Helping to create Ashwoods Lightfoot® and enable fleet managers to reduce the fuel costs and CO2 footprint from 2,500 vehicles

Submitting Institution

University of BathUnit of Assessment

Aeronautical, Mechanical, Chemical and Manufacturing EngineeringSummary Impact Type

TechnologicalResearch Subject Area(s)

Engineering: Civil Engineering

Psychology and Cognitive Sciences: Psychology

Summary of the impact

Economic impact

- Design of a new and award winning product called Lightfoot®

that gives reductions of at least 10% in fuel use and CO2

emissions.

- The creation of a new business, Ashwoods Lightfoot® and

three new jobs, with a sales value to date in excess of £625,000 and a

subscription base of over £10,000 per month.

- Economic performance of 200 vehicle fleets, including six major

operators, has been improved by 2,500 installations of the system,

saving over £83,000 per month in fuel costs.

Environmental impact

- Saving an estimated 2,000 tonnes of CO2 per year.

Underpinning research

Key researchers

Members of the Powertrain and Vehicle Research Centre (PVRC): Professor CR

Burrows (Professor since 1987, emeritus since 2007); Dr ND Vaughan (Senior

Lecturer 1993-2002); Dr CJ Brace (Research Officer 1992-2000, Lecturer

2000-2006, Senior Lecturer 2006-2012, Reader since 2012); and Mr R Daniel

(Masters Student 2007)

Research at Bath to understand driver behaviour began during a DTI

project in collaboration with Ford, Lucas Diesel Systems and Johnson

Matthey (1992-1996). The project exploited the capability of a diesel

engine, coupled with a continuously variable transmission, to operate the

engine at its most efficient level at all times. It was found that the

strategy of optimising only for fuel efficiency led to low driver

acceptance, with the driver finding the vehicle unresponsive. This was a

major barrier to adoption, which motivated further research at Bathin this

field [1].

This led to an EPSRC funded research programme in collaboration with Ford

and Torotrak (GR/K99664/01, 1996-2000), using the insight gained during

the initial DTI project to improve driver acceptance. An extensive series

of fundamental experiments were performed to understand and quantify

driver perception during a wide range of simulated vehicle acceleration

scenarios.

An important conceptual parameter in this work was driver aggression,

which is a measure of the driver demand and the vehicle's ability to

respond. The resulting data allowed the formulation of models to describe

the driver's perception of vehicle behaviour. These models provided a

means of predicting driver response to novel engine control strategies,

for the first time defining a relationship between driver aggression and

fuel consumption [3]. This advance meant that vehicle driveability could

be included in the optimisation process, allowing the trade-off between

driveability and fuel consumption to be addressed during the simulation

phases of a vehicle development programme. This reduced the duration and

cost of the entire development process by reducing the number of

iterations required [2].

Research in this area was extended through driving experiments that

demonstrated that for some specific road conditions, for example,

stop-start urban traffic and ring roads with high permitted speeds and

many traffic islands, the most aggressive drivers use up to 50% more fuel

than the least aggressive [4]. This surprising finding has significant

implications for both traffic planners and for vehicle designers. Further

research in partnership with Mahle Powertrain applied the techniques

developed by the Bath team to understand the impact of real-world driving

behaviour on the accuracy of engine diagnostic algorithms. This resulted

in the development of an algorithm (Universal Driver Aggression Algorithm

or UDAA) to measure driver aggression [5]. An important aspect of the UDAA

is its inherent robustness across differing vehicle types and road

configurations. The UDAA offers a step change in vehicle management

technology as it is directly applicable across a wide range of situations

with minimal requirement for labour intensive fine tuning. The UDAA

subsequently inspired activity within a project in collaboration with

Ashwoods Automotive as described below.

References to the research

(* references that best indicate quality)

1*. M Deacon, CJ Brace, ND Vaughan, CR Burrows and RW Horrocks RW. Impact

of alternative controller strategies on emissions from a diesel CVT

powertrain, 1999, Proceedings IMechE, Part D, Journal of Automobile

Engineering, 213, 95-107. DOI: 10.1243/0954407991526711

2*. V Wicke, CJ Brace and ND Vaughan. The potential for simulation of

driveability of CVT vehicles, 2000, Transactions of the SAE, Journal of

Passenger Cars - Mechanical Systems, 109, Paper 00PC-218 (6

pages). DOI: 10.4271/2000-01-0830

3*. SG Pickering and CJ Brace. Automated data processing and metric

generation for driveability analysis, 2007, Proceedings IMechE, Part D,

Journal of Automobile Engineering, 221, 429-441. DOI:

10.1243/09544070JAUTO347

4. S Malek, CJ Brace and S Liu S. Effect of driving behaviour on fuel

consumption, 5th International Conference on Driver Behaviour and

Training, 29-30 November 2011, Paris 375-82. ISBN: 9781409443049

5. R Daniel, T Brooks and D Pates. Analysis of US and EU drive styles to

improve understanding of market usage and the effects on OBD monitor

IUMPR, 2009, SAE Technical Paper 2009-01-0236. DOI: 10.4271/2009-01-0236

Details of the impact

In 2009, a Knowledge Transfer Account (KTA) funded project between Bath

and Ashwoods Automotive, an Exeter based SME, was focused on the

optimisation of hybrid electric powertrains. It became clear that

realistic driver behaviour had a far more significant effect on CO2

production and fuel efficiency than that possible through design

improvements, as is the case in conventional vehicles.

Because of the importance of driver behaviour for all types of vehicles,

and following discussions between Bath and Ashwoods based on these

findings, a new product (Lightfoot®) was created by Ashwoods

that incorporated the Universal Driver Aggression Algorithm (or UDAA)

which arose from the Bath research [5]. The development of this product

relied heavily on the Bath team to ensure that the full benefits of the

research findings could be realised. Ashwoods engineers were seconded to

Bath during the product development, ensuring effective knowledge exchange

and exploitation of the research.

Lightfoot® was launched in 2011 through a new business

venture, Ashwoods Lightfoot, which owns the IP relating to the product,

creating three new jobs. The product is marketed to fleet operators of

light commercial vehicles. The system consists of a data processing module

and a driver display system that can be integrated into the existing

dashboard instrumentation and is connected over the mobile phone network

to Ashwoods' central servers. The system makes use of data readily

available from the vehicle's diagnostic computer. The data are processed

using the UDAA algorithm developed in the underpinning research both to

quantify driver aggression and to optimise gear shift strategy. This

approach allows Lightfoot® to be fundamentally more effective

than competing products, which simply aim to indicate to the driver when

to change gear, due to its ability to modify driver behaviour in a robust

and universally applicable manner. This represents an important strategic

advantage to Lightfoot®, significantly improving driver

acceptance and minimising the application support needed for each new

fleet user.

Lightfoot® uses visual and audible feedback to drivers to

help them improve the fuel efficiency of their driving. In addition, the

system reports back to the fleet manager who oversees a ranking and

monitoring system to reward the best drivers and encourage those who need

to improve. The reduction in CO2 emissions is achieved solely

through behavioural improvements, with no modification to the vehicle

engine.

During the development phase, trials run on customer fleets by Ashwoods

demonstrated that Lightfoot® saved an average of around 7% in

fuel/CO2 when compared with baseline measurements across a wide

range of drivers and duty cycles. The savings were even higher for

exceptionally aggressive drivers and highly dynamic duty cycles; in these

cases savings of up to 20% were achieved [A, B]. In service, the product

has consistently returned a saving of at least 10% [C].

Lightfoot® has been a commercial success and is the sector

leading product, winning a number of industry awards [D]. The work

undertaken by Bath, exploiting the underpinning research has been central

to this success. In the words of the Ashwoods Managing Director [C]:

`The innovative work of the PVRC has contributed directly to our

business. The novel driver aggression monitoring algorithms developed

with the University have helped our Lightfoot product to become the

leading offering of its class.'

The impact here is immediate and persistent. The beneficiaries are

Ashwoods Automotive, through increased sales (value of the 2,500 unit

sales to date are around £625,000) and a rising profile within a new

product sector [C].

In addition, the six major fleet operators that use the technology have

gained significant reductions in fuel costs, valued at over £83,000 per

month on the current number of installations. Over 50 subsequent trials

have now been run by large fleet operators with savings ranging from 8 to

23%. Northumberland County Council saved 13.5%, Coventry City council

12.7%, DAF 9.9%, and May Gurney 14.3%. User experience has been positive,

for example, Wiltshire County Council [E] states:

`We have improved our consumption by 8-10% on these vehicles. The

system is easy to manage, relies on the driver to drive correctly to

make the savings, and therefore does not take up officer time. As the

potential savings are significant, it is our intention to invest in

Lightfoot in the future.'

The largest user is Autoglass, which has adopted Lightfoot® across

its entire fleet and has seen rapid and significant improvements. In the

words of the Autoglass Managing Director [F]:

`Within a couple of days of using the tool we see many of our drivers

go from spending 55— 60% of their time in the green zone to hitting 90%

and higher. Our savings in fuel costs speak for themselves. ...

... Our technicians have really embraced the technology...We've even

seen some light-hearted competitiveness emerging when the manager

reports go up on the notice board every week.'

Fleet operators spend around 25% of their cash flow on fuel, so any

saving in this area can be passed on to the general public through a

reduced price of goods and services. The wider environment benefits

through reduced CO2 from the vehicle fleet are clear. The

annual impact of the 2,500 currently operational systems can be estimated

by considering the effect of a 10% saving relative to the current fleet

average CO2 emissions from light commercial vehicles, estimated

in 2010 by AEA at 207.6 gCO2/km across a fleet of 2500 vehicles

travelling an average of 25,000 miles each year [G]. The saving is in over

2,000 tonnes of CO2 per year.

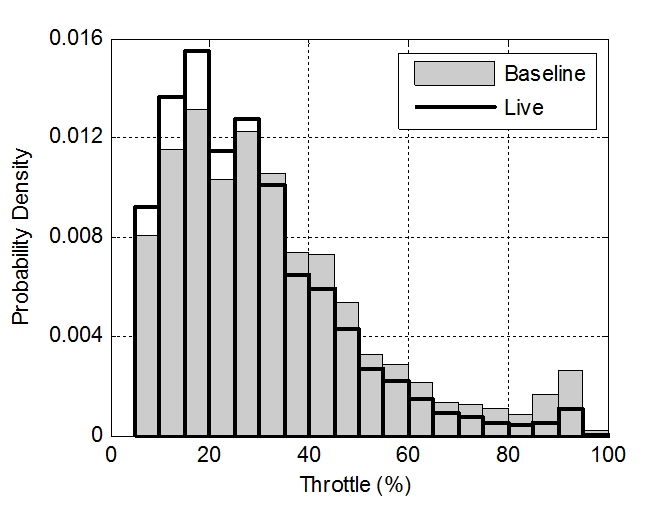

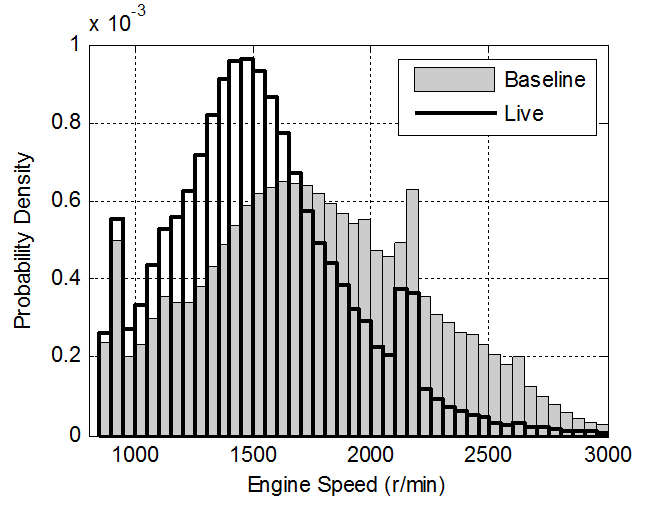

Figures 1 and 2 show actual changes in driver accelerator pedal activity

before (Baseline) and after (Live) activation of Lightfoot®.

These changes, represented as probability density distributions, give rise

to the savings determined in [G].

Fig. 1: Accelerator pedal (throttle) activation probability density

before (Baseline) and after Lightfoot® was activated (Live).

Note the shift towards lighter pedal activation when the device is active.

Fuel use is proportional to accelerator pedal position.

Fig. 1: Accelerator pedal (throttle) activation probability density

before (Baseline) and after Lightfoot® was activated (Live).

Note the shift towards lighter pedal activation when the device is active.

Fuel use is proportional to accelerator pedal position.

Fig. 2: Engine speed probability density before

(Baseline) and after Lightfoot® was activated

(Live). Note the considerable shift towards lower

engine speeds when the device is active. Lower

engine speeds are typically more efficient for an

equivalent power output due to reduced friction.

Fig. 2: Engine speed probability density before

(Baseline) and after Lightfoot® was activated

(Live). Note the considerable shift towards lower

engine speeds when the device is active. Lower

engine speeds are typically more efficient for an

equivalent power output due to reduced friction.

Sources to corroborate the impact

A. C Vagg, CJ Brace, R Wijetunge, S Akehurst and L Ash. Development of a

new methodology to assess fuel saving using gear shift indicators, 2012,

Proceedings IMechE, Part D, Journal of Automobile Engineering, 226,1630-1639.

DOI: 10.1177/0954407012447761

B. C Vagg, CJ Brace, D Hari, S Akehurst, J Poxon and L Ash. Development

and field trial of a driver assistance system to encourage eco-driving in

light commercial vehicle fleets, 2013, IEEE Intelligent Transportation

Systems Transactions, 14, Issue 2, 796-805. DOI:

10.1109/TITS.2013.2239642

C. Corroborative statement from Lightfoot Operations Manager, Ashwoods

Automotive, 30 September 2013.

D. List of awards won by Lightfoot (http://www.ashwoodslightfoot.co.uk/awards/).

E. Testimonial from Ashwoods Lightfoot Website (http://www.ashwoodslightfoot.co.uk/testimonials/).

F. J Challen. Autoglass to save 15 per cent on fuel with Lightfoot,

Article published in Transport Engineer, 11 July 2013

(http://www.transportengineer.org.uk/transport-engineer-

news/autoglass-to-save-15-per-cent-on-fuel-with-lightfoot/52916).

G. AEA report — Light Goods Vehicle — CO2 Emissions Study: Final report.

Report Ref ED05896/TR Issue Number 2, 2010.