pac200072122275. This is a key paper

which demonstrated to the ionic liquid research community the importance

of understanding and maintaining knowledge of the purity of ionic liquid

systems.

2. The phase behaviour of 1-alkyl-3-methylimidazolium tetrafluoroborates;

ionic liquids and ionic liquid crystals, JD Holbrey, KR Seddon, J. Chem.

Soc., Dalton Trans., 1999, 2133, DOI: 10.1039/a902818h. This fundamental

study demonstrates the effects of systematic structural changes on the

thermophysical properties of ionic liquid systems.

3. Efficient, halide free synthesis of new, low cost ionic liquids:

1,3-dialkylimidazolium salts containing methyl-and ethyl-sulfate anions,

JD Holbrey, WM Reichert, RP Swatloski, GA Broker, WR Pitner, KR Seddon, RD

Rogers, Green Chem., 2002, 4, 407, DOI: 10.1039/b204469b. New ionic

liquids were described prepared using simple, clean and halide-free

syntheses.

*4. Desulfurisation of oils using ionic liquids: selection of cationic

and anionic components to enhance extraction efficiency, JD Holbrey, I

Lopez-Martin, G Rothenberg, KR Seddon, G Silvero, X Zheng, Green Chem.,

2008, 10, 87, DOI: 10.1039/b710651c. The paper applied analysis of

structure-activity relationships to determine the `best' cations to use in

the design of ionic liquids for desulfurisation of diesel fuel.

*5. Small angle neutron diffraction from 1,3-dimethylimidazolium

chloride, C. Hardacre, J. D. Holbrey, S. E. J. McMath, D. T. Bowron, and

A. K. Soper, J. Chem. Phys., 2003, 118, 272, DOI: 10.1063/1.1523917. This

paper was the first to demonstrate the use of neutron scattering (using

STFC large-scale facilities at ISIS) to directly visualise ionic liquid

structure. This allows us to uniquely link bulk properties of ionic liquid

systems with their behaviour at the atomic level.

The materials that form the basis of the HycaPure™ technology are

proprietary knowledge and form a suite of 4 patents the most relevant

being:

*6. Process for removing metals from hydrocarbons, M. Abai, M. Atkins, K.

Y. Cheun, J. D. Holbrey, P. Nockemann, K. R. Seddon, G. Srinivasan, Y.

Zou, World Patent Application PCT/WO 2012/046057 A2

Details of the impact

QUB and PETRONAS in a unique partnership have developed a novel mercury

removal technology HycaPure Hg™ based on ionic liquids which offers

advantaged performance and flexibility to treat a full range mercury types

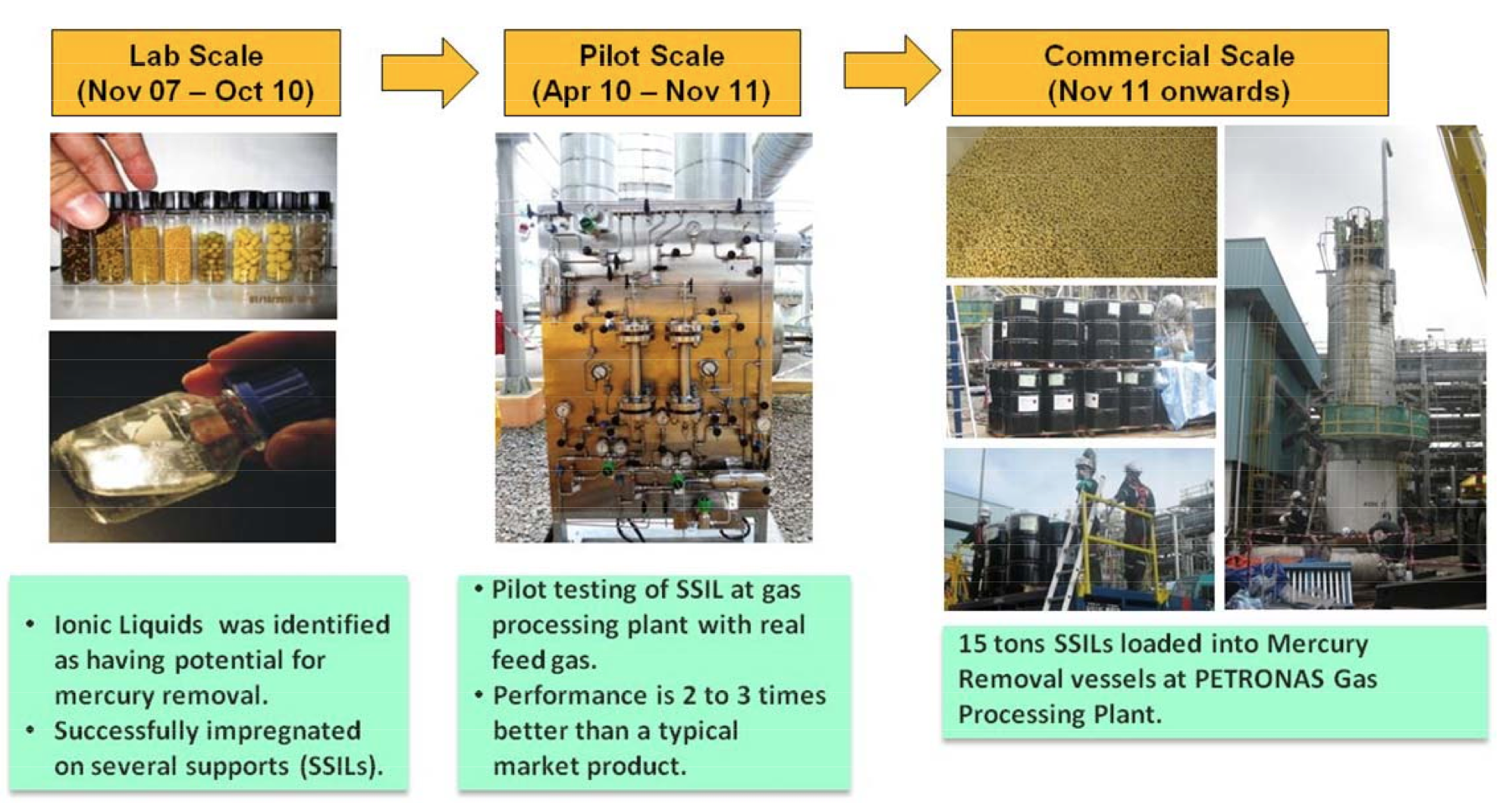

and gas composition (Figure 1). The first full-scale HycaPure Hg™ units

containing 1 and 15 tons of absorbent were installed at a PETRONAS gas

processing plant in Malaysia in Oct 2011 and have been successfully

producing ethane for PETCHEM and sales-quality gas since commissioning

(references 1-4 in section 5). The mercury content has been

consistently below the legal safe limits, with no excursions. The new

technology has a number of benefits over the competing commercial systems,

e.g. the kinetics of mercury absorption are 10-20 times faster, allowing

the operating plant to cope with large spikes of mercury with no risk to

the downstream plant, and the mercury absorption capacities of the new

materials are 2-3 times better on a volume/volume (reactor) basis. The new

system is a direct retrofit to commercial plants and installs without any

additional costs or modification to procedures (see PETRONAS' Technology

Products and Technical Solutions literature).

A typical medium-sized mercury removal unit contains around 15 tons of

material, and costs in the order of US$180,000 per fill. By comparison,

the increased absorption capacity of HycaPure Hg™ materials represents a

potential cost saving of over 20% per vessel, and with a market size

running into hundreds of thousands of tons, this new technology is not

only efficient but highly competitive.

Figure 1 Development of the mercury capture technology

for natural gas clean up in conjunction with PETRONAS

Figure 1 Development of the mercury capture technology

for natural gas clean up in conjunction with PETRONAS

The potential market for our SSIL technology in the hydrocarbon industry

is huge: MRUs are required in almost every gas and oil terminal and

refinery/petchem complexes in addition to the produced waters from

drilling platforms. Mercury contamination ranges from 0.02 micrograms per

cubic metre in the Gulf of Mexico to more than 100 in Europe, South

America, Gulf of Thailand, Malaysia and Indonesia. In extreme cases, such

as in North Germany, levels can reach 5000 micrograms per cubic metre.

Even 1 ppm of mercury contamination has significant cumulative effects if

we consider a typical plant processes 2000 tons every day. In addition to

its well-documented health and environment effects, mercury also damages

industrial facilities through corrosion, such as embrittlement of

aluminium heat exchangers with catastrophic consequences. Hg is also a

strong catalyst poison for downstream units.

The current technologies used to remove mercury are chemically-modified

activated carbons (with sulphur for gas treatment, and potassium iodide

for liquid hydrocarbon treatment) and more expensive technologies, such as

silver-impregnated molecular sieves and mixed metal sulphide/oxide

scrubbers. But there are issues with these technologies when it comes to

efficiency, the removal of all types of mercury species, robustness when

other contaminants are present in the feed and the ability to deal with

fluctuating mercury levels. The HycaPure Hg™ is proving robust and durable

in operation. The technology is being extended to other gas treatment

facilties in PETRONAS facilities and licensing/manufacturing partners are

planning to launch the product globally in 2014. .

The (anticipated) greater life-time of HycaPure Hg™ scrubbers will lead

to lower total volumes of hazardous mercury-contaminated waste for

post-unit remediation and reduced frequency of scheduled scrubber

replacement, along with reduced occupational exposure to mercury. The

issue of mercury exposure was recently recognised by governments in a

global, legally-binding treaty to prevent emissions and releases, the

Minamata Convention on Mercury.

The impact of this work was recently recognised in the Government's Great

British Innovation Vote in March 2013 (reference 5 in section 5).

Sources to corroborate the impact

- The contribution of QUB, through the partnership with PETRONAS, is

acknowledged in a letter of corroboration from the Head of Technology

Management Department of Technology & Engineering Division,

PETRONAS.

- The PETRONAS Laboratory at the QUILL (Queen's University Ionic Liquids

Laboratories) Research Centre was officially opened by The Northern

Ireland Assembly Minister for Employment and Learning who recognised it

as "an exemplar of industry and academic collaboration, not just for

Northern Ireland but for the United Kingdom as a whole."

(http://www.northernireland.gov.uk/index/media-centre/newsdepartments/news-del/news-del-april-2008/news-del-170408-minister-opens-new.htm

and Petronas 2009 Annual Financial Statement, page 68 (www.petronas.com.my/investor-relations/Documents/annual-report/AnnualReport_FinancialStatement_2009.pdf)"

- 2011 Annual Financial Statement (www.petronas.com.my/investor-relations/Documents/annual-report/AnnualReport_FinancialStatement_2011.pdf)

Notes the collaboration with QUB and the first commercial commission of

HycaPure Hg™ at PETRONAS Gas Bhd (PGB).

- Strategic presentations describing the technology at the International

Gas Union Research Conference (19-21 Oct 2011, Seoul, Korea; http://www.igrc2011.com/programme),

EUCHEM 2012 (5-10 Aug 2012, Celtic Manor, Wales; http://www.euchem2012.org/index.php/scientific-programme)

and Green Solvents (7-10th October 2012, Boppard, Germany;

http://events.dechema.de/events/en/gsfs2012.html).

- Listed in the Government's Great British Innovation Vote, March 2013

http://www.topbritishinnovations.org/FutureInnovations/IonicLiquid.aspx