Case 1 – Efficient and Economical Plant Management via Model Predictive Control

Submitting Institution

Imperial College LondonUnit of Assessment

Electrical and Electronic Engineering, Metallurgy and MaterialsSummary Impact Type

TechnologicalResearch Subject Area(s)

Mathematical Sciences: Applied Mathematics, Numerical and Computational Mathematics

Information and Computing Sciences: Computation Theory and Mathematics

Summary of the impact

Model Predictive Control (MPC) is a controller design methodology

involving on-line dynamic optimisation of a user-defined objective. The

research of Prof. D.Q. Mayne FRS and his colleagues at Imperial

College has resulted in the first MPC algorithms capable of dealing with

both linear and nonlinear systems and hard constraints on controls and

states, thus making MPC a viable technique for industrial applications.

His research in linear and nonlinear MPC has been exploited by

multinational companies such as Honeywell and ABB. Evidence of impact is

found in: 1) ethylene production by Basell Polyolefins GmbH resulting in

economic benefits in millions of dollars annually; 2) Sinopec's JinShan

power plant efficiency, reducing fuel consumptions of 500 tons of coal and

1,700 tons of coke per annum; 3) automotive powertrain design creating new

business for Honeywell (based on OnRAMP design suite); 4) ABB's cpmPlus

Expert Optimizer tools used for cement manufacturing, affecting companies

such as Untervaz (Switzerland), Lägerdorf (Germany) and Buzzi (Italy); 5)

ABB's BoilerMaz system for optimising boiler start-up mechanism resulting

in energy savings per start-up of around 15%.

Underpinning research

The combined use of optimal control and optimization methods conceptually

enables the optimized operation of complex processes. The most significant

contribution of Model Predictive Control (MPC) resides in the construction

of a feedback mechanism which approximately, and in real-time, optimizes

process operation, while satisfying operational constraints. These goals

cannot be achieved by any other control mechanisms. The underpinning

research in MPC at Imperial was conducted in the EEE Department by

Professor D.Q. Mayne. He has pioneered a number of research breakthroughs

in the analysis, design and development of both linear and nonlinear MPC,

which have resulted in him being awarded the prestigious "I EEE Control

Systems Award" (http://www.ieee.org/about/awards/bios/controlsys_recipients.html)

and the IFAC Quazza Medal (http://www.ifac-control.org/awards/major-medals).

The underpinning research in MPC by Mayne and his team are:

1. Receding horizon control [R1, R2] - In receding horizon

control the current control is determined by solving on-line a constrained

open-loop optimal control problem and applying this control over the

following sampling interval after which this procedure is repeated. It is

thus able to handle hard constraints on controls and states: this property

is one of its main advantages and the cornerstone of the stability

properties of MPC controlled nonlinear processes.

Since in large-scale applications on-line solution of nonlinear optimal

control problems may be impractical, Mayne provided a practical

alternative: sub-optimal MPC that ensures closed-loop stability even if

the optimal control problem is not solved exactly [R1]. Subsequently, the

ambitious task of evaluating systematically the stability and optimality

properties of MPC methods was presented in his 2000 paper [R2]. The paper

provides a rigorous analysis of solved problems and a lucid description of

open problems in MPC. As stated in [R2]:

``We distill ..... essential principles that ensure stability and use

these to present a concise characterization of most of the model

predictive controllers that have been proposed in the literature. In

some cases the finite horizon optimal control problem solved on-line is

exactly equivalent to the same problem with an infinite horizon; in

other cases it is equivalent to a modified infinite horizon optimal

control problem. In both situations, known advantages of infinite

horizon optimal control accrue.''

After its publication in 2000, this paper has become the most widely

cited MPC paper and was recognized in 2011 by the first IFAC High Impact

Paper Award (http://www.ifac-control.org/awards/major-medals).

2. Combined MPC and moving-horizon estimator [R3] - When not all

key variables can be measured — as is typical in industrial practice —

moving horizon estimators play the role of virtual sensors, which can be

combined, as shown in [R3], to yield an integrated control architecture.

In later work, Mayne developed a new moving horizon observer for nonlinear

systems that extends the memory of the observer in [R2]. Forward dynamic

programming was employed to effect this improvement.

3. Robust MPC for linear and nonlinear systems [R4, R5] - When

uncertainties and un-modelled nonlinearities are present — as typical in

industry — the standard implementation of MPC computes the control by

solving an open-loop optimal control problem that neglects the presence of

disturbances. [R4] and [R5] improve the standard MPC algorithm by the

addition of a local feedback loop that is relatively easily computed and

counteracts the disturbances thereby maintaining almost optimal

performance throughout the process operation.

References to the research

(* References that best indicate quality of underpinning research.)

R1.* Scokaert, P.O.M., Mayne, D.Q., Rawlings, J.B., "Suboptimal

model predictive control (feasibility implies stability)", IEEE

Transactions on Automatic Control, 44, 648-654, 1999,

DOI: 10.1109/9.751369.

R2.* Mayne, D.Q., Rawlings, J.B., Rao, C.V., Scokaert, P.O.M.

"Constrained model predictive control: Stability and optimality",

Automatica, 36, 789-814, 2000 (winner of the 1st IFAC High

Impact Paper Award, 2011 with over 3,500 citations), DOI:

10.1016/S0005-1098(99)00214-9.

R3.* Rao, C.V, Rawlings, J.B., Mayne, D.Q,, "Constrained State

Estimation for Nonlinear Constrained Discrete-Time Systems: Stability and

Moving Horizon Approximations ", IEEE Transactions on Automatic Control,

48 (2), 246-258, 2003, DOI:

10.1109/TAC.2002.808470.

R4. Mayne, D.Q., Rakovic, S.V., Findelsen, R., Allgöwer, F.,

"Robust output feedback model predictive control of constrained linear

systems", Automatica, 42, (7), 1217-1222, 2006, DOI: 10.1016/j.automatica.2006.03.005.

R5. Mayne, D.Q, Kerrigan, E.C., "Tube-based nonlinear model

predictive control", Proceedings of the 7th IFAC Symposium on

Nonlinear Control Systems, 110-115, 2007, DOI: 10.1002/rnc.1758

Details of the impact

Mayne's pioneering research in robust MPC for linear and nonlinear

systems made the MPC approach to controlling plants viable in practical,

industrial applications. The impact of his work on industry can be

quantified from two main vantage points: technical and economic. The

technology relying on linear and nonlinear MPC is used for improving

process performance, environmental impact and reliable operation.

The impact of Mayne's MPC research includes a number of industrial cases

of success. In the following five success stories in two multinational

companies, Honeywell and ABB, nonlinear MPC was the essential (or

fundamental) component. In addition, direct reference to the company

pioneering the introduction of MPC in the specific sector during the

current REF period is made.

• Honeywell — The impact of Mayne's research to Honeywell's

advanced control technology is evidenced by their testimony [E1]:

".... Professor Mayne has introduced several significant advances in

the area, especially in the extension of MPC to nonlinear systems."

They also stated that Professor Mayne's contributions in nonlinear MPC "...

has had the greatest impact on (our) industrial practice."

Honeywell specifically cited three areas of their operations in which

Mayne's MPC research work has been applied [E1]:

1) Ethylene production [E1, E2]: Ethylene is one of the

largest-volume industrial bulk commodity in the world. The majority of

ethylene is used in the production of ethylene oxide, ethylene dichloride,

ethyl-benzene, and a variety of plastics ranging from plastic food wrap to

impact-absorbing dashboards inside cars. Honeywell assisted Basell

Polyolefins GmbH, the world's largest producer of polypropylene (PP) and

advanced polyolefins products, in the implementation of nonlinear MPC

solutions to maximize profits from their ethylene plant. This

implementation has resulted, starting from 2008, in these key benefits: a)

substantial economic benefits, including ".. millions of dollars from

increase production annually" [E1]; b) improved quality control on

key units as a result of reduced control-variable standard deviations

(including a 52% reduction in standard deviation of top quality on the

PP-Splitter and 58% reduction in standard deviation of bottoms quality on

the PP-Splitter) [E2]; c) increased uptime: Basell has achieved an

Advanced Process Control online time in excess of 90% [E2].

2) Power plants [E1, E3]: Fuel costs, energy conversion

efficiency, and environmental impacts of fossil-fuelled plants have become

priorities in both developed and developing countries. Since 2008, the

Honeywell MPC tool has been particularly effective in the operation of

power plants [E1]. As a significant example, the deployment of a MPC-

based tool in the JinShan power plant (China) has enabled Sinopec to

increase the boiler efficiency by 0.5%, to increase the operating steam

temperature by 2.8°C and to improve stability of key combustion process

variables. In addition, the air pollutant emissions from the fuel and

limestone consumption have been decreased to comply with environmental

standards in the region. The reductions in coal and coke consumption are

500 tons and 1,700 tons per annum. [E3]

3) Automotive Powertrains [E4]: Automotive engines are highly

nonlinear plants with significant model uncertainty due to production

variability and ageing. At the same time the control must satisfy both

input and output constraints. Honeywell developed a fully functional

nonlinear MPC-based controller that can be deployed on an engine in 2-3

weeks of engine test time, and with superior performance, as contrasted

with the performance achieved via several months required for traditional

techniques [E4]. Based on this technology, they have established a new

business division based around their OnRAMP design suite for automotive

powertrains (http://www.honeywellonramp.com).

• ABB — ABB is another company where the successes of MPC for

industrial applications are amply demonstrated [E5]. Based on their

cpmPlus Expert Optimizer, an advanced process optimization product, they

have successfully used MPC in a number of manufacturing systems. Two

examples are cited [E5]:

4) Cement Manufacturing [E5, E6]: The cement industry of the 21st

century is confronted with disparate goals that at first glance seem to

conflict. For example, there is enormous pressure to increase profit and

margins, while at the same time there is considerable public interest in

the sustainable and environmentally friendly use of natural resources. In

other words, plant operators find themselves in a situation where they

need to react fast and optimally to continuously changing conditions while

still meeting various and probably conflicting objectives. MPC-based

feedback operates the plants to their optimal economic performance within

the technological, environmental, and contractual constraints. ABB has

installed MPC on-line optimizers in the Untervaz material blending plant

(Switzerland). Starting from 2008, the benefits achieved by the

installation are reduction by 20% of raw mix quality variability and

reduced kiln process variability. The nonlinear MPC-based optimizer has

been also installed in the Holcim's Lägerdorf precalciner for temperature

control (Germany), and Buzzi's Guidonis cements grinding system (Italy).

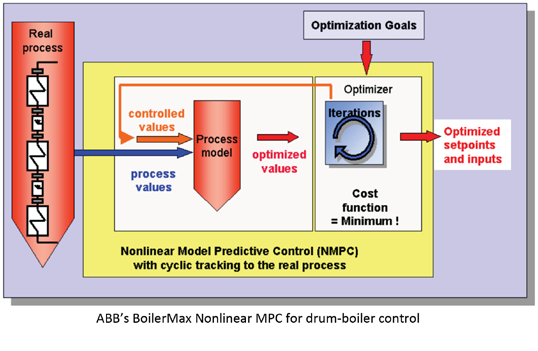

5) Coal-Fired Power Plants [E7]: Renewable energy sources have

pushed conventional power plants to be more flexible and efficient. This

has led to coal-fired power plants needing to have efficient boiler

start-up mechanisms. ABB has successfully developed, commercialised and

deployed numerous nonlinear model-predictive optimization solutions for

boiler start-up in power plants [E7]. The complex dynamics of the boiler

start-up mechanism are described by a nonlinear model subject to numerous

constraints on energy usage and thermal stress. The ABB solution based on

nonlinear MPC implementation has successfully shown to be able to solve

the boiler start-up problem nearly optimally. On average, the energy

savings per start-up are around 15%, while starting up is much faster than

with standard procedures [E5].

Sources to corroborate the impact

E1. Letter from Corporate Fellow, Honeywell Automation and Control

Solutions, Minneapolis, USA, stating the impact of Mayne's work in

nonlinear MPC on their process control business.

E2. Basell Optimize Ethylene Plant with Honeywell MPC and RTO",

https://www.honeywellprocess.com/library/marketing/case-studies/SuccessStory_Basell-"

Wesseling.pdf. Archived here

on 23/10/2013.

E3. "Sinopec Saves More than $1 Million in Energy Costs with Honeywell's

Advanced Energy Solutions", https://www.honeywellprocess.com/library/marketing/case-

studies/SuccessStory_Sinopec_AES.1.pdf.Archived here

on 23/10/2013.

E4. "Streamlining Powertrain Control Development: A Systematic Approach

to Model Based Control", https://www.honeywellonramp.com/TechnicalResources/Documents/2012

Workshop Madellbasierte Kalibriermethoden HONEYWELL v05.pdf.

Archived here

on 23/10/2013

E5. Letter from Head of ABB AG Corporate Research Centre Germany (on 5th

March 2013) on how nonlinear MPC has impacted on their business.

E6. "Advanced Control for the Cement Industry", The Impact of Control

Technology, 2011.

http://ieeecss.org/sites/ieeecss.org/files/documents/IoCT-Part2-05CementIndustry-LR.pdf

Archived here

on 23/10/2013.

E7. "Boiler control and optimization", FFWD 1/11, Power Generation

Special Issue, ABB Switzerland Ltd. pg 12. Archived here.

http://www02.abb.com/global/gbabb/gbabb905.nsf/bf177942f19f4a98c1257148003b7a0a/4951ad3b82277aaec12579210051feda/$FILE/FFWD+Power+Generation+Special+Issue.pdf